Http://Educareers - Co.cc Http://Educareers - Co.cc

Diunggah oleh

brahimbb19Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Http://Educareers - Co.cc Http://Educareers - Co.cc

Diunggah oleh

brahimbb19Hak Cipta:

Format Tersedia

http://educareers.co.

cc

http://educareers.co.cc

Why the little of tool insert does micro milling easily?

485

While the milling of micro was successfully applied in the biomedical compo

nents of manufacture, the matrices of embossing and the coders microphone,

the rupture of little tool was identified per many users like problem of st

arting.

To Get FREE Information on Top Schools, Colleges and Universities please v

isit http://educareers.co.cc

micro milling, micro machining, tool, microphone, little tool, milling, mac

hining, precision, precision machining, suwa, technology, manufacture, Japa

n, miniature

Micro milling is one of the three techniques microphone communes of cutti

ng used in micro machining.

In micro milling, little of tool with the diameter as small as 0.1mm is hel

d in an axis at high speed revolving to 20.000 to 150.000 t/mn, and used to

mill steel, brass and aluminum with the depth of cutting to approximately

30 microns and rate of entry of 120mm/m with 240mm/m to provide completions

of external quality as good as 0.2 micron.

While the milling of micro was successfully applied in the biomedical compo

nents of manufacture, the matrices of embossing and the coders microphone,

the rupture of little tool was identified per many users like problem of st

arting.

Why the little of tool so much easily insert does micro milling compared to

conventional milling?

There are 3 primary reasons:

Firstly, when metal is removed by machining, there is a substantial increase

in specific energy required like reductions thickness of piece. This means th

http://educareers.co.cc

http://educareers.co.cc

at in the case of micro machining, because the piece becomes meaner with smal

ler depth of cutting, the micro not very of tool prone to a greater resistanc

e will once be compared with conventional machining. It is as if the material

of object becomes harder during micro machining. This force of resistance is

enough strong to exceed the limit of resistance of the inflection of the too

l bitten even before the tool tests any significant use, and leads to the rup

ture of little tool. The one-way to prevent this is to make the thickness of

piece smaller than the ray of edge of little tool.

Secondly, a big rise of the forces of cutting and the effort of the obstructin

g piece during the process of milling micro would make break the little of too

l. In the majority of milling operations microphone using the miniature micro

tool bit with two edges, each edge removes the pieces of the sector of machini

ng only in half of a rotation. However, if to block piece occurs, the forces a

nd the efforts of cutting will increase beyond the limit of resistance of the

inflection of the tool bitten in some rotations of tool, and the little of too

l will break. Some users prefer the little of high-speed cutting steel tool be

cause they are much more flexible and tolerate to block better than the little

of carbide tool.

Thirdly, the little of tool tends to lose its edge due to the edge made up and

cannot machine effectively. Because the object starts to push on the end of lit

tle tool, the little of tool will guide slightly. The increase in the clearance

of tool and the effort produced by milling with each rotation will cause there

after the rupture of little tool. This process is also called the rupture to su

bject to constraint-related wide.

Because of the phenomena above occurring in micro milling, the micro majori

ty of the milling machines are sold with the probes to measure the forces a

cting on the little of tool, and the advanced software of FAO to envisage t

he load of piece in all the process of machining micro. In this way, the ma

nufacturers of precision seeking a place in the milling of microphone could

try to continue their machines to function without jolt with the minimal t

ime of breakdown of machine.

Anda mungkin juga menyukai

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen4 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Washington DDokumen3 halamanWashington Dbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen4 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen4 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen3 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen4 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- Http://Educareers - Co.cc Http://Educareers - Co.ccDokumen2 halamanHttp://Educareers - Co.cc Http://Educareers - Co.ccbrahimbb19Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Piping Material Specification OverviewDokumen308 halamanPiping Material Specification OverviewPinak Projects100% (1)

- Parafusos InglesDokumen58 halamanParafusos InglesheitormartBelum ada peringkat

- Calculation of Thermophysical Properties of Carbon and Low Alloyed Steels For Modeling of Solidification ProcessesDokumen8 halamanCalculation of Thermophysical Properties of Carbon and Low Alloyed Steels For Modeling of Solidification ProcessesFernanda ClainBelum ada peringkat

- Effect of Post Weld Heat Treatment On The Oxide Scaling of Cr-Mo Steel WeldmentsDokumen7 halamanEffect of Post Weld Heat Treatment On The Oxide Scaling of Cr-Mo Steel WeldmentsFebriant SchweinsteigerBelum ada peringkat

- The Effect of Filler ER4043 and ER5356 On Porosity Distribution of Welded AA6061 Aluminum AlloyDokumen6 halamanThe Effect of Filler ER4043 and ER5356 On Porosity Distribution of Welded AA6061 Aluminum AlloydietersimaBelum ada peringkat

- KBR Inspection Test Plan For Shop Fabricated PipingDokumen4 halamanKBR Inspection Test Plan For Shop Fabricated PipingSyafril AkbarBelum ada peringkat

- Complete Guide: How To Order Velan ValvesDokumen12 halamanComplete Guide: How To Order Velan ValvesParthibanBelum ada peringkat

- Jsa JSM E..Dokumen6 halamanJsa JSM E..natchallelyBelum ada peringkat

- Threading Inserts and GradesDokumen3 halamanThreading Inserts and GradeskarthikeyanBelum ada peringkat

- Alligation Sheet 2Dokumen4 halamanAlligation Sheet 2Ranjan RajBelum ada peringkat

- Taha Associates. Surface Grinding WheelsDokumen2 halamanTaha Associates. Surface Grinding WheelsTaha AssociatesBelum ada peringkat

- Turcont Catalogue EnglishDokumen23 halamanTurcont Catalogue EnglishHusain EbrahimBelum ada peringkat

- Product Information Flyer: Cimstar® GPDokumen2 halamanProduct Information Flyer: Cimstar® GPsobheysaidBelum ada peringkat

- Gaussian Pulsed Current Waveform Welding For Aluminum AlloysDokumen8 halamanGaussian Pulsed Current Waveform Welding For Aluminum AlloysmeleileiwangBelum ada peringkat

- 2 67 1587472886 2.ijmperdjun20202Dokumen12 halaman2 67 1587472886 2.ijmperdjun20202TJPRC PublicationsBelum ada peringkat

- Flotation Cell Technology and Circuit Design-An Anglo Platinum PerspectiveDokumen8 halamanFlotation Cell Technology and Circuit Design-An Anglo Platinum PerspectiveriveramaytaBelum ada peringkat

- Corrater Probe Selection GuideDokumen4 halamanCorrater Probe Selection GuideLWYenBelum ada peringkat

- Viii Chapter 14Dokumen6 halamanViii Chapter 14Shubh tiwari TiwariBelum ada peringkat

- TE Connectivity DEUTSCH 983 Series/EN2997 Series Connectors: ApplicationsDokumen20 halamanTE Connectivity DEUTSCH 983 Series/EN2997 Series Connectors: ApplicationsNgân Hàng Ngô Mạnh TiếnBelum ada peringkat

- Consumables Catalogue Eng PDFDokumen658 halamanConsumables Catalogue Eng PDFnrusydBelum ada peringkat

- Welder SyllabusDokumen52 halamanWelder Syllabussantosh0% (1)

- Nickel and Its AlloysDokumen162 halamanNickel and Its AlloysAnonymous TI2bUT100% (1)

- Experimental Investigation of SS 316 by Using TIG-MAG WeldingDokumen3 halamanExperimental Investigation of SS 316 by Using TIG-MAG WeldingKaushik Sengupta100% (1)

- Non-Traditional Machining Processes: A) Primary Manufacturing Processes: B) Secondary Manufacturing ProcessesDokumen36 halamanNon-Traditional Machining Processes: A) Primary Manufacturing Processes: B) Secondary Manufacturing ProcessesGbm RajBelum ada peringkat

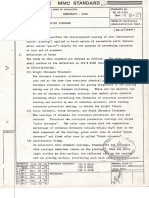

- No.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Dokumen7 halamanNo.29 MMC Standard-Zinc Electroplating Standard. MS82-3701Alejandro Tique100% (1)

- ISO 9001:2008 Certified Capitol Steel Reinforcing Bar Price ListDokumen1 halamanISO 9001:2008 Certified Capitol Steel Reinforcing Bar Price Listeg choloBelum ada peringkat

- WPS and PQR ChecklistDokumen2 halamanWPS and PQR Checklistshabbir626Belum ada peringkat

- Construction Materials and Testing ModuleDokumen66 halamanConstruction Materials and Testing Moduleacurvz2005Belum ada peringkat

- CaseHard BS970-1955EN36ADokumen2 halamanCaseHard BS970-1955EN36AtechzonesBelum ada peringkat

- Plating Specification ListDokumen11 halamanPlating Specification Listsursh60% (5)