Effect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 Steel

Diunggah oleh

Cường BéoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Effect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 Steel

Diunggah oleh

Cường BéoHak Cipta:

Format Tersedia

J.Cent.SouthUniv. (2013) 20: 866870 DOI: 10.

1007/s117710131559y

Effectoftemperingtemperatureonmicrostructureand mechanicalpropertiesofAISI6150steel

1 1 2 1 1 LIHongying() ,HUJidong() ,LIJun() ,CHENGuang() ,SUNXiongjie()

1.SchoolofMaterialsScienceandEngineering,CentralSouthUniversity,Changsha410083,China 2.ResearchInstitute,BaoshanIron&SteelCo.Ltd,Shanghai201900,China CentralSouthUniversityPressandSpringerVerlagBerlinHeidelberg2013

Abstract: EffectoftemperingtemperatureonthemicrostructureandmechanicalpropertiesofAISI6150steelwasinvestigated.All sampleswereaustenitizedat870Cfor45minfollowedbyoilquenching,andthentemperedattemperaturesbetween200and600 Cfor60min.Theresultsshowthatthemicrostructureoftemperedsampleat200Cmainlyconsistsoftemperedmartensite.With increasingthetemperedtemperature,themartensitetransformstotheferriteandcarbides.Theultimatetensilestrength,thehardness andtheretainedaustenitedecreasewithincreasingtemperedtemperature,and0.2%yieldstrengthincreaseswhenthetemperature increasesfrom200to300Candthendecreaseswithincreasingthetemperature,buttheelongationandimpactenergyincreasewith increasingthetemperingtemperature. Key words: temperingtemperatureAISI6150steel microstructure mechanicalproperty

1Introduction

AISI 6150 steel is a fine grained, highly abrasionresistantchromiumvanadiumalloysteel,which has high strength, high fatigue strength and large hardenability. In recent years, AISI 6150 steel has been commonly used in many industries, particularly the automotive industry [1-2]. However, some industries demandhighermechanicalpropertiesandlongerservice lifeofthematerials.Inordertoimprovethemechanical propertiesofAISI6150steel,somemodificationstothe steel must be required. Considerable efforts have been directed towardimproving the mechanicalproperties by compositional modifications and various heattreatment techniques. The small addition of Cr, V, Ni and Mn elements has improved its mechanical properties. Then, the technique of heattreatment should be employed to improvethe mechanical propertiesofAISI6150steel. Generally, quenching and tempering are wellestablishedmeanstoproducestrengtheninginsteel, while at the same time retaining or even increasing its impact toughness. This is mainly due to the martensitic structure produced by quenching and the subsequent precipitation of the fine carbides during the tempering process [3-4]. However, as large internal stresses associated with the martensitic transformation cause the material to be lack of ductility, the martensite steel is

rarely used in nontempered condition. Tempering can increase both the ductility and toughness, which are essential for enhancing impact energy absorption. And tempered martensite lath structure also provides best dynamic strength in steel [5]. In order to explore and understandtheeffect ofheattreatment processes on the microstructure and mechanical properties of the materials,manyresearchershavedonealotofworkover thepastfewyears[6-11].SAYEDetal[6]havestudied the effect of the tempering temperature on the microstructure and mechanical properties of dual phase steels, and the results showed that tempering at temperatureslowerthan300Cfor1hwassuitablefor attaining optimum strength and ductility. QIN et al [7] have researched the properties of 0Cr16Ni5Mo stainless steels which were normalized at 1 000 C followed by tempering inthetemperaturerange of 525-625C.The results showed that the samples tempered at 550 and 600 C for 2 h had an excellent combination of tensile strength, elongation, impact energy, hardness and corrosionresistance.SALEMIetal[8]haveexploredthe effect of tempering temperature on the mechanical properties and fracture morphology of a NiCrMoV steel, anditwasfoundthatthetensilestrengthdecreasedandthe ductility increased with the increasing of tempering temperature. However,verylimitedeffortshavebeendirectedto the effects of theheat treatment onthe AISI 6150 steel.

Foundationitem:Project(2011BAE13B03)supportedbytheNationalKeyTechnologyR&DProgramofChina Receiveddate:2012-09-24Accepteddate:2013-01-17 Correspondingauthor:LIHongying,Professor,PhDTel/Fax:+86-731-88836328Email:lhying@csu.edu.cn

J. Cent.SouthUniv. (2013)20: 866870

867

Therefore, in order to find out the effect of tempering temperature on the microstructure and mechanical properties of the steel, in the present work, the tensile properties, hardness, impact toughness and microstructures of tempered samples at different temperatureswerestudied.

2Experimental

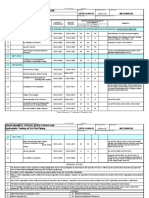

The chemical composition of mediumcarbon AISI 6150 steel used in the presentwork is given inTable 1. Before this work, we had conducted a series of experimentsatquenchingtemperaturesof800-1000C for variousholdingtime of 15-120min,and found that 870 C, 45 min is the best quenching condition for the AISI 6150 steel. In the present work, all the samples were austenitizedat 870C for 45 min, followed by oil quenchingto produce themartensite,andthentempered at200-600 Cwiththeinternalof50C.Comparedwith the previous works conducted, it was found that temperingtimeof60minwasthe bestforthesteel.

Table 1 Chemical compositions of AISI 6150 steel (mass fraction, %) C Cr V Si Mn Ni P S Fe 0.53 1.02 0.15 0.23 0.83 0.03 0.01 0.01 Bal.

speed of 0.5 ()/min. The volume fraction of retained austenite in the steel was determined by comparing the integrated Xray diffraction intensities of the ferrite and austenitephaseswiththetheoreticalintensities. Themechanicalpropertiesoftheheattreatedsamples wereevaluatedbytensiletest,impacttoughnesstestand hardnesstest.Thetensilespecimensweremachinedfrom the heat treated samples in parallel to the rolling direction. The tensile test was conducted on an Instron Universal Testing Machine (Instron 5581) at room temperature according to ISO 68922009. The test speed was 30 mm/min, which corresponded to a strain rate of 10-2s-1. Atleast,five specimens were tested and average values were calculated for each condition. Key parameters obtained from stress-strain curves include 0.2%yieldstrength(YS),ultimatetensilestrength(UTS), and percentage elongation. Standard Charpy Vnotched specimens withthe size of 55 mm10 mm10 mm was machinedtofindouttheimpactproperties.Atleastfive samples of each heat treatment process were tested and their average value was taken as the impact toughness value of plates under those conditions. The Vickers hardness of all specimens was measured under 5 N applied load for 10 s. The average hardness of one sample was reported from measurements over 10 locations.

Before the microstructures of samples were observed by scanning electron microscopy (SEM), they were mechanically polished and etched with 4% nital solution. The phase constituents in samples were analyzedbyaD/max2500Xraydiffractometry(XRD), which was operated at 40 kVand 40 mA with scanning

3Results

3.1Microstructure The microstructure of the steel in quenched conditionisshowninFig.1(a),wherethemicrostructure consists of the martensite (M). The microstructures of

Fig. 1SEM micrographs of heattreated samples: (a) Asquenched sample (b) Temperedat 200C (c) Tempered at 400 C(d) Temperedat600C

868

J. Cent. South Univ. (2013) 20: 866870

samples temperedat200-600C for 60 minare shown in Figs. 1(b)-(d). Tempering is a diffusion type phase transformation from the quenched martensite to the tempered martensite (M), ferrite (F) and carbides (C). The microstructure of the sample tempered at 200 C (Fig. 1(b))mainly consists of thelath martensite, which differs slightly from the quenched sample. Both the quenchedmartensiteandtemperedmartensiteareoflath shape. With the increase of the tempering temperature, the lath martensite transforms to ferrite and carbides. Oncethetemperingtemperatureincreasesto400C,the microstructureofthetemperedsampleisclearlydifferent fromthatofthequenchedsample.Figure1(c)showsthat themicrostructureofsampletemperedat400Cconsists of lathmartensite, ferriteandrodshape carbides. When the tempering temperature increases to 600 C, the microstructureofthetemperedsamplemainlyconsistsof ferriteandcarbides,andthecarbideschangetheirshape fromrodtospheroidalshape. 3.2Tensileproperties The tensile properties of the AISI 6150 steel samples depend on the tempering temperature. The propertiesofthequenchedsamplearealsoevaluatedfor comparison. The variations of ultimate tensile strength (UTS), 0.2% yield strength (YS) and elongation as a functionoftemperingtemperatureareshowninFig.2.It can be seen thatthe variations of tensile properties with temperature consist of several stages: 1) With the temperingtemperatureincreasingupto200C,theUTS and elongation slightly increase, and YS slightly decreases2)From200to300C,theUTSdecreasesby about100MPa,whiletheYS risessharplyandreachesa peakvalueof1 685MPa,andtheelongationincreasesby about 1.2% 3)From 300 to 600C,the UTS decreases sharplyfrom1946to1115MPa,andtheYS decreases continuouslyfrom1685to1050MPa,whileelongation risessharplyandcontinuouslyfrom7.5%to15.9%.

3.3Impactenergy Impactenergygivesagoodindicationoftheenergy required to initiate and propagatea crack. The variation ofimpactenergywithtemperingtemperatureisshownin Fig.3.AscanbeseenfromFig.3,theimpactenergyof the quenched sample is 10 J. With the tempering temperature increasing up to 200 C, the impact energy rises to 16 J. However, the impact energy changes slightly after tempering at 200-350 C. With further increasing tempering temperature from 350 to 600 C, the impact energy increases continuously and reaches 43Jatthetemperingtemperatureof600C.

Fig.3 Variationofimpactenergywithtemperingtemperature

3.4Hardness Figure 4 exhibits the influence of tempering at varioustemperaturesfor60minontheaveragevalueof Vickershardness.ItcanbeseenthatthehardnessofAISI 6150 steelgradually decreases fromHV 608to HV 360 withincreasingthe tempering temperatures in therange of 200-600C. When comparing theresults of samples tempered in various temperature ranges, it is found that the rate of decrease of the Vickers hardness in lower tempering temperature range of 200-500 C is higher thanthatintemperaturerangeof550-600C.Moreover,

Fig.2 Variationsoftensilepropertieswithtemperingtemperature

Fig.4 Variationofhardnesswithtemperingtemperature

J. Cent.SouthUniv. (2013)20: 866870

869

thehardnessofthesteelwithouttemperingisthehighest andreachesHV689.

4Discussion

As can be seen from Figs. 2-4, the mechanical properties of AISI 6150 steel are quite sensitive to the tempering temperature. Compared with the samples tempered at different temperatures, the strength and hardness of quenched sample are the highest, but the ductility is the lowest. This can be explained based on the phase transformation of steel during the quenching process, where the lattice structure of the steel changes immediately from a facecentered cubic to a bodycentered tetragonal phase. Martensite formation is accompanied by a large amount of distortion, which rapidly increases the strength and hardness of steel. However,theinternalstressgeneratedduringmartensite formation causes significant reduction of the ductility andtoughness. Tempering process relieves the internal stresses across the lath boundaries by permitting local rearrangement of atoms [11]. Below the tempering temperature of300C,internalstressesgeneratedarenot fully released. With complete recovery of stresses at temperingtemperatureof300C,arearrangementofthe dislocation structure takes place, which restricts their movement and leads to an increase in 0.2% yield strength.Withincreasingthetemperingtemperature,the concentration of the tempered martensite decreases and thepresenceoftheferriteandcarbidesincreases,mainly due to the diffusion of carbon atoms into cementite and themovementofdislocationsbythermalassistance[12]. Therefore, the ultimate tensile strength and 0.2% yield strengthdecreaseandtheelongationincreases. AISI 6150 steels are susceptible to tempered martensite embrittlement (TME) within a specified temperature range. The phenomenon is usually characterizedonaplotofimpactenergyasafunctionof tempering temperature. And it can be observed that a maximum in the ductile-brittle transition temperature correspondingtotheminimumintheimpactenergy[13]. It is seen from Fig. 3 that the impact energy increases withincreasingthetemperingtemperature. Figure 5 depictsthe XRD patterns of the tempered sample at 200 C for 60 min. The peaks represent the diffraction intensity of different crystal orientations of the ferrite. The volume fraction of retained austenite is achievedbytheresultofRietveldspectrumfittingofthe tempered samples after XRD phase testing. Figure 6 showsthevariationsofretainedaustenitewithtempering temperature. As can be seen in Fig. 6, the quenched sample contains the maximum amount of retained austenite. With thetempering temperature increasing up

to 200 C, the volume fraction of retained austenite varies from 3.60% to 2.93%. When the tempering temperature increases from 200 to 300 C, the volume fractionofretainedaustenitesharplydecreasesto0.62%, mainlyduetothefactthatmostoftheretainedaustenites transformtotemperedmartensiteaftertemperingatthese temperatures. These lead to an increase in 0.2% yield strengthandelongation,andaslightdecreaseinultimate tensilestrength.Theretainedaustenitedecreasesslightly in the tempering temperature range of 300-500 C. At temperingtemperatureabove550 C,thevolumefraction ofretainedausteniteisclosetozero.

Fig.5 XRDpatternoftemperedsampleat200 C

Fig.6 Variationofretainedaustenitewithtemperingtemperature

According to the HollomonJaffe relation of the hardness and a tempering parameter M: H=f(M)= f(T(t+lgt))[14],itisknownthatthehardnessisaffected by the tempering temperatureif the tempering time isa constant. Tempering can be considered as a phase transformation promoted by diffusion from an unstable state towards a quasi equilibrium state. Therefore, the hardness can be used to define any tempering state. As theevolutionsofthetemperingtimeandtemperatureare

870

J. Cent. South Univ. (2013) 20: 866870

[2] LIC S, LIU X H, WANG G D. Simulation on temperature field of 50CrV4automobilegearbar steelincontinuousrolling byFEM[J]. JournalofMaterialsEngineeringPerformance,2002,120(1):26-29. [3] BANDYOPADHYAY N, MCMAHON C J. The micromechanisms of tempered martensite embrittlement in 4340 type steels [J]. MetallurgicalandMaterials Transactions A,1983,14(7):1313-1325. [4] CHANG E, CHANG C Y, LIU C D. The effect of double austenitization on the mechanical properties of a 0.34C containing lowalloy NiCrMoV steels [J]. Metallurgical and Materials Transactions A,1994,25(7):545-555. [5] JENA P K, MISHRA BIDYAPATI, RAMESHBADU M, BAHU ARVINDHA, SINGH A K, SIVAKUMAR K, BHAT

also controlled by diffusion mechanisms (particularly carbides precipitation and growth), a tempering kinetic lawisproposedintheformoftheJohnsonMehlAvrami typeequation[15]:

H v = H 0 + ( H - H 0) exp( - ( D t ) m)

(1)

where H0 is the hardness after quenching, H is the hardness in the tempered state, Hv is thehardness of an intermediate state between the quenched state and the tempered state, t is the tempering time, m is the ageing exponent depending on the material and the previous heattreatment,andDdependsontemperingtemperature andfollowstheArrheniusequation: D=D0 exp[-Q/(RT)] (2)

BALAKRISHNA T. Effect of heat treatment on mechanical and ballistic properties of a high strength armour steel [J]. International JournalofImpactEngineering,2010, 37(3):242-249.

where D0 is the preexponential constant, Q is the activation energy of the tempering transformation, R is theperfectgasconstant(equalto8.31J/(Kmol-1))andT isthetemperingtemperaturein K.AccordingtotheEq. (1) and Eq. (2), if the activation energy of tempering transformation and tempering time remain constant during the tempering process, it can be calculated that the hardness of the AISI 6150 steel decreases with the increase of the tempering temperature.These calculated results closely agree with the measured experimental valuesofFig.4.

[6]

SAYED A A, KHEIRANDISH S H. Effect of the tempering temperature onthe microstructureand mechanicalpropertiesofdual phase steels[J].MaterialsScienceandEngineeringA,2012,532(1): 21-25.

[7]

QIN B, WANG Z Y, SUN Q S. Effect of tempering temperature on properties of 0Cr16Ni5Mo stainless steel [J]. Materials

Characterization,2008,59(8):1096-1100. [8] SALEMI A, ABDOLLAHZADEH A. The effect of tempering temperatureonthemechanicalpropertiesandfracturemorphologyof a NiCrMoV steel [J]. Materials Characterization, 2008, 59(4): 484-487. [9] NASERYISFAHANYA,SAGHAFIANH,BORHANIG.Theeffect of heat treatment on the mechanical properties and corrosion behaviorofAISI420martensiticstainlesssteel[J].JournalofAlloys

5Conclusions

1) At low tempering temperature of 200 C, the tempered microstructure mainly consists of lath martensite. With increasing the tempered temperature, themartensitebecomeslessandtransformstoferriteand carbides. The microstructures of the AISI 6150 steel consist of ferrite and carbides at the high tempering temperatureof600C. 2) Increasing the tempering temperature decreases the ultimate tensile strength and the hardness, but increases the elongation and impact energy. However, 0.2% yield strength increases when the temperature increases from 200 to 300 C and then decreases with increasingthetemperature. 3) The retained austenite sharply decreases at the temperedtemperaturesof200-300C,andthendecreases slightly in the temperature range of 300-500 C. When the tempering temperature is higher than 550 C, the contentof retainedaustenitedecreasestozero.

andCompounds,2011,509(9):3931-3936. [10] LIYanghua,ZHAOYankuo,WUYue,LIUJiaojiao,LIHongying. Effects of tempering temperature on microstructures and properties ofV150casingandtubingwithultrahighstrengthandtoughness[J]. Journal ofCentralSouthUniversity:ScienceandTechnology,2012, 43(6):2128-2136.(inChinese) [11] ZOUDening,HANYing,ZHANGWei,FANGXudong.Influence of tempering process on mechanical properties of 00Cr13Ni4Mo supermartensitic stainless steel [J]. Journal of Iron and Steel Research,International,2010,17(8):50-54. [12] ANANDL,GURLANDJ.Effectofinternalboundariesontheyield strengths of spheroidized steel [J]. Metallurgical and Materials TransactionsA,1976,7(2):191-197. [13] JENAPK,SIVAKUMARK,BHATTB.Effectofheattreatmenton mechanical and ballistic properties of ultra high strength DMR700 steel[J].MetalsMaterialsandProcesses,2007,19(1/4):339-346. [14] DARWISH F A, PEREIRA L, GRACA M L. On the tempered martensite embrittlement in AISI 4140 low alloy steel [J]. Materials ScienceandEngineering A,1991,132(1):5-9.

References

[1] GUOWenyuan,LIJun,JIANGXifeng.Subcriticalspheroidization of mediumcarbon 50CrV4 Steel [J]. Journal of Materials EngineeringPerformance,2012,21(6):1003-1007.

[15] ZHANG Z, DELAGNES D, BERNHART G. Microstructure evolutionofhotworktoolsteelsduringtemperinganddefinitionofa kinetic law based on hardness measurements [J]. Materials Science andEngineeringA,2004,380(1/2):222-230. (Editedby YANGBing)

Anda mungkin juga menyukai

- The Effect of Heat Treatment On Mechanical Properties and Corrosion Behavior of AISI420 Martensitic Stainless SteelDokumen6 halamanThe Effect of Heat Treatment On Mechanical Properties and Corrosion Behavior of AISI420 Martensitic Stainless Steelanon_506964735Belum ada peringkat

- Phase Transformation in AISI 410 Stainless Steel PDFDokumen10 halamanPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiBelum ada peringkat

- Investigation of Microstructures and Properties ofDokumen4 halamanInvestigation of Microstructures and Properties oftiagoness85Belum ada peringkat

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDari EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysBelum ada peringkat

- Heat Treatment of Commercial Steels For Engineering ApplicationsDokumen34 halamanHeat Treatment of Commercial Steels For Engineering ApplicationsmeBelum ada peringkat

- Decomposition of Austenite in Austenitic Stainless SteelsDokumen13 halamanDecomposition of Austenite in Austenitic Stainless SteelsregistrosegBelum ada peringkat

- Effects of Inclusions On Microstructure and Properties of Heat-Affected-Zone For HSLA SPFH 590Dokumen4 halamanEffects of Inclusions On Microstructure and Properties of Heat-Affected-Zone For HSLA SPFH 590IJRASETPublicationsBelum ada peringkat

- Revealing Prior-Austenite Grain Boundaries in Heat-Treated SteelsDokumen5 halamanRevealing Prior-Austenite Grain Boundaries in Heat-Treated Steelsmp87_ingBelum ada peringkat

- Role of Vanadium in Microalloyed Steels - Lagneborg PDFDokumen86 halamanRole of Vanadium in Microalloyed Steels - Lagneborg PDFYogi173Belum ada peringkat

- Review of Creep Resistant SteelsDokumen4 halamanReview of Creep Resistant SteelsAleš NagodeBelum ada peringkat

- Precipitation in The Ni-Cu-Base Alloy Monel K-500Dokumen13 halamanPrecipitation in The Ni-Cu-Base Alloy Monel K-500farhadeeBelum ada peringkat

- Hsla SteelDokumen22 halamanHsla SteelriteshbarmanBelum ada peringkat

- Alloy And Microstructural DesignDari EverandAlloy And Microstructural DesignJohn TienBelum ada peringkat

- Steel CleanlinessDokumen22 halamanSteel CleanlinessfondershellBelum ada peringkat

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDari EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelBelum ada peringkat

- Diagramas TT de Ferro e Aço - Aço de Alta ResistênciaDokumen111 halamanDiagramas TT de Ferro e Aço - Aço de Alta ResistênciaFernando VenceslauBelum ada peringkat

- WJ 1985 10 s281 PDFDokumen15 halamanWJ 1985 10 s281 PDFbabaaromeBelum ada peringkat

- 1.the Basics of Ferrous MetallurgyDokumen83 halaman1.the Basics of Ferrous MetallurgyfenasikerimBelum ada peringkat

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDari EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceBelum ada peringkat

- ISSF Martensitic Stainless SteelsDokumen56 halamanISSF Martensitic Stainless Steelsarjun prajapati100% (1)

- Advances in Research on the Strength and Fracture of Materials: An OverviewDari EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinBelum ada peringkat

- Effects of MN Content and Heat TreatmentDokumen5 halamanEffects of MN Content and Heat TreatmentTrần Xuân VịnhBelum ada peringkat

- A New Role For Microalloyed SteelsDokumen11 halamanA New Role For Microalloyed SteelsMuhammed SulfeekBelum ada peringkat

- Aluminium 2014 t6 2014 t651Dokumen3 halamanAluminium 2014 t6 2014 t651Agung Sapto AjiBelum ada peringkat

- Porosity in Castings AFS Transactions 2005Dokumen28 halamanPorosity in Castings AFS Transactions 2005jlplazaolaBelum ada peringkat

- Corrosion and Heat Resistant Nickel AlloysDokumen14 halamanCorrosion and Heat Resistant Nickel AlloysWahid Muhamad Furkon RahmatullohBelum ada peringkat

- Austenitic Stainless SteelsDokumen23 halamanAustenitic Stainless SteelsAndrea VieyraBelum ada peringkat

- Austenitizing Heat Treatment PDFDokumen20 halamanAustenitizing Heat Treatment PDFsivajirao70100% (1)

- DIN50602 Microscopic Examination of Special Steels Using Standard Diagrams To Assess The Content of Non Metallic InclusionsDokumen12 halamanDIN50602 Microscopic Examination of Special Steels Using Standard Diagrams To Assess The Content of Non Metallic InclusionsAgustinMorann100% (1)

- Stainless Steel Microstructure, Mechanical Properties and Methods of Application - 2015Dokumen291 halamanStainless Steel Microstructure, Mechanical Properties and Methods of Application - 2015Ariel NemcoBelum ada peringkat

- Incoloy Alloy 825Dokumen4 halamanIncoloy Alloy 825Roman PaduaBelum ada peringkat

- Microstructure-Property Relationships in High Chromium White Iron Alloys PDFDokumen24 halamanMicrostructure-Property Relationships in High Chromium White Iron Alloys PDFLuis AcevedoBelum ada peringkat

- Development and Processing of Low Carbon Bainite SteelDokumen486 halamanDevelopment and Processing of Low Carbon Bainite Steelpaimpilly100% (1)

- Diagramas TT de Ferro e Aço - Aço FerramentaDokumen141 halamanDiagramas TT de Ferro e Aço - Aço FerramentaFernando VenceslauBelum ada peringkat

- The Precipitation Hardening SSsDokumen3 halamanThe Precipitation Hardening SSsClaudia MmsBelum ada peringkat

- Recovery and Recrystallization Kinetics in AA1050 and AA3003 Aluminium AlloysDokumen196 halamanRecovery and Recrystallization Kinetics in AA1050 and AA3003 Aluminium AlloysRavjManjunathBelum ada peringkat

- Adiabatic Shear Localization: Frontiers and AdvancesDari EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddBelum ada peringkat

- Graphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundDokumen2 halamanGraphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundMuhammad Noman ButtBelum ada peringkat

- Welding - Ferritic Stainless Steel 1.4003Dokumen9 halamanWelding - Ferritic Stainless Steel 1.4003Danut RusBelum ada peringkat

- Specification For Solid Surfacing Welding Rods and ElectrodesDokumen23 halamanSpecification For Solid Surfacing Welding Rods and ElectrodesDmitriyBelum ada peringkat

- Interpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Dokumen10 halamanInterpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Nick pilipenkoBelum ada peringkat

- A 487Dokumen6 halamanA 487arockia1977100% (2)

- 42 Crmo 4Dokumen2 halaman42 Crmo 4Shiva Kumar MBelum ada peringkat

- Vanadium Alloyed SteelsDokumen8 halamanVanadium Alloyed Steelskarthik vasan bBelum ada peringkat

- Aco HadfieldDokumen22 halamanAco HadfieldFelipe ZanellaBelum ada peringkat

- Stress Corrsion Cracking Behavion of Austenitic Stainless Steel PDFDokumen5 halamanStress Corrsion Cracking Behavion of Austenitic Stainless Steel PDFJEISON CONTRERAS HOYOSBelum ada peringkat

- Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeDokumen4 halamanAustenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeJosé Ramón GutierrezBelum ada peringkat

- Nitriding 4340 ADokumen8 halamanNitriding 4340 AyanuarBelum ada peringkat

- Aerospace Material SpecificationDokumen6 halamanAerospace Material Specificationvsraju2Belum ada peringkat

- Is Phosphorus Bad For SteelDokumen19 halamanIs Phosphorus Bad For SteelKarun Dev100% (1)

- 701 Steel InclusionRating DIN-50602 PDFDokumen1 halaman701 Steel InclusionRating DIN-50602 PDFbiancogallazzi0% (1)

- Nickel Alloy HandbookDokumen23 halamanNickel Alloy HandbookRocksyBelum ada peringkat

- Effect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIDokumen6 halamanEffect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIgiokniessBelum ada peringkat

- Special Alloys and Overmatched Welding Products SolveDokumen14 halamanSpecial Alloys and Overmatched Welding Products SolveBhanu Pratap ChoudhuryBelum ada peringkat

- Advance StructuresDokumen6 halamanAdvance StructuresManju NishaBelum ada peringkat

- Hvac Load Calculations of A VillaDokumen72 halamanHvac Load Calculations of A VillaKhalil YoussefBelum ada peringkat

- Revit MEP 2013 EssentialsDokumen3 halamanRevit MEP 2013 EssentialsCADsoft ConsultingBelum ada peringkat

- MS For Site Mobilization Work Rev.0Dokumen11 halamanMS For Site Mobilization Work Rev.0nijasBelum ada peringkat

- For The Steam and Condensate Loop - 01Dokumen4 halamanFor The Steam and Condensate Loop - 01zoraze32Belum ada peringkat

- Figure 9-9 Hubless Cast Iron Pipe 9.10 Figure 9-10 Riser Bracing For Hubless Pipes 9.11Dokumen18 halamanFigure 9-9 Hubless Cast Iron Pipe 9.10 Figure 9-10 Riser Bracing For Hubless Pipes 9.11Amro Metwally El HendawyBelum ada peringkat

- Allotment Letters (SAVIOUR Green Isle)Dokumen12 halamanAllotment Letters (SAVIOUR Green Isle)Sonakshi ChauhanBelum ada peringkat

- Offshore Piping Design CriteriaDokumen1 halamanOffshore Piping Design CriteriaDhakshina K100% (1)

- Pow 17J00012Dokumen41 halamanPow 17J00012amroussyBelum ada peringkat

- Investigation of Methods of Improving The Application Workmanship of WaterproofingDokumen16 halamanInvestigation of Methods of Improving The Application Workmanship of Waterproofingniran_udayangaBelum ada peringkat

- Finishes 4 - ExternalDokumen24 halamanFinishes 4 - ExternalMuhammad FakhriBelum ada peringkat

- Iot Based Real Time Early Age Concrete Compressive Strength MonitoringDokumen6 halamanIot Based Real Time Early Age Concrete Compressive Strength MonitoringKhizra SarwarBelum ada peringkat

- 2014CC BC Chapter 33 Safeguards During Construction or DemoDokumen109 halaman2014CC BC Chapter 33 Safeguards During Construction or DemoMannyBelum ada peringkat

- Papercrete4 PDFDokumen9 halamanPapercrete4 PDFPrasad TekadeBelum ada peringkat

- ANSI Thread Series DesignationsDokumen1 halamanANSI Thread Series DesignationsAbby BurchBelum ada peringkat

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDokumen10 halamanSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadBelum ada peringkat

- 1 - Introduction To Vernacular Architecture - Part2Dokumen51 halaman1 - Introduction To Vernacular Architecture - Part2jashndeep100% (1)

- mc10224 09 13 HydromaxDokumen8 halamanmc10224 09 13 Hydromaxapi-221502147Belum ada peringkat

- Welding QuizDokumen5 halamanWelding QuizHamza NoumanBelum ada peringkat

- Asme BPVC - Ii.A-2017 Sa-530/Sa-530M: P2St/Dorsppd/2TDokumen1 halamanAsme BPVC - Ii.A-2017 Sa-530/Sa-530M: P2St/Dorsppd/2TGOWTHAMBelum ada peringkat

- Fire Sprinkler Systems#Dokumen8 halamanFire Sprinkler Systems#aimiza50% (2)

- Bamboo Joints and Joinery Techniques - Guadua BambooDokumen13 halamanBamboo Joints and Joinery Techniques - Guadua Bambooupendar reddy Mallu50% (2)

- Bolted Composite JointDokumen28 halamanBolted Composite JointHitesh Parghi50% (2)

- Affa Tiles BookletDokumen41 halamanAffa Tiles BookletAnonymous iTzCnMBelum ada peringkat

- Full Overlay European Concealed Hinges Model Description Opening HDokumen2 halamanFull Overlay European Concealed Hinges Model Description Opening HMel TorresBelum ada peringkat

- Atal Mission For Rejuvenation and Urban TransformationDokumen3 halamanAtal Mission For Rejuvenation and Urban TransformationAshutosh MasgondeBelum ada peringkat

- Multi ChemDokumen5 halamanMulti ChemKiran Kumar JhaBelum ada peringkat

- Hemp LimeDokumen18 halamanHemp LimePranav Chovatiya0% (1)

- Magnaloy ProductsDokumen223 halamanMagnaloy ProductsvankarpBelum ada peringkat

- Wip 17Dokumen18 halamanWip 17Ankit BinjolaBelum ada peringkat

- Module 4 Construction ContractsDokumen47 halamanModule 4 Construction ContractsNiki DimaanoBelum ada peringkat