1/4 Inch CCD Image Sensor For Ccir Camera S5F429PX02: 14pin Cer - DIP

Diunggah oleh

dragon-red0816Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1/4 Inch CCD Image Sensor For Ccir Camera S5F429PX02: 14pin Cer - DIP

Diunggah oleh

dragon-red0816Hak Cipta:

Format Tersedia

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

INTRODUCTION

The S5F429PX02 is an interline transfer CCD area image sensor developed for CCIR 1/4 inch optical format video cameras, surveillance cameras, object detectors and image pattern recognizers. High sensitivity is on-chip micro lenses and HAD (Hole Accumulated Diode) photosensors. This chip features a field integration read out system and an electronic shutter with variable charge storage time.

14Pin Cer - DIP

FEATURES

High Sensitivity Optical Size 1/4 inch Format No Adjust Substrate Bias Low Dark Current Horizontal Register 3.3 to 5.0V Drive 14pin Ceramic DIP Package Field Integration Read Out System No DC Bias on Reset Gate

ORDERING INFORMATION

Device S5F429PX02-LAB0 Package 14Pin Cer-DIP Operating -10 C +60 C

STRUCTURE

Number of Total Pixels: Number of Effective Pixels: Chip Size: Unit Pixel Size: Optical Blacks & Dummies: 537(H) 597(V) 500(H) 582(V) 4.80mm(H) 4.04mm(V) 7.30 m(H) 4.70 m(V) Refer to Figure Below Vertical 1 Line (Even Field Only)

16 7

500

30 1 Dummy Pixels Optical Black Pixels

Effective Imaging Area

OUTPUT

V-CCD

582 14

Effective Pixels

H-CCD

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

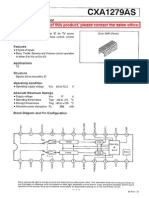

BLOCK DIAGRAM

(Top View)

7 VOUT

6 GND

5 NC

V1

V2

V3

V4

Vertical Shift Register CCD

Vertical Shift Register CCD

Vertical Shift Register CCD

Horizontal Shift Register CCD

Vertical Shift Register CCD

8 VDD

9 GND

SUB

10

11 VL

RG

12

H1

13

H2

14

Figure 1. Block Diagram

PIN DESCRIPTION

Table 1. Pin Description Pin 1 2 3 4 5 6 7 Symbol V4 V3 V2 V1 NC GND VOUT Description Vertical register transfer clock Vertical register transfer clock Vertical register transfer clock Vertical register transfer clock No connection Ground Signal output Pin 8 9 10 11 12 13 14 Symbol VDD GND SUB VL RG H1 H2 Description Output stage drain bias GND Substrate clock Protection transistor bias Reset gate clock Horizontal register transfer clock Horizontal register transfer clock

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

ABSOLUTE MAXIMUM RATINGS (NOTE)

Table 2. Absolute Maximum Ratings Characteristics Substrate voltage SUB - GND VDD, VOUT - SUB Vertical clock input voltage V1, V3, - GND V2, V4 - GND V1, V3, - VL V2, V4 - VL V1, V2, V3, V4 - SUB Horizontal clock input voltage H1, H2 - VL H1, H2 - SUB Voltage difference between vertical and horizontal clock input pins V1, V2, V3, V4 H1, H2 H1, H2 - V4 Output clock input voltage RG - GND RG - SUB Protection circuit bias voltage Operating temperature Storage temperature VL - SUB TOP TSTG -17 -0.3 -40 -40 -10 -30 Symbols Min. -0.3 -40 -0.3 -0.3 -0.3 -0.3 -40 -0.3 -30 Max. 40 10 30 17 30 17 10 7 7 15 16 16 16 16 10 60 80 Unit V V V V V V V V V V V V V V V C C

NOTE: The device can be destroyed, if the applied voltage or temperature is higher than the absolute maximum rating voltage or temperature.

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

DC CHARACTERISTICS

Table 3. DC Characteristics Item Output stage drain bias Protection circuit bias voltage Output stage drain current Symbol VDD VL IDD Min. 14.55 Typ. 15.0 Max. 15.45 Unit V

The lowest vertical clock level 5 mA

CLOCK VOLTAGE CONDITIONS

Table 4. Clock Voltage Conditions Item Read-out clock voltage Vertical transfer clock voltage Symbol VVH1, VVH3 VVM1 ~ V VM4 VVL1 ~ V VL4 Horizontal transfer clock voltage VHH1, VHH2 VHL1, VHL2 Charge reset clock voltage VRGH VRGL Substrate clock voltage VSUB Min. 14.55 -0.2 -8.0 3.0 -0.05 4.75 -0.2 21.5 Typ. 15.0 0.0 -7.5 5.0 0.0 5.0 0.0 22.5 Max. 15.45 0.2 -7.0 5.25 0.05 5.25 0.2 23.5 Unit V V V V V V V V Remark High level Middle Low High Low High Low Shutter

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

DRIVE CLOCK WAVEFORM CONDITIONS

Read Out Clock Waveform

100% 90%

VVH 1, VVH3

10% 0% tr twh tf 0V

Vertical Transfer Clock Waveform

V 1

VVH1

V VH VVHH VVHL

V 3

VVHH V V HL V VH L VVHL V VH3 V VHH

V VH H

V VH

V VL H V VL 1 V VL L V VL 3 V VL L V VL H V VL

V VL

V 2

V VH H

V VHH

V VH V VHL

V 4

V VH V VH H

V V HH

V VH2

V VHL

V VHL

V VH 4

V VHL

V VL 2

V VL H

V VL H

V VL L V VL V VH = ( V V H 1 + V V H 2)/ 2

V VL 4

V VL L V VL

V VH H

= V V H + 0. 3V

V V L = (V V L 3 + V V L 4)/ 2 V V = V V H n - V V L n

(n =1~4)

V V H L = V V H - 0. 3 V V V L H = V V L + 0. 3V V V L L = V V L - 0. 3 V

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

Horizontal Transfer Clock Waveform Diagram

tr twh tf

90% VH 10% VH L twl

Reset Gate Clock Waveform Diagram

tr twh tf VR GH twl VRG Point A RG waveform VRGLH VRGLL VRGL + 0.5V VRGL

H1 waveform 10%

VRGLH is the maximum value and VRGLL is the minimum value of the coupling waveform in the period from Point A in the diagram about to RG rise VRGL = (VRGLH + VRGLL)/2, VFRG = VRGH - VRGL

Substrate Clock Waveform

100% 90%

VSU B 10% VSU B 0% tr twh tf

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

CLOCK EQUIVALENT CIRCUIT CONSTANT

Table 5. Clock Equivalent Circuit Constant

twh Item Read-out clock Vertical clock Symbol Min. VH V1, V2 V3, V4 H1 Horizontal clock Reset clock Substrate clock H2 RG SUB 41 41 11 1.5 46 46 14 2.0 41 41 76 46 46 80 6.5 6.5 6.0 0.5 9.5 9.5 Typ. Max. 2.5 Min. Typ. Max. Min. Typ. 0.5 15 6.5 6.5 5.0 0.5 Max. Min. Typ. 0.5 250 9.5 9.5 Max. s ns ns ns ns s twl tr tf Unit

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

EQUIVALENT CIRCUIT PARAMETERS

Table 6. Equivalent Circuit Parameters Item Capacitance between vertical transfer clock and GND Symbol C V1, CV3 C V2, CV4 Capacitance between vertical transfer clocks CV12, CV34 CV23, CV41 CV13 CV24 Capacitance between horizontal transfer clock and GND Capacitance between horizontal transfer clocks Capacitance between substrate clock and GND Vertical transfer clock serial resistor Vertical transfer clock ground resistor Horizontal transfer clock serial resistor Reset gate clock serial resistor CH1, CH2 CH12 CSUB RV1 ~ RV4 RVGND RH1, RH2 RRG Typ. 680 820 180 180 60 60 30 30 180 40 15 10 100 Unit pF pF pF pF pF pF pF pF pF Remark

V1 R V1 C V1

V2 R V2 C V2 R H1 H1 C H12 R H2 H2 C H2

C V12

C V41

C V24

C V13 R VGND

C V23

C H1

C V4 R V4 V4 C V34

C V3 R V3 V3

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

OPERATING CHARACTERISTICS

Device Temperature = 25 C Table 7. Operating Characteristics Item Sensitivity Saturation signal Smear Blooming margin Uniformity Dark signal (NOTE) Dark shading (NOTE) Image lag Flicker Y

NOTE: Test Temperature = 60 C

Symbol S YSAT SM BM U D D YLAG FY

Min. 85 800

Typ. 95

Max.

Unit mV/lux mV

Remark 1 2 3 4 5 6 7 8 9

0.007 1,000

0.01

% times

20 2 2 0.5 2

% mV mV % %

TEST CONDITION

1. Use a light source with color temperature of 3,200K hallogen lamp and CM-500S for IR cut filter. The light source is adjusted in accordance with the average value of Y signals indicated in each item.

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

TEST METHODS

1. Measure the light intensities (L) when the averaged illuminance output value (Y) is the standard illuminance output value, 150mV (YA) and when half of 150mV (1/2 YA).

1 Y A --- Y A 2 S = ---------------------------LY L 1

A

--- Y A 2

2. Adjust the light intensity to 15 times of the value with which Y is YA, then measure the averaged illuminance output value (Y = YSAT).

3. Adjust the light intensity to 500 times of the value with which Y is YA, then remove the read-out clock and drain the signal in photosensors by the electronic shutter operation in all the respective horizontal blanking times with the other clocks unchanged. Measure the maximum illuminance output value (YSM).

Y SM 1 1 SM = ---------- ---------- ------ 100 ( % ) Y A 500 10

4. Adjust the light intensity to 1,000 times of the value with which Y is YA, then inspect whether there is blooming phenomenon or not.

5. Measure the maximum and minimum illuminance output value (YMAX, YMIN) when the light intensity is adjusted to make Y to be YA.

Y MAX Y MIN - 100 ( % ) U = ----------------------------------YA

6. Measure YD with the horizontal idling time transfer level as reference, when the device ambient temperature is 60 C and all of the light sources are shielded.

7. Follow test method 6, measure the maximum (DMAX) and minimum illuminance output (DMIN).

D = D MAX D MIN

10

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

8. Adjust the light intensity of Y signal output value by strobe light to 150mV (YA), calculate by below formula with measuring the image lag signal which is qenerated by below timing diagram.

Y LAG = ( Y lag 150 ) 100 ( % )

FLD

SG1 Light Strobe Timing Y Signal Output 150mV

YLag

Output

9. Adjust the light intensity of Y signal average value to 150mV (YA), calculate by below formula with measuring the signal differences (Yf [mV]) between fields.

F Y = ( Y f Y A ) 100 ( % )

11

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

SPECTRAL RESPONSE CHARACTERISTICS

Excluding Light Source Characteristics

1 0.9 0.8 Spectral Response 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 400 425 450 475 500 525 550 575 600 625 650 675 700 Wave Length (nm)

Figure 2. Spectral Response Characteristics

12

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

APPLICATION CIRCUITS

-7.5V

CCD Out

1M 10/16V

+ -

100

3.9K 152 2SK1070

104 MA110 10/16V

7 VOUT

VDD 8

+ -

- +

S5F429PX02

100K

1/35V

6 5 4 3 2 1

GND NC V1 V2 V3 V4

GND 9 SUB 10 VL 11 RG 12 H1 13 H2 14

103

10

20

19

18

17

16

15

14

13

12

11

S5C7221X01

1 2 3 4 5 6 9

10

10/16V

+ -

XSUB XV2 XV1 XSG1 XV3 XSG2 XV4

H2 H1

RG

15V

Figure 3. Application Circuits

13

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

READ-OUT CLOCK TIMING CHART

Unit: [s]

HD

V1 Odd Field V2 2.5

V3

V4 38.5 1.2 1.5 2.5 2.0

0.3 V1

V2 Even Field V3

V4

Figure 4. Read-out Clock Timing Chart

14

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

CLOCK TIMING CHART (VERTICAL SYNC.)

FLD VD BLK HD 620 625 1 2 3 4 5 10 15 20 25 310 315 320 325 330 335 340

SG1 SG2

V1 V2 V3 V4 CCD OUT CLP1 582 581 246 135 246 135 582 581 2468 135 7 2468 1357

Figure 5. Clock Timing Chart (Vertical Sync.)

15

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

CLOCK TIMING CHART (HORIZONTAL SYNC.)

5 3 2 1 7 5 3 2 1 16 15

10

5 3 2 1

30

25

20

15

10

5 3 2 1 500

495

490

XSHD

XSHP

CLP1

Figure 6. Clock Timing Chart (Horizontal Sync.)

16

SUB

BLK

HD

RS

H1

H2

V1

V2

V3

V4

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

S5F429PX02

PACKAGE DIMENSIONS

(Unit = mm) Glass 7583 Ceramicframe Al 2O 3 90%Min. (black) 0.38 Ceramic Base Al 2O 3 90%Min. (black) Lead Frame Alloy 42 ( Inner AI Outer Sn ) 4-R 0.50 (L/F CL) Y #14 #8 0.25 4-R 0.30

10.000.12 5.400.10 7.400.10 X 2.50 X (L/F CL) 10.000.12 R0.70 0.900.08 1.000.08 0.350.08 4-R0.50 2.600 0.800.15

9.46 0.12 10.160.30

#1

Y 6.000.10 10.000.12

#7

NOTES:

0.460.10 Glass (7583)

1. Max. Leakage by Hellium Detector 2. Resistance Between Leads 3. Insulation Resistance

:10-8atm. cc/sec at 10 -5 mmHg :Above 10 100HM at 25 , 60% R>H :Electrical leakage shall not exceed 5 nano AMP at 100V D.C

1.270.25

4. Ceamic Material 5. Lead Frame - Coplanarity

:Min. 90% al20 3 (black)

:0.25 Max. (after L/F attach) :0.076/mm, -0.102/mm

4.13

- Planarity - Al clad

1.27 0.05 0.30 0.10 1.27 x 6 = 7.620.10 9.600.12

. Thickness . Thickness . Coverage - Sn thickness 6. Flatness - DIE attach pad - LID seal area 7. Other

:5um to 10um (f or stamp) :2.5um to 12.7um (for etch) :Min. 0.762mm from lead tip :4um to 20um

:Max. 0.051mm :Max. 0.051mm :In according to semi standards.

Figure 7. Package Dimensions

17

S5F429PX02

1/4 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

HANDLING INSTRUCTIONS

Static Charge Prevention CCD image sensors can be easily damaged by static discharge. Before handling, be sure to take the following protective measures. Use non chargeable gloves, clothes or material. Also use conductive shoes. When handling directly, use an earth band. Install a conductive mat on the floor or working table to prevent generation of static electricity. Ionized air is recommended for discharging when handling CCD image sensor. For the shipment of mounted substrates, use boxes treated for the prevention of static charges.

Soldering Make sure the package temperature does not exceed 80 C. Solder dipping in a mounting furnace causes damage to the glass and other defects. Use a grounded 30W soldering iron and solder each pin in less than 2 seconds. For repairs and remount, cool sufficiently. To dismount an imaging device, do not use a solder suction equipment. When using an electronic disoldering tool, use a thermal controller of the zero cross on/off type and connect to ground.

Dust and Dirt Protection Operate in the clean environments (around class 1000 will be appropriate). Do not either touch glass plates by hand or have object come in contact with glass surface. Should dirt stick to a glass surface blow it off with an air blow(for dirt stuck through static electricity ionized air is recommended). Clean with a cotton bud and ethyl alcohol if the glass surface is grease stained. Be careful not to scratch the glass. Keep in case to protect from dust and dirt. To prevent dew condensation, preheat or precool when moving to a room with great temperature differences. When a protective tape is applied before shipping, just before use remove the tape applied electrostatic protection. Do not reuse the tape.

Do not expose to strong light (sun rays) for long period, color filter are discolored.

Exposure to high temperature or humidity will affect the characteristics. accordingly avoid storage or usage in such conditions.

CCD image sensors are precise optical equipment that should not be subject to mechanical shocks.

18

Anda mungkin juga menyukai

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- The Diary of Anne Frank PacketDokumen24 halamanThe Diary of Anne Frank Packetcnakazaki1957Belum ada peringkat

- 110 Waveform Generator Projects for the Home ConstructorDari Everand110 Waveform Generator Projects for the Home ConstructorPenilaian: 4 dari 5 bintang4/5 (1)

- Department of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityDokumen2 halamanDepartment of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityRica Tano50% (2)

- Instrumentation and Test Gear Circuits ManualDari EverandInstrumentation and Test Gear Circuits ManualPenilaian: 5 dari 5 bintang5/5 (1)

- Statement Bank MBBDokumen11 halamanStatement Bank MBBminyak bidara01Belum ada peringkat

- Beginning Digital Electronics through ProjectsDari EverandBeginning Digital Electronics through ProjectsPenilaian: 5 dari 5 bintang5/5 (1)

- Professional Builder - Agosto 2014Dokumen32 halamanProfessional Builder - Agosto 2014ValBelum ada peringkat

- CE ProblemDokumen5 halamanCE ProblemJho FBelum ada peringkat

- Judges - God's War Against HumanismDokumen347 halamanJudges - God's War Against HumanismgypsylanternBelum ada peringkat

- Intelligent Transportation System SolutionsDokumen38 halamanIntelligent Transportation System SolutionsWisnu AjiBelum ada peringkat

- Gantt Chart Engr110 - Gantt Chart Template 3Dokumen1 halamanGantt Chart Engr110 - Gantt Chart Template 3api-375485735Belum ada peringkat

- Manual de Instruções Iveco Eurocargo Euro 6Dokumen226 halamanManual de Instruções Iveco Eurocargo Euro 6rsp filmes100% (1)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Dari EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Penilaian: 4.5 dari 5 bintang4.5/5 (3)

- Surface Coating ProcessesDokumen7 halamanSurface Coating ProcessesSailabala ChoudhuryBelum ada peringkat

- What Are Universities ForDokumen19 halamanWhat Are Universities ForBikash Ranjan MishraBelum ada peringkat

- ICX098AK: Aaaaa Aaaaa AaaaaDokumen22 halamanICX098AK: Aaaaa Aaaaa AaaaaFrancis TaisantBelum ada peringkat

- Diagonal 4.5mm CCD Image Sensor SpecificationsDokumen21 halamanDiagonal 4.5mm CCD Image Sensor SpecificationsEduardo AlamillaBelum ada peringkat

- PM 150 CSD 120Dokumen7 halamanPM 150 CSD 120elecompinnBelum ada peringkat

- DENON AVR 1802 882 Service Manual PDFDokumen94 halamanDENON AVR 1802 882 Service Manual PDFatvstereo50% (4)

- Chassis Sanyo Con UOC TMPA8823-5VA4 Manual de ServicioDokumen16 halamanChassis Sanyo Con UOC TMPA8823-5VA4 Manual de ServicioRobert Vicuña100% (1)

- 15-inch Monitor SpecsDokumen49 halaman15-inch Monitor Specsfvb_spamBelum ada peringkat

- 20065819114669071Dokumen58 halaman20065819114669071Andrei BistriceanuBelum ada peringkat

- TA1270BF: Pal / NTSC Video Chroma and Sync Processing System For Pip / Pop / PapDokumen39 halamanTA1270BF: Pal / NTSC Video Chroma and Sync Processing System For Pip / Pop / PapAzmi PlgBelum ada peringkat

- Iraudamp15: 35W/4 X 2 Channel Class D Audio Power Amplifier Using The IR4311Dokumen13 halamanIraudamp15: 35W/4 X 2 Channel Class D Audio Power Amplifier Using The IR4311Megosah SagemegosBelum ada peringkat

- Ic CJ125Dokumen7 halamanIc CJ125Valerio Millan RandoBelum ada peringkat

- CXD3400N: 6-Channel CCD Vertical Clock DriverDokumen9 halamanCXD3400N: 6-Channel CCD Vertical Clock DriverJaffer SultanBelum ada peringkat

- Data Sheet TC 14433Dokumen20 halamanData Sheet TC 14433Heriberto Flores AmpieBelum ada peringkat

- Energy Metering Ic With Pulse Output: DescriptionDokumen7 halamanEnergy Metering Ic With Pulse Output: DescriptionvungocduongBelum ada peringkat

- Bosch Cj120Dokumen7 halamanBosch Cj120Thiago BronoskiBelum ada peringkat

- ADF4110/ADF4111/ADF4112/ADF4113 RF PLL Frequency SynthesizersDokumen24 halamanADF4110/ADF4111/ADF4112/ADF4113 RF PLL Frequency SynthesizersMichael LiuBelum ada peringkat

- PLL Frequency Synthesizer ADF4107: Features General DescriptionDokumen20 halamanPLL Frequency Synthesizer ADF4107: Features General DescriptionThanh Son NguyenBelum ada peringkat

- 3 3/4 Digit Auto DMM with Frequency CounterDokumen23 halaman3 3/4 Digit Auto DMM with Frequency CounterBluff FlersBelum ada peringkat

- 1267379259Dokumen7 halaman1267379259sinasayedanaBelum ada peringkat

- Ansys Workbench TutorialsDokumen13 halamanAnsys Workbench Tutorialsmech118Belum ada peringkat

- sc7001q Ay 961Dokumen18 halamansc7001q Ay 961r2c1Belum ada peringkat

- AD4112Dokumen24 halamanAD4112cbernal73Belum ada peringkat

- AN8806SB: Three-Beam Method Head Amplifier IC For CD PlayerDokumen10 halamanAN8806SB: Three-Beam Method Head Amplifier IC For CD PlayeraldoBelum ada peringkat

- MSM6544Dokumen13 halamanMSM6544Shuvamay GuhaBelum ada peringkat

- Cxa1645 TV EncoderDokumen14 halamanCxa1645 TV EncoderkorrekaminosBelum ada peringkat

- Energy Metering IC With On-Chip Fault Detection: 8% (30 PPM/ C Typical)Dokumen16 halamanEnergy Metering IC With On-Chip Fault Detection: 8% (30 PPM/ C Typical)saandoBelum ada peringkat

- Service Manual For 25LXDokumen14 halamanService Manual For 25LXLuis Carlos100% (1)

- Plugin-LDICA LAB ManualDokumen83 halamanPlugin-LDICA LAB Manualnainesh goteBelum ada peringkat

- Daewoo Osdtd29n001Dokumen21 halamanDaewoo Osdtd29n001miltoncgBelum ada peringkat

- Akira Ss1 Con Lc863320a y La 76810Dokumen12 halamanAkira Ss1 Con Lc863320a y La 76810pepino464Belum ada peringkat

- Mitsubishi Ics (TV) : DD DD DDDokumen15 halamanMitsubishi Ics (TV) : DD DD DDJoel MarvalBelum ada peringkat

- Dual D-Type Flip-Flop: Integrated CircuitsDokumen8 halamanDual D-Type Flip-Flop: Integrated CircuitsRakesh Kumar DBelum ada peringkat

- ADF4351 DatasheetDokumen28 halamanADF4351 DatasheetpravinrautrautBelum ada peringkat

- 3Y11 FullDokumen24 halaman3Y11 FulltodorloncarskiBelum ada peringkat

- SC 9711Dokumen14 halamanSC 9711dragon-red0816Belum ada peringkat

- Build A Cheap Oscilloscope and Sensor Probes For Physics Experiments in SchoolDokumen45 halamanBuild A Cheap Oscilloscope and Sensor Probes For Physics Experiments in SchooltecsupportBelum ada peringkat

- Datasheet Micro M65582AMF-105FPDokumen46 halamanDatasheet Micro M65582AMF-105FPsel_mor100% (1)

- TDA7396Dokumen12 halamanTDA7396Caravela CienxcuatroBelum ada peringkat

- Motor Driver For CD-ROMsDokumen10 halamanMotor Driver For CD-ROMscostpopBelum ada peringkat

- PLL Frequency Synthesizer: Data SheetDokumen20 halamanPLL Frequency Synthesizer: Data SheetngayhevuiBelum ada peringkat

- Adf4110 4111 4112 4113Dokumen28 halamanAdf4110 4111 4112 4113Juan Manuel MuñozBelum ada peringkat

- Data Sheet of ADE7751Dokumen17 halamanData Sheet of ADE7751NithyaBelum ada peringkat

- Harman Kardon Avr2550Dokumen50 halamanHarman Kardon Avr2550videosonBelum ada peringkat

- Colour TV Set: ModelsDokumen19 halamanColour TV Set: ModelsLefter TironBelum ada peringkat

- 244LD Intelligent Buoyancy Transmitter With Torque Tube and Displacer For Level, Interface and Density - All VersionsDokumen48 halaman244LD Intelligent Buoyancy Transmitter With Torque Tube and Displacer For Level, Interface and Density - All VersionsTreeBelum ada peringkat

- LA7209V ISO/IEC-14443 RF amplifier overview and specsDokumen14 halamanLA7209V ISO/IEC-14443 RF amplifier overview and specsmika000Belum ada peringkat

- TMPA 8823-5VA4 Service Manual: IC Functions and I2C Bus ControlDokumen16 halamanTMPA 8823-5VA4 Service Manual: IC Functions and I2C Bus ControlAndy AnsahBelum ada peringkat

- 10.709 Gbps Laser Diode Driver Chipset: A To 1200 ADokumen12 halaman10.709 Gbps Laser Diode Driver Chipset: A To 1200 ABanyugeaBelum ada peringkat

- ADE7753Dokumen38 halamanADE7753Kunal KundanamBelum ada peringkat

- CB900K e 0203Dokumen73 halamanCB900K e 0203Vuong NguyenBelum ada peringkat

- Galaxy Electrical: Zener DiodesDokumen3 halamanGalaxy Electrical: Zener Diodesdragon-red0816Belum ada peringkat

- Galaxy Electrical: Zener DiodesDokumen3 halamanGalaxy Electrical: Zener Diodesdragon-red0816Belum ada peringkat

- MM 74 HCDokumen6 halamanMM 74 HCdragon-red0816Belum ada peringkat

- N-Channel TrenchMOS Transistor IRF540, IRF540SDokumen9 halamanN-Channel TrenchMOS Transistor IRF540, IRF540Spalupo8708Belum ada peringkat

- NCP1653 DDokumen19 halamanNCP1653 Ddragon-red0816Belum ada peringkat

- 15n03gh PDFDokumen6 halaman15n03gh PDFdragon-red0816Belum ada peringkat

- N-Channel Enhancement Mode FET Technical OverviewDokumen6 halamanN-Channel Enhancement Mode FET Technical Overviewdragon-red0816Belum ada peringkat

- DatasheetDokumen6 halamanDatasheetdragon-red0816Belum ada peringkat

- Kia34063a AfDokumen7 halamanKia34063a Afdragon-red0816Belum ada peringkat

- Aod 4189Dokumen6 halamanAod 4189dragon-red0816Belum ada peringkat

- Max 9247Dokumen17 halamanMax 9247dragon-red0816Belum ada peringkat

- Three Phase Bridge Power Modules Thermal and Electrical SpecificationsDokumen6 halamanThree Phase Bridge Power Modules Thermal and Electrical Specificationsdragon-red0816Belum ada peringkat

- BTA26 A/B Btb26 B: Standard TriacsDokumen5 halamanBTA26 A/B Btb26 B: Standard Triacsdragon-red0816Belum ada peringkat

- Critical Conduction Mode PFC Controller: Features DescriptionDokumen20 halamanCritical Conduction Mode PFC Controller: Features DescriptionRogerio E. SantoBelum ada peringkat

- A 1266Dokumen1 halamanA 1266dragon-red0816Belum ada peringkat

- Ic Cxa1279asDokumen12 halamanIc Cxa1279ascintaka2000Belum ada peringkat

- Sensor EpcosDokumen16 halamanSensor Epcosdragon-red0816Belum ada peringkat

- Symbol Rating Unit Parameter: APPLICATION:High-Voltage, High-Speed Power Switching ApplicationsDokumen1 halamanSymbol Rating Unit Parameter: APPLICATION:High-Voltage, High-Speed Power Switching Applicationsdragon-red0816Belum ada peringkat

- BD9275FDokumen5 halamanBD9275Fproctep100% (1)

- LA78040B Vertical Deflection Output ICDokumen3 halamanLA78040B Vertical Deflection Output ICdragon-red0816Belum ada peringkat

- Dsa 00228843Dokumen2 halamanDsa 00228843dragon-red0816Belum ada peringkat

- Tps 2051 BDokumen29 halamanTps 2051 Bdragon-red0816Belum ada peringkat

- 120V - 100W Dmos Audio Amplifier With Mute/St-By: Multipower BCD TechnologyDokumen13 halaman120V - 100W Dmos Audio Amplifier With Mute/St-By: Multipower BCD Technologydragon-red0816Belum ada peringkat

- Tda 7235Dokumen6 halamanTda 7235dragon-red0816Belum ada peringkat

- R2A20121SP: Synchronous Phase Shift Full-Bridge Control ICDokumen28 halamanR2A20121SP: Synchronous Phase Shift Full-Bridge Control ICdragon-red0816Belum ada peringkat

- An17831 PDFDokumen9 halamanAn17831 PDFBalmiroHernandezBelum ada peringkat

- Tda 8588 AjDokumen54 halamanTda 8588 AjAngel Fig100% (1)

- Dla001d L6599DDokumen36 halamanDla001d L6599DBRIGHT_SPARK50% (6)

- Matrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEDokumen41 halamanMatrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEkhateeb ul islam qadriBelum ada peringkat

- Electronics HubDokumen9 halamanElectronics HubKumaran SgBelum ada peringkat

- Health Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4Dokumen7 halamanHealth Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4John Wilfred PegranBelum ada peringkat

- Elective Course (2) - Composite Materials MET 443Dokumen16 halamanElective Course (2) - Composite Materials MET 443يوسف عادل حسانينBelum ada peringkat

- Turabian Sample PaperDokumen9 halamanTurabian Sample Paperemme_lopez908133% (3)

- The Seven Kings of Revelation 17Dokumen9 halamanThe Seven Kings of Revelation 17rojelio100% (1)

- Institutional Competency Assessment Instrument (ICAI)Dokumen12 halamanInstitutional Competency Assessment Instrument (ICAI)Bea EtacBelum ada peringkat

- Magnets Catalog 2001Dokumen20 halamanMagnets Catalog 2001geckx100% (2)

- Bolt Jul 201598704967704 PDFDokumen136 halamanBolt Jul 201598704967704 PDFaaryangargBelum ada peringkat

- AD 251 - Equivalent Uniform Moment Factor, M (Italic)Dokumen1 halamanAD 251 - Equivalent Uniform Moment Factor, M (Italic)symon ellimacBelum ada peringkat

- Defining Public RelationsDokumen4 halamanDefining Public RelationsKARTAVYA SINGHBelum ada peringkat

- Comparing Financial Performance of Conventional and Islamic BanksDokumen9 halamanComparing Financial Performance of Conventional and Islamic BanksIkbal HardiyantoBelum ada peringkat

- Pmls 1 Final Exam Reviewer: Clinical Chemistry ContDokumen14 halamanPmls 1 Final Exam Reviewer: Clinical Chemistry ContPlant in a PotBelum ada peringkat

- OS9000 AOS 6.1.5 R01 Network Configuration GuideDokumen846 halamanOS9000 AOS 6.1.5 R01 Network Configuration GuideclaupasinaBelum ada peringkat

- Reasons Why Coca Cola Has A Large Market Share in Kenya and The WorldDokumen9 halamanReasons Why Coca Cola Has A Large Market Share in Kenya and The WorldAludahBelum ada peringkat

- Canopen-Lift Shaft Installation: W+W W+WDokumen20 halamanCanopen-Lift Shaft Installation: W+W W+WFERNSBelum ada peringkat

- Assignment 2Dokumen4 halamanAssignment 2maxamed0% (1)

- J-Garlic in CheeseDokumen12 halamanJ-Garlic in CheeseMary GinetaBelum ada peringkat

- Assessment in Southeast AsiaDokumen17 halamanAssessment in Southeast AsiathuckhuyaBelum ada peringkat