Aao Aluminum Porous

Diunggah oleh

Dr-naser MahmoudJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aao Aluminum Porous

Diunggah oleh

Dr-naser MahmoudHak Cipta:

Format Tersedia

Controllable fabrication of highly ordered thin AAO template on Si substrate for electrodeposition of nanostructures Khaled M.Chahrour, Naser M.

Ahmed, M.R.Hashim, Nezar G.Elfadill & M.A.Qaeed

Applied Physics A Materials Science & Processing ISSN 0947-8396 Appl. Phys. A DOI 10.1007/s00339-014-8242-5

1 23

Your article is protected by copyright and all rights are held exclusively by SpringerVerlag Berlin Heidelberg. This e-offprint is for personal use only and shall not be selfarchived in electronic repositories. If you wish to self-archive your article, please use the accepted manuscript version for posting on your own website. You may further deposit the accepted manuscript version in any repository, provided it is only made publicly available 12 months after official publication or later and provided acknowledgement is given to the original source of publication and a link is inserted to the published article on Springer's website. The link must be accompanied by the following text: "The final publication is available at link.springer.com.

1 23

Author's personal copy

Appl. Phys. A DOI 10.1007/s00339-014-8242-5

Controllable fabrication of highly ordered thin AAO template on Si substrate for electrodeposition of nanostructures

Khaled M. Chahrour Naser M. Ahmed M. R. Hashim Nezar G. Elfadill M. A. Qaeed

Received: 30 November 2013 / Accepted: 8 January 2014 Springer-Verlag Berlin Heidelberg 2014

Abstract In this work, simple fabrication of hexagonally highly ordered porous anodic aluminum oxide (AAO) of Al thin lm (1 lm) on Si substrate is described using two-step anodization method for electrochemical synthesis of nanostructures. In this method, the templates were prepared under the controllable conditions of the parameters, which give rise to the possibility of highly ordered nanopore arrays with a well aspect ratio. Pore widening was then fullled in 5 wt% phosphoric acid solution at 25 C. The pore diameter and spacing are proportional to the applied voltage, which is due to the mechanical stress associated with the volume expansion of the aluminum during the anodization according to the mechanical stress model. Pore-widening solution adjusted the pore diameter and thinned the AAO barrier layer at room temperature under the control of etching time. As an application, Cu nanorods arrays embedded in anodic alumina (AAO) template were fabricated by dc electrodeposition. The characterization of the AAO templates and the Cu nanorods produced was made by X-ray diffraction, eld emission scanning microscope, energy dispersive X-ray spectroscopy and atomic force microscope (AFM). The images of AFM show that porous AAO template under constant voltage is 40 V which presents the optimum ordering.

1 Introduction Template technique is one of the most successful approaches for obtaining size-controllable nanomaterials [1]. Recently, porous anodic aluminum oxide (AAO) templates have received considerable attention in synthetic nanostructure materials due to particular characters such as controllable pore diameter and periodicity [2]. The porous AAO template fabrication process and mechanisms of pore formation have been studied [3, 4]. Using porous AAO templates for nanostructure deposition needs no costly nanolithography. There are two major kinds of porous AAO templates, the rst-type of porous AAO template is grown on a bulk pure aluminum foil [5], while the second-type is grown on a substrate such as silicon [3]. The second-type of the template is preferable due to fact that this silicon substrate usually functions as an electrode as well as a mechanical support [6]. Most of the developed methods for producing porous AAO templates generally yield highly ordered arrays on bulk Al foil [7]. Until now, the fabrication of highly ordered thin lms of porous AAO on Si substrate is difcult to be formed mainly due to the complicated surface states (roughness and crystallite sizes) and nonuniformity of the deposited Al lm [8, 9] and still remains a major challenge from the scientic and technological point of review [10]. In spite of the wide range of promising applications of the AAO templates, the biggest problem remains is the barrier layer formed at the bottom of the AAO pores, which prevents direct physical and electrical contact to the substrate [11]. To remove the barrier layer, various techniques such as pore widening, cathodic polarization, voltage drop, plasma assisted etching, etc. were employed [1214]. However, there are some challenges posed by the thin lm AAO templates, including achieving highlyordered AAO templates with open-through pore structure.

K. M. Chahrour (&) N. M. Ahmed M. R. Hashim N. G. Elfadill M. A. Qaeed Nano-Optoelectronics Research and Technology Laboratory, School of Physics, Universiti Sains Malaysia, 11800 Penang, Malaysia e-mail: skhaled_66@yahoo.com

123

Author's personal copy

K. M. Chahrour et al.

In this work, we show that highly ordered thin porous AAO templates can be grown on Si substrate under controllable condition sets of anodizing process with thin Al lms using two-step anodizing process [15], leading to perfect hexagonal pore structure, since the ordering of the pore arrangement of porous AAO templates control the regularity of further nanostructures fabricated using AAO templates as host material [16]. This work focused on the inuence of voltage and pore-widening time on the structure, order of thin porous AAO template. The advantages of our work over the past studies are that we used a simple pore-widening solution for adjusting the pore diameter and thinning the AAO barrier layer at room temperature under control of etching time for only few minutes to prepare nanostructures scaffolds with desirable pore diameters that we need.

2 Experimental method P-type (100) Si substrate with area of (1.5 cm 9 1.5 cm) was cleaned with (RCA) method prior to deposit 20 nm of Ti lm using RF sputtering, subsequently an Al (purity 99.99 %) was evaporated by e-beam on Ti lm with thickness of 1 lm. All samples were annealed at 500 C for 2 h in a conventional furnace under nitrogen ambient.

Our experimental results show that the use of a Ti adhesion layer prevented the pealing-off the Al lm from the Si wafer during anodization. The anodizing process was performed in a special design electrochemical cell using a platinum rod as a cathode. The electric contact was made at the backside of the Si substrate. The samples were anodized in acidic aqueous solution of 0.3 M oxalic acid under different voltages for a certain time. After the nishing of the rst anodizing, an aluminum oxide layer was removed by wet etching in aqueous solution of 6 wt% phosphoric acid and 1.8 wt% chromic acid at 60 C for 30 min. The second anodizing was carried out with the same controllable conditions of the rst anodizing until all of the residual aluminum was oxidized. Pore widening is controlled by immersing the AAO template into 5 wt% phosphoric acid solution at 25 C for different times. The electrochemical cell was cooled with circulating water bath system to ensure a constant temperature below 20 C. During anodizing process, the electrolyte was vigorously stirred. Some as-synthesized AAO templates are further annealed at 800 C for 5 h in atmosphere. As an application, copper nanorods were deposited potentiostatically, with AAO template serving as working electrode, platinum rod and Ag/AgCl(sat) as the counter and reference electrodes, respectively, using a EDAQ Model potentiostat. The electrolyte was 0.45 M of CuSO2

Fig. 1 a FESEM images show top view and a cross-sectional view of the AAO templates. AAO templates were prepared under parameter conditions; time of rst anodization is 10 min and anodizing voltage

40, 45, 50 V, respectively. Pore-widening time is 20 min, b curve correlating mean pore diameter with voltage, and c AFM images (i ) AAO prepared under 50 V and (ii) AAO prepared under 40 V

123

Author's personal copy

Controllable fabrication of highly ordered thin AAO template on Si substrate

dissolved in 3 M lactic acid. The solutions PH was adjusted to 9 using sodium hydroxide. The electrodeposition was performed at an applied potential of -1 V for 5 min. The temperature was maintained at 60 C, with constant stirring throughout electrodeposition. Upon completion, the AAO template was rinsed by deionized water and dried. The surface morphology and structure of the fabricated AAO templates and the deposited Cu nanorods were studied using FESEM, EDX, AFM and XRD.

3 Results and discussion The morphology of the fabricated AAO templates was characterized by FESEM and AFM images. Figure 1a shows typical top view and a cross-sectional view of the AAO templates under 40, 45 and 50 V, respectively. The results show distinctly that an ordered honeycomb structure with uniformity in pore diameter and spacing can be fabricated with two-step anodization under controllable conditions; also Fig. 1a illustrates that the pore diameter and interpore distance increase with increasing voltage. The mean of pore diameter is 65 nm and mean of interpore

distance is 110 nm for AAO template prepared under 40 V. AAO template prepared under 45 V has a mean pore size of 70 nm and a mean interpore distance of 115 nm, while AAO template prepared under 50 V has a mean pore size of 85 nm and a mean interpore distance of 128 nm. A curve correlating mean pore diameter with anodizing voltage described in Fig. 1b illustrates that the mean pore diameter is increased with increasing the voltage. In addition, AAO sample prepared under lower voltage is more regular as shown in AFM images (Fig. 1c). The mechanism of selforganization is not fully understood, even though it can be explained by the mechanical stress model proposed by Jessensky et al. [4]. Pores are rst formed at certain microrough region where the current density is concentrated on after the formation of steady oxide layer and then the pores grow vertically to surface with equilibrium of eldenhanced oxide dissolution at the oxide/electrolyte interface and oxide growth at the metal/oxide interface, and the horizontal growth is performed simultaneously. In this process, the compressive stress between the pores which are associated with the volume expansion of the aluminum during anodization impulses the structural adjustment to form honeycomb like pore arrays. With the enhancement of

Fig. 2 FESEM images show top view of the AAO templates. AAO templates were prepared under parameter conditions; time of rst anodization is 10 min and anodizing voltage 40 V. Time of pore

widening t = 10, t = 15 and t = 20 min, respectively. Curve correlating mean pore diameter with pore-widening time

123

Author's personal copy

K. M. Chahrour et al.

Fig. 3 XRD spectra of AAO template a with annealing and b without annealing

anodizing voltage, the horizontal growth of the pores increases leading to the enlargement of the pore diameter and spacing. At the same time, the arrangement among the pores cannot keep up with the growth velocity of AAO and the ordering of this structure might decrease. Although AAO template prepared after two-step anodization possesses controllable pore diameter and periodicity, further pore adjustment can be actualized by exposure to phosphoric acid, which is called pore widening. The FESEM images of the AAO templates were prepared under 40 V after pore widening for 10, 15 and 20 min at 25 C as shown in Fig. 2a. The pore diameter increases, while the pore spacing almost keeps unchanged.

Fig. 4 a, b FESEM image shows the deposition of Cu inside of AAO template and EDX spectra. c, d FESEM image shows a cross-sectional view of Cu nanorods perpendicular to the Si substrate after removal of AAO template and EDX spectra, respectively

123

Author's personal copy

Controllable fabrication of highly ordered thin AAO template on Si substrate

4 Conclusions Highly ordered pore arrays in AAO templates with uniform pore size and vertically aligned nanotubes with well aspect ratio were successfully fabricated by anodization of thin Al lm on Si wafer. Anodizing voltage and time of pore widening are explored in our experimental conditions. FESEM analysis show that the pore diameter depends on both anodizing voltage and time of pore widening, also the AAO template prepared under 40 V present the optimum ordering as shown in the AFM images. The relation between the ordering of the pore arrays and anodizing voltage is explained by a growthdissolution model. A simple wet etching process is used for thinning the bottom barrier layer of AAO template and widening of any desired pore diameter that we need under a control of etching time. FESEM analysis show that highly orderly self-aligned Cu nanorods have been prepared on AAO template/Si substrate using electrochemical process. Finally, stirring and maintaining the electrolyte below 20 C are critical steps in obtaining ordered pore arrays.

Acknowledgments We gratefully acknowledge the support of the School of Physics, University Saince Malaysia under short term Grant No. 304/PFIZIK/6312076.

Fig. 5 XRD spectra of copper nanorods embedded in AAO template

A curve correlating mean pore diameter with widening time described in Fig. 2b illustrates that the mean pore diameter is monotonously increased with increasing the pore-widening time. The increase of pore diameter after the thinning of the outer and inner surface of AAO template might be due to the wet etching effect of phosphoric acid. This provides a convenient route to prepare AAO template of any desired pore diameter that we need. Then, any desired nanostructure diameter can be grown in its pore. Figure 3 shows XRD spectra of AAO template after annealing, the reection peak of (222) corresponding to the Al2O3 phase appear [17], which implies that the AAO transforms from amorphous to crystalline after annealing at 800 C. With the aid of AAO template and electrodeposition process, highly ordered and vertical arrays of Cu nanorods can be prepared. Figure 4a, b shows the plane view for AAO template on a Si substrate after deposition of Cu, almost all the nanopores were lled by Cu and conrmed with the EDX spectra. The lengths of Cu nanorods grown inside the AAO template were longer than the depth of AAO template whereby all the nanorods showed sign of overgrowth. Figure 4c shows the Cu nanorods remained vertically to the Si substrate and could be observed clearly. It is worth noting that the heights of the nanorods were uniform and remained separated from each other after the removal of the AAO template. The length of the nanorods was 1.25 lm and the approximate diameter was 50 nm. Note that some of the Cu nanorods near the front edge were broken during the splitting process for the preparation of cross-sectional FESEM samples. Figure 4d shows EDX spectra that conrm the compositions of the nanorods on Si substrate after the removal of the AAO template. Figure 5 shows the X-ray diffraction patterns of copper nanorods embedded in AAO template. The nanorods were polycrystalline with cubic structure indicated by the presence of two prominent peaks close to 2h angles of 43.41 and 50.60, corresponding to Cu (111) and Cu (200) diffractions, respectively.

References

1. C.H. Martin, Chem. Mater. 8, 1739 (1996) 2. H. Masuda, H. Yamada, M. Satoh, H. Asoh, M. Nakao, T. Tamamura, Appl. Phys. Lett. 71, 2770 (1997) ztu ztu rk, N. Klnc zer, Z. O rk, Appl. 3. N. Tas altn, S. O , H. Yu Phys. A 95, 781 (2009) 4. O. Jessensky, F. Muller, U. Gosele, Appl. Phys. Lett. 72, 1173 (1998) 5. N. Saidin, Y. Kok, I. Ng, F.A. Bustamam, N.M. Zali, S.Z. Abidin, AIP Conference Proceedings. p. 104 (2012) 6. L. Piao, P.S. Vijay, R. Suresh, Nanotechnol. 21, 11 (2010) 7. A.F. Feil, M.V. da Costa, P. Migowski, J. Dupont et al., Nanosci. Nanotechnol. 11, 2330 (2011) 8. S.Z. Chu, K. Wada, S. Inoue, S.I. Todoroki, Y.K. Takahashi, K. Hono, Chem. Mater. 14, 4595 (2002) 9. D. Crouse, Y.H. Lo, A. Miller, M. Crouse, Appl. Phys. Lett. 76, 49 (2000) 10. T.S. Kustandi, W.W. Loh, H. Gao, H.Y. Low, ACS Nano 4, 2561 (2010) 11. S.H. Park, S.B. Kim, D.J. Lee, S.J. Yun, Z.G. Khim, K.B. Kim, J. Electrochem. Soc. 156, 181 (2009) 12. O. Rabin, P.R. Herz, Y.M. Lin, A.I. Akinwanda, B.S. Cronin, M.S. Dresselhaus, Adv. Funct. Mater. 13, 8 (2003) 13. M. Tian, S. Xu, J. Wang, N. Kumar, E. Wertz, Q. Li, P.M. Campbell et al., Nano Lett. 5, 4 (2005) 14. M. Shaban, H. Hamdy, F. Shahin, J. Park, S.W. Ryu, J. Nano Sci. Nanotechnol. 10, 3380 (2010) 15. H. Masuda, K. Fukuda, Science 268, 1466 (1995) 16. M.H. Huang, S. Mao, H. Feick, H. Yan, Y. Wu, H. Kind, Science 292, 1897 (2001) 17. X. Wang, G.R. Han, Micro. Eng. 66, 166 (2003)

123

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- What Are Protons?Dokumen48 halamanWhat Are Protons?Dr-naser MahmoudBelum ada peringkat

- CNCDokumen2 halamanCNCDr-naser MahmoudBelum ada peringkat

- Binding Energy & Mass DefectDokumen36 halamanBinding Energy & Mass DefectDr-naser MahmoudBelum ada peringkat

- Nuclear StabilityDokumen21 halamanNuclear StabilityDr-naser MahmoudBelum ada peringkat

- Flash Lamp DesignDokumen10 halamanFlash Lamp DesignDr-naser MahmoudBelum ada peringkat

- L 1 2019Dokumen53 halamanL 1 2019Dr-naser MahmoudBelum ada peringkat

- Lecture - 2-Introduction To Radiation and Nuclear PhysicsDokumen52 halamanLecture - 2-Introduction To Radiation and Nuclear PhysicsDr-naser MahmoudBelum ada peringkat

- Lecture - 2-Introduction To Radiation and Nuclear PhysicsDokumen52 halamanLecture - 2-Introduction To Radiation and Nuclear PhysicsDr-naser MahmoudBelum ada peringkat

- Lecture - 2-Introduction To Radiation and Nuclear PhysicsDokumen52 halamanLecture - 2-Introduction To Radiation and Nuclear PhysicsDr-naser MahmoudBelum ada peringkat

- Phd. ProposalDokumen2 halamanPhd. ProposalDr-naser MahmoudBelum ada peringkat

- L 2 2020Dokumen43 halamanL 2 2020Dr-naser MahmoudBelum ada peringkat

- Kazakh - ReachedDokumen3 halamanKazakh - ReachedDr-naser MahmoudBelum ada peringkat

- 14 1077 1086Dokumen10 halaman14 1077 1086Dr-naser MahmoudBelum ada peringkat

- L 4 2020Dokumen17 halamanL 4 2020Dr-naser MahmoudBelum ada peringkat

- Laser Power Meter: How They WorkDokumen5 halamanLaser Power Meter: How They WorkDr-naser MahmoudBelum ada peringkat

- CNCDokumen2 halamanCNCDr-naser MahmoudBelum ada peringkat

- Characterization and Application of Activated Carbon Prepared From Waste Coir PithDokumen5 halamanCharacterization and Application of Activated Carbon Prepared From Waste Coir PithDr-naser MahmoudBelum ada peringkat

- Computer Numerical ControlDokumen3 halamanComputer Numerical ControlDr-naser MahmoudBelum ada peringkat

- Attenuation of Radiation VFDokumen16 halamanAttenuation of Radiation VFDr-naser MahmoudBelum ada peringkat

- Brock University Physics Department: St. Catharines, Ontario, Canada L2S 3A1Dokumen40 halamanBrock University Physics Department: St. Catharines, Ontario, Canada L2S 3A1Dr-naser MahmoudBelum ada peringkat

- Qty Items Part Numbers: PascoDokumen7 halamanQty Items Part Numbers: PascoDr-naser MahmoudBelum ada peringkat

- ACDokumen4 halamanACDr-naser MahmoudBelum ada peringkat

- 태양전지의 원리와 종류Dokumen45 halaman태양전지의 원리와 종류Dr-naser MahmoudBelum ada peringkat

- Types of Nuclear Reactors and Their ComponentsDokumen31 halamanTypes of Nuclear Reactors and Their ComponentsDr-naser MahmoudBelum ada peringkat

- Project1 DoneDokumen15 halamanProject1 DoneDr-naser MahmoudBelum ada peringkat

- Session I.4.9g: Review of Fundamentals Sources of Radiation Fuel Cycle - Power GenerationDokumen5 halamanSession I.4.9g: Review of Fundamentals Sources of Radiation Fuel Cycle - Power GenerationDr-naser MahmoudBelum ada peringkat

- Gamma Ray Interaction With Matter: A) Primary InteractionsDokumen10 halamanGamma Ray Interaction With Matter: A) Primary InteractionsDr-naser MahmoudBelum ada peringkat

- Projection Radiography (X-Ray) : Instructors: Brian Fleming and Ioana Fleming Flembri@pha - Jhu.edu, Ioana@cs - Jhu.eduDokumen67 halamanProjection Radiography (X-Ray) : Instructors: Brian Fleming and Ioana Fleming Flembri@pha - Jhu.edu, Ioana@cs - Jhu.eduDr-naser MahmoudBelum ada peringkat

- 4 - Interactions of Radiation With MatterDokumen15 halaman4 - Interactions of Radiation With MatterDr-naser MahmoudBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Nature Milestone Complete EbookDokumen145 halamanNature Milestone Complete Ebookvishal040393_9824775Belum ada peringkat

- Reducing Heavy Hydrocarbons in Fuel Gas.Dokumen74 halamanReducing Heavy Hydrocarbons in Fuel Gas.Ayuob ElsharefBelum ada peringkat

- Atomic Structure, Bonding and Mass SpectrometryDokumen7 halamanAtomic Structure, Bonding and Mass SpectrometryHumoon AfsardeirBelum ada peringkat

- Paper 2 Nov 2006Dokumen6 halamanPaper 2 Nov 2006MSHBelum ada peringkat

- Fosroc Solutions For: AdmixturesDokumen9 halamanFosroc Solutions For: Admixturesjanuarto jamadiBelum ada peringkat

- Twi Ut2Dokumen48 halamanTwi Ut2Bhavani Prasad33% (3)

- Thermal Physics: Kinetic Molecular Model and Thermal PropertiesDokumen18 halamanThermal Physics: Kinetic Molecular Model and Thermal PropertiesHakim Abbas Ali Phalasiya100% (1)

- Chapter 3 SolutionsDokumen49 halamanChapter 3 SolutionsOmy BiryaniBelum ada peringkat

- Lecture Notes First Semester Yr 2 BPham BMLS BDSDokumen57 halamanLecture Notes First Semester Yr 2 BPham BMLS BDSKarin AdraiBelum ada peringkat

- Test Bank For Organic Chemistry Structure and Function 6th Edition VollhardtDokumen15 halamanTest Bank For Organic Chemistry Structure and Function 6th Edition Vollhardtverawinifredtel2Belum ada peringkat

- Absolute Virtual Instrument TCHDokumen6 halamanAbsolute Virtual Instrument TCHNAdreaBelum ada peringkat

- Ijser: Computational Fluid Analysis of Lithium-Ion Battery Using ANSYS FluentDokumen5 halamanIjser: Computational Fluid Analysis of Lithium-Ion Battery Using ANSYS FluentSusheel WankhedeBelum ada peringkat

- Phys2 CH1 MecafluidDokumen55 halamanPhys2 CH1 MecafluidLam Pham Phuoc Loc100% (1)

- Radiation ExamplesDokumen21 halamanRadiation ExamplesPriyankaBelum ada peringkat

- Rishika Individual InvetigationDokumen9 halamanRishika Individual InvetigationAviman Pratap SinghBelum ada peringkat

- Liquid - Liquid ExtractionDokumen27 halamanLiquid - Liquid ExtractionRob LadrillonoBelum ada peringkat

- GrapheneDokumen37 halamanGrapheneNazia AslamBelum ada peringkat

- Measuring Temperature with ThermometersDokumen57 halamanMeasuring Temperature with ThermometersCyril Lyn Natividad Credo91% (11)

- SFT Kruss Application NoteDokumen22 halamanSFT Kruss Application NoteSouza TcharBelum ada peringkat

- Pressure Vessels Data SheetDokumen1 halamanPressure Vessels Data SheetAndrés SepúlvedaBelum ada peringkat

- Five Fluid PDFDokumen14 halamanFive Fluid PDFاحمد ابوبكر اشقيفهBelum ada peringkat

- Ansi Ashrae 133-2015Dokumen25 halamanAnsi Ashrae 133-2015Jesus Andres SuarezBelum ada peringkat

- R717Dokumen1 halamanR717Otto OttoBelum ada peringkat

- Xps PDFDokumen40 halamanXps PDFIyan MaulanaBelum ada peringkat

- En Product-Info Sigma Family Rel-2.5Dokumen33 halamanEn Product-Info Sigma Family Rel-2.5Julio CasalloBelum ada peringkat

- Combined Science Chemistry 1HDokumen28 halamanCombined Science Chemistry 1HAje DavidBelum ada peringkat

- Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDokumen45 halamanProf. K.K.Pant Department of Chemical Engineering IIT DelhiApaar MudgalBelum ada peringkat

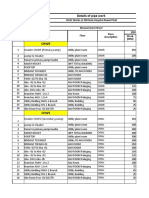

- Details of Pipe Work: Header CHWR (Primary Pump) Pump To HeaderDokumen15 halamanDetails of Pipe Work: Header CHWR (Primary Pump) Pump To Headermurshid badshahBelum ada peringkat

- A Segmented Cell Approach For Studying The Effects of Serpentine Flow Field Parameters On PEMFC Current DistributionDokumen9 halamanA Segmented Cell Approach For Studying The Effects of Serpentine Flow Field Parameters On PEMFC Current DistributionQadirBelum ada peringkat