LGT - SWMS - Bored Pile Works

Diunggah oleh

sinthianJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

LGT - SWMS - Bored Pile Works

Diunggah oleh

sinthianHak Cipta:

Format Tersedia

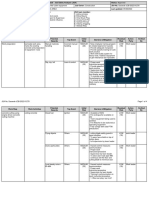

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 1 OF 9

ITEM 1

JOB ACTIVITIES / PROCESS Pile setting out

POTENTIAL HAZARD Pile points are marked on the ground with steel bars of length less than a foot by surveyor Over turning of boring unit INCORRECT USE OF boring unit

Risk Class P1

PREVENTIVE ACTIONS Tie a brightly coloured barrier tape for easy identification to steel peg and drive below ground.

ACTION BY Surveyor

ACTION WHEN Pegging works

STATUS

Positioning of Boring unit. (Operator and Boring unit PMA enclosed in APP1)

P1

Operator to be duly certified and inducted to Boring this method statement, the machine to be operator visually inspected for any defects and if any identified the boring unit cannot start works. Also the boring operator to inspect the ground conditions. If necessary steel plates shall be lay on the ground. The operator to ensure he is aware of capacity of boring rigs and operation not to exceed the rated capacity. The boring operator is in control of the machine and if he believes that his works are unsafe he is empowered to stop the works until the issue rectified this includes but is not limited to a) A defect is observed in the equipment. b) Incorrect rigging is being used. c) Banksmen is not provided for the moving of equipment. The barricade shall be erected surrounding the working area/bored hole with warning sign Danger to prevent unauthorized

Prior to start of boring works.

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 2 OF 9

ITEM

JOB ACTIVITIES / PROCESS

POTENTIAL HAZARD

Risk Class

PREVENTIVE ACTIONS personnel from entering the dangerous area.

ACTION BY

ACTION WHEN

STATUS

Gravitational, falling Use of Crawler over falling off cranes to assist installation - lifting of boring tools and casing - setting up platform by arranging steel plates prior to boring operation. - Lifting of reinforcement bars prior to concreting works. (Operator and Crawler crane PMA in APP1)

P1

Operator to be duly certified and inducted to this method statement, the machine to be visually inspected for any defects and if any identified the crane cannot start works. Also the crane driver to inspect the ground conditions and if necessary steel plates shall be lay on the ground. Visually inspect the lifting equipment slings and ensure no damage is evident if so the slings will be not used. The operator to ensure he is aware of capacity of crane and operation not to exceed the rated capacity as detailed in the crane charts. The crane operator is in control of the machine and if he believes that his works are unsafe he is empowered to stop the works until the issue rectified this includes but is not limited to: a) A defect is observed in the equipment. b) Incorrect rigging is being used. c) Watchmen is not provided for the moving of equipment. The barricade shall be erected surround the working area/bored hole with warning sign Danger to prevent unauthorized personnel from entering the dangerous area.

Crane operator

Prior To lifting

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 3 OF 9

ITEM 4

JOB ACTIVITIES / PROCESS

POTENTIAL HAZARD Accidental contact between human and Equipments

Risk Class P1

PREVENTIVE ACTIONS

ACTION BY

ACTION WHEN Prior to lifting During drilling works

STATUS

Drilling works Fixing and changing of boring tools

Supervisor to direct the equipment when Supervisor moving around the site to ensure all personnel are clear of equipment. Boring operator to ensure the swinging Boring radius shall be free from any personnel by Operator, Signalman referring to the signal man

Hand injuries due to fingers being caught in between objects

P2, P3

Ensure 1 signal man is in charge during Signalman Ditto boring , the boring operator to take direction from 1 signal man not multiple. Only in All in team emergency should commands be given by to understand anyone. Ensure signalman is nominated with the signal agreed by boring operator and signalman. Rigger and operator must adhere to hand Boring Operator, signal given by the signalman Signalman, Rigger During drilling works, changing of drilling Boring augers might become necessary to ensure operator. the right tools are used for the right soil conditions. These boring tools shall be placed within the boring unit swinging radius by keying it into the ground for stability. AUGER SHALL BE drilled into Ditto

Fall of person due to slips or poor coordination between rigger and operator Fall of drilling tools due to unstable standing positions

P1

P1

Ditto

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 4 OF 9

ITEM

JOB ACTIVITIES / PROCESS

POTENTIAL HAZARD

Risk Class

PREVENTIVE ACTIONS the ground at minimum of 650mm or 50% of its length to prevent toppling.

ACTION BY

ACTION WHEN

STATUS

Snapping of wireropes Fall of person into bored holes.

P1 P1

Regular maintenance checks by the boring Boring operator operator Casing to be extended 0.5-1.0m above Boring ground and protected by barricade. The operator, barricade (using steel frame) with the height banksman of at least 1.0m will be erected surround the bored hole. No persons are allowed within the barricaded area. The measurement of bored hole depth only allowed to be carried out by skilled worker from out-side of the erected barricade. In most cases, bored piles shall be concreted within the same day of boring works. Holes must be protected with proper covers if concreting cannot be done immediately. Concreted holes shall be backfilled with earth prior to casing being removed.

Always During boring works

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 5 OF 9

ITEM 5

JOB ACTIVITIES / PROCESS Casing drive in and extraction using crawler crane and vibro hammer.

POTENTIAL HAZARD Fall of casing due to failure of slings or opening of vibro clamp

Risk Class P1

PREVENTIVE ACTIONS

ACTION BY

ACTION WHEN Prior to lifting casing and during installation

STATUS

Supervisor to direct the equipment when Supervisor, moving around the site to ensure all crane operator, personnel are clear of equipment. signalman and riggers

P1

always Ensure 1 signal man is in charge of the Signalman lifting, the crane operator to take direction from 1 signal man not multiple. Only in All in team emergency should commands be given by to understand anyone. Ensure signal man is nominated with signals agreed by crane operator and signalman. None of the workers shall be allowed to be under the lifting loads. AS ABOVE, ONLY 1 MAN DIRECTING CRANE DRIVER

Hand injuries due to fingers being caught up in between objects Fall from height when disconnecting shackle from casing

P2

Use hand gloves during fixing up

All team riggers

always

P1

Use safety harness while working at height more than 3.0 meters. The safety harness should anchor to the steel plate welded to the casing. Alternatively, the re-drive in of casing maybe carried out to fix the disconnecting of shackle from casing.

banksman

During casing extraction

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 6 OF 9

ITEM 6

JOB ACTIVITIES / PROCESS Reinforcement, tremie pipes installation and concreting works Lifting of tremie pipe and steel cages by crane Steel cage shall be jointed with another steel cage with necessary lapping joints provided in the construction drawing. To hold this steel cage together, spot weld on the rebar using E7018 welding rods for high tensile bars.

POTENTIAL HAZARD

Risk Class

PREVENTIVE ACTIONS

ACTION BY

ACTION WHEN

STATUS

Reinforcement bars/ tremie pipes falling during lifting Welding fumes and radiation during joining cage, eye injury and respiratory damages. Hand injuries due to fingers being caught up in between objects Accidental collision

P1

Refer to Item (3) Use of crawler crane

Supervisor, crane operator and sgnalman

Prior to lifting/ concreting works During welding works

P2, P3

Welder must be equipped with all relevant Welder PPE for welding works

P2, P3

Use Hand Gloves during fixing up

All in team to understand

Always

P1

- Lowering steel bars and tremie pipes inside the bored hole.

Signalman shall be assign to control the concrete trucks during reversing. He shall be Signalman wearing reflective vests. None of the banksman shall be near the holes during trucks reversing.

Prior to concreting works

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 7 OF 9

ITEM

JOB ACTIVITIES / PROCESS - Reversing the concrete trucks to the tremie hopper. - Splashing of wet concrete in contact with skin. Task Lighting for working at night

POTENTIAL HAZARD Skin irritation due to chemical effects

Risk Class P3

ACTION BY Hand gloves shall be used by the banksman Banksman at all times. Water shall be use to wash away the cement if it is unavoidable. PREVENTIVE ACTIONS

ACTION WHEN During concreting works

STATUS

Electrocution

P1

Electrical lighting to be used at all times Supervisor during night works All electrical equipment to be inspected prior to use. These Works will be scheduled during daytime. All site personnel shall at all times wear the All minimum personnel Protection Equipment Personnel for the site those being safety footwear, Hardhat, reflective vest.. The above method statement shall be Supervisor communicated to the workforce prior to commencing the site works. The communication will be firstly communicated to the supervisory staff, following which at the daily toolbox talk. At the induction meeting the designation are to be defined as the responsibilities.

If night works become necessary.

Personnel Protection

Personnel injury

P2

Always

Communication

P1,P2, P3

Prior to start and then Daily at toolbox

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : LGT TOWER : : DATE REV PAGE : 04/03/2014 : 00 : 8 OF 9

ITEM 10

JOB ACTIVITIES / PROCESS Records.

POTENTIAL HAZARD

Risk Class

PREVENTIVE ACTIONS

ACTION BY

ACTION WHEN Always

STATUS

Copy of this method statement to be retained Site Safety in the security house in Safe Work method officer Statements and attendance sheets to induction and records of tool box talks with reference to the specific SWMS to be maintained in this file. P1 THE CRANE/BORING OPERATOR IS RESPONSIBLE TO CEASE WORKS IF HE FEELS THAT WEATHER CONDITOIONS ARE NOT SUITABLE FOR THE TASK AT HAND, BUT IF RAIN, LIGHTNING, OR WINDS ABOVE 20 KM PER HOUR ARE EXPERIENCED WORKS WILL BE SUSPENDED. Provide dust mask and adequate ventilation. Empty bag directly over the mixer to avoid emission. P2, P3 Clean up spillage immediately after occurrence. Ensure that bentonite to be kept in container and to be disposed at the designated area. Supervisor Crane operator/ Boring operator

11

Weather conditions

In the event of bad WEATHER

12

Dust nuisance

Bentonite dust emission during mixing Creation of slippery working surface Damage to the environment

P3

Supervisor

Mixing Bentonite

13

Bentonite slurry spillage

There is spillage of bentonite Always

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY NAME WORK ACTIVITY DURATION : ANEKA JARINGAN SDN BHD : BORED PILING WORK : PROJECT PROJECT MANAGER SAFETY OFFICER : PLATINUM PARK PHASE 3 : TEH W.L / TUNG S.T : FIRDOUS DATE REV PAGE : Aug 11, 2009 : 01 : 9 OF 9

RISK CLASS P1 Potential Death, Permanent Disability or Major Structural Damage or Potential Incident resulting in permanent or significant detrimental impact on the natural or built environment. Potential Temporary Disability or Minor Structural Damage or Potential Incident that could impact on environmental elements (natural or built) that can be contained and remediate with no long-term effect. Any potential for exceedence of a Statutory Licence/Permit condition.

PREVENTATIVE ACTION TYPE

STATUS

Design Design hazards out. Substitution Replace the material or process with a less hazardous one. O = OPEN Redesign Redesign the equipment to reduce or move the hazard. SWP/PPE Separation Using safe work procedures with personal protective safety equipment. Isolate the hazard by enclosing or guarding. C = CLOSED

P2

P3

Anda mungkin juga menyukai

- MITISA HOLDINGS PILE CAP JSADokumen8 halamanMITISA HOLDINGS PILE CAP JSAknabpshoBelum ada peringkat

- JSA NO 2-Piling WorkDokumen3 halamanJSA NO 2-Piling WorkKarthik GanesanBelum ada peringkat

- JSA NO 3-Pile CapDokumen8 halamanJSA NO 3-Pile Capknabpsho50% (2)

- Risk Assessment for Sheet Piling Work by Excavator-Mounted Vibro MachineDokumen8 halamanRisk Assessment for Sheet Piling Work by Excavator-Mounted Vibro MachineWr ArBelum ada peringkat

- Installation of Bakau Pile Risk AssessmentDokumen2 halamanInstallation of Bakau Pile Risk AssessmentWr Ar100% (5)

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Dokumen7 halamanHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Jsa - ExcavationDokumen7 halamanJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- HIRA Batching PlanDokumen9 halamanHIRA Batching Plannitish tiwariBelum ada peringkat

- Risk AssessmentDokumen3 halamanRisk AssessmentAkinbami Olorunnifemi100% (1)

- Mitisa Holdings SDN BHD Jobs Safety Analysis: Jsa No: 002 - Piling WorksDokumen6 halamanMitisa Holdings SDN BHD Jobs Safety Analysis: Jsa No: 002 - Piling Worksknabpsho100% (5)

- Hazards of Piling WorksDokumen6 halamanHazards of Piling Worksjoaonunes.40544364% (11)

- Job Safety Analysis: Manual ExcavationDokumen2 halamanJob Safety Analysis: Manual Excavationfdfddf dfsdfBelum ada peringkat

- New Pta Complex: Jsa For Reinforcing Steel BarsDokumen12 halamanNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTBelum ada peringkat

- JSA-002 Civil WorksDokumen6 halamanJSA-002 Civil WorksMoaatazz NouisriBelum ada peringkat

- Project Lifting Plan (Rev 00)Dokumen10 halamanProject Lifting Plan (Rev 00)M AzharBelum ada peringkat

- Rapid P20ai Jsa Box CulvertDokumen10 halamanRapid P20ai Jsa Box CulvertChung May Lynn100% (2)

- Work Method Statement For Sub Structure Works: (Pile Cap)Dokumen9 halamanWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviBelum ada peringkat

- JSA-010 Excavation Sampling PDFDokumen5 halamanJSA-010 Excavation Sampling PDFArgaYurIstiawanBelum ada peringkat

- Proposed Damansara Shah Alam Elevated Expressway (Dash)Dokumen8 halamanProposed Damansara Shah Alam Elevated Expressway (Dash)Nurulhidayah Abdul JalilBelum ada peringkat

- Method Statement For Culverts REV.BDokumen19 halamanMethod Statement For Culverts REV.BAmila Priyadarshana DissanayakeBelum ada peringkat

- JSA For Concrete Pouring Using Crane and Bucket3Dokumen8 halamanJSA For Concrete Pouring Using Crane and Bucket3Mohammed MinhajBelum ada peringkat

- MS & JSA Piling Work PDFDokumen11 halamanMS & JSA Piling Work PDFmesmerize59100% (2)

- Excavations JSA Final 2015Dokumen5 halamanExcavations JSA Final 2015jithin shankarBelum ada peringkat

- JHA ConcretePlacingOperationDokumen3 halamanJHA ConcretePlacingOperationAnonymous XJ9663C6N4Belum ada peringkat

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDokumen5 halamanRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaBelum ada peringkat

- JACK IN Piling WorkDokumen9 halamanJACK IN Piling WorkShaheed AzharBelum ada peringkat

- MST For REINFORCEMENT WORKSDokumen6 halamanMST For REINFORCEMENT WORKSsudhir patkarBelum ada peringkat

- JOB SAFETY ANALYSIS FOR EARTHWORKS (37Dokumen32 halamanJOB SAFETY ANALYSIS FOR EARTHWORKS (37Hilbrecht De Pedro100% (1)

- Tower Crane HirarcDokumen3 halamanTower Crane HirarcSagar Bhavsar100% (1)

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDokumen7 halamanHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambBelum ada peringkat

- Job Hazard Analysis for SurveyingDokumen1 halamanJob Hazard Analysis for SurveyingYogesh Gowda100% (1)

- 18 - Aluminum Glazing & Glass WorksDokumen1 halaman18 - Aluminum Glazing & Glass WorksRafee Pie100% (1)

- 32 - Working at HeightDokumen2 halaman32 - Working at HeightRafee PieBelum ada peringkat

- Jsa PCC & RCCDokumen2 halamanJsa PCC & RCCNilesh koliBelum ada peringkat

- Rapid P20ai Jsa Box CulvertDokumen8 halamanRapid P20ai Jsa Box Culvertfadli.lpgBelum ada peringkat

- Jsa For Pilling WorkDokumen12 halamanJsa For Pilling WorkLakhan kumar100% (1)

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Dokumen3 halaman1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahBelum ada peringkat

- Rebar Job Hazard AnalysisDokumen1 halamanRebar Job Hazard Analysisjoker batmanBelum ada peringkat

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Dokumen2 halamanRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueBelum ada peringkat

- CIT-CON-01-CMT-MTS-000..-V0.. Method Statement For Construction Work at Night ShiftDokumen13 halamanCIT-CON-01-CMT-MTS-000..-V0.. Method Statement For Construction Work at Night Shiftumuhuza salomonBelum ada peringkat

- Risk Assessment - Wall Reinforcement and FormworkDokumen4 halamanRisk Assessment - Wall Reinforcement and FormworkSarfraz Randhawa100% (1)

- RS Concrete Pumping Risk AssessmentDokumen8 halamanRS Concrete Pumping Risk AssessmentLito PanchoBelum ada peringkat

- Sarawak JSA for Concrete CuttingDokumen4 halamanSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailBelum ada peringkat

- 6.0 ISOLATION JSA CONCRETE WORK HanesDokumen7 halaman6.0 ISOLATION JSA CONCRETE WORK HanesMc Loki100% (3)

- File - 20200905 - 105458 - Jsa Wind PowerDokumen10 halamanFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnBelum ada peringkat

- Risk Assessment Construction of Lighting Pole at Site OfficeDokumen9 halamanRisk Assessment Construction of Lighting Pole at Site OfficeSinaBelum ada peringkat

- Risk Assessment For Sheet PilingDokumen33 halamanRisk Assessment For Sheet Pilingsajin75% (24)

- Demolition 4 PDFDokumen19 halamanDemolition 4 PDFazrulBelum ada peringkat

- MemoDokumen3 halamanMemoNethiyaaRajendran100% (2)

- Piling Hazards and RisksDokumen4 halamanPiling Hazards and RisksAbhishek Gupta100% (2)

- JHA Worksheet Safety TipsDokumen6 halamanJHA Worksheet Safety TipsAbdul Khairul RiduanBelum ada peringkat

- Jha For Cfa PilingDokumen10 halamanJha For Cfa PilingFaremi Oluwaseun BabatundeBelum ada peringkat

- Method Statement For Foundation InstallationDokumen5 halamanMethod Statement For Foundation InstallationFrancis GonzalesBelum ada peringkat

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Dokumen7 halamanJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinBelum ada peringkat

- ULSADO-JSA-Demolation Existing Concrete FoundationDokumen2 halamanULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- OSHA Training and Reference Materials Library - PPE AssessmentDokumen10 halamanOSHA Training and Reference Materials Library - PPE AssessmentOluwafemi Samuel AdesanmiBelum ada peringkat

- RA - For Precast ChambersDokumen5 halamanRA - For Precast ChambersKallem RajashekarBelum ada peringkat

- Vibro Hammer ChecklistDokumen2 halamanVibro Hammer ChecklistAbdus Samad100% (1)

- Safe Work ProcedureDokumen19 halamanSafe Work Procedureshihab67% (3)

- Pile Load Test MethodologyDokumen4 halamanPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Earth Retaining Structure LayoutDokumen1 halamanEarth Retaining Structure LayoutsinthianBelum ada peringkat

- Instructions On Chinese Visa Supplementary Form (Effective 01st February 2011)Dokumen3 halamanInstructions On Chinese Visa Supplementary Form (Effective 01st February 2011)If HassanBelum ada peringkat

- InfoDokumen5 halamanInfoAdil1313Belum ada peringkat

- Girder DesignDokumen2 halamanGirder DesignsinthianBelum ada peringkat

- Method Statement Pipe JackingDokumen7 halamanMethod Statement Pipe Jackingsinthian88% (8)

- Aurora Tower - Method StatementDokumen27 halamanAurora Tower - Method StatementsinthianBelum ada peringkat

- Updated Work Programme 22.02.15Dokumen5 halamanUpdated Work Programme 22.02.15sinthianBelum ada peringkat

- Method Statement For Prelim Test PileDokumen4 halamanMethod Statement For Prelim Test PilesinthianBelum ada peringkat

- Updated Work Programme 22.02.15Dokumen5 halamanUpdated Work Programme 22.02.15sinthianBelum ada peringkat

- Instructions On Chinese Visa Supplementary Form (Effective 01st February 2011)Dokumen3 halamanInstructions On Chinese Visa Supplementary Form (Effective 01st February 2011)If HassanBelum ada peringkat

- BORED PILE GEOTECHNICAL DESIGN (TENSION CAPACITYDokumen4 halamanBORED PILE GEOTECHNICAL DESIGN (TENSION CAPACITYsinthianBelum ada peringkat

- Rectangular Beam Shear Design Material PropertiesDokumen1 halamanRectangular Beam Shear Design Material PropertiessinthianBelum ada peringkat

- Lifting Plan Layout - Tandem Layout2Dokumen1 halamanLifting Plan Layout - Tandem Layout2sinthianBelum ada peringkat

- Site Plan For Partial HandoverDokumen1 halamanSite Plan For Partial HandoversinthianBelum ada peringkat

- 10 Grammar Mistakes That Make You Look Stupid PDFDokumen3 halaman10 Grammar Mistakes That Make You Look Stupid PDFPrachi MahajanBelum ada peringkat

- Comprehensive PSC Girder Bridge DesignDokumen316 halamanComprehensive PSC Girder Bridge DesignWilfredo Salgado0% (1)

- JKR Spec 2005Dokumen188 halamanJKR Spec 2005rex79x98% (60)

- Reduce Stop End Proposal Layout1Dokumen1 halamanReduce Stop End Proposal Layout1sinthianBelum ada peringkat

- Cage InstallDokumen1 halamanCage InstallsinthianBelum ada peringkat

- Lifting Plan Layout - Tandem - Mobile Layout2Dokumen1 halamanLifting Plan Layout - Tandem - Mobile Layout2sinthianBelum ada peringkat

- Lifting Plan Layout Excav 2Dokumen1 halamanLifting Plan Layout Excav 2sinthianBelum ada peringkat

- P10 Remedial Prop SketchesDokumen2 halamanP10 Remedial Prop SketchessinthianBelum ada peringkat

- Lifting Plan Layout - ExcavDokumen1 halamanLifting Plan Layout - ExcavsinthianBelum ada peringkat

- Cage HoistDokumen1 halamanCage HoistsinthianBelum ada peringkat

- Cage Shift KH180Dokumen1 halamanCage Shift KH180sinthianBelum ada peringkat

- USACE Manual on Gravity Dam DesignDokumen88 halamanUSACE Manual on Gravity Dam DesignOmar Castro ZeballosBelum ada peringkat

- Cage Shift HitachiDokumen1 halamanCage Shift HitachisinthianBelum ada peringkat

- B1 - Zoning Layout1Dokumen1 halamanB1 - Zoning Layout1sinthianBelum ada peringkat

- A Seminar On The PAM 2006 Contract IsmDokumen113 halamanA Seminar On The PAM 2006 Contract IsmsinthianBelum ada peringkat

- Cement Grouted Rock Bolts PDFDokumen28 halamanCement Grouted Rock Bolts PDFSushmit SharmaBelum ada peringkat

- Detail of Mesh-1 Reinforcement Details of Pier Cap Section D-DDokumen1 halamanDetail of Mesh-1 Reinforcement Details of Pier Cap Section D-DSaurabh PandeyBelum ada peringkat

- Kluberplex AG 11 462Dokumen2 halamanKluberplex AG 11 462razvanBelum ada peringkat

- A Lucas Alternator and Zener Charging CircuitDokumen8 halamanA Lucas Alternator and Zener Charging CircuitderryukBelum ada peringkat

- Roman Blacksmithing TechniquesDokumen11 halamanRoman Blacksmithing TechniquesaoransayBelum ada peringkat

- BS 410 1986 - Specification For Test SievesDokumen22 halamanBS 410 1986 - Specification For Test Sievesminhhieu.qcBelum ada peringkat

- UK SP MB Kingspan Multibeam Brochure PDFDokumen144 halamanUK SP MB Kingspan Multibeam Brochure PDFhemendraengBelum ada peringkat

- Production of Formaldehyde From MethanolDokumen7 halamanProduction of Formaldehyde From MethanolThrese AreolaBelum ada peringkat

- SPC PDH /PP Project: General Safety Procedure For FRP PipingDokumen10 halamanSPC PDH /PP Project: General Safety Procedure For FRP PipingAshish PattanaikBelum ada peringkat

- Machinist Hammers and Tools Product ListingDokumen34 halamanMachinist Hammers and Tools Product ListingFJH ALZBelum ada peringkat

- Probeta JiskootDokumen2 halamanProbeta JiskootFrank Mathews GBelum ada peringkat

- Bostik Seal N Flex One Plus TDS 05102021Dokumen3 halamanBostik Seal N Flex One Plus TDS 05102021Pro. devBelum ada peringkat

- Thermal properties of polycarbonateDokumen20 halamanThermal properties of polycarbonateThụy Thảo LinhBelum ada peringkat

- 2019-Use of A Switchable-Hydrophilicity SolventDokumen5 halaman2019-Use of A Switchable-Hydrophilicity SolventManpreet SinghBelum ada peringkat

- Prodem Chapter 7 Gas Dehydration: Presented By: Rr. Sri Hastiyatisatiyah Ecp/Pro April 13th, 2015Dokumen64 halamanProdem Chapter 7 Gas Dehydration: Presented By: Rr. Sri Hastiyatisatiyah Ecp/Pro April 13th, 2015andi dipayadnya100% (1)

- Toshiba CodesDokumen5 halamanToshiba Codesbruxo70Belum ada peringkat

- Water for Pharma ValidationDokumen14 halamanWater for Pharma ValidationPépé TechopathamBelum ada peringkat

- DLP 6 LO2 Safe Disposal of Tools and MaterialsDokumen13 halamanDLP 6 LO2 Safe Disposal of Tools and MaterialsReybeth Tahud Hamili - Matus100% (2)

- V An de G Raff G Enerator SF-9722Dokumen4 halamanV An de G Raff G Enerator SF-9722JonhGonzálezBelum ada peringkat

- Double Layer Peltier DeviceDokumen2 halamanDouble Layer Peltier Deviceapi-129748480Belum ada peringkat

- Compact Repeater 972-0RB12 3Dokumen16 halamanCompact Repeater 972-0RB12 3Kelly Perez LopezBelum ada peringkat

- Paper On Plastic To RoadDokumen6 halamanPaper On Plastic To RoadSumskrutha Kosgi ShroffBelum ada peringkat

- KGD KGD: Ouble Acting Piston Seal With Wear RingsDokumen6 halamanKGD KGD: Ouble Acting Piston Seal With Wear RingsTeddy NsBelum ada peringkat

- ADAPT TN388 Vibration Footfall ExampleDokumen11 halamanADAPT TN388 Vibration Footfall ExampleMohammadreza MollaeiBelum ada peringkat

- Comparison of NDT Methods and Their CostsDokumen11 halamanComparison of NDT Methods and Their Costskailash100% (1)

- Heat Loss CalculationDokumen2 halamanHeat Loss CalculationdsborwankarBelum ada peringkat

- Manual of Green Building MaterialsDokumen153 halamanManual of Green Building MaterialsKawser HossainBelum ada peringkat

- Igcse e Electricity With MSCDokumen94 halamanIgcse e Electricity With MSCaliBelum ada peringkat

- Weight Optimization of Buck Stays Using PDFDokumen4 halamanWeight Optimization of Buck Stays Using PDFIvan Fernando MosqueraBelum ada peringkat

- ASTM Volume 01.01 Steel Piping StandardsDokumen4 halamanASTM Volume 01.01 Steel Piping StandardsPrasanna UmapathyBelum ada peringkat