Lower Order Theory

Diunggah oleh

jmcc2Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lower Order Theory

Diunggah oleh

jmcc2Hak Cipta:

Format Tersedia

European Journal of Mechanics A/Solids 22 (2003) 771778

On lower order strain gradient plasticity theories

Christian F. Niordson

a,

, John W. Hutchinson

b

a

Department of Mechanical Engineering, Technical University of Denmark, DK-2800 Kgs. Lyngby, Denmark

b

Division of Engineering and Applied Sciences, Harvard University, Cambridge, MA 02138, USA

Received 9 May 2003; accepted 28 May 2003

Abstract

By way of numerical examples, this paper explores the nature of solutions to a class of strain gradient plasticity theories that

employ conventional stresses, equilibrium equations and boundary conditions. Strain gradients come into play in these modied

conventional theories only to alter the tangent moduli governing increments of stress and strain. It is shown that the modication

is far from benign from a mathematical standpoint, changing the qualitative character of solutions and leading to a new type of

localization that is at odds with what is expected from a strain gradient theory. The ndings raise questions about the physical

acceptability of this class of strain gradient theories.

2003 ditions scientiques et mdicales Elsevier SAS. All rights reserved.

Keywords: Strain gradient plasticity; Non-local mechanics

1. Introduction

Conventional continuum theories of plasticity have no constitutive length scale. Any size-dependence in the relationship

between load and deformation depends entirely on geometric dimensions. There is now ample experimental evidence that

geometric dimensions alone cannot account for observed size-dependence of the plastic response of micron-sized solid objects.

Typically, at a scale below tens of microns, but depending on object shape and the type of loading, departures are observed

which can only be interpreted within the connes of conventional theory as an apparent increase in ow strength. It is generally

accepted that this apparent increase in ow strength is due to the generation of geometrically necessary dislocations that

accompany non-uniform plastic straining. It is argued that micron-scale gradients produce geometrically necessary dislocations

at a density comparable to that of statistically stored dislocations, thereby increasing the total dislocation density and the

resistance to plastic ow.

Continuum theories have been proposed recently to extend the validity of conventional plasticity down to roughly the micron

scale. For a continuum theory to have validity, the number of dislocations within a typical representative volume element must be

sufciently large such that meaningful averages over the dislocations can be taken, at least in principle. Based on experimental

observation of load-deformation responses, the apparent range of applicability of a continuum plasticity theory in most instances

appears likely to extend upward from the micron, or possibly sub-micron, scale. The limit of any such theory when the length

characterizing the deformation eld becomes large compared to the constitutive length parameters should be the corresponding

conventional theory. Continuum strain gradient plasticity theories have been proposed for single crystals (e.g., Gurtin, 2000;

Arsenlis and Parks, 1999; Busso et al., 2000) and as extensions of the classical phenomenological theories of plasticity (e.g.,

de Borst and Mhlhaus, 1992; Gao et al., 1999; Bassani, 2001; Fleck and Hutchinson, 2001). These theories divide into two

classes: those with conventional stresses, equilibrium equations and boundary conditions (e.g., Bassani, 2001; Arsenlis and

Parks, 1999; Busso et al., 2000); and those having additional stress quantities and additional boundary conditions (e.g., de Borst

*

Corresponding author.

E-mail addresses: cn@mek.dtu.dk (C.F. Niordson), hutchinson@husm.harvard.edu (J.W. Hutchinson).

0997-7538/$ see front matter 2003 ditions scientiques et mdicales Elsevier SAS. All rights reserved.

doi:10.1016/S0997-7538(03)00069-X

772 C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778

and Mhlhaus, 1992; Gao et al., 1999; Gurtin, 2000; Fleck and Hutchinson, 2001). For want of a better terminology, a member

of the former class is referred to here as a lower order strain gradient theory, while a member of the latter is termed a higher

order gradient theory.

Lower order gradient theories are addressed in the present paper. These theories are intrinsically incremental in nature with

stresses, incremental equilibrium equations and boundary conditions that are taken to be the same as in conventional theory.

Only the incremental constitutive relation is different fromconventional theory. In the rate-independent version of these theories,

which will be considered here, the constitutive relation is altered by incorporating a dependence on the gradient of plastic strain

in the tangent moduli, reecting the increased ow resistance.

In the course of carrying out a numerical analysis of a basic boundary value problem with one particular version of the

lower order gradient theories, it was noticed that some seemingly anomalous behavior emerged in the form of an inexplicable

localization of ow. This lead us to step back and analyze several elementary problems with the aim of more clearly revealing

the nature of solutions to this class of theories. For the two problems explored here, it will be seen that solutions with an unusual

form of localization occurs that appears to be unphysical in nature. Contrary to a smoothing of steep gradients that is expected

to follow from the introduction of a gradient theory, the lower order gradient theory promotes the development of certain kinds

of discontinuities. These ndings raise issues as to the soundness of this class of theories, which are discussed at the conclusion

of the paper.

2. A lower order strain gradient theory

A generalization of J

2

-ow theory proposed by Acharya and Bassani (1996) and Bassani (2001) to account for size

effects due to hardening by plastic strain gradients is employed here. This lower order isotropic hardening theory represents

the most direct and simplest generalization of classical theory that incorporates size-dependence associated with a material

length parameter. The version of the formulation introduced below assumes small strains and small rotations. The strain-

displacement relation is the conventional one,

ij

=

1

2

(u

i,j

+u

j,i

), as are the stresses,

ij

=

ji

, and the incremental equations

of equilibrium,

ij,j

=0 (no body forces). Plastic strain gradients are introduced through a positive invariant, , of the gradient

of the plastic strain tensor

p

ij

dened below. The constitutive relations are dened by (see Bassani, 2001)

e

=

_

1

2

s

ij

s

ij

, (1)

e

=h

_

p

e

, l

_

p

e

, (2)

p

ij

=

_

p

e

2

e

_

s

ij

, (3)

ij

=C

ijkl

_

kl

p

kl

_

, (4)

where s

ij

is the stress deviator and

e

is the effective shear stress. The effective plastic strain,

p

e

=

_

_

2

p

ij

p

ij

, is work

conjugate to

e

. The isotropic elastic stiffness tensor is C

ijkl

. The effect of plastic strain gradients are included through Eq. (2),

where it is noted that the incremental hardening modulus, h, depends on the plastic strain gradient measure, , in addition

to the effective plastic strain

p

e

. The material length parameter l must be included for dimensional consistency. The specic

denition of used in the present work is

2

= 2

ij

ij

where

ij

= e

jkl

p

il,k

. The expression for h is taken from Bassani

(2001), and can be written as

h

_

p

e

, l

_

=

G

n

_

p

e

0

+1

_

1/n1

_

1 +

(l/

0

)

2

1 +c(

p

e

/

0

)

2

_

1/2

, (5)

where G is the elastic shear modulus,

0

is the initial yield strain in shear, and c is an adjustable parameter taken to be unity in

the present work. In the limit when the combination l/

0

is small, h reduces to classical J

2

ow theory with a commonly used

strain hardening relation. Under uniform shearing,

p

e

/

0

(

e

/

0

)

n

as the stress becomes large, with

0

=G

0

as the initial

yield stress in shear. The role of the gradient of plastic strain in (5) is to increase the incremental hardening modulus. It should

be emphasized that the specic form (5) is not critical to our discussion or qualitative ndings, as will be discussed later.

3. Shear of an innite layer

Consider an innitely long elasticplastic layer of the material of Section 2 of thickness 2D bonded to two rigid platens

whose surfaces coincide with x

1

= D and x

1

= D, as in Fig. 1 with L = . The platens are displaced parallel to one

C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778 773

Fig. 1. A slab of material between rigid platens is analyzed under shear deformation. The elasticplastic solid occupies the region Lx

2

L

and Dx

1

D, and the platens are displaced the distance 2U relative to each other in the direction of the x

2

-axis.

another according to u

2

= U on x

1

= D and u

2

= U on x

1

= D imposing an average shear strain = 2

12

= U/D on

the layer. In the absence of any initial non-uniformity the layer will undergo a uniform shear strain with uniform plastic strain

across the layer and no gradient of plastic strain. The conventional solution satises the eld equations even if is non-zero. To

activate gradient effects, one must consider some initial non-uniformity. For this purpose, the layer is assumed to have an initial

parabolic distribution of plastic strain across the width of the solid with

p(i)

(x

1

) =

(i)

(1 (x

1

/D)

2

). This can be regarded

as a pre-existing, non-uniform dislocation density across the width of the layer with

(i)

0 being the magnitude of the initial

plastic strain prole.

When the platens are displaced, the layer undergoes non-uniform shearing where the total strain, 2

12

, elastic strain,

e

=/G (

12

), and plastic strain,

p

=

e

, depend only on x

1

. One can readily show that the problem for the plastic

strain reduces to solving the equation = h(

p

, l|

p

,1

|)

p

where

p

,1

is the derivative of the plastic shear strain. Equilibrium

dictates that the shear stress, , is uniform throughout the layer, and hence so is the elastic shear strain,

e

.

Two distributions of the initial yield stress,

Y

, will be considered, although it will be seen that the choice has little

effect on the essential outcome. The simplest choice is a uniform distribution,

Y

=

0

= G

0

, taking no account of the

initial plastic strain on initial yield. The other choice accounts for an increase in the initial yield stress due to the initial

dislocation density through the hardness function. The material is assumed to have reached the initial distribution of plastic

strain proportionally such that initial distribution of plastic strain evolves according to

p

(x

1

) = t

p(i)

(x

1

) with t being a

parameter increasing from zero to unity. Using this assumption the initial yield stress,

y

(x

1

), can be obtained by integrating

the relation

y

(x

1

) =h(

p

, l|

p

,1

|)

p(i)

(x

1

) t .

Attention will be limited to initial distributions and solutions that are symmetric with respect to the mid-plane of the layer.

Numerical solutions are obtained through a nite-difference approach, where the half width of the layer, from x

1

=0 to x

1

=D,

is modeled and discretized into 81 nodes. Load integration is performed using a Forward Euler method with load increments

equal to 10

5

0

. A central difference scheme is employed throughout the inner nodes to evaluate the gradient of the plastic

strain. Skew differences, also of second order accuracy, are employed at x

1

=0 and x

1

=D. The skew difference at x

1

=0 has

the effect of allowing for a non-smooth development of the plastic strain distribution at this point, which is indeed necessary to

obtain the correct solution for the problem.

The overall shear stress versus shear strain response is shown in Fig. 2 for the amplitude of the initial plastic strain distribution

given by

(i)

=

0

=

0

/G and the associated non-uniform initial yield stress distribution. The curves in the gure correspond

to different values of the material length scale l, with n = 5. As expected, an increase in l gives an increase in the predicted

overall stressstrain response. For the curve corresponding to l =0, proles of plastic shear strain for x

1

between 0 and D are

shown for different values of the overall shear strain in Fig. 3. Since the initial yield stress and the plastic strain are exactly

matched, a constant level of plastic strain develops, and for overall strains above /

0

=1.5 the plastic strain prole is constant

across the entire layer. Before yield occurs across the layer, the derivative of the plastic strain has a discontinuity at the current

elasticplastic boundary. For materials with l > 0 this presents a problem for the nite difference scheme. To circumvent this

problem, the derivative of the plastic strain is interpolated between values of the derivative at a distance of l/40 on each side of

the elasticplastic boundary. Specically, if the coordinate of the current elasticplastic boundary is denoted x

p

, the gradient of

plastic strain is interpolated linearly between the values of the gradient at x

1

=x

p

l/40 and that at x

1

=x

p

+l/40, for nodes

within the interval [x

p

l/40; x

p

+l/40].

In Figs. 4(a) and 4(b) proles of the plastic shear strain are shown for various levels of overall deformation, /

0

, when

the internal material length scale is l/D =3. The solid curves correspond to a material where the initial yield stress has been

774 C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778

Fig. 2. Shear stress as a function of shear strain, for different

values of the internal material length scale, and L/D =.

Fig. 3. Development of the plastic strain prole for a conventional

material, with an initial imperfection of plastic strain, and L/D =.

Fig. 4. The development of the proles of effective plastic strain, along the x

1

-axis, for an innite slab of material (L/D =) with an initial

distribution of plastic strain, and an internal material length scale given by l/D = 3. The solid curves show results for a material where the

initial yield stress distribution is matched to the initial plastic strain distribution, while the dashed curves show results for a material with a

constant yield stress,

y

=

0

, which is independent of the initial plastic strain prole. In gure (a) the proles of plastic strain are shown for an

overall deformation level of up to /

0

=10, and in gure (b) the proles are shown for an overall deformation level of up to /

0

=2.

matched to the initial level of plastic strain as described earlier, while the dashed curves show results for a material where the

initial yield stress is assumed to be constant and equal to

0

. The lower curve in each of these gures shows the initial plastic

strain prole corresponding to loading below initial yield, while the curves above correspond to an overall shear strain that

C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778 775

gives rise to additional plastic straining. The difference between the plastic strain distributions for the two choices of initial

yield stress at relatively small levels of overall plastic strain is due to the way plastic yielding spreads across the layer. However,

the difference becomes insignicant as the overall shear increases.

The essential feature of the solution that emerges in Fig. 4 is the development of a vertex in the plastic strain distribution

corresponding to a discontinuous derivative of the plastic strain at the center of the layer at x

1

= 0. This unusual form of

shear localization is unexpected because the incorporation of strain gradients is generally expected to smooth plastic strain

distributions. Indeed, the rst introduction of a gradient theory of plasticity by Aifantis (1984) was for the purpose of smoothing

abrupt shear locations leading to nite width shear bands. It has become common practice to employ strain gradient dependence

as a localization limiter in the analysis of materials prone to localization (e.g., Jirasek and Bazant, 2002). By contrast, the lower

order strain gradient theory appears to promote an unusual formof localization. The occurrence of the plastic strain vertex in the

present context is particularly troubling from a physical standpoint because the conventional solution to the shearing problem

with = 0 is perfectly smooth. Shear localization is excluded in the small strain formulation for a conventional hardening

material (h > 0).

The shear problem is sufciently simple that the reason for the development of the vertex localization is transparent. Consider

the equation governing the plastic strain, =h(

p

, l|

p

,1

|)

p

. In the lower order gradient theory, for xed

p

, h is necessarily

a minimum with respect to

p

,1

at

p

,1

=0, since it is essential to this class of theories that gradients increase the tangent modulus.

This is the case in (5). Moreover, for xed

p

,1

, h decreases with increasing

p

. It follows that any smooth distribution of h with

a local maximum in

p

will have the lowest tangent modulus at the maximum. Because is uniform, it follows that

p

must

also be maximum at that point. Moreover, if

p

,1

=0 were to be maintained at this point, the plastic strain in the vicinity of that

point would run away because h decreases most rapidly at this point. Instead, as seen in Fig. 4, a vertex in the distribution of

plastic strain develops at the point with a discontinuity in

p

,1

. When =0, the combined roles of

p

and

p

,1

allow the balance

required for satisfaction of a constant value of = h(

p

, l|

p

,1

|)

p

to be achieved at the mid-point. The above argument is

quite general suggesting that any hardening relation proposed for this class of lower order theories would lead to vertex-type

localizations given an initial non-uniformity with a region that is locally hard.

The same qualitative reasoning can be applied to a situation where the plastic strain distribution begins with a smooth

minimum such that the material is locally soft at the mid-point. Now, in the absence of any effect of

p

,1

, h would have a

maximum at the point and

p

a minimum. However, the two contributions to the tangent modulus, from both

p

and

p

,1

, no

longer both conspire to depress

p

at the mid-point. Now, they work to opposite effect. Numerical calculations similar to those

described above with

p(i)

(x

1

) =

(i)

(x

1

/D)

2

indeed revealed that no vertex development occurs at x

1

=0 if the initial plastic

strain distribution has a smooth minimum at the mid-point.

The existence of solutions to the lower order theory such as those in Fig. 4 is related to the ndings reported by Volokh and

Hutchinson (2002) on a similar innite layer problem in the absence of any initial non-uniformity. These authors have shown

that the solution to the lower order formulation for the elementary shear problem is not unique for a material with continuous

tangent modulus at the onset of yield. They produced a family of solutions, including members that are similar to those that

emerge in Fig. 4. The existence of multiple solutions to the lower order theory arises from the fact that higher order terms have

been introduced into the theory without an increase in the number of boundary conditions. In any problem, such as the shear

problem, where initial yield occurs simultaneously over all or part of the body and where the tangent modulus is continuous

at yield, the emergence of the gradient of plastic strain at the onset of yielding is indeterminate. The initial tangent modulus

is also indeterminate. Multiple solutions are possible depending on how the initial gradient is specied. In the shear problem,

it is possible to specify the initial gradient by requiring that an extra boundary condition be satised. Alternatively, an initial

non-uniformity has the effect of selecting one of the many possible solutions. Although we have not attempted to do so, it

would be interesting to conduct a systematic study to relate the initial imperfection to solution selection.

Finally, it should be mentioned that a well-formulated higher order gradient theory of plasticity does not admit multiple

solutions to problems like the shear problem, nor does it lead to localization. If constraints to plastic ow at the interface with

the platens are not imposed, these theories predict uniform shearing across the layer as in the case of the conventional solution.

However, if the additional boundary conditions associated with the theory are used to impose constraints at the platens, non-

uniform plastic ow results. For example, Fleck and Hutchinson (2001) and Bittencourt et al. (2003) model blocked dislocations

at an interface by an additional boundary condition requiring the plastic strain to vanish at the platens. Even if the layer is initially

uniform, non-uniform plastic deformation develops due to the boundary constraint.

4. Shear of a nite layer

In the problem analyzed thus far, strain gradients are triggered by an initial non-uniformity. For problems where conventional

theory predicts an inhomogeneous plastic strain distribution, due to object shape or to spatial variation of the applied loads,

776 C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778

gradients of plastic strain develop naturally. For these problems, gradient effects will be predicted by both classes of gradient

theories. A problem of this type will be studied in this section.

A nite slab of elasticplastic material between to rigid platens is considered as depicted in Fig. 1. The slab has the thickness

2D and the length 2L, and it occupies the region D x

1

D and L x

2

L. As before, at x

1

= D displacements

u

2

= U, respectively, are prescribed with no displacement in the other two directions. The ends of the elasticplastic slab

at x

2

= L are traction free. Now, the requirement

12

= 0 on the ends results in distinctly non-uniform behavior. Initial

non-uniformity is not considered. The problem has a plane strain solution. Let

e

=

3

e

and

p

e

=(1/

3)

p

e

. Replace (2) by

e

=h

_

p

e

, l

_

p

e

, (6)

where instead of (5), let

h

_

p

e

, l

_

=

E

n

_

p

e

0

+1

_

1/n1

_

1 +

(l/(

3

0

))

2

1 +c(

p

e

/

0

)

2

_

1/2

. (7)

Now, E is Youngs modulus, is Poissons ratio,

0

=

y

/E is the uniaxial yield strain, and

y

is the initial yield stress in

uniaxial tension. (There is a slight difference from the constitutive relation in the last section, but they coincide for =1/2.)

Numerical solutions are obtained by use of the Finite Element Method with quadrilateral elements each subdivided into 4

linear displacement triangles. The gradient of the plastic strain tensor is found by assigning nodal values of the plastic strain

tensor as the average of the plastic strain tensors in the elements connected to a node. Then, the gradient is evaluated for each

quadrilateral at the center point by interpolating the components of the plastic strain tensors from the four nodal values of the

quadrilateral using bilinear shape functions. This procedure rests on the assumption that the plastic strain eld is smooth. As

shown in the previous section, this will not necessarily be true for the gradient dependent solids, even though the initial plastic

strain eld is smooth. Load integration is performed using the Forward Euler method.

A slab of material with aspect ratio L/D =1 is analyzed. The material parameters are

0

=0.01, =0.3 and n =5. This

problem corresponds to the shear problem analyzed by Niordson and Hutchinson (2003), within the framework of the higher

order strain gradient plasticity theory proposed by Fleck and Hutchinson (2001). In Fig. 5 the normalized average traction,

/

y

, as computed from the lower order gradient theory under consideration here is shown as a function of =U/(D

0

) for

different values of the internal material length scale. The gure illustrates the predicted strengthening effect due to plastic strain

gradients. For l/D =0.25 an increase in the average traction of around 7% relative to the conventional response is found at the

overall deformation U/(D

0

) = 20, while for l/D =0.5 the increase is approximately 16%. These results are obtained using

20 times 20 quadratic quadrilaterals covering one fourth of the slab, enabled by the double symmetry of the problem.

In Fig. 6 the development of the effective plastic strain prole along the x

1

-axis is shown. In each sub-gure the prole of

the effective plastic strain,

p

e

, is shown for ve overall deformation levels; U/(D

0

) =4, 8, 12, 16, and 20. Each row of sub-

gures shows results for different mesh renements; the rst row shows results for 10 times 10 elements covering one fourth

of the slab, and the second and third row show results for 20 times 20 and 40 times 40 elements, respectively. Each column

shows the development of the effective plastic strain prole for a different value of the internal material length scale normalized

with respect to the half width of the slab. The rst column shows the conventional predictions, while the second and third

column show results for l/D =0.25 and l/D = 0.5, respectively. For a given spatial discretization it is seen from Fig. 6, that

Fig. 5. Average shear stress as a function of the overall deformation, for a rectangular slab of material between rigid platens with L/D=1. The

curves show results for different values of the internal material length scale.

C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778 777

Fig. 6. Plastic strain proles along the x

1

-axis for a rectangular slab (L/D =1), at different levels of overall deformation. The gure illustrates

how the plastic strain proles are predicted for different values of the internal material length scale, and for different mesh renements.

the predicted peak value of effective plastic strain along the x

1

-axis increases with an increasing internal material length scale.

Furthermore, the peak, which remains quite smooth for the conventional solid, becomes more pronounced as the deformation

progresses and increasingly narrower the larger l/D. It is evident that a vertex in the plastic strain distribution is developing

for the solids with l/D > 0. The vertex is located along the ridge where the effective plastic strain has a local maximum in

the conventional solution. The tangent modulus develops a signicant decit along the ridge for reasons analogous to those

discussed in the previous section, leading to the vertex localization. We note in passing that the problem for same geometry and

loading but characterized by a higher order strain gradient theory gives rise to smooth distributions of plastic strain (Niordson

and Hutchinson, 2003).

The evolution of the effective plastic strain prole is rather insensitive to mesh renement for the conventional material with

l/D =0. By contrast, the peak value of effective plastic strain increases signicantly upon mesh renement when l/D =0.25,

and even more so when l/D =0.5. Furthermore, for the most highly rened mesh for l/D = 0.5, it is evident that the plastic

strain prole becomes increasingly non-smooth with increasing deformation. As the vertex develops, the numerical method has

778 C.F. Niordson, J.W. Hutchinson / European Journal of Mechanics A/Solids 22 (2003) 771778

increasing difculty rendering an accurate solution. If one were interested in following the development much further than that

shown, a method specialized to cope with vertex-like behavior would have to be developed, but that is not our objective.

5. Conclusions

Both examples studied here reveal that vertex-type shear localization develops as deformation proceeds in a hardening

material characterized by a lower order, strain gradient theory of plasticity. In the innite layer subject to shear, strain gradients

are triggered by an initial non-uniformity, while in the nite layer gradients are present from the start. The vertex distribution

of plastic strain is unusual and it is our belief that it is unlikely to have any physical basis. Indeed, in these examples, rather

than smoothing the plastic strain distribution as would normally be expected of a strain gradient theory, the lower order gradient

theory has the opposite effect. A qualitative explanation of the emergence of vertex localization is given for the innite layer.

The vertex develops at locations where the effective plastic strain is a maximum and its gradients vanish.

Although the two problems investigated here are fairly simple, it is unlikely that they are exceptional as far as the behavior

they reveal. The unusual behavior is a consequence of the mathematical formulation of the lower order gradient theories. On the

face of it, the modication introduced to create the lower order theory would appear to leave the mathematical character of the

eld equations unchanged. The order of the eld equations for the incremental quantities is the same as for conventional theory.

However, the strain gradients introduced into the tangent moduli result in terms in the total (or integrated) quantities appearing

in these equations that are more highly differentiated than any that appear in conventional theory. The presence of these terms

is directly related to existence of a multiplicity of solutions in problems such as that studied by Volokh and Hutchinson (2002).

The present examples provide further evidence that modifying the tangent moduli by a dependence on strain gradients is not

necessarily a benign process from a mathematical point of view.

In conclusion, it is worth viewing lower order theories in light of strain gradient elasticity theory, which is a simpler system

to envision. If one postulates that the strain energy density of an elastic solid depends on both the strains and gradient of strains,

then the resulting theory is inescapably higher order with additional stress quantities and boundary conditions (Mindlin, 1964).

The lower order gradient plasticity theory retains the order of conventional theory because only the tangent moduli that appear

in the eld equations for the incremental quantities are modied using strain gradients in the current state. Additional stress

quantities never arise, and, in general, additional boundary conditions for the incremental boundary value problem are neither

required nor allowed. The seductive simplicity of this lower order modication strategy would not work for elasticity. Whether

it can be justied from a physical standpoint for plasticity remains an open question. The examples presented here indicate that

there exist solutions to the lower order formulation that are unexpected and, probably, unphysical.

References

Acharya, A., Bassani, J.L., 1996. On non-local ow theories that preserve the classical structure of incremental boundary value problems. In:

Pineau, A., Zaoui, A. (Eds.), IUTAMSymposium on Micromechanics of Plasticity and Damage of Multiohase Materials. Kluwer Academic,

pp. 39.

Aifantis, E.C., 1984. On the microstructural origin of certain inelastic models. Trans. ASME J. Engrg. Mat. Tech. 106, 326330.

Arsenlis, A., Parks, D.M., 1999. Crystallographic aspects of geometrically-necessary and statistically-stored dislocation density. Acta Mater. 47,

15971611.

Bassani, J.L., 2001. Incompatibility and a simple gradient theory of plasticity. J. Mech. Phys. Solids 49, 19831996.

Bittencourt, E., Needleman, A., Gurtin, M.E., Van der Giessen, E., 2003. A comparison of nonlocal continuum and discrete dislocation plasticity

predictions. J. Mech. Phys. Solids 51, 283310.

Busso, E.P., Meissonneir, F.T., ODowd, N.P., 2000. Gradient-dependent deformation of twophase single crystals. J. Mech. Phys. Solids 48,

23332362.

de Borst, R., Mhlhaus, H.-B., 1992. Gradient-dependent plasticity: Formulation and algorithmic aspects. Int. J. Numer. Methods Engrg. 35,

521539.

Fleck, N.A., Hutchinson, J.W., 2001. A reformulation of strain gradient plasticity. J. Mech. Phys. Solids, 22452271.

Gao, H., Huang, Y., Nix, W.D., Hutchinson, J.W., 1999. Mechanism-based strain gradient plasticity I. Theory. J. Mech. Phys. Solids 47,

12391263.

Gurtin, M.E., 2000. On the plasticity of single crystals: free energy, microforces plastic-strain gradients. J. Mech. Phys. Solids 48, 9891036.

Jirasek, M., Bazant, Z.P., 2002. Inelastic Analysis of Structures. Wiley, UK.

Mindlin, R.D., 1964. Micro-structure in linear elasticity. Arch. Rational Mech. Anal. 16, 5178.

Niordson, C.F., Hutchinson, J.W., 2003. Non-uniform plastic deformation of micron scale objects. Int. J. Numer. Methods Engrg. 56, 961975.

Volokh, K.Yu., Hutchinson, J.W., 2002. Are lower-order gradient theories of plasticity really lower order?. J. Appl. Mech. 69, 862864.

Anda mungkin juga menyukai

- Khazana Mil GayaDokumen45 halamanKhazana Mil GayaSandipan DharBelum ada peringkat

- Elasto-Plastic Analysis of Internally Pressurized Thick Walled CylinderDokumen11 halamanElasto-Plastic Analysis of Internally Pressurized Thick Walled Cylinderjeddins_1Belum ada peringkat

- Journal of The Mechanics and Physics of Solids: N.A. Fleck, J.R. WillisDokumen17 halamanJournal of The Mechanics and Physics of Solids: N.A. Fleck, J.R. WillisMohan ChandraBelum ada peringkat

- The Boussinesq Problem in Dipolar Gradient ElasticityDokumen35 halamanThe Boussinesq Problem in Dipolar Gradient ElasticityAnshul PanwarBelum ada peringkat

- 430 PDFDokumen33 halaman430 PDFPeterBelum ada peringkat

- Constitutive Law PolycarbonateDokumen10 halamanConstitutive Law PolycarbonateajaykumarKBSBelum ada peringkat

- Elastic-Plastic Large Deformation Analysis Using SPHDokumen5 halamanElastic-Plastic Large Deformation Analysis Using SPHRanjan PramanikBelum ada peringkat

- Rheological Modelling of Complex Fluids. I. The Concept of Effective Volume Fraction RevisitedDokumen9 halamanRheological Modelling of Complex Fluids. I. The Concept of Effective Volume Fraction RevisitedodexBelum ada peringkat

- Reference BooksDokumen23 halamanReference BooksIgor Gabriel Teixeira GómezBelum ada peringkat

- Harris ThesisDokumen22 halamanHarris ThesisTanu RdBelum ada peringkat

- Chapter 21: Design Consideration in Material Selection: Design For Enhanced Material DampingDokumen8 halamanChapter 21: Design Consideration in Material Selection: Design For Enhanced Material DampingKhurram KirmaniBelum ada peringkat

- 03 PDFDokumen62 halaman03 PDFKenneth James Matias BenavidezBelum ada peringkat

- Experiments and Theory in Strain Gradient PDFDokumen32 halamanExperiments and Theory in Strain Gradient PDFAnonymous 17ihTauS5Belum ada peringkat

- Amit Acharya 4Dokumen6 halamanAmit Acharya 4Disha ChatterjeeBelum ada peringkat

- Journal of The Mechanics and Physics of Solids: Noureddine Damil, Michel Potier-FerryDokumen15 halamanJournal of The Mechanics and Physics of Solids: Noureddine Damil, Michel Potier-FerryBoumediene BakhaddaBelum ada peringkat

- Elastic/plastic Buckling of Thick Plates: C.M. Wang, Y. Xiang, J. ChakrabartyDokumen24 halamanElastic/plastic Buckling of Thick Plates: C.M. Wang, Y. Xiang, J. Chakrabartyguojie zhouBelum ada peringkat

- ME501 L3 Stress-Strain Relations Oct 2017Dokumen8 halamanME501 L3 Stress-Strain Relations Oct 2017Firas RocktBelum ada peringkat

- 3-A O - Vatulyan,-S A - NesterovDokumen15 halaman3-A O - Vatulyan,-S A - Nesterovwedha rayhanantoBelum ada peringkat

- Finite Element of Composites PlateDokumen20 halamanFinite Element of Composites PlaterushckyBelum ada peringkat

- Analytical Solutions in Elasto-Plastic Bending of Beams With PDFDokumen12 halamanAnalytical Solutions in Elasto-Plastic Bending of Beams With PDFMariusz Milewski50% (2)

- The Classical Theory of ElasticityDokumen2 halamanThe Classical Theory of ElasticityeradiBelum ada peringkat

- Practical Aspects of Finite Element SimulationDokumen11 halamanPractical Aspects of Finite Element SimulationChandrashekar HiremathBelum ada peringkat

- Effect of Strain Gradients and Heterogeneity On Flow Strength of Particle Reinforced Metal-Matrix CompositesDokumen7 halamanEffect of Strain Gradients and Heterogeneity On Flow Strength of Particle Reinforced Metal-Matrix CompositestkslibBelum ada peringkat

- The Resilience of The Logarithmic Law To Pressure Gradient Evidence From Direct Numerical SimulationDokumen13 halamanThe Resilience of The Logarithmic Law To Pressure Gradient Evidence From Direct Numerical Simulationraashid83Belum ada peringkat

- On Two Micromechanics Theories For Determining Micro Macro Relations in Heterogeneous SolidsDokumen16 halamanOn Two Micromechanics Theories For Determining Micro Macro Relations in Heterogeneous Solidsdavibarbosa91Belum ada peringkat

- Plane Elasticity Solutions For Beams With Fixed EndsDokumen15 halamanPlane Elasticity Solutions For Beams With Fixed EndsMustafaMahdiBelum ada peringkat

- Crystals 07 00235 v2Dokumen12 halamanCrystals 07 00235 v2MERT EKEMENBelum ada peringkat

- Numerical Modelling of Shocks in SolidsDokumen12 halamanNumerical Modelling of Shocks in SolidsSam vermBelum ada peringkat

- TMP 24 BBDokumen10 halamanTMP 24 BBFrontiersBelum ada peringkat

- Effect of Void Cluster On Ductile Failure Evolution: Tvergaard, ViggoDokumen21 halamanEffect of Void Cluster On Ductile Failure Evolution: Tvergaard, ViggoYuleppo ABelum ada peringkat

- Plasticity: Monotonic Stress / Strain Diagram For Elastic-Plastic BehaviourDokumen15 halamanPlasticity: Monotonic Stress / Strain Diagram For Elastic-Plastic Behaviourkarrar333 ALIYAHIABelum ada peringkat

- Finite Strain - Isotropic HyperelasticityDokumen26 halamanFinite Strain - Isotropic HyperelasticityvilukBelum ada peringkat

- Plastic Limit State of Frame StructuresDokumen62 halamanPlastic Limit State of Frame Structuresprabhu81Belum ada peringkat

- Combined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureDokumen13 halamanCombined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureNaida AdemovicBelum ada peringkat

- An Asymptotic Finite-Deformation Analysis of The Elastostatic FieldDokumen41 halamanAn Asymptotic Finite-Deformation Analysis of The Elastostatic FieldkhalilmansouriBelum ada peringkat

- (3 - 4) A General Analytical Model Based On Elastic Foundation Beam TheoryDokumen14 halaman(3 - 4) A General Analytical Model Based On Elastic Foundation Beam Theoryshahbazbegian.uniBelum ada peringkat

- Constitutive Models For Compressible Nonlinearly Elastic Materials With Limiting Chain ExtensibilityDokumen16 halamanConstitutive Models For Compressible Nonlinearly Elastic Materials With Limiting Chain Extensibility2007rlwjdtnBelum ada peringkat

- Transversely Isotropic Plasticity With Application To Fiber - Reinforced PlasticsDokumen20 halamanTransversely Isotropic Plasticity With Application To Fiber - Reinforced Plasticsshossain1987Belum ada peringkat

- A Critical Review of Triaxiality Based Failure CriteriaDokumen9 halamanA Critical Review of Triaxiality Based Failure CriteriaKevinBelum ada peringkat

- Elastic ConstantsDokumen18 halamanElastic ConstantsÑM balochBelum ada peringkat

- Inter-Facial Crack OpeningDokumen25 halamanInter-Facial Crack OpeningChukwuemeka JosephBelum ada peringkat

- CH 12Dokumen64 halamanCH 12LeonardoMadeira11Belum ada peringkat

- 1 s2.0 S0013794412000999 MainDokumen11 halaman1 s2.0 S0013794412000999 MainDivyanshu LalBelum ada peringkat

- Flexural Analysis of Deep Beam Subjected To Parabolic Load Using Refined Shear Deformation TheoryDokumen10 halamanFlexural Analysis of Deep Beam Subjected To Parabolic Load Using Refined Shear Deformation Theoryakash kumarBelum ada peringkat

- Finite Element Model For Linear Elastic Thick Shells Using Gradient Recovery MethodDokumen28 halamanFinite Element Model For Linear Elastic Thick Shells Using Gradient Recovery MethodFongho Eric SinclairBelum ada peringkat

- Plastic Deformation of Glassy Polymers: Correlation Between Shear Activation Volume and Entanglement DensityDokumen7 halamanPlastic Deformation of Glassy Polymers: Correlation Between Shear Activation Volume and Entanglement DensityCatherine CcasaBelum ada peringkat

- Modal Analysis of Laminated Composite Plates by A New Hybrid Assumed Strain Finite ElementDokumen11 halamanModal Analysis of Laminated Composite Plates by A New Hybrid Assumed Strain Finite ElementKarthik KBelum ada peringkat

- Optimal Plastic Design of A Bar Under Combined Torsion, Bending and ShearDokumen13 halamanOptimal Plastic Design of A Bar Under Combined Torsion, Bending and ShearKeerthi KumarBelum ada peringkat

- Interface Crack Between Two Shear Deformable Elastic Layers: Jialai Wang, Pizhong QiaoDokumen15 halamanInterface Crack Between Two Shear Deformable Elastic Layers: Jialai Wang, Pizhong QiaoideepujBelum ada peringkat

- A N Analysis of A New Class of Integration Algorithms For Elastoplastic Constitutive RelationsDokumen14 halamanA N Analysis of A New Class of Integration Algorithms For Elastoplastic Constitutive RelationsArunBelum ada peringkat

- Modeling of Large Deformations of Hyperelastic MaterialsDokumen4 halamanModeling of Large Deformations of Hyperelastic MaterialsSEP-PublisherBelum ada peringkat

- Program A Cao Nao LinearDokumen5 halamanProgram A Cao Nao LinearJerfsonLimaBelum ada peringkat

- Flexural High Order-PandyaDokumen26 halamanFlexural High Order-Pandyavenkataanand palankiBelum ada peringkat

- Influence of The Initial Void Ratio On The Evolution of The Passive Earth PressureDokumen6 halamanInfluence of The Initial Void Ratio On The Evolution of The Passive Earth PressureLaboratoire LTGCBelum ada peringkat

- Volo Voi Hodges 2000Dokumen7 halamanVolo Voi Hodges 2000mihailmiBelum ada peringkat

- Seismic Design of Structures With Supplemental Maxwell Model-Based Brace-Damper SystemsDokumen8 halamanSeismic Design of Structures With Supplemental Maxwell Model-Based Brace-Damper SystemsDac PiBelum ada peringkat

- 3 Chaboche - IJP - 2005Dokumen26 halaman3 Chaboche - IJP - 2005Donald ZekaBelum ada peringkat

- Crack Velocity Dependent Toughness in Rate Dependent MaterialsDokumen6 halamanCrack Velocity Dependent Toughness in Rate Dependent MaterialsFahmi AzisBelum ada peringkat

- Lode Parameter and The Stress TriaxialityDokumen18 halamanLode Parameter and The Stress Triaxialityonnly1964Belum ada peringkat

- EM 1110-2-2005 - Standard Practice For Shotcrete 1Dokumen66 halamanEM 1110-2-2005 - Standard Practice For Shotcrete 1PDHLibraryBelum ada peringkat

- Lenton Steel Fortress: A Shear Reinforcement SystemDokumen2 halamanLenton Steel Fortress: A Shear Reinforcement Systemjmcc2Belum ada peringkat

- EFNARC European Specification For Sprayed Concrete Euro Concrete Spec EngDokumen35 halamanEFNARC European Specification For Sprayed Concrete Euro Concrete Spec Engengineerh100% (1)

- Legacy Report: ICC Evaluation Service, IncDokumen2 halamanLegacy Report: ICC Evaluation Service, Incjmcc2Belum ada peringkat

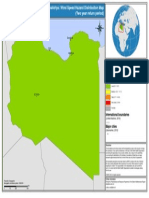

- Libyan Arab Jamahiriya: Wind Speed Hazard Distribution Map (Two Year Return Period)Dokumen1 halamanLibyan Arab Jamahiriya: Wind Speed Hazard Distribution Map (Two Year Return Period)jmcc2Belum ada peringkat

- 154 Excel MacrosDokumen64 halaman154 Excel Macrosjmcc2Belum ada peringkat

- Earthquake Vulnerability and Risk Modeling For The Area of Greater Cairo, Egypt - T.liesch Et AlDokumen1 halamanEarthquake Vulnerability and Risk Modeling For The Area of Greater Cairo, Egypt - T.liesch Et Aljmcc2Belum ada peringkat

- All ProblemsDokumen107 halamanAll ProblemsjoshiabhijeetBelum ada peringkat

- Pyramid e A4Dokumen0 halamanPyramid e A4jmcc2Belum ada peringkat

- Macalloy Cable StructuresDokumen12 halamanMacalloy Cable Structuresjmcc2Belum ada peringkat

- Flow Chart - Frame AnalysisDokumen4 halamanFlow Chart - Frame Analysisjmcc2Belum ada peringkat

- RR23 Rail BenchmarkingDokumen26 halamanRR23 Rail Benchmarkingjmcc2100% (1)

- Kalzip Systems Brochure MEDokumen72 halamanKalzip Systems Brochure MEjmcc2Belum ada peringkat

- Bailey Bridges Fm5 277Dokumen373 halamanBailey Bridges Fm5 277jmcc2Belum ada peringkat

- L1 Piles Subject To Lateral Soil MovementDokumen32 halamanL1 Piles Subject To Lateral Soil Movementedward the iiiBelum ada peringkat

- Course Title Course Level: UG Credit Units: Course Code: MAE301Dokumen3 halamanCourse Title Course Level: UG Credit Units: Course Code: MAE301Himanshu JangidBelum ada peringkat

- Lotte Titanpro PM803 Product DataDokumen1 halamanLotte Titanpro PM803 Product DataJoni Sie MssBelum ada peringkat

- Grade 5 Vs Grade 8 Fasteners - TineLokDokumen5 halamanGrade 5 Vs Grade 8 Fasteners - TineLokTodd AlexanderBelum ada peringkat

- API-653-Mar 2016Dokumen7 halamanAPI-653-Mar 2016Khaled Gamal100% (3)

- 2003 Novovic The Effect of Machined Topography and Integrity On Fatigue LifeDokumen10 halaman2003 Novovic The Effect of Machined Topography and Integrity On Fatigue LifeMaría Cristina CapaceBelum ada peringkat

- Effect of Synthetic and ProteinDokumen10 halamanEffect of Synthetic and Proteinprem adhikariBelum ada peringkat

- Laboratory Testing and Interpretation of Rock PropertiesDokumen13 halamanLaboratory Testing and Interpretation of Rock PropertiesIslemBelum ada peringkat

- Reinforced Concrete Design: Lecturer: CHOU Soklin, Ph.D. Department: Civil Engineering Academic Year: 2017/2018Dokumen56 halamanReinforced Concrete Design: Lecturer: CHOU Soklin, Ph.D. Department: Civil Engineering Academic Year: 2017/2018Mouy PhonThornBelum ada peringkat

- What Is Young's ModulusDokumen2 halamanWhat Is Young's ModulusAbdullah Al AsikBelum ada peringkat

- Timber Rivet ConnectionsDokumen25 halamanTimber Rivet ConnectionsJoe HowardBelum ada peringkat

- FlotopDokumen2 halamanFlotoppravi3434Belum ada peringkat

- SP-62 2004 CC RoadsDokumen38 halamanSP-62 2004 CC Roadsnimm1962Belum ada peringkat

- ABS Modu Part 4Dokumen232 halamanABS Modu Part 4yaenggBelum ada peringkat

- Geotechnical Notes and Problems NotesDokumen131 halamanGeotechnical Notes and Problems NotesNarcisa RudnicBelum ada peringkat

- Computer Aided Structural Analysis of AxDokumen21 halamanComputer Aided Structural Analysis of AxKarran KapurBelum ada peringkat

- Automated Seed Sowing MachineDokumen40 halamanAutomated Seed Sowing MachineRaja Mane67% (3)

- Curriculum M Tech Structural Construction Engineering 2019Dokumen27 halamanCurriculum M Tech Structural Construction Engineering 2019SumanBelum ada peringkat

- Flexural Behaviour of High-Strength Rectangular Concrete-Filled Steel Hollow SectionsDokumen16 halamanFlexural Behaviour of High-Strength Rectangular Concrete-Filled Steel Hollow SectionsnurhishammBelum ada peringkat

- L.A.B Mabhali, N. Sacks, S. Pityana: Article InfoDokumen9 halamanL.A.B Mabhali, N. Sacks, S. Pityana: Article InfoRakesh ChandraBelum ada peringkat

- Repair and Structural Performance of Initially Cracked RC SlabsDokumen9 halamanRepair and Structural Performance of Initially Cracked RC SlabsHari SankarBelum ada peringkat

- Online Course. 1-StrengthDokumen12 halamanOnline Course. 1-StrengthFatima Zahra SAIDIBelum ada peringkat

- Materials: Understanding The Thickness Effect On The Tensile Strength Property of Dyneema HB26 LaminatesDokumen18 halamanMaterials: Understanding The Thickness Effect On The Tensile Strength Property of Dyneema HB26 LaminatesPankaj MunjalBelum ada peringkat

- The Practicing Engineer's Guide To Designing by Strut and Tie Modeling (ACI 318-14)Dokumen6 halamanThe Practicing Engineer's Guide To Designing by Strut and Tie Modeling (ACI 318-14)jabh311Belum ada peringkat

- Stability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Dokumen11 halamanStability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Editor IJAERDBelum ada peringkat

- Ejercicios Resueltos: Ingenieria de MaterialesDokumen6 halamanEjercicios Resueltos: Ingenieria de MaterialesNicole AguilarBelum ada peringkat

- Guide EN13155 A1 Rev0Dokumen18 halamanGuide EN13155 A1 Rev0EdivaldoBelum ada peringkat

- Installation Instructions RISE CableDokumen14 halamanInstallation Instructions RISE CableABDUL GHAFOORBelum ada peringkat

- Engineers: My Notes StructuralDokumen14 halamanEngineers: My Notes StructuralGladies Mhay Binay SandovalBelum ada peringkat

- EXP 7 - MaterialsDokumen18 halamanEXP 7 - MaterialsLeslie CatindigBelum ada peringkat