Jacketed Vessel

Diunggah oleh

nithansaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Jacketed Vessel

Diunggah oleh

nithansaHak Cipta:

Format Tersedia

Chemical Engineering Department

TUTORIAL NO.

JACKETED VESSEL(MECHANICAL DESIGN)

TUTORIAL NO.

JACKETED VESSEL(MECHANICAL DESIGN)

1

JACKETED VESSEL(MECHANICAL DESIGN)

Chemical Engineering Department

(A) INTRODUCTION : Jacketed vessel is pressure vessel to carry out reactions under controlled condition. The reaction vessel requires cover or head that can be fitted tightly to the vessel shell. So the pressure and temperature can be maintained as desired inside. Capacities of the vessel vary from 100 lit to 1500 lit. and diameter may vary from 50 cm to 50 cm. !ead used for vessels are shallo"#dished$ torispherical or elliptical. Several no%%les inlet$ &utlet$ sight glass and light glass$ Thermo "ell$ hand holes and man holes are provided to satisfy the process requirements. Jacket is used to circulate heating or cooling media. (B) AGITATION ' (gitation of the content of reaction vessel increasing heat and mass transfer. )addle agitator$ turbine agitator and propeller agitator are most "idely used. The agitator "ith drive assembly must be located at the top of the vessel "ith preferably in independent supporting structure. (C) HEATING/COOLING' *f the heating is required then the hot fluid is supplied in the +acket. Jacket surrounds the vessel "all. ,luid such as hot oil$ hot "ater or air$ molten salt mi-ture$ special organic compounds such as therminol and do"# therm are used as heating media. *f cooling is desired than air$ liquid ammonia$ cold "ater or brine$ oil can be used. The space bet"een the vessel "all and the +acket shell should be narro" for obtaining good heat transfer rates. .arious types of +acket are used for this purpose. Special types of +acket such as channel and coiled +acket provides high velocity of circulating fluid and hence high heat transfer rates. (D) DESIGN PROCEDURE : /esign is based on pressure and temperature condition. This types of reaction vessel is nothing but pressure vessel "ith heads and no%%les. /ue to +acket there is e-ternal pressure on the vessel "all. So the vessel is designed for both internal 0 e-ternal pressure and the higher value of "all thickness is accepted. ( plain +acket is simplest arrangement for heating or cooling. *n most cases +acket e-tends over the base of the reactor and provision must be made for applying the vessel as "ell as for removing fluid from the +acket.

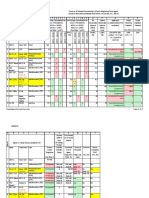

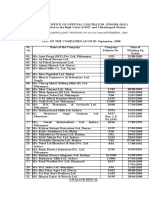

112 Thickness of shell '

,or the cylindrical shell '# [ i ] Fo I!"# !$% & #''( # : ) /esign pressure 3 *nternal pressure 4 105 of internal pressure Shell thickness 1t2 3 p /i 61 f J # p2 3 p /o 61 f J 4 p23 p / 61 f J2

7here p3 /esign pressure / 3 8ean diameter /i 3 *nternal diameter /0 3 &utside /iameter J 3 Joint efficiency 9 3 /esign or permissible stress at design temperature

JACKETED VESSEL(MECHANICAL DESIGN)

Chemical Engineering Department

.alue of permissible stress for different material of construction "ill be different. [ ii ] Fo E*"# !$% & #''( # :) /esign pressure 3 )ressure in the +acket 4105 of pressure in the +acket. ,irst calculate the critical e-ternal pressure using above shell thickness calculated for internal pressure ' pc 3 .: ; 1t6/0256 6<11# 2=6:>1?6/02 @ 0.:5 1t6/0216 AB 7here$ ?3 Cnsupported length of vessel ;3 8odulus of elasticity 3poisonDs ratio Eo" allo"able e-ternal "orking pressure$ )a 3 pc 6: Eo"$ )a must be grater than design pressure and if )a F design pressure then increase the shell thickness until this condition satisfies.

1 2 Stiffening ring '

This ring can provide considerable saving in "eight and material. Gings are attached to the inside6outside surface of the shell. They e-tend over the "hole circumference and serve the purpose of end support. T#beams and flat plate ring are simple$ light and effective. Eo" effective length of vessel is considered the length bet"een stiffening ring . The stiffening ring must have movement of interna given by * 3 pc /o=?6 1 : ;2

The value of H*D may be reduced by about =05 to taken into account the resistance of the shell.

1=2 Thickness of +acket '

*nternal design3 )ressure inside +acket 4105 of pressure inside the +acket t+ 3 p/i 61 f J # p2 7here /i 3 Jacket internal diameter.

JACKETED VESSEL(MECHANICAL DESIGN)

Chemical Engineering Department

1:2 !ead thickness '

,or Torispherical head '# th 3 p Gc 7 61 f J 2 7here Gc 3 Cro"n radius 7 3 Stress intensification factor 3 116:2 >= 4 1 Rc 6 R12 A Gi 3 Inuckle radius (bove head thickness should be checked for e-ternal pressure also. th 3 :.: Gc

11 # 2 p 61 E 2

7here )3/esign e-ternal pressure1)ressure inside the +acket2 3333333333333333333333333333J J J J J J J 3333333333333333333333333

JACKETED VESSEL(MECHANICAL DESIGN)

Anda mungkin juga menyukai

- Dimple Jacket Heat Transfer EstimationDokumen3 halamanDimple Jacket Heat Transfer EstimationicingrockBelum ada peringkat

- Jacketed Vessel DesignDokumen5 halamanJacketed Vessel DesignfunkkkkyBelum ada peringkat

- Agitated Vessel Heat Transfer (K.J. Carpenter)Dokumen9 halamanAgitated Vessel Heat Transfer (K.J. Carpenter)Clarence AG Yue100% (2)

- Heat Transfer in Agitated VesselsDokumen33 halamanHeat Transfer in Agitated VesselsGanesh.Mahendra100% (1)

- Tank Coils - Design and UseDokumen7 halamanTank Coils - Design and UseMartin DanzeBelum ada peringkat

- Heat Transfer in Jacketed Vessels with Half Pipe CoilsDokumen5 halamanHeat Transfer in Jacketed Vessels with Half Pipe CoilsabubackersiddieqBelum ada peringkat

- HCL Scrubber DesignDokumen5 halamanHCL Scrubber DesignManish0301198375% (4)

- Chapter - 9-Heat Transfer in Agitated VesselsDokumen44 halamanChapter - 9-Heat Transfer in Agitated VesselsSata Ajjam100% (2)

- Mechanical design of sieve plate columnDokumen65 halamanMechanical design of sieve plate columnLi Ann Chung92% (12)

- Design of Compact Plate Fin Heat ExchangerDokumen61 halamanDesign of Compact Plate Fin Heat ExchangerIndra Uchiha100% (3)

- Bubble Cap Plate For Distillation ColumnDokumen26 halamanBubble Cap Plate For Distillation Columnsanjukec100% (2)

- Storage Tank Venting CalculationDokumen1 halamanStorage Tank Venting Calculationام يمنى ايمنBelum ada peringkat

- Jacketed Vessel Design CalculusDokumen4 halamanJacketed Vessel Design Calculusmaspiqdo100% (1)

- Plate Heat ExchangersDokumen7 halamanPlate Heat ExchangersBaneMarkovicBelum ada peringkat

- Jacket and Coils of Agitated Vessels PDFDokumen2 halamanJacket and Coils of Agitated Vessels PDFlolofm25Belum ada peringkat

- Agitated VesselsDokumen24 halamanAgitated VesselsAnuj Kumar100% (1)

- Liquid Distributor DesignDokumen3 halamanLiquid Distributor Designanon_414493592Belum ada peringkat

- Predict Storage Tank Heat Transfer Precisely Rev2Dokumen16 halamanPredict Storage Tank Heat Transfer Precisely Rev2zefiloBelum ada peringkat

- Heat Transfer in Jacketed VesselDokumen2 halamanHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Design of AbsorberDokumen9 halamanDesign of Absorberhaseeb tahir50% (2)

- Minimum Wetting Rates in Falling Film EvaporatorsDokumen9 halamanMinimum Wetting Rates in Falling Film EvaporatorsDavid GutiérrezBelum ada peringkat

- Shell and Tube Heat Exchanger DesignDokumen5 halamanShell and Tube Heat Exchanger DesignDominic CareoBelum ada peringkat

- IMTPDokumen16 halamanIMTPDHAVALESH AMBelum ada peringkat

- Jacket Area CalculationDokumen12 halamanJacket Area CalculationPraveen Prajapati100% (2)

- Heat Exchanger Design CalculationsDokumen6 halamanHeat Exchanger Design CalculationsryanarthurBelum ada peringkat

- Distillation Column Design 2014Dokumen4 halamanDistillation Column Design 2014John PortlandBelum ada peringkat

- Design of Limpet Coil as per Appendix EEDokumen10 halamanDesign of Limpet Coil as per Appendix EEmaheshspawar0% (1)

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Dokumen5 halamanCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiBelum ada peringkat

- Types of EvaporatorsDokumen12 halamanTypes of Evaporatorsapi-377437388% (8)

- Conventional JacketsDokumen4 halamanConventional JacketsTerence TanBelum ada peringkat

- Shell and Tube Heat Exchanger DesignDokumen3 halamanShell and Tube Heat Exchanger Design1AdityaPathania1Belum ada peringkat

- Internal Coil CalculationDokumen19 halamanInternal Coil CalculationMr Incognito100% (3)

- Brian JR Geoffroy CHNG 3012 Part II PDFDokumen103 halamanBrian JR Geoffroy CHNG 3012 Part II PDFjanelle ramdahinBelum ada peringkat

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDokumen2 halamanSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1Belum ada peringkat

- Design of Distillation TraysDokumen25 halamanDesign of Distillation Trayssatishchemeng100% (8)

- Veturi Design ProcedureDokumen2 halamanVeturi Design Procedureshivanandr2481Belum ada peringkat

- Condenser & EvaporatorDokumen21 halamanCondenser & EvaporatorfitratulqadriBelum ada peringkat

- Design of Bubble Cap TrayDokumen5 halamanDesign of Bubble Cap TrayVirendra BhagatBelum ada peringkat

- Design 2 ReboilerDokumen5 halamanDesign 2 ReboilerAbdulrazzaqAL-MalikyBelum ada peringkat

- Limpet Coil CalculationDokumen1 halamanLimpet Coil Calculationkirandas_mullassery100% (1)

- Heating Coil CalculationDokumen1 halamanHeating Coil Calculationyatin888100% (1)

- Coil DesignDokumen7 halamanCoil DesignSajal Kulshrestha100% (2)

- Design of AgitatorDokumen3 halamanDesign of Agitatorkaps12Belum ada peringkat

- Switch CondenserDokumen14 halamanSwitch CondenserKader GüngörBelum ada peringkat

- 3G4 Distillation CalculationsDokumen22 halaman3G4 Distillation CalculationsMahmoud Nasr0% (1)

- Handbook for Transversely Finned Tube Heat Exchanger DesignDari EverandHandbook for Transversely Finned Tube Heat Exchanger DesignBelum ada peringkat

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDari EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationBelum ada peringkat

- Agitated Vessel Heat TransferDokumen7 halamanAgitated Vessel Heat TransferalokbdasBelum ada peringkat

- An Alternative Way To Support Horizontal Pressure Vessels Subject To To Thermal LoadingDokumen7 halamanAn Alternative Way To Support Horizontal Pressure Vessels Subject To To Thermal LoadingDavid RodriguesBelum ada peringkat

- Mechanical Design Standards for Shell and Tube Heat ExchangersDokumen46 halamanMechanical Design Standards for Shell and Tube Heat ExchangersDawitBelum ada peringkat

- Chap. 7 - Pressure VesselsDokumen37 halamanChap. 7 - Pressure VesselsGritz Kay Labucay MarforiBelum ada peringkat

- Cooling& Heating Time CalculationDokumen6 halamanCooling& Heating Time CalculationSandesh LawandBelum ada peringkat

- Tks 3245 Perancangan Alat ProsesDokumen38 halamanTks 3245 Perancangan Alat Prosesfadhillah ivanBelum ada peringkat

- Chapter One: 1.1) Introduction of Pressure VesselDokumen55 halamanChapter One: 1.1) Introduction of Pressure VesselAbenezer BirhanuBelum ada peringkat

- Agitated Vessel Heat Transfer DesignDokumen3 halamanAgitated Vessel Heat Transfer Designvasudevanrv9405Belum ada peringkat

- Agitated Vessel Heat Transfer Design PDFDokumen3 halamanAgitated Vessel Heat Transfer Design PDFmrariffBelum ada peringkat

- Wellheads, Flow Control Eqpmt N FlowlinesDokumen131 halamanWellheads, Flow Control Eqpmt N FlowlinesEbenezer Amoah-KyeiBelum ada peringkat

- Storage TanksDokumen62 halamanStorage Tankstoychom2013Belum ada peringkat

- Design of Pressure VesselsDokumen23 halamanDesign of Pressure VesselsSuryaprakashBelum ada peringkat

- CHE 480 Practice Questions-10Dokumen15 halamanCHE 480 Practice Questions-10harisjawedBelum ada peringkat

- Identification of PolymersDokumen5 halamanIdentification of Polymersnithansa100% (1)

- CephalaxinDokumen2 halamanCephalaxinnithansaBelum ada peringkat

- M-Di Nitro BenzeneDokumen4 halamanM-Di Nitro Benzenenithansa100% (1)

- Estimation of Carboxylic GroupDokumen4 halamanEstimation of Carboxylic GroupnithansaBelum ada peringkat

- DensityDokumen3 halamanDensitynithansaBelum ada peringkat

- Bourden Tube Pressure GaugeDokumen2 halamanBourden Tube Pressure GaugenithansaBelum ada peringkat

- Study of Primary and Secondary Refrigeration FINDDokumen1 halamanStudy of Primary and Secondary Refrigeration FINDnithansaBelum ada peringkat

- NotchesDokumen3 halamanNotchesnithansaBelum ada peringkat

- Kadva Patidar HistoryDokumen2 halamanKadva Patidar HistorynithansaBelum ada peringkat

- POs &GraduateAttributes ChemicalDokumen2 halamanPOs &GraduateAttributes ChemicalnithansaBelum ada peringkat

- Preparation of B-NaphtholDokumen4 halamanPreparation of B-NaphtholnithansaBelum ada peringkat

- Preparation of PotassiumSulphateDokumen5 halamanPreparation of PotassiumSulphatenithansaBelum ada peringkat

- Preparation of SoapDokumen3 halamanPreparation of Soapnithansa0% (1)

- Preparation of AlumDokumen3 halamanPreparation of AlumnithansaBelum ada peringkat

- VehicleDriveCalculation PDFDokumen1 halamanVehicleDriveCalculation PDFnithansaBelum ada peringkat

- Body TestDokumen2 halamanBody TestnithansaBelum ada peringkat

- Ammonia and Urea ProductionDokumen10 halamanAmmonia and Urea Productionwaheed_bhattiBelum ada peringkat

- Calendar 2017 Public HolidaysDokumen2 halamanCalendar 2017 Public HolidaysnithansaBelum ada peringkat

- List of BooksDokumen1 halamanList of BooksnithansaBelum ada peringkat

- HMT Extra NotesDokumen22 halamanHMT Extra NotesramskokyBelum ada peringkat

- Ghar Ek MandirDokumen22 halamanGhar Ek MandirnithansaBelum ada peringkat

- MT 1Dokumen34 halamanMT 1Vishal VnBelum ada peringkat

- Government Polytechnic, Rajkot: Academic Calendar - 2017Dokumen1 halamanGovernment Polytechnic, Rajkot: Academic Calendar - 2017nithansaBelum ada peringkat

- Indian Rail Fare Effective 25-Dec-2015Dokumen34 halamanIndian Rail Fare Effective 25-Dec-2015nithansaBelum ada peringkat

- Natural Gas ConversionDokumen91 halamanNatural Gas ConversionHassan HaiderBelum ada peringkat

- Green ChemistryDokumen30 halamanGreen ChemistrynithansaBelum ada peringkat

- Interview QuestionsDokumen3 halamanInterview QuestionsnithansaBelum ada peringkat

- New Year Resolution 2017Dokumen18 halamanNew Year Resolution 2017nithansaBelum ada peringkat

- PesticidesDokumen12 halamanPesticidesNachiappan CN100% (2)

- Rail concession certificate for orthopedically handicappedDokumen1 halamanRail concession certificate for orthopedically handicappedTushar AhujaBelum ada peringkat

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Dokumen16 halamanTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Planview Innovation Management Maturity Model PDFDokumen1 halamanPlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaBelum ada peringkat

- Tender Notice and Invitation To TenderDokumen1 halamanTender Notice and Invitation To TenderWina George MuyundaBelum ada peringkat

- Covey - Moral CompassingDokumen5 halamanCovey - Moral CompassingAsimBelum ada peringkat

- Major Bank Performance IndicatorsDokumen35 halamanMajor Bank Performance IndicatorsAshish MehraBelum ada peringkat

- Modul-Document Control Training - Agus F - 12 Juli 2023 Rev1Dokumen34 halamanModul-Document Control Training - Agus F - 12 Juli 2023 Rev1vanesaBelum ada peringkat

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDokumen11 halamanOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanBelum ada peringkat

- Feasibility StudyDokumen47 halamanFeasibility StudyCyril Fragata100% (1)

- Unit 1 - International Banking Meaning: Banking Transactions Crossing National Boundaries Are CalledDokumen6 halamanUnit 1 - International Banking Meaning: Banking Transactions Crossing National Boundaries Are CalledGanesh medisettiBelum ada peringkat

- sl2018 667 PDFDokumen8 halamansl2018 667 PDFGaurav MaithilBelum ada peringkat

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinDokumen36 halamanTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- Individual Sports Prelim ExamDokumen13 halamanIndividual Sports Prelim ExamTommy MarcelinoBelum ada peringkat

- Clean Agent ComparisonDokumen9 halamanClean Agent ComparisonJohn ABelum ada peringkat

- Cisco CMTS Feature GuideDokumen756 halamanCisco CMTS Feature GuideEzequiel Mariano DaoudBelum ada peringkat

- Material Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008Dokumen6 halamanMaterial Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008suckrindjink100% (1)

- Cianura Pentru Un Suras de Rodica OjogDokumen1 halamanCianura Pentru Un Suras de Rodica OjogMaier MariaBelum ada peringkat

- Ks3 Science 2008 Level 5 7 Paper 1Dokumen28 halamanKs3 Science 2008 Level 5 7 Paper 1Saima Usman - 41700/TCHR/MGBBelum ada peringkat

- GIS Arrester PDFDokumen0 halamanGIS Arrester PDFMrC03Belum ada peringkat

- Neuropathology of Epilepsy: Epilepsy-Related Deaths and SUDEPDokumen11 halamanNeuropathology of Epilepsy: Epilepsy-Related Deaths and SUDEPTeuku AvicennaBelum ada peringkat

- Programming Manual Magic 308/616-CLI Quick ReferenceDokumen16 halamanProgramming Manual Magic 308/616-CLI Quick ReferencekrishnamarajublrBelum ada peringkat

- Childrens Ideas Science0Dokumen7 halamanChildrens Ideas Science0Kurtis HarperBelum ada peringkat

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Dokumen4 halamanStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20Belum ada peringkat

- SEMICONDUCTORS AssignmentDokumen8 halamanSEMICONDUCTORS AssignmentMaryam MuneebBelum ada peringkat

- Identifying The TopicDokumen2 halamanIdentifying The TopicrioBelum ada peringkat

- Janome DC6030 Sewing Machine Instruction ManualDokumen56 halamanJanome DC6030 Sewing Machine Instruction ManualiliiexpugnansBelum ada peringkat

- Abinisio GDE HelpDokumen221 halamanAbinisio GDE HelpvenkatesanmuraliBelum ada peringkat

- Learning Stations Lesson PlanDokumen3 halamanLearning Stations Lesson Planapi-310100553Belum ada peringkat

- Microsoft Word 2000 IntroductionDokumen72 halamanMicrosoft Word 2000 IntroductionYsmech SalazarBelum ada peringkat

- Binomial ExpansionDokumen13 halamanBinomial Expansion3616609404eBelum ada peringkat

- Design and Analysis of Crankshaft ComponentsDokumen21 halamanDesign and Analysis of Crankshaft Componentssushant470% (1)