3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1

Diunggah oleh

Pradeep Kumar MaraptlaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1

Diunggah oleh

Pradeep Kumar MaraptlaHak Cipta:

Format Tersedia

PROJECT / CONTRACT REF.

: 3281 / GC 12108800 CONTRACT TITLE: -

EPIC FOR REPAIR OF SERVICE BERTH NO.4, BUND FOR RECLAMATION AREA AT WAKRA DOCK RLC PORT AND NEW BERTH FOR MARPOL RECEPTION FACILITIES AT RAS LAFFAN

DOCUMENT TITLE :

METHOD STATEMENT FOR CABLE INSTALLATION.

CONTRACTOR

SUB CONTRACTOR

23 MARCH14 DATE

0 REV. NO.

ISSUED FOR REVIEW / COMMENTS

MKR

SV

CHECKED BY

SR

REASON FOR REVISION

PREP

CHKD NEC

APPD. Q.P.

DOCUMENT NO.

3281

RP124

19

0001

SHT

01

OF REV

16

0

3281-RP124-2-19-0001

Rev0

Page 1 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

Table of Contents 1

Page

INTRODUCTION.......................................................................................................... 03

1.1 BACK GROUND........................................................................................................................ 03 1.2 PROJECT OBJECTIVES.............................................................................................................. 03 2 3 4 BRIEF SCOPE OF WORK- ELECTROMECHANICAL..................................................................... 04 DOCUMENT CONTROL............................................................................................................. 04 HEALTH, SAFETY AND ENVIRONMENTAL................................................................................ 05 05

4.1 HEALTH AND SAFETY HAZARDS..............................................................................................

4.2 ADVERSE ENVIRONMENTAL IMPACTS.................................................................................... 05 5 6 CABLING WORK SCOPE............................................................................................................. 05 RESOURCES............................................................................................................................. 06

6.1 EQUIPMENT............................................................................................................................ 06 6.2 PERSONNEL (SITE TEAM)........................................................................................................ 06 7 8 9 METHODOLOGY........................................................................................................................ 07 ANNEXURE 1... ..................................................................................................................... 10 ANNEXURE 2. ....................................................................................................................... 14

10 REFERENCE ............................................................................................................................. 16

3281-RP124-2-19-0001

Rev0

Page 2 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

1.

INTRODUCTION

1.1 Background

Part 1 - Repair to Service Berth no. 4

Service Berth No. 4 was constructed as part of seven service berths in 2000-2001. Four of these berths have developed cracking of mass concrete blocks in the quay wall structure attributed to Delayed Ettringite Formation (DEF). Three of the most severely affected berths were replaced in 2010-2011 with more stringent specification to avoid DEF. The fourth berth, Berth No. 4 was put under monitoring at that time. In light of an increase in the number of cracked blocks in the most recent observation and in line with the earlier service berths repair and replacement work, repairs to this existing Service Berth No.4, has been initiated.

Part 2 - New Berth for MARPOL Reception Facilities

i) MARPOL 73/78 is a marine pollution control convention under International Maritime Organisation (IMO) that ensures that the signatories shall provide reception facilities for ship generated wastes. State of Qatar has ratified MARPOL 73/78 all annexes. For the partial fulfilment of the obligations under the MARPOL Convention, a berth with basic provisions to receive ship generated waste is to be constructed. The facilities and plant to receive, treat and dispose the effluents will be executed separately under a different contract. A barge will collect the slops and liquid waste from ships at other locations and deliver the waste cargo, which will be received at this berth. To utilise the new berth to the maximum, the importation of stone aggregates through this berth is under consideration.

ii)

iii)

iv)

1.2 Project Objectives

The Project objectives are: 1) To repair Service Berth No.4, which has cracks in the mass concrete blocks making up the quay wall and to construct a bund to demarcate the disposal area at Wakra Dock to contain the dumped material within the bunded area? 2) To construct new berth for MARPOL reception facilities.

3281-RP124-2-19-0001

Rev0

Page 3 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

2.

BRIEF SCOPE OF WORK - ELECTROMECHANICAL Part 1 - Repair to Service Berth no. 4

UNITECHs scope includes EPC for the process, mechanical & piping, electrical, instrumentation, safety and environmental design of the following systems: a) Utilities Diesel, Potable Water and Fire Water b) Lighting, Earthing and Lightning Protection

Part 2 - New Berth for MARPOL Reception Facilities

UNITECHs scope includes EPC for the electrical and environmental design of the following systems: a) Lighting, Earthing and Lightning protection b) Traffic Control

3.

DOCUMENT CONTROL

This method statement is a controlled document as required by the system procedure Quality Planning and issued in accordance with the system procedure Control of Documents and Data. The method statement is subject to amendment during the execution of the Works as a result of periodic review and whenever circumstances require. Revisions will be issued in accordance with the system procedure Control of Documents and Data whenever the main text changes or when an appendix is added or removed. Revised appendices for substitution will be issued separately and, where appropriate, will include a separate schedule of contents.

4.

HEALTH , SAFETY AND ENVIRONMENTAL 4.1 Health and Safety Hazards

As required by the Project Health & Safety Plan, the significant health and safety hazards of this work have been analyzed and are listed below: Electrical hazards Falling, slips, trips. Weather condition. Damage to body parts Ergonomic hazards

Control for the above will be implemented to minimize these hazards as set out in the form of Risk Assessment included in Annexure-1 which is enclosed with this document.

3281-RP124-2-19-0001

Rev0

Page 4 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

4.2 Adverse Environmental impacts.

As required by the Project Environmental Plan (CEMP Plan), the significant adverse environmental impacts of this work have been analyzed and control will be implemented to minimize these adverse effects as set out in the form of Environmental Impact Statement included in Annexure-2 which is enclosed with this document.

5.

CABLE INSTALLATION WORK SCOPE

UNITECH shall carry out listed above works, in order to: a) Power up all the newly installed facilities in the project. b) Tap up the power safely from existing power feeder in substation/feeder.

6.

RESOURCES 6.1 Equipment

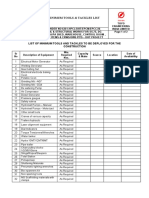

The following equipment will be used Equipment Crane Winch Slings D Shackles Safety Cones (Traffic cones) Pick-Up Cable drum jack Meggers Gas torch Crimpers Hydraulic Knockout punch Hydraulic Crimper Hydraulic hammer Drill machine Heat Gun Cabling & termination tool box. Spindle & Cable drum Jack Nos 1 No. 1 No. A set, as required A set, as required A set, as required 1 No. 2 No. 2 No. 2 No. 2 set. 1 No. 2 No. 1 No. 2 No. 2 No. 4 No. 2 set.

3281-RP124-2-19-0001

Rev0

Page 5 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

6.2 Personnel (Site Team) The following personnel will be involved for the site execution work. Sr. No. 1 2 3 4 5 6 7 Designation Construction Manager E&I Engineer Safety Officer Electrician Rigger Helpers Fitter Nos 1 No. 1 No. 1 No. 6 No. 2 Nos 12 Nos 2 Nos

7. METHODOLOGY A. DESCRIPTION OF WORK METHOD A.1: Pre-Installation Checks for cable laying All necessary permits and personnel presence from contractor side & client side (if applicable) should be ensured for clearance before commencement of the cable pulling activity. The entire route shall be inspected to ensure that the routing is complete, proper bends are used and free from any sharp edges. Ensure that last revision drawings are used. Location of the panels / equipments shall be identified. Termination point inside the panels / equipment shall be considered for suitable spare length to be left available during pulling of cable termination. The maximum length shall be equal to depth + height + width of panels. Personnel involved in cable pulling will at all times have safety harness fixed firmly to overhead support. Before start of pulling Cable, the actual route length shall be measured and checked for adequate length of cable. Confirm that all Tools & Tackles required for installation are available. As a minimum the following shall be made. Check adequate place for unloading the cable drums. Check suitable position for placing the Cable pulling winch depending on the length of the cable and the site condition. Personnel involved in the activity are made aware of the risks and the steps to be taken to mitigate any hazard or unsafe situation.

A.2:Pre-Installation Checks for Termination All necessary Permits from QP to be received for working in panels. Exiting system should not be disturbed while working in panel. Ensure that last revision drawings are used. Location of the panels / equipments shall be identified.

3281-RP124-2-19-0001

Rev0

Page 6 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

Termination point inside the panels / equipment shall be considered for suitable spare length to be left available during pulling of cable termination. The maximum length shall be equal to depth + height + width of panels Personnel involved in cable termination will at all times have safety harness Before start of termination checked for adequate length of cable. Ensure sufficient quantities of Cable Tags are readily available. Ferrule and core marking should be done. Personnel involved in the activity are made aware of the risks and the steps to be taken to mitigate any hazard or unsafe situation.

B.

Material withdrawn from warehouse Material inspection will be carried out to ascertain that no damage has occurred to the cables. In case of any damages common inspection and report will be issued. Cable shall be tested on cable drums prior to removal and work site with insulation tester. The values will be noted for Core to Core and Armor. After the test, the end of the cable shall be sealed to prevent the ingress of moisture. Store material requisition shall be made. The material shall be transported in their original packing to location. The cable drums shall be off-loaded at the site location. It shall be ensured that there is no obstruction to movement of vehicles or any hindrance to works of other companies.

C.

Description of sequence

1. In Trench Cable Pulling

All the permits for opening the trench to be received. Crane/forklift for opening the trench should be stand and movement to be plan prior to the lifting in such a way the make an ease to move the lifted block without fouling own movement. Cables shall be laid mainly in trench cable trays perforated and ladder type. Cable rollers shall be placed at every 6-12 meters or less if required to avoid touching of the cable to tray. Cable winch, if used, shall be positioned in proper place for cable pulling. The cable drum intended for cable pulling shall be identified as per that indicated in the drum schedule. The cable drums shall be unpacked. The cable shall be fixed in the winch by means of a cable sock or gripper. Required number of persons will be posted at the winch, if used, and near the drum. Cable laying will generally start from one end of the route length from other suitable point if required. Depending on the weight and size of the drum, suitable size of the cable rolling shaft (Spindle) shall be placed inside the central axis of the drum. Suitable jacks shall be placed firm ground and jacked-up to allow clearance from the ground depending on the size of the cable drum. The drum shall be lifted by required equipment and placed on the jacks. The cable drum will be correctly positioned and the direction of cable pulling as indicated by arrow on the drum shall be complied.. Cables will be laid / pulled by hand and / or winch.

Rev0 Page 7 of 16

3281-RP124-2-19-0001

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

Cable laying in tray maximum portion of laying will be done manually to avoid the cable damage from tray sharp edges. Cables will be pulled according to drum-cable cutting schedule and as shown in the relevant drawings. Bending radius of cables shall comply to cable manufacturers recommendation. Unless the lengths exceed the maximum drum lengths joints shall be avoided. Before cutting the cable, both ends must be inspected to ensure sufficient length is for proper dressing and end termination. The open ends will be sealed till termination. Soon after completion of every cable the cables will be tested for insulation resistance. Cable tags shall be installed as per Client Specification The cable schedule and drum schedule will be updated with the information on cable pulling. Daily progress report will be submitted for the activity. After completion of all cables in the same route the cables shall be dressed and clamped. Cables shall be fixed in horizontal or vertical runs with or plastic type straps. Interval of clamping will be as per Client Specification but will not exceed 10Mtr for the horizontal runs and 1.0Mtr for vertical runs. Inspection of the installation and punch list. As-Built mark-up drawings certified by Contractors Supervisor and Engineer will be prepared. Empty cable drums will be transported back to stores.

2.

TERMINATION & GLANDING

Updated drawing and cable schedule to be checked Check the terminal detail, panel detail & tag. As per the termination schedule start termination. As per the cable size, respective cable gland hole to be fabricate in gland plate and gland to be installed. Ensure all joints and terminations and glanding are made by appropriately qualified Person. Cut all cable ends immediately prior to terminating. Seal cables left unconnected for more than 24 hours to prevent the ingress of moisture. Armored cable will be strapped properly, a hacksaw is used to cut the cables, a suitable angle to the cable for making a cut through one section of the spiral amour and care will be taken not to cut the wires. The glands for various single core and multi core cables will be on the purposed made and suitable for rigid mounting to the enclosure. All glands shall be of weatherproof and water tight type as per QP specification. Ensure cable glands complete with earth tag, shroud, locknut, seal etc. Earthling tags shall be fitted to each gland, on assembly. Where cable sheaths are used as earth continuity conductors, glands shall have the necessary contact surfaces or straps to provide a low resistance path under fault conditions. Strip cables to bring out the cores and expose conductors, for the minimum length required for connection, to leave no exposed length of conductor after termination. Ensure that strands are not damaged when stripping cable cores. Twist strands together. Do not reduce number of strands. Secure all strands at terminations. Clean arm our thoroughly prior to terminating. At connections to equipment and switchgear, use compression type lugs for bolted terminal connections. All cable connections shall be made with approved cable lugs, compression type together with the usage of proprietary tools. Cable terminals will be suitable for the specified cable sizes. Adequate space will be provided for cable terminations.

Rev0 Page 8 of 16

3281-RP124-2-19-0001

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

Continuity tests of all cables before finally making off ends and connecting up. Mark cable conductor phasing, or other core identification, at each end of all cables. The neutral cable is connected to the neutral strip, which is turning in grounded with a bare wire. Do not bunch more than three cores at clamping terminals or bolted connections. Dressing of cables will be done by using ferrules, sizes suitable for accommodating all stands of the cables. For instrument cable termination SP, 2 pair & 3 pair, pin type or flat type lug will be used Lug will be crimp by hand crimper. Termination as per the JB termination schedule will be done. All the instrument pair will be ferruled before termination as per the schedule.

3281-RP124-2-19-0001

Rev0

Page 9 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

ANNEXURE-1 HAZARDS, CONSEQUENCES / IMPACT, RISK ASSESSMENT & CONTROL MEASURES

3281-RP124-2-19-0001

Rev0

Page 10 of 16

EPIC FOR REPAIR TO SERVICE BERTH NO. 4, BUND FOR RECLAMATION AREA AT WAKARA DOCK RLC PORT AND NEW BERTH FOR MARPOL RECEPTION FACILITIES AT RAS LAFFAN GC12108800

JOB SAFETY ANALYSIS

Task Name:Electrical work Excavation,Sand Bedding,Cable Laying,BackFilling & Compaction

Team Composition: Construction Manager, Site Engineer and Supervisor, Safety Officer

Date: 29.03.2014

Step No.

Description of Task Step/Activity

HAZARD - potential incident

Who or what might be harmed

Control measures/ Recovery measures

Action/ Responsible party

1.

Work permit from Client to be obtained.

Unauthorized commencement of works may result in exposing workers and or potential to harm or danger

working crew and equipment

Authorized PTW holder shall ensure obtaining and maintaining valid work permit. The worksite supervisor responsible for this activity has to check the PPE of his staff to ensure that all Construction Manager, required items are available and properly used. Site Engineer and M Inform all workers regarding permit condition before Supervisor, Safety Officer work starts. Worksite supervisor shall conduct toolbox talks about nature of works and associated potential hazards and their essential precautionary measure. Ensure that the pre task briefing is given out in a language understood by the work force, have it translated. Ask question regarding the briefing to get feedback from the staff, this ensures full comprehension. M Issue required appropriate PPE and replace PPE that has signs of defect. PPE must include both hearing protection as well as dust inhalation protection.

2.

Pre-task briefing toolbox talks.

The work force does not understand the pre task briefing therefore does not understand the potential dangers and control working crew and equipment measures to be implemented. Some of the workers could be lacking PPE or using defective PPE.

Construction Manager, Site Engineer and Supervisor, Safety Officer

3.

Transportation of materials to site.

Traffic Accidents, Fatality, Serious personnel injury, Property damage, Damage to the truck or third party if involved in an accident, Driving working crew and equipment against the road traffic rules, Unsecured materials on the truck, Overloading of truck.

Before transporting the loads to the site, rest assure that the materials are secured and tight with nylon rope for the safe transporting. Ensure that a driver is having knowledge to the hazard Construction Manager, Site Engineer and M while transporting the materials. The driver shall not have driving attitude while using Supervisor, Safety Officer the road. Driver is driving only in the minimum speed limit. Isolate the work zone. Construction Manager, Site Keep barricading and post signage. M Inspect site and clear area of any obstructing material Engineer and Supervisor, Safety Officer or debris. Ensure that the access and egress are clear from any material and people are free to access and safe to any risk. M Ensure proper housekeeping to the working area and free of any objects or materials from construction activities.

4.

Preparation of working area

Slips, trips and falls to the workers working in the vicinity.

working crew and equipment

5.

Material scattered to access and Providing proper access before egress of work area that causing starting the works slips, trips and falls for the person passing through to the area.

working crew and equipment

Construction Manager, Site Engineer and Supervisor, Safety Officer

3281-RP124-2-19-0001

Rev0

Page 11 of 16

EPIC FOR REPAIR TO SERVICE BERTH NO. 4, BUND FOR RECLAMATION AREA AT WAKARA DOCK RLC PORT AND NEW BERTH FOR MARPOL RECEPTION FACILITIES AT RAS LAFFAN GC12108800

JOB SAFETY ANALYSIS

Task Name: Electrical work Excavation,Sand Bedding,Cable Laying,BackFilling & Compaction Step No. Description of Task Step/Activity HAZARD - potential incident

Team Composition: Construction Manager, Site Engineer and Supervisor, Safety Officer

Date: 29.03.2014

Who or what might be harmed

Control measures/ Recovery measures

Action/ Responsible party

6.

Pre works activity

Location of underground / above ground services (such pipeline, cables etc.) Non compliance of QPExcavation Procedure-Ras-laffan Fields and QP HSE Regulations for Contractors.

working crew and equipment

Locate underground / above ground services referring to the site maps / drawings. Endorsement of excavation notification from the concerned teams for the services in the area being excavates. Ensure that department representative have conducting underground locator to identify the underground Construction Manager, utilities. Site Engineer and M Ensure to clearly mark at the drawing the possible Supervisor, Safety Officer underground utilities. Hold pre-job safety meeting. Ensure prior to start the activity, the excavation certificate has done and completely signed by every QP department authority. Ensure the work permits are signed by the HSE department prior to work. Avoid improper positioning during excavation works. Avoid manual lifting of heavy debris materials If manual handling is unavoidable, ensure operatives involved are train in basic lifting techniques. Selection maybe required of suitable, fit individuals depending upon the nature of the task. Ensure workers are wearing dust mask to protect from dust inhalation that cause respiratory infection Use hand protection to avoid blistering and any other hand injury Construction Manager, Site Proper positioning required M Ensure that workers are wearing appropriate eye Engineer and Supervisor, Safety Officer protection to avoid dust particles that can cause eye irritation. Proper arrangements regards weather condition. Proper shoring, benching, sloping must apply to any kind of excavation to avoid trench collapse. Include in the toolbox talk regarding emergency procedure in case of gas leak

7.

Excavation Of Route Marker And Rectification Of Route Marker Position

Back Pain Dust inhalation Hand blistering Ergonomics Eye injury Cave-in

working crew and equipment

3281-RP124-2-19-0001

Rev0

Page 12 of 16

EPIC FOR REPAIR TO SERVICE BERTH NO. 4, BUND FOR RECLAMATION AREA AT WAKARA DOCK RLC PORT AND NEW BERTH FOR MARPOL RECEPTION FACILITIES AT RAS LAFFAN GC12108800

JOB SAFETY ANALYSIS

Task Name: Electrical work Excavation,Sand Bedding,Cable Laying,BackFilling & Compaction

Team Composition: Construction Manager, Site Engineer and Supervisor, Safety Officer

Regular housekeeping at site shall be performed Adequate and correct stacking of materials Regular inspection and immediate corrective action. Keep always clear of obstruction. Regular clearing of work site shall be implemented Waste bins with cover shall be provided for oily rags Flammable materials shall be stored separately away from possible ignition source Minimal inventory to be stored at work area Appropriate fire extinguisher shall be provided when necessary Keep 9kg dry powder fire extinguisher to the area during the excavation activities Daily housekeeping shall be done, Closed bins for foods waste. Regular housekeeping at site shall be performed Adequate and correct stacking of materials Regular inspection and immediate corrective action. Keep always clear of obstruction. Regular clearing of work site shall be implemented Waste bins with cover shall be provided for oily rags Flammable materials shall be stored separately away from possible ignition source Minimal inventory to be stored at work area Appropriate fire extinguisher shall be provided when necessary Keep 9kg dry powder fire extinguisher to the area during the excavation activities Daily housekeeping shall be done, Closed bins for foods waste. Valentine Onyeakazi HSE Manager Approved by NEC

Date: 29.03.2014

8.

Housekeeping

Debris causing Slips, trips and falls Fire risk due to presence of combustible materials / debris Infestation of rodents leading to working crew and equipment equipment & materials damage (Cables, cords, documents, etc.)

Construction Manager, Site Engineer and Supervisor, Safety Officer

Electrical Manager Date Prepared by

Valentine Onyeakazi HSE Manager Reviewed by NEC

3281-RP124-2-19-0001

Rev0

Page 13 of 16

METHOD STATEMENT FOR POWER CONTROL & INSTRUMENT CABLE INSTALLATION

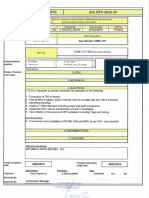

ANNEXURE-2 ENVIRONMENTAL ASPECT AND IMPACT RISK ASSESSMENT (RISK REGISTER)

3281-RP124-2-19-0001

Rev0

Page 14 of 16

ENVIRONMENTAL IMPACT CEMP PLAN

WORK ACTIVITY: _________________________________________________________________________________________________________________ SITE SUPERVISOR:__________________________

No Environmental impact Contents Contaminated waste due to tyrex suites, rollers brushes, filter masks, paint stirrers, drop cloth, masking tape, plastic bag, waste paints and solvent, cements waste etc.

JOB LOCATION:___________________________

Who/ What Might Be Harmed Human

PERMIT NO. :_________________________

Responsible/ Action By Site supervisor and Site Safety Officer.

Control / Recovery Measures Waste deduction program, Waste reprocessing program, Waste disposal program Waste deduction program, Vehicle inspection and maintenances Transportation program. Excavation program Vehicle inspection and maintenance Power tools inspection and maintenance Heavy machine inspection and maintenance program

1.

Earth pollution

Air Pollution

Chemical waste, transport waste, Dust dirt during excavation

Human

Site supervisor and Site Safety Officer.

Noise pollution

Transportation Power tools Heavy machine

Human

Site Supervisor and Safety Officer

Water pollution

waste due to tyrex suites, rollers brushes, filter masks, paint stirrers, drop cloth, masking tape, plastic bag, waste paints and solvent, cements waste etc.

Human

Waste deduction program, Waste reprocessing program, Waste disposal program

Site Supervisor and Safety Officer

3281-RP124-2-19-0001

Rev0

Page 15 of 16

METHOD STATEMENT FOR CABLE INSTALLATION.

Reference: 1. 2. 3. 4. 3281-RP124-2-66-0001 3281-RP124-2-64-0001 3281-RP124-2-63-0001 3281-MS-ELE-0005

3281-RP124-2-19-0001

Rev0

Page 16 of 16

Anda mungkin juga menyukai

- Distribution Conductor StringingDokumen21 halamanDistribution Conductor Stringingmadhava_srinivasan174Belum ada peringkat

- Tata Steel Iron Ore Tailing Dams Safety DisclosureDokumen103 halamanTata Steel Iron Ore Tailing Dams Safety DisclosureSappidi Manoj KumarBelum ada peringkat

- Stringing EquipmentDokumen90 halamanStringing EquipmentMuhammad Vicky100% (1)

- DNV StandardDokumen2 halamanDNV Standardbabu0% (1)

- Quality Assurance For Manufacturers of Hazardous Area Equipment (QAN & QAR) - Business Assurance - DNV GLDokumen4 halamanQuality Assurance For Manufacturers of Hazardous Area Equipment (QAN & QAR) - Business Assurance - DNV GLWaleed AlzoudBelum ada peringkat

- Tps OHLDokumen88 halamanTps OHLNaseem AhmedBelum ada peringkat

- DNV GL Standard2-22Dokumen1 halamanDNV GL Standard2-22Sinoj V AntonyBelum ada peringkat

- CICA & CANZ Guidance Note Crane Stability and Ground PressureDokumen23 halamanCICA & CANZ Guidance Note Crane Stability and Ground PressureAchmad ChusnadiBelum ada peringkat

- Anti Climb DevicesDokumen8 halamanAnti Climb DevicesBijaya Kumar MohantyBelum ada peringkat

- Training ReportDokumen11 halamanTraining ReportUdit MittalBelum ada peringkat

- HEMM Dumper24Dokumen15 halamanHEMM Dumper24miningnova2Belum ada peringkat

- Tower Crane Slew Brakes SalmanDokumen2 halamanTower Crane Slew Brakes SalmanAbbas RoziminBelum ada peringkat

- Safety and Maintenance of Haual RoadDokumen42 halamanSafety and Maintenance of Haual RoadajaykumarprasadBelum ada peringkat

- Installation - A - EarthmatDokumen11 halamanInstallation - A - Earthmatpdky yadavBelum ada peringkat

- Model K580: ResistiveDokumen2 halamanModel K580: Resistivegsantosh06Belum ada peringkat

- Changes in Coal Mine RegulationsDokumen56 halamanChanges in Coal Mine RegulationsSunil0% (1)

- Ractical Training Seminar: Balveer Singh 132 KV G.S.S. Ultratech Cement LTDDokumen14 halamanRactical Training Seminar: Balveer Singh 132 KV G.S.S. Ultratech Cement LTDAnupriya PandeyBelum ada peringkat

- 10 Yrs Mine FatalityDokumen20 halaman10 Yrs Mine FatalityChiranjib BanerjeeBelum ada peringkat

- Mobile Crane Operator Candidate Handbook - 120122aDokumen33 halamanMobile Crane Operator Candidate Handbook - 120122a전우영Belum ada peringkat

- Accident Inquiry GuidelinesDokumen71 halamanAccident Inquiry GuidelinesSoami Saran BhatnagarBelum ada peringkat

- Shinu Sam Resume-3Dokumen1 halamanShinu Sam Resume-3Junaid Mundoden PannipparaBelum ada peringkat

- Petrofac Limited Hsseia StandardDokumen15 halamanPetrofac Limited Hsseia Standardrodman823Belum ada peringkat

- Lock Out Tag OutDokumen7 halamanLock Out Tag Outharry mulyafitBelum ada peringkat

- 2.LOAD CHART AT-22 T133750C (Color) PDFDokumen21 halaman2.LOAD CHART AT-22 T133750C (Color) PDFRoy Ferdy MassoloBelum ada peringkat

- Red & Orange Stripe Master ListDokumen2 halamanRed & Orange Stripe Master ListShahid RazaBelum ada peringkat

- 11-2.1.01 Safety Policy, Roles & ResponcibilitiesDokumen22 halaman11-2.1.01 Safety Policy, Roles & ResponcibilitiesFrancisco M. RamosBelum ada peringkat

- Tips For Heavy Lifting AND Rigging Engineering: Inspection: 1Dokumen25 halamanTips For Heavy Lifting AND Rigging Engineering: Inspection: 1pablodugalBelum ada peringkat

- Standard Operating Procedure For HSDDokumen3 halamanStandard Operating Procedure For HSDisjglfdskBelum ada peringkat

- Strong Dual Hawk Tandem Rev H 2008Dokumen70 halamanStrong Dual Hawk Tandem Rev H 2008FaderBelum ada peringkat

- Crane Lift Work PlatformDokumen13 halamanCrane Lift Work PlatformsheqarayzanBelum ada peringkat

- ER-MO - 02 Preparing and Installing Components1Dokumen17 halamanER-MO - 02 Preparing and Installing Components1Alex IgnatBelum ada peringkat

- DC Cable LayingDokumen8 halamanDC Cable LayingAhamed UmarBelum ada peringkat

- DNV GL Certification of Wave Energy ConverterDokumen26 halamanDNV GL Certification of Wave Energy ConverterSupasart ChanindhapongsathonBelum ada peringkat

- Osha Guidance On Safe Sling UseDokumen6 halamanOsha Guidance On Safe Sling UsePerwez21Belum ada peringkat

- Wire Rope Slings PDFDokumen9 halamanWire Rope Slings PDFmpcd07Belum ada peringkat

- ErectionDokumen20 halamanErectionpulilathaBelum ada peringkat

- JSA PRE-TEST UploadDokumen2 halamanJSA PRE-TEST UploadDenny Kurniawan PrawiraBelum ada peringkat

- 012 Piling WorkDokumen17 halaman012 Piling WorkSarah HaiderBelum ada peringkat

- Dump TruckDokumen4 halamanDump TruckHugo RodriguezBelum ada peringkat

- JAPL-F-HE-007-Concrete Pump ChecklistDokumen1 halamanJAPL-F-HE-007-Concrete Pump ChecklistAli HassanBelum ada peringkat

- HEMP-005 Excavation Manual & Mechanical Rev.2Dokumen9 halamanHEMP-005 Excavation Manual & Mechanical Rev.2saravana.bBelum ada peringkat

- Infrastructure Maintenance Vehicle Specific Interface RequirementsDokumen42 halamanInfrastructure Maintenance Vehicle Specific Interface RequirementsIon Logofătu AlbertBelum ada peringkat

- Automatic Fire Detection and Suppression SystemDokumen2 halamanAutomatic Fire Detection and Suppression SystemProdip SarkarBelum ada peringkat

- Pre Installationfor Opgw 48 FDokumen5 halamanPre Installationfor Opgw 48 FMayank PorwalBelum ada peringkat

- Water Tanker 1Dokumen1 halamanWater Tanker 1Arjun SatheesanBelum ada peringkat

- Diesel Generator Inspection Procedure PDFDokumen6 halamanDiesel Generator Inspection Procedure PDFSelva GanapathiBelum ada peringkat

- Closed Vs Open Loop SafetyDokumen5 halamanClosed Vs Open Loop SafetyRyanBelum ada peringkat

- Pipeline Leak Detection SystemDokumen9 halamanPipeline Leak Detection SystemMohamad PizulBelum ada peringkat

- Safety Belt PDFDokumen9 halamanSafety Belt PDFPraful E. PawarBelum ada peringkat

- List of Minimum Tools and Tackles To Be Deployed For The ConstructionDokumen2 halamanList of Minimum Tools and Tackles To Be Deployed For The ConstructionRashid Ahmed SiddiquiBelum ada peringkat

- Application Form Osh TrainingDokumen1 halamanApplication Form Osh Trainingchapisha incBelum ada peringkat

- MJEC HSE Req For Contractors Second Issue V2 2017 ApprovedDokumen27 halamanMJEC HSE Req For Contractors Second Issue V2 2017 Approvedadnanakhtarhrp100% (1)

- 004-MS For Earthing System PDFDokumen10 halaman004-MS For Earthing System PDFKöksal Patan100% (1)

- VA2-DD09-P0ZEN-140004 Method Statement For Cable Tray System - Rev ADokumen26 halamanVA2-DD09-P0ZEN-140004 Method Statement For Cable Tray System - Rev AHau Nguyen VanBelum ada peringkat

- Method Statement For CB Replacement Job at MarmulDokumen4 halamanMethod Statement For CB Replacement Job at MarmulJohn George100% (2)

- MM ZTK 1A ONEP ELE PRC 0002 - Electrical Installation ProcedurDokumen18 halamanMM ZTK 1A ONEP ELE PRC 0002 - Electrical Installation ProcedurAbdelaziz Abdelaziz100% (1)

- If TCCDokumen38 halamanIf TCCKasturi MJBelum ada peringkat

- Optcl System in Orissa 400kv Bid DocumentDokumen223 halamanOptcl System in Orissa 400kv Bid Documentranjish_007100% (1)

- RFP RefDokumen31 halamanRFP RefHicham MedgazBelum ada peringkat

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Dokumen20 halamanMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Abb-Mcc Method StatementDokumen50 halamanAbb-Mcc Method StatementKrishnakumar PaiBelum ada peringkat

- Industrial AutomationDokumen16 halamanIndustrial AutomationPradeep Kumar MaraptlaBelum ada peringkat

- Modern Insulation TestingDokumen49 halamanModern Insulation TestingAdan SolanoBelum ada peringkat

- Fundamentals of Electrical DistributionDokumen30 halamanFundamentals of Electrical DistributionPradeep Kumar MaraptlaBelum ada peringkat

- Transformer TestingDokumen10 halamanTransformer Testingdheerajkumar02527289100% (1)

- Transformer ChecklistDokumen50 halamanTransformer ChecklistGaurav YadavBelum ada peringkat

- IEP - Industrial Ethernet ConnectionDokumen58 halamanIEP - Industrial Ethernet ConnectionPradeep Kumar MaraptlaBelum ada peringkat

- Industrial AutomationDokumen16 halamanIndustrial AutomationPradeep Kumar MaraptlaBelum ada peringkat

- Substation Design Guideliness PDFDokumen40 halamanSubstation Design Guideliness PDFLimuel EspirituBelum ada peringkat

- Modern Insulation TestingDokumen49 halamanModern Insulation TestingAdan SolanoBelum ada peringkat

- ABB XLPE Cable Systems Users Guide Rev 3Dokumen28 halamanABB XLPE Cable Systems Users Guide Rev 3vijaypshindeBelum ada peringkat

- 3281 MS Ele 0005Dokumen45 halaman3281 MS Ele 0005Pradeep Kumar MaraptlaBelum ada peringkat

- Testing and Commissioning of MetalClad SwitchgearDokumen3 halamanTesting and Commissioning of MetalClad SwitchgearPradeep Kumar MaraptlaBelum ada peringkat

- Abb-Mcc Method StatementDokumen50 halamanAbb-Mcc Method StatementKrishnakumar PaiBelum ada peringkat

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Dokumen20 halamanSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Pradeep Kumar MaraptlaBelum ada peringkat

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Dokumen20 halamanSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Pradeep Kumar MaraptlaBelum ada peringkat

- PTW V6.5 TutorialDokumen360 halamanPTW V6.5 TutorialPradeep Kumar MaraptlaBelum ada peringkat

- 2532 2-63-0001 Typical Earthing DetailsDokumen21 halaman2532 2-63-0001 Typical Earthing DetailsPradeep Kumar MaraptlaBelum ada peringkat

- SEM Hand BookDokumen203 halamanSEM Hand BookkrishnamanikandanBelum ada peringkat

- Power TFDokumen6 halamanPower TFPradeep Kumar MaraptlaBelum ada peringkat

- PTW V6.5 TutorialDokumen360 halamanPTW V6.5 TutorialPradeep Kumar MaraptlaBelum ada peringkat

- PTW V6.5 TutorialDokumen360 halamanPTW V6.5 TutorialPradeep Kumar MaraptlaBelum ada peringkat

- PTW V6.5 TutorialDokumen360 halamanPTW V6.5 TutorialPradeep Kumar MaraptlaBelum ada peringkat

- Power TFDokumen6 halamanPower TFPradeep Kumar MaraptlaBelum ada peringkat

- HTP070Dokumen8 halamanHTP070Pradeep Kumar MaraptlaBelum ada peringkat

- Electrical SpecificationDokumen40 halamanElectrical SpecificationChandrasekar KaruppasamyBelum ada peringkat

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Dokumen20 halamanSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Pradeep Kumar MaraptlaBelum ada peringkat

- AttitudeDokumen6 halamanAttitudePradeep Kumar MaraptlaBelum ada peringkat

- State Electricity Boards', Departments, Generation, TransmissionDokumen23 halamanState Electricity Boards', Departments, Generation, TransmissionPradeep Kumar MaraptlaBelum ada peringkat

- Critical Analysis of The Hong Kong International Convention On Ship RecyclingDokumen9 halamanCritical Analysis of The Hong Kong International Convention On Ship RecyclingKanu Priya JainBelum ada peringkat

- Current Affairs Top 60 Q&A PDF July 2023 2nd Week by AffairsCloudDokumen38 halamanCurrent Affairs Top 60 Q&A PDF July 2023 2nd Week by AffairsCloudSumit Suman ChaudharyBelum ada peringkat

- SolasDokumen7 halamanSolasShobhit GajbhiyeBelum ada peringkat

- Model Course 3.24 Security Awareness Training For Port Facility Personnel With Designated Security Duties, 2018Dokumen75 halamanModel Course 3.24 Security Awareness Training For Port Facility Personnel With Designated Security Duties, 2018st86% (7)

- Usual Things Everyone Does On Loadicator: Res. MEPC.248 (66) Res. MSC.369 (93) Res. MSC.370Dokumen27 halamanUsual Things Everyone Does On Loadicator: Res. MEPC.248 (66) Res. MSC.369 (93) Res. MSC.370Swarg VibhaBelum ada peringkat

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210 Telex: 23588 IMOLDN GDokumen67 halaman4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210 Telex: 23588 IMOLDN GsabaingiBelum ada peringkat

- Captain Harun - MASTER ORALS Answers - Docx-1Dokumen22 halamanCaptain Harun - MASTER ORALS Answers - Docx-1yousudz100% (5)

- Codigo IspsDokumen42 halamanCodigo IspsGaby CastilloBelum ada peringkat

- Flash On English For Transport and Logistics Answer Key and TranscriptsDokumen7 halamanFlash On English For Transport and Logistics Answer Key and TranscriptslounescherifablaBelum ada peringkat

- ImdgintroDokumen31 halamanImdgintroVitalie FricatelBelum ada peringkat

- MSC-MEPC 6 - Circ 10-Annex2 (SOPEP) - 30september2012 PDFDokumen66 halamanMSC-MEPC 6 - Circ 10-Annex2 (SOPEP) - 30september2012 PDFEshna JoshiBelum ada peringkat

- Civ-su-1.28-A Helidecks On Offshore InstallationsDokumen12 halamanCiv-su-1.28-A Helidecks On Offshore InstallationsBolarinwaBelum ada peringkat

- Watchkeeping StandardsDokumen36 halamanWatchkeeping Standardstejmayer100% (2)

- MEPC 76-7-13 - Comprehensive Impact Assessment of The Short-Term Measure Approved by MEPC 75 (Secretariat)Dokumen31 halamanMEPC 76-7-13 - Comprehensive Impact Assessment of The Short-Term Measure Approved by MEPC 75 (Secretariat)P Venkata SureshBelum ada peringkat

- Wartsila O E RT Flex68 D MIM Part 2.Dokumen331 halamanWartsila O E RT Flex68 D MIM Part 2.Uhrin Imre100% (2)

- List of MEPC.1 Circulars PDFDokumen29 halamanList of MEPC.1 Circulars PDFangel3330Belum ada peringkat

- Pages From Ship-Maintenance-Checklist-Rev1Dokumen10 halamanPages From Ship-Maintenance-Checklist-Rev1Ck DhiyanBelum ada peringkat

- p2tl Bahasa InggrisDokumen17 halamanp2tl Bahasa Inggrisdya indahBelum ada peringkat

- Interpretations For SOLASDokumen331 halamanInterpretations For SOLASmorgothsBelum ada peringkat

- OCIMFDokumen28 halamanOCIMFadiet pradanaBelum ada peringkat

- IMO Conventions January 2023Dokumen94 halamanIMO Conventions January 2023Kazem LoveBelum ada peringkat

- STCW-F International Convention On International Convention On Standards of Training, Certification and Watchkeeping For Fishing Vessel Personnel, 1995Dokumen16 halamanSTCW-F International Convention On International Convention On Standards of Training, Certification and Watchkeeping For Fishing Vessel Personnel, 1995Sapriyun S100% (1)

- AMSA Report of Safe Navigation in The GBRDokumen30 halamanAMSA Report of Safe Navigation in The GBRLoka Radhakrishna Narasaiah100% (1)

- 2009 MODU Code A.1023Dokumen148 halaman2009 MODU Code A.1023Praveen BalachandranBelum ada peringkat

- TSS PDFDokumen13 halamanTSS PDFWing WingBelum ada peringkat

- Assignment 2 IMPC July 2019Dokumen21 halamanAssignment 2 IMPC July 2019Iklima MariamBelum ada peringkat

- IALA 1014-Ed.3-Accreditation-and-Approval-Process-for-VTS-Training - Dec2011Dokumen37 halamanIALA 1014-Ed.3-Accreditation-and-Approval-Process-for-VTS-Training - Dec2011nacho363Belum ada peringkat

- IMO Audit Canada Final ReportDokumen35 halamanIMO Audit Canada Final ReportVenkat RamanBelum ada peringkat

- Here Is What You Need To Know About Enhanced Survey ProgrammeDokumen24 halamanHere Is What You Need To Know About Enhanced Survey ProgrammePrajesh T VBelum ada peringkat

- Mooring Ammendments PDFDokumen121 halamanMooring Ammendments PDFAMSBelum ada peringkat