White Paper Faulted Phase Earthing

Diunggah oleh

Ahmed EldalyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

White Paper Faulted Phase Earthing

Diunggah oleh

Ahmed EldalyHak Cipta:

Format Tersedia

USE OF FAULTED PHASE EARTHING USING A CUSTOM

BUILT EARTH FAULT CONTROLLER

N. McDonagh*, W. Phang

*MIET, MIEI, ESBI Ireland, neil.mcdonagh@esbi.ie, 00-353-1-7038418

MIET, MIEI, MIEEE, ESBI, Ireland

Keywords: Faulted Phase Earthing, Earth Fault Controller,

Continuity of Supply, High Impedance Fault

Abstract

In order to reduce customer hours lost (CHL) and customer

interruptions (CI), the use of Faulted Phase Earthing (FPE) is

being considered on the Irish 20kV distribution system. The

operation of this particular FPE system is enabled by the use

of a custom built Earth Fault Controller (EFC) that has the

ability to detect high impedance faults of up to 12k. The

EFC can also successfully identify single pole switching

events, which have at times caused the mal-operation of

existing protection. FPE involves the earthing of a faulted

phase during a single line to ground fault. This ensures that

the fault site is made safer and that no customers are

interrupted during the fault.

This paper details the algorithms associated with the EFC and

outlines simulated tests which highlight the EFCs sensitivity

and ability to discriminate between high impedance earth

faults and single pole switching events.

1 Introduction

1.1 Background

In order to reduce customer hours lost (CHL) and customer

interruptions (CI), changes in the method of operation of the

Irish 20kV distribution system are being investigated [1-3].

Two of the methods described in [1] are currently on trial.

The first involves earthing 20kV transformer neutrals via an

automatically tuned Peterson coil. The second is the use of

Faulted Phase Earthing (FPE) through the use of a custom

built Earth Fault Controller (EFC) [2], [3]. The proposed

system will operate as an interchangeable high resistance

earthed/isolated system in conjunction with faulted phase

earthing (FPE), by the use of a custom designed EFC. The

proposed system uses a 300 Neutral Earth Resistor (NER),

which is switched out during sustained faults. This NER is

required to restrict switching over-voltages. During a single

line to ground fault, the faulted phase will be earthed and

transformer neutral will be isolated, as shown in Figures 1

and 2. As the phase to phase voltage is unchanged with the

FPE applied, and load is connected via delta windings the

supply voltage to customers is maintained. The concept for

this controller was initially developed and was patented by

the ESB in 1997 [2] and as described in [3].

Figure 1 20kV system under normal operation

Figure 2 Operation under single line to ground fault

1.2 Existing Methods of Operation

At present operations policy is to earth the 20kV transformer

neutrals via a 20 Neutral Earth Resistor (NER). Sensitive

Earth Fault (SEF) protection on the earthed neutrals is

installed to detect and trip for high resistance earth faults.

This existing system has the ability to detect single line to

ground faults with a resistance of not more than 3k. The

20kV network includes extensive two phase sections resulting

in a high level of capacitive unbalance on the 20kV system.

Single pole switching on a two phase spur may in some cases

lead to mal-operation of protection even though there is no

fault on the system.

1.3 Controller Development

Initial attempts at deployment of the EFC have failed due to

issues surrounding the algorithms used by the EFC; also a

lack of priority around the project until CHL/CI penalties and

incentives were introduced meant that the project remained

dormant. In late 2007 ESB International (Ireland), was

commissioned to reassess the function of the controller, and

significant changes have been made to the methods used

which addresses the limitations of earlier attempts at

implementation. This paper presents the development of

algorithms associated with the EFC, and the testing of these

algorithms. The controller provides a robust method of

detecting earth faults of up to 12k, and can distinguish

between high resistance faults and single pole switching

events. The benefit of this method of system operation is to

maintain supply during a single line to ground fault.

1.4 Existing HIF Detection Methods

With regards to High Impedance Fault (HIF) detection a good

overview of current market solutions and ongoing research is

given in [4], a number of techniques in existence to detect

HIFs are described, such as:

a) Change in third harmonic current on the feeder.

b) Voltage imbalance in negative and zero sequence.

c) Energy algorithms looking at high frequency energy

d) detection of non-synchronous noise

e) Analysis of wave distortion

f) neural networks

g) wavelet transforms

h) Multiple algorithm HIF detectors

i) Comparison of the squares of positive and negative

sequence current

A comprehensive HIF detection algorithms for compensated

and isolated networks is outlined in [5], however these do not

seem to account for single pole switching. A commercial

solution produced by ABB is detailed in [6], uses a multi-

algorithm approach and has detection rates of 80%. None of

above listed methods is completely successful [4], or enables

continuity of supply to customers during single line to ground

faults.

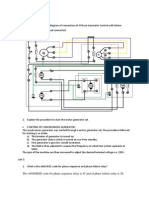

2 Hardware/Software System of The EFC

The controller algorithms are designed using Labview

graphical programming language, which is produced by

National Instruments. All the hardware associated with the

controller is also supplied by National Instruments. The

program was developed on a conventional PC and installed

on a stand alone industrial computer which has real time

capability. An illustration of the system hardware is shown in

Figure 3. All I/O functions are channelled through a signal

processing unit. The EFC performs each of the following:

Measures individual phase currents on three feeders as

well as the neutral current, three phase voltages,

Operates digital outputs to control four switches within

the substation compound on the neural and three phases.

Signals a number of alarms, which identify the nature of

the fault, which are connected to the SCADA system.

Figure 3 System Interface of EFC

A flow chart detailing the function of the controller is shown

in Figure 4, which is accompanied by Tables 1 and 2 detailing

the name of each event and process shown in Figure 4.

Figure 4 Flow chart of EFC

Event Description

0 Start up

1 Scanning Phasors

2 Scanning after 2 seconds

3 FPE cycle

4 Scanning Post FPE cycle

5 FPE lock-out and alarms

6 Wait for trip/low voltage/reset

7 Remove FPE switches

8 Reset/low volt, reset

Table 1 EFC Functions

Process Description

0-1 Start up and initialisation

All-0 Voltage signals lost, EFC disabled

1-2 A 0.5A change in neutral current is detected

2-3 This change is still present after two seconds

3-4 FPE auto reclose cycle

4-5 Sustained fault, reapply FPE

4-1 SLG has cleared or initial event was switching

5-6 Lock out FPE and raise appropriate alarms

6-7 Wait for trip command

7-4 FPE switches reset

6-8 Voltage lost or reset command received

8-1 System is reset and reinitialised

Table 2 EFC Flows

3. Algorithm Development

The EFC detects Single Line to Ground (SLG) faults and

single pole switching events. When a SLG is applied to a

network the voltages and currents of that network will change

accordingly. Changes that occur will include:

Drop in the faulted phase & rise in healthy phase voltages

Increase in current flowing in the faulted phase

Change in Current flowing in the system neutral

It is this change in neutral current that the EFC uses as a

trigger to detect for SLGs or switching events. The controller

continually analyses the voltage and current phasors for each

feeder and the neutral current. Upon a change of 0.5A or

more in the neutral current the EFC carries out calculations,

using the change in zero sequence current, to identify the

possible faulted phase and feeder. If this 0.5A change of

persists for two seconds then an FPE cycle is carried out to

determine the nature of the disturbance (single pole switching

or single line to ground fault). The zero sequence current I

0

is

defined as the phasor average of the three currents flowing in

any line, as illustrated in Equation 1.

Figure 5 shows a simplified illustration of a typical network

in the steady state situation. For the network shown in Figure

5 the zero sequence current is calculated via Equation 2 [7],

this value is determined entirely by the capacitance of the

feeders, leakage resistances, and voltage drops due to loads

flows have been neglected for the purposes of this discussion.

In the case of a network with a single line to ground fault the

zero sequence current may be calculated using Equation 3[7].

0 T S R

I 3 I I I = + +

Equation 1

0 N _ C

T

R N

N

I 3 Y V =

(

=

Equation 2

( )

0 N _ C

T

R N

N F P _ F

I 3 Y V Y V =

(

\

|

+

=

Equation 3

Figure 5

Where:

N

V : Voltage to earth of the R, S or T phase.

P _ F

V : Faulted phase voltage

N _ C

Y : Capacitive admittance of R, S and T

F

Y : Fault admittance

I

0

: Zero sequence current

On the Irish 20kV system there are significant sections of

feeders with only two wires (commonly referred to as single

phase feeders), and single pole switching is allowed. There

are circumstances that may arise where the zero sequence

current, or change of this quantity, as a result of a fault may

be identical to that of a single pole switching event. During a

single line to ground fault, the zero sequence current will

increase closely in phase with the faulted phase voltage. As

shown in Equation 2, the zero sequence current is made up of

the capacitive line currents and the fault current. As this is a

resistance earthed system, the single line to ground fault

current will dominate Equation 2, this means that the change

in zero sequence current will be closely aligned to the faulted

phase voltage (generally within 30

o

). During certain single

pole switching events, the change in zero sequence current

may also be in close phase alignment to one of the phase

voltages. A clear example of this may be seen in Figure 6.

Figure 6

In this example a single pole switch is opened on a two phase

line. As a result of the single pole switching, the capacitance

of the opened sections is connected to the other phase through

the load. Therefore, capacitive current will be dropped by one

phase and picked up by another. In this case an R phase

switch on an RT two phase spur is pulled, resulting in a

change in zero sequence current in phase with the S phase

voltage. There are numerous single pole switching

combinations that may give a similar effect which are

outlined in [2].

Initial attempts [2] at solving this issue were unsuccessful.

Therefore a change was needed to how the EFC identified

single line to ground faults as opposed to switching events.

The EFC now computes the change in currents and voltages

before, during and after the FPE cycle, as opposed to only

analysing the data before and after the initial event as set forth

in [2]. During this analysis the controller specifically looks

zero sequence current to determine if there is an earth fault on

the system. Using this method in conjunction with an

elaboration of Equation 3 yields a set of equations that enable

the EFC to successfully identify earth faults and switching

events. Resolving Equation 3 into both active and reactive

parts yields Equations 4 and 5.

V

S_E

3I

0

V

T_E

I

T+

V

R_E

I

R

-

( ) x I 3 Y y V Y x V

0 N _ C

T

R N

N F P _ F

=

(

\

|

+

=

Equation 4

( ) y I 3 Y x V Y y V

0 N _ C

T

R N

N F P _ F

=

(

\

|

+

=

Equation 5

Applying Equations 3 and 4, both during and after the FPE

cycle, yields four equations which may be combined to form

a non-singular matrix, as shown in Equation 6. As there are

four unknowns that must be solved for the system, as per

Equation 2, the capacitances of each phase and the fault

admittance, and four separate system equations have been

developed and these set of equations can be solved.

Rearranging the Equation 6 as Equation 7 and solving for [Y]

identifies if there is a fault admittance of significance

resulting in the successful identification of single line to

ground faults. If the initial change in zero sequence current is

caused by a single pole switching event the calculated

admittance will be very small or negative. Using this method

single line to ground faults of 12,000 (~1A) and even up to

16,000 (~0.75A) may be detected, identified, and earthed.

This full calculation is displayed clearly in Equation 8, which

corresponds to a calculation for a suspected fault on the R

phase. The development of these equations is discussed

further in [8]

[V]*[Y]=[I] Equation 6

[Y]=[V

-1

]*[I] Equation 7

(

(

(

(

=

(

(

(

(

(

(

(

(

(

(

y _ I 3

x _ I 3

y _ I 3

x _ I 3

Y

Y

Y

Y

x V x V x V y V

y V y V y V x V

x V x V x V y V

y V y V y V x V

E 0

E 0

F 0

F 0

T _ C

S _ C

R _ C

R _ F

E _ T E _ S E _ R E _ R

E _ T E _ S E _ R E _ R

F _ T F _ S F _ R F _ R

F _ T F _ S F _ R F _ R

Equation 8

Where:

F refers to the values when the FPE switches have not been

applied, as per Figure 1.

E refers to values when the FPE has been applied, as per

Figure 2.

Equation 7 makes the following assumptions:

That no significant network changes resulting in a change

in network capacitance take place during the FPE cycle

Voltage drops along feeders due to load flows, resulting in

a change in capacitive current have been neglected.

Leakage resistance of the network is neglected, and will

not have a major impact on calculations. This is due to the

leakage resistance being considerably larger than the

highest fault resistance to be detected by the EFC

3 Simulation and Testing

A software model of the system was created in order to assist

in algorithm development. The results from this model were

used as inputs to verify the function of the controller

algorithms in the developmental stage. Due to the high level

of unbalance and asymmetry on this network, it would not be

acceptable to use conventional program using sequence

components [9], for this reason an Electromagnetic Transient

Program (EMTP) is preferred, and Alternative Transient

Program (ATP) was selected for this purpose.

This model consists of transformers, three phase feeders,

single phase feeders, three phase loads, single phase loads,

NER and FPE switches. A simplified illustration of the ATP

model is shown in Figure 7, which displays the application of

a fault. The actual model has three feeders, but for this

illustration only one feeder is shown in Figure 7. Voltage and

current results were taken from this model to test the

controller. These results were taken upon the application of a

fault; 2 seconds after fault application, during the FPE auto

reclose cycle and after the FPE reclose cycle. The phasor

values were than used to test the algorithm created with

Labview. Numerous faults and switching events were

simulated and the phasor data was used to test the controller.

Figure 7

4 Simulated Results

Results show that the controller is successful in the detection

of single line to ground faults up to 12k and the algorithm

can successfully distinguish single pole switching events. For

the purposes of illustration three events are considered here:

SLG with a fault resistance of 50

SLG with a fault resistance of 10,000

Single pole switching causing a 1A change in neutral

current

Relevant voltages and currents from the software model are

used to populate the matrix shown in Equation 8. The fault

admittance is calculated and inverted to give the calculated

fault resistance. The first two incidents considered the FPE is

applied on the R phase, while in the single pole switching

event the FPE is applied on the S phase, thus changing

Equation 8 accordingly.

Case 1 SLG with a fault resistance of 50

(

(

(

(

=

(

(

(

(

(

(

(

(

(

38 . 7

09 . 7

9 . 0

16 . 32

Y

Y

Y

Y

18775 18585 0 0

10578 10830 0 0

15416 15164 3211 1975

12662 8755 1975 3211

T _ C

S _ C

R _ C

R _ F

From Equation 8 the calculated fault admittance

R _ F

Y is

10.4 mS, therefore the calculated fault resistance is 96, and

an SLG is successfully detected.

Case 2 SLG with a fault resistance of 10,000

(

(

(

(

=

(

(

(

(

(

(

(

(

(

28 . 8

26 . 0

0

93 . 0

Y

Y

Y

Y

18775 18583 0 0

10579 10833 0 0

6532 6270 12156 311

10786 10682 311 12156

T _ C

S _ C

R _ C

R _ F

From Equation 8 the calculated fault admittance

R _ F

Y is

0.1055 mS, therefore the calculated fault resistance is 9.5k,

and an SLG is successfully detected.

These two examples show that this method is capable of

detecting single line to ground faults. For the 50 fault the

calculation of the fault impedance is higher than the actual

fault resistance due to the line impedance as fault is placed

40km from the measurement location, meaning that there is

significant line impendence included in the fault impedance

calculation.

Case 3 Single Pole Switching

(

(

(

(

=

(

(

(

(

(

(

(

(

(

6 . 4

2 . 10

8 . 1

3 . 0

Y

Y

Y

Y

146 0 18310 0

21163 0 10572 0

5939 5892 12207 10030

10954 10030 419 5892

T _ C

S _ C

R _ C

S _ F

From an altered Equation 8 to account for the suspected fault

being on the S phase, the calculated fault admittance

S _ F

Y is

13S, therefore the calculated fault resistance is 75k, this is

distinguished as not being an earth fault, due to the low

admittance. This shows that the algorithm is successful in

identifying switching events which result in a change in

neutral current of greater than 0.5A, as not being a single line

to ground faults.

5 Conclusions

Faulted phase earthing using a custom built earth fault

controller has been successfully implemented. The new

system has the capability to both detect high impedance faults

and maintain supply during single line to ground faults.

Numerous benefits as a result of this work have been

identified such as:

Improved Sensitivity: Existing SEF protection can

identify a fault of about 3,000 (~4A) while the EFC can

identify a High Impedance Faults (HIF) of up to 12,000

(~1A).

Selectivity: Existing SEF protection may mal-operate due

to single pole switching on a long two phase spur. The

controller using FPE can identify this event as not being a

fault

Fault Location: With the existing system, network

technicians may have no indication of the phase or feeder

on which a fault has occurred; The EFC will identify the

faulted feeder and phase thus saving time in fault location.

There are also a number of benefits associated with the

FPE method of operation but not specifically associated

with this work, such as:

Supply Continuity: With the use of FPE on the 20kV

system no customers need be interrupted during a single

line to ground fault, until the fault is found and an

adequate plan is formulated how to remove the fault,

which may involve temporarily switching out customers.

Fault Site Safety: Previous work carried out by Tobin et

al [3] has shown that fault site GPR using the FPE is

generally lower than a similar fault on a system with a

neutral earthed via a Peterson coil.

Future work involving the development of the EFC will

involve further live testing and the creation of algorithms to

detect remote side breaks on the network.

Acknowledgements

The authors would like to show their gratitude to all the asset

management team in ESB Networks with special thanks to

Martin Hand and Hugh Borland, to all in ESB Networks,

Gracedieu, and to the Power System Studies Group at ESBI,

with special thanks to James Dooley and Tony Higgins for

their proof reading of this text, and to all at National

Instruments with a special mention to Seamus Casserly.

References

[1] H.Borland, Influence of fault handling techniques on supply

security IEE Colloquium on Improving Supply Security on 11 kV

Overhead Networks, May 1990

[2] Electricity Supply Board, of Ireland, 1997, Fault Detection

Apparatus and Method of Detecting Faults in An Electrical Distribution

Network, Patent Application Number S970641.

[3] N. Tobin, B. Brady, Managing Earth Faults on Distribution

Networks, Paper Presented to Institution of Engineers of Ireland. (1997)

[4] L. Li, M. Redfern, A review of techniques to detect downed

conductors in overhead distribution systems, Seventh International

Conference on Developments in Power System Protection, 2001, IEE

Conference publication, April 2001

[5] S. Hanninen, Single phase earth faults in high impedance

grounded networks Characteristics, indication and location, VTT

Energy 2001.

[6] R. Das et al, Detected! A vote of confidence of ABBs high

impedance fault detection system. ABB review 3/2007.

[7] M. Lethonan & T. Hakola Neutral Earthing and Power System

Protection

[8] N. McDonagh Faulted Phase Earthing Using a Custom Built

Controller Dissertation as part of MSc, University of Bath, 2009

[9] D. Tziouvaras, EMTP Applications for Power System Protection,

Protection, Automation & Control World, Spring 2008.

Biography

Neil McDonagh, neil.mcdonagh@esbi.ie,

Phone: 00-353-1-7038418.

Born 1981, received a Bachelor of Engineering from University College

Dublin in Mechanical Engineering, 2003, and an MSc with distinction, from

the University of Bath, in Electrical Power Systems, 2009. Mr McDonagh

has worked in the area of power system studies for over 5 years with ESB

International, specialising in: system modelling, earthing of high and medium

voltage substations, lightning protection, and insulation coordination.

Anda mungkin juga menyukai

- Performance Analysis of Closed Loop and Open Loop Control Methods in Dynamic Voltage RestorerDokumen4 halamanPerformance Analysis of Closed Loop and Open Loop Control Methods in Dynamic Voltage RestorerInnovative Research PublicationsBelum ada peringkat

- Frequency RelayDokumen9 halamanFrequency RelayLanya AramBelum ada peringkat

- Fault Tolerant MLIDokumen11 halamanFault Tolerant MLIGp NAYAGRAH ELECTRICALBelum ada peringkat

- RP P9788770229630C11Dokumen10 halamanRP P9788770229630C11srikanth velpulaBelum ada peringkat

- Auto-Adaptive Fault Passage IndicatorDokumen4 halamanAuto-Adaptive Fault Passage IndicatortunghtdBelum ada peringkat

- Types KBCH 120, 130, 140 Differential Protection For Transformers and GeneratorsDokumen20 halamanTypes KBCH 120, 130, 140 Differential Protection For Transformers and Generatorsjjcanoolivares100% (1)

- Der 035Dokumen8 halamanDer 035Sthitaprajnyan SharmaBelum ada peringkat

- A Platform For For Valodation of FACTS ModelsDokumen8 halamanA Platform For For Valodation of FACTS ModelsJorge ZuluagaBelum ada peringkat

- Complex Engineering ProblemDokumen9 halamanComplex Engineering ProblemEmmara ZulfiqarBelum ada peringkat

- The ANSI/IEEE Code For Phase Sequence Relay Is 47 and of Phase Failure Relay Is 58Dokumen9 halamanThe ANSI/IEEE Code For Phase Sequence Relay Is 47 and of Phase Failure Relay Is 58ax33m144Belum ada peringkat

- Ref24 PDFDokumen8 halamanRef24 PDFashwiniBelum ada peringkat

- Overcoming Leakage Current by Output Precharging in Error AmplifiersDokumen4 halamanOvercoming Leakage Current by Output Precharging in Error AmplifiersSudhakar SpartanBelum ada peringkat

- Alstom L3-KBCH-BR-04-05-0910-GBDokumen8 halamanAlstom L3-KBCH-BR-04-05-0910-GBsteve_osullivanBelum ada peringkat

- The Measurement Layer of The Virtual Synchronous Generator Operation in The Field TestDokumen5 halamanThe Measurement Layer of The Virtual Synchronous Generator Operation in The Field TestmartinmunozbaBelum ada peringkat

- Analysis of Ac Transmisson System Using Ipfc For Damping of Low Frequency Oscillations Using Pi ControllerDokumen20 halamanAnalysis of Ac Transmisson System Using Ipfc For Damping of Low Frequency Oscillations Using Pi ControllerPeram AnushaBelum ada peringkat

- ArresterFacts 016 Selecting Arrester MCOV-UcDokumen20 halamanArresterFacts 016 Selecting Arrester MCOV-UcIsra MarajBelum ada peringkat

- White Paper ESBs ADOPTION SMART NEUTRAL TREATMENTS ON ITS 20 KV SYSTEMDokumen4 halamanWhite Paper ESBs ADOPTION SMART NEUTRAL TREATMENTS ON ITS 20 KV SYSTEMkotiniBelum ada peringkat

- Power CEPDokumen5 halamanPower CEPhamzadaud032Belum ada peringkat

- Ungrounded System Fault Section Detection Method by Comparison of Phase Angle of Zero-Sequence CurrentDokumen7 halamanUngrounded System Fault Section Detection Method by Comparison of Phase Angle of Zero-Sequence Currentjobpei2Belum ada peringkat

- Transformer REFDokumen4 halamanTransformer REFs_banerjeeBelum ada peringkat

- A Norton Model of A Distribution Network For Harmonic EvaluationDokumen7 halamanA Norton Model of A Distribution Network For Harmonic Evaluationbubo28Belum ada peringkat

- A Low Cost High Efficiency Inverter For Photovoltaic ApplicationsDokumen6 halamanA Low Cost High Efficiency Inverter For Photovoltaic ApplicationsbpchimeraBelum ada peringkat

- 1 s2.0 S0142061506000755 MainDokumen11 halaman1 s2.0 S0142061506000755 MainLaazou AbderrahimBelum ada peringkat

- Relay Coordination Calculations and Time Current CurvesDokumen7 halamanRelay Coordination Calculations and Time Current CurvesFareh KhanBelum ada peringkat

- Load Flow Studies On SubstationsDokumen40 halamanLoad Flow Studies On Substationsjilanlucky222100% (1)

- SOGI-FLL For Synchronization and Fault Detection in An Inverter Connected To The GridDokumen6 halamanSOGI-FLL For Synchronization and Fault Detection in An Inverter Connected To The GridLivia Faria PeresBelum ada peringkat

- Loss of Mains Detection For Embedded Generation by System Impedance MonitoringDokumen4 halamanLoss of Mains Detection For Embedded Generation by System Impedance Monitoringjaved765Belum ada peringkat

- Voltage Control in Power System Using Expert System Based On SCADA SystemDokumen5 halamanVoltage Control in Power System Using Expert System Based On SCADA SystemFABIANCHO2210100% (1)

- 2001 - Multiloop ControlDokumen9 halaman2001 - Multiloop ControlPradeep Kumar SahuBelum ada peringkat

- A Practical Guide For Detecting Single-Phasing On A Three-Phase Power SystemDokumen55 halamanA Practical Guide For Detecting Single-Phasing On A Three-Phase Power SystemGunadevan ChandrasekaranBelum ada peringkat

- A 50A, 1-S-Rise-Time, Programmable Electronic Load Instrument For Measurement of Microprocessor Power Supply Transient PerformanceDokumen5 halamanA 50A, 1-S-Rise-Time, Programmable Electronic Load Instrument For Measurement of Microprocessor Power Supply Transient PerformanceAnonymous 3mJfZEBelum ada peringkat

- 06714863Dokumen6 halaman06714863Miguel LnBelum ada peringkat

- 2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFDokumen5 halaman2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFreza515heiBelum ada peringkat

- A2 306Dokumen8 halamanA2 306Carlos Lino Rojas AgüeroBelum ada peringkat

- UPFC Control Based On New IP Type Controller: Mojtaba Shirvani, Babak Keyvani, Mostafa Abdollahi and Ahmad MemaripourDokumen8 halamanUPFC Control Based On New IP Type Controller: Mojtaba Shirvani, Babak Keyvani, Mostafa Abdollahi and Ahmad MemaripourMmillion AlemayehuBelum ada peringkat

- Fault Isolation in Distributed Generation ConnectedDokumen24 halamanFault Isolation in Distributed Generation ConnectedQais AlsafasfehBelum ada peringkat

- HVDC VSC 2L BenchmarkDokumen7 halamanHVDC VSC 2L BenchmarkRavi VermaBelum ada peringkat

- 29.a Versatile Control Scheme For A Dynamic Voltage Restorer ForDokumen69 halaman29.a Versatile Control Scheme For A Dynamic Voltage Restorer ForShruthi NayakBelum ada peringkat

- Submitted To: Mr. Sachin AngadiDokumen5 halamanSubmitted To: Mr. Sachin AngadiSachin AngadiBelum ada peringkat

- Line Differential Protection Scheme Modelling (PDF Library)Dokumen6 halamanLine Differential Protection Scheme Modelling (PDF Library)Nirmal RajaBelum ada peringkat

- Design and Analysis of Dynamic Voltage Restorer For Deep Voltage Sag and Harmonic CompensationDokumen14 halamanDesign and Analysis of Dynamic Voltage Restorer For Deep Voltage Sag and Harmonic CompensationJoffie Jacob PulpelBelum ada peringkat

- Live Testing Method DBsDokumen9 halamanLive Testing Method DBsMohamed AshrafBelum ada peringkat

- Implementation and Performance Evaluation of A Fast Dynamic Control Scheme For Capacitor-Supported Interline DVRDokumen14 halamanImplementation and Performance Evaluation of A Fast Dynamic Control Scheme For Capacitor-Supported Interline DVRRamphani NunnaBelum ada peringkat

- AuthorDokumen6 halamanAuthorjeos20132013Belum ada peringkat

- Auto Phase Switching in A 3 Phase SytemDokumen10 halamanAuto Phase Switching in A 3 Phase SytemAnshu HilsaBelum ada peringkat

- Knowledge-Based Algorithms For Security/Economy Control of Distribution Systems C. Chang T.S. Chung Department Electrical Engineering Hong Kong PolytechnicDokumen6 halamanKnowledge-Based Algorithms For Security/Economy Control of Distribution Systems C. Chang T.S. Chung Department Electrical Engineering Hong Kong Polytechnicbluemoon1172Belum ada peringkat

- Digital Simulation of Thyristor Controlled Interphase Power Control Technology (TC-IPC) To Limit The Fault CurrentsDokumen7 halamanDigital Simulation of Thyristor Controlled Interphase Power Control Technology (TC-IPC) To Limit The Fault CurrentstchettoBelum ada peringkat

- CIRED2011 0644 FinalDokumen4 halamanCIRED2011 0644 FinalIsnam JukicBelum ada peringkat

- Anusha Semiar 1Dokumen23 halamanAnusha Semiar 1Peram AnushaBelum ada peringkat

- Transformer Protection Sugg Spec1Dokumen6 halamanTransformer Protection Sugg Spec1Tareq_EELBelum ada peringkat

- Areva KBCH Transformer Diff RelayDokumen451 halamanAreva KBCH Transformer Diff RelaybirjueBelum ada peringkat

- A Fast Current-Based MPPT Technique Employing Sliding Mode ControlDokumen6 halamanA Fast Current-Based MPPT Technique Employing Sliding Mode ControlNguyen Thanh TuanBelum ada peringkat

- Voltage Sag Compensation Using Dynamic Voltage Restorer: Mayank Paliwal, Rohit Chandra Verma and Shaurya RastogiDokumen10 halamanVoltage Sag Compensation Using Dynamic Voltage Restorer: Mayank Paliwal, Rohit Chandra Verma and Shaurya RastogiKumar RajanBelum ada peringkat

- Test Method of End To End Test For Protection Relay and SIPSDokumen14 halamanTest Method of End To End Test For Protection Relay and SIPSzinab90Belum ada peringkat

- Design of Automatic Phase Selector From Any Available Three Phase With The Use of Logic Gate and Relay DriverDokumen18 halamanDesign of Automatic Phase Selector From Any Available Three Phase With The Use of Logic Gate and Relay DriverVivek Kumar SinghBelum ada peringkat

- 2006 Crte IV Curve Measurement PV SecDokumen5 halaman2006 Crte IV Curve Measurement PV Secmoussa1986Belum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsDari EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsBelum ada peringkat

- Gas Fuel 2Dokumen1 halamanGas Fuel 2Ahmed EldalyBelum ada peringkat

- Training List enDokumen3 halamanTraining List enAhmed EldalyBelum ada peringkat

- Gas Fuel 2Dokumen1 halamanGas Fuel 2Ahmed EldalyBelum ada peringkat

- Documents Matching - GeneratorDokumen3 halamanDocuments Matching - GeneratorAhmed EldalyBelum ada peringkat

- Gas Fuel 1Dokumen1 halamanGas Fuel 1Ahmed EldalyBelum ada peringkat

- Gas Fuel 3Dokumen1 halamanGas Fuel 3Ahmed EldalyBelum ada peringkat

- TUGA Performance Test 2 DaysDokumen2 halamanTUGA Performance Test 2 DaysAhmed EldalyBelum ada peringkat

- Humidity Air CalculationDokumen1 halamanHumidity Air CalculationAhmed EldalyBelum ada peringkat

- Humidity Air CalculationDokumen1 halamanHumidity Air CalculationAhmed EldalyBelum ada peringkat

- Humidity Air CalculationDokumen1 halamanHumidity Air CalculationAhmed EldalyBelum ada peringkat

- Gas Engine FundamentalsDokumen13 halamanGas Engine Fundamentalsherdin56Belum ada peringkat

- Sterility in Wheat in Subtropical Asia Part 3 16401Dokumen25 halamanSterility in Wheat in Subtropical Asia Part 3 16401Ahmed EldalyBelum ada peringkat

- Comparison of Different Gas Turbine Inlet Air Cooling MethodsDokumen6 halamanComparison of Different Gas Turbine Inlet Air Cooling Methodsbabis1980Belum ada peringkat

- HumidityDokumen8 halamanHumidityAhmed EldalyBelum ada peringkat

- General Electric CC2D23S DatasheetDokumen4 halamanGeneral Electric CC2D23S DatasheetAhmed EldalyBelum ada peringkat

- Humidity Air CalculationDokumen1 halamanHumidity Air CalculationAhmed EldalyBelum ada peringkat

- Sterility in Wheat in Subtropical Asia Part 3 16401Dokumen25 halamanSterility in Wheat in Subtropical Asia Part 3 16401Ahmed EldalyBelum ada peringkat

- Water Vapor Capacity of AirDokumen3 halamanWater Vapor Capacity of AirAhmed EldalyBelum ada peringkat

- Water Vapor Capacity of AirDokumen3 halamanWater Vapor Capacity of AirAhmed EldalyBelum ada peringkat

- CP3 HumidityDokumen20 halamanCP3 HumidityKhoerul Umam100% (1)

- Psychrometry: H MH MH MH Etc P P P P EtcDokumen9 halamanPsychrometry: H MH MH MH Etc P P P P EtcAhmed EldalyBelum ada peringkat

- Steam TableDokumen6 halamanSteam Tablexian_putraBelum ada peringkat

- App FDokumen3 halamanApp FAhmed EldalyBelum ada peringkat

- SaturationDokumen3 halamanSaturationAhmed EldalyBelum ada peringkat

- Symbols HydraulicsDokumen9 halamanSymbols Hydraulicssanjeevi_008Belum ada peringkat

- BearingDokumen4 halamanBearingapi-261675277Belum ada peringkat

- Universal Motor Starting Relay: Enhanced Series UMSRDokumen1 halamanUniversal Motor Starting Relay: Enhanced Series UMSRAhmed EldalyBelum ada peringkat

- EarthingDokumen5 halamanEarthingKrishna MohanBelum ada peringkat

- EarthingDokumen5 halamanEarthingKrishna MohanBelum ada peringkat

- Konica Minoltamagicolor 5650 5670 Service Manual PDFDokumen370 halamanKonica Minoltamagicolor 5650 5670 Service Manual PDFRadovan JaicBelum ada peringkat

- Datasheet Flatpack2 48V HE Rectifiers (DS - 24111X.105.DS3 - 1 - 2.1)Dokumen2 halamanDatasheet Flatpack2 48V HE Rectifiers (DS - 24111X.105.DS3 - 1 - 2.1)David More CalderonBelum ada peringkat

- A Finite Difference Numerical Analysis of Galvanic Corrosion For Semi-InfiniteDokumen7 halamanA Finite Difference Numerical Analysis of Galvanic Corrosion For Semi-InfiniteThiagoCarvalhoBelum ada peringkat

- Modul 10 Mesin Listrik 1 PDFDokumen13 halamanModul 10 Mesin Listrik 1 PDFaswardiBelum ada peringkat

- Service Manual: Chassis No. GA-7SDokumen29 halamanService Manual: Chassis No. GA-7SErry Kusuma WardanaBelum ada peringkat

- Gs01c50h01-01en 001Dokumen13 halamanGs01c50h01-01en 001Alvaro Quinteros CabreraBelum ada peringkat

- Antenna-Exp - 1 1Dokumen9 halamanAntenna-Exp - 1 1Julian SignoBelum ada peringkat

- Installation Manual Trina SolarDokumen11 halamanInstallation Manual Trina SolarJonathan Alejandro Elgueta NaranjoBelum ada peringkat

- Experiment 5Dokumen3 halamanExperiment 5Farhana LisaBelum ada peringkat

- IB PHYSICS 4.2,4.3,4.4 Google SlidesDokumen126 halamanIB PHYSICS 4.2,4.3,4.4 Google SlidesJustCallMeLarryBelum ada peringkat

- Differential Protection Logic in Siprotec 5Dokumen28 halamanDifferential Protection Logic in Siprotec 5Usman Saeed100% (1)

- MR9270S enDokumen48 halamanMR9270S enJacco TimmermansBelum ada peringkat

- Xerox Phaser+7400+Options+Parts+Service+ManualDokumen1.102 halamanXerox Phaser+7400+Options+Parts+Service+ManualMarshall Holzderber100% (1)

- 6.1. Circuit ManipulationsDokumen11 halaman6.1. Circuit ManipulationsZia AteeqBelum ada peringkat

- Generator ProtectionDokumen30 halamanGenerator ProtectionShahzad Bhatti100% (2)

- S800nf-S800rf-Cat1 - MCCB TerasakiDokumen2 halamanS800nf-S800rf-Cat1 - MCCB Terasakihakiman.irecBelum ada peringkat

- Inexpensive 17-Meter VerticalDokumen10 halamanInexpensive 17-Meter VerticalSwlVUBelum ada peringkat

- Successful Testing Service Performance of FCLDokumen9 halamanSuccessful Testing Service Performance of FCLbpd21Belum ada peringkat

- Kollmorgen KBM Series 2011 CatalogDokumen80 halamanKollmorgen KBM Series 2011 CatalogElectromateBelum ada peringkat

- Project - Water Level Alarm Using 555 TimerDokumen16 halamanProject - Water Level Alarm Using 555 TimerAnuragBelum ada peringkat

- Compufire20100 Hd-1m Dual FireDokumen4 halamanCompufire20100 Hd-1m Dual Fire12dan11Belum ada peringkat

- Bhel RSC VaranasiDokumen29 halamanBhel RSC Varanasishobhan1984Belum ada peringkat

- Motorola1981-82OptoelectronicDataBook Text PDFDokumen287 halamanMotorola1981-82OptoelectronicDataBook Text PDFFLAVIOBelum ada peringkat

- Induction Motors Stiff ShaftDokumen2 halamanInduction Motors Stiff ShaftJuan Jose AraqueBelum ada peringkat

- Manual - CRATE, BassAmp PDFDokumen8 halamanManual - CRATE, BassAmp PDFwiseeapBelum ada peringkat

- Practical Electronics 1978 01 DrumsDokumen6 halamanPractical Electronics 1978 01 DrumsDATrevinoBelum ada peringkat

- EASSDokumen64 halamanEASSWaqas AhmedBelum ada peringkat

- SLS 40 ELE CAL 002 Cable Sizing CalculationDokumen10 halamanSLS 40 ELE CAL 002 Cable Sizing Calculationmringkel50% (2)

- Hemoweld-T: Service ManualDokumen28 halamanHemoweld-T: Service ManualCarlos Ubaldo100% (3)