Comparison Study of 8 Mat System

Diunggah oleh

Muhamad HisyamJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Comparison Study of 8 Mat System

Diunggah oleh

Muhamad HisyamHak Cipta:

Format Tersedia

Comparison studies of scrap tyres and expanded polystyrene-ferrocement for slope stabilization system.

Abstract. The increase in cost to produce the geo material for soil stabilization had attracted researchers around the world to find alternative solution for this problem. A study of difference of physical and mechanical strength of tyres and expanded polystyrene-ferrocement (EPS-ferrocement) had been conducted based on previous researches.. The comparison is based on the tensile test and also the pullout test of both materials. In this paper, the result of both material will be compare to choose the more suitable material as the soil reinforcement system. It is shown that scrap tyres having higher tensile strength and pullout strength compare to the EPS-ferrocement. The tensile strength of tyres is about five times better than the expanded polystyrene-ferrocement strengths which are 45.78 kN and 8.21 kN respectively. Instead of high tensile strength, the pull out force of the 8 shaped tyres is also much better compare to EPSferrocement.

Introduction Slope failure have become one of major problem around the world. There had been so many cases of landslides that cause fatal casualties to human lives. One of the sectoral reports of Malaysia clearly mentioned about 49 landslides cases out of which 88% are recognized with manmade slope (Qasim et al, 2013) Other than that Gue and Tan (2007) also declares that along with poor designing, incompetency, casualness, raw input data are also contributing in this frequent fact of landslides. To improve the slope stability, a lot of geotextiles and geomaterial using natural material or recycle waste had been invented instead of using the commercial geotextiles available from supplier. The awareness for sustainability and the cost for the petroleum based synthetic geotextiles have lead researchers around the world to find other solution to this problem. In this studies, the tensile strength of both material has been determined by standard method. The reason for this experiment to be carried out is because tensile strength is the key parameter to measure the strength of the slope reinforcement system.

Soil reinforcement material In this literature studies two types of material had been choose which are scrap tyres and also the expanded polystyrene-ferrocement concrete. These two materials were chose based on their properties which are durable and easy to handle during the construction. From previous researches, these two materials will not easily break when exposed to ground condition.

Scrap tires as slope reinforcement system

The annual waste tyres generation had been rapidly increase as the vehicle industry keep expanding. It is reported that scrap tyres that been produced on advance countries like United stated, Japan and Canada are 300 million, 104 million and 30 million respectively (RMA, 2009). The huge amount of tyres

generated annually had cause disposing problem for this waste material. It is mentioned by Kim et al (2010) that this tyres contain tire derived fuel and it is available as an alternative for fossil fuel. However, TDF is significantly undesirable because it is extremely dangerous to human health and to the natural environment. Incineration of tires emits toxic pollutants (dioxins, and furans), and a number of other harmful chemicals known as carcinogen (PCBs, chlorine based pollutants, and non-chlorinated hydrocarbon pollutants) as well as greenhouse gas. Scrap tires that been exposed to rainfall will retain some water. This condition are perfect for the mosquitos to breed (Yee, 2008). Basically, this scrap tyres will give a lot environmental problem if it disposal is not properly managed. So, some researchers has started to use the scrap tyres as part of their slope stabilization studies. This tyres had been transformed into 8 shaped and some test had been done to investigate the properties of the material.

Expanded polystyrene-ferrocement as slope reinforcement system

Expanded polystyrene beads are usually use as the basis of packing material. A lot of factory around the world were using this material because of it insulating and it protective properties to prevent fragile product from their factory from breaking. Recently, the use of this material had been increase cause by the demand on the fragile product around the world. This had caused some environmental problem to dispose this material because of it cause air pollution when burned. It is estimated that, almost 1 thousand ton of this material is dumped on the landfill annually. So, to cope with the disposable problem of this expanded polystyrene, this material can be reused for other purpose. It is stated by Park and Chisholm (1999) that this material could be granulated and be used to obtain a lightweight concrete when it is use as lightweight aggregate.

Figure 1: Expanded polystyrene By combining the ferrocement with this expanded polystyrene, new type of ferrocement with lightweight properties will be produce. In geotechnical part, the best thing is to have a lightweight material as the slope reinforcement. A lot of slope failure happen is caused by the heavy loading is exposed on the reinforcement. So, having a lightweight reinforcement may turn to be a favourable property in geotechnical design. For this study, the mortar mixture had been classified into 2 mixture proportions which are EPB10 and EPB30 with 10% and 30% respectively.

Table 1: Mortar mixture properties Constituents Expanded polystyrene beads (EPB) Cement Sand Water EPS Mixture Proportion EPB10 EPB30 1 2.25 0.45 0.25 1 1.75 0.45 0.75

Experimental program

In this study, both tyres and expanded polystyrene-ferrocement had been test to measure it physical and mechanical strength properties. These two materials had been turned into 8 shaped and been test for pull out strength, tensile strength flexural strength. The knowledge of this known strength will be able to be used for the evaluation for it performance when being used on the field. The tests also need to be done to obtain it properties for designing purposes. Sample preparation In producing the 8 shaped EPS-ferocement, there are few steps need to be done. This 8 shaped EPSferrocement was produce by using hand made. This is caused by some time constraint that happen to wait for ordered 8 shaped molds. With reference, 1000mm length and 140mm width of wire mesh is cut to form the reinforcement layer. The wire is then tied from end to end to form circular loop. The loop is pressed into half and tied to form shape of 8. All ties and connections of the mesh are performed using number 19 gauge steel wire. The mixture proportion of EPS-ferrocement follows the table of Mortar mixture properties.

Figure 2: Procedures of 8 shaped EPS-ferrocement geomats production

Result and analysis Tensile test

(a) Whole tires with side wall remove being stretched Source: Bujang et al (2008)

(b) Failure Source: Bujang et al (2008)

From studies done by Bujang et al (2008) the mean tensile strength was 55.81 kN, with standard deviation 15.19 kN. Other than that, it is also stated that the probability for the scrap tyres to have tensile strength greater than 20 kN is 99.08% based on statistical analysis carried out. Long (1996) also reported to have similar ranges of values. For this study, the test was carried out on the 8 samples of 8 shaped tyres, the highest tensile strength is about 45.78 kN and the mean tensile strength is 36.12 kN. Actually, there is a big difference in the strength maybe due to the shaped of the tyres. Table 2: Result of tensile test carried out on 8 shaped samples Sample No. T1 T2 T3 T4 T5 T6 T7 T8 Mean Standard deviation Maximum Tensile Load (kN) 26.06 26.69 28.46 36.22 39.35 42.7 43.2 45.78 36.12 8.05

For expanded polystyrene-ferrocement, this material also had been casted into 8-shaped geomat. The tensile test of this material had been investigated by using different method. This 8 shaped expanded polystyrene-ferrocement were test using flexural test. It needs to be test using flexural test because the nature of concrete that is bad in tensile strength.

Table 3: Result of tensile test carried out on 8 shaped samples Sample EPB101 EPB102 Mean Standard deviation EPB301 EPB302 Mean Standard deviation Pullout test Kim et al (2010) have determined that, the pull out strength of tyres depend on it size and also it shape. From previous studies, it shows that the maximum pull out force of round shape is higher than the 8 shape tyres. The reason behind this behavior is because the mobilize area of the tires with the sand. OShaugneyssy and Garga (2000) and Gerscovich et al (2001) have obtained quite similar value of pullout test with the same setup compare to result reported from Kim et al (2010). The reason behind this differences had been explained. Kim et al (2010) assume that, the compaction of all part of slope can increase pullout strength compare to letting the soil at the first row of tyres in a loosen state.From test done on single 8 shaped tyres, the maximum pullout strength is 2.89 kN and the mean is 2.69 kN. Table 4: Summary of pull-out tests Sample 1 2 3 Mean Maximum Pull-Out Force (kN) 2.76 2.42 2.89 2.69 Ultimate flexural force (kN) 5.66 6.76 6.21 0.55 6.17 8.21 7.19 1.02

The pullout behavior of expanded polystyrene-ferrocement is depending on the overburden load exerted on the mechanism. In this study, the overburden force is set to 332 kg. Palmeira and Milligan (1989) confirm that the pullout resistance is strongly influenced by the bearing member space ratio, S/D, in which S is the bearing member spacing and D is the bearing member thickness. Higher bearing resistance from an individual bearing member is expected when the S/D ratio is higher. Jewell (1990) identified limiting values of the S/D50 ratio as 10 that characterize either interface shear or full interaction mechanisms. The table shows that the pull out force of EPB10 is better than EPB30. This maybe cause by mixture proportions of the EPB. The difference in pullout strength depends on the percentage of the expanded polystyrene bead in the sample. In this study, by increasing the EPB percentages from 10% to 30% reduce the pull out strength by 3.11%.

Table 5: Summary of pull-out tests Sample EPB10 EPB30 Maximum Pull-Out Force (kN) 1.61 1.56

Conclusion From the past research on both of these two materials, it shown that scrap tyres have higher tensile strength compare to the expanded polystyrene-ferrocement. The difference of tensile strength is too great which the scrap tyres having tensile strength of 47.58 kN and the expanded polystyrene-ferrocement with 6.72 for EPB10 and 8.21 for EPB30. This may be due to the bond created between the particles of tyres compare to the rigid properties of expanded polystyrene-ferrocement. In addition, tyres tensile strength also had been enhanced by the help wire inside the rubber. In term of pull out stress, the EPS-ferrocement is lower than the pullout test of tires with same condition. In comparison between the EPS-ferrocement itself, it can be conclude that higher amount of EPB percentages will reduce the strength of the EPSferrocement. From the founding of this studies, it can be conclude that, scrap tyres were having better properties to be used as the slope reinforcement system based on it durability, mechanical and physical strength.

References Gue, S.S. and Y.C. Tan, 2007. Landslides: Abuses of the prescriptive method. International Conference on Slope 2006 Kuala Lumpur, Malaysia Gerscovich, D. M. S., Medeiros, L. V., and Sayao, A. S. F. J. (2001). Field pullout test of scrap tire reinforcement layers under different soil surcharges. Proceeding of the 15th International Conference on Soil Mechanics and Geotechnical Engineering, Istanbul, Vol. 2, pp. 1587-1590. Hausmann, M. R. (1990) Huat, Bujang BK, Azlan A. Aziz, and Loh Wooi Chuan. "Application of scrap tyres as earth reinforcement for repair of tropical residual soil slope." Electronic Journal of Geotechnical Engineering 13 (2008). K. S. Kim, Y. W. Yoon, and G. L. Yoon (2011), Pullout Behavior of Cell-Type Tires in Reinforced Soil Structures KSCE Journal of Civil Engineering 15(7):1209-1217 Long, N.T. (1996) Utilization of Used Tyres in Civil Engineering The Pneusol Tyresoil. Proceedings of 2nd International Congress on Environmental Geotechnic. Osaka, Japan, pp. 809-814. OShaughnessy, V., Garga, V.K., 2000. Tyre-reinforced earth fill. Part3: environmental assessment. Canadian Geotechnical Journal 37, 117131. Palmeira, E.M., Milligan, G.W.E., 1989. Scale and other factors affecting the results of pull-out tests of grid buried in sand. Geotechnique 39 (3), 511524. Qasim, S., Harahap, I. S. H., & Osman, S. B. S. (2013). Causal Factors of Malaysian Landslides: A Narrative Study. RMA (2009). Scrap tire markets in the united states-9th biennial report, Rubber Manufacturers Association, Federal Highway Administration, U.S. Department of Transportation, Washington, D.C. Yee DA 2008. Tyres as habitats for mosquitoes: A review of studies within the eastern United States. Journal of Medical Entomology 45: 581-593.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Layers of The EarthDokumen105 halamanLayers of The Earthbradbader100% (11)

- SBT Mechanics TH 1Dokumen535 halamanSBT Mechanics TH 1Shreyas Singh100% (2)

- Check Samsung indoor unit LED errorsDokumen84 halamanCheck Samsung indoor unit LED errorsbluerosedtuBelum ada peringkat

- Product Note PD30 en RevA 2011 Anti-Sway Control ProgramDokumen2 halamanProduct Note PD30 en RevA 2011 Anti-Sway Control ProgramkumarBelum ada peringkat

- Wireless Pick and Place RobotDokumen26 halamanWireless Pick and Place RobotAshok GudivadaBelum ada peringkat

- Parameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisDokumen9 halamanParameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisAtsis PapadopoulosBelum ada peringkat

- Fastener Process SimiulationDokumen4 halamanFastener Process SimiulationMehran ZaryounBelum ada peringkat

- X3 HydrostaticForceOnPlaneSurfaces BautistaDerwinDanielDokumen18 halamanX3 HydrostaticForceOnPlaneSurfaces BautistaDerwinDanielNadine Pascual100% (2)

- 11P Trusses ProblemsDokumen39 halaman11P Trusses ProblemsHoward Johann Gomez VBelum ada peringkat

- Autodesk ConstraintsDokumen16 halamanAutodesk ConstraintsrkoGearBelum ada peringkat

- Normal Distribution & Z-ScoresDokumen82 halamanNormal Distribution & Z-Scoresgela tinBelum ada peringkat

- Unconfined Compression Test: Experiment No. 3Dokumen6 halamanUnconfined Compression Test: Experiment No. 3Patricia TubangBelum ada peringkat

- Operation Stages HDI SIEMENSDokumen9 halamanOperation Stages HDI SIEMENSSergio SambuelliBelum ada peringkat

- Astm D 2036-98 Standard Test Methods For Cyanides in Water PDFDokumen20 halamanAstm D 2036-98 Standard Test Methods For Cyanides in Water PDFGianinaRoncalChávezBelum ada peringkat

- Electrical Charges and Fields Chapter - 1 PhysicsDokumen61 halamanElectrical Charges and Fields Chapter - 1 PhysicsPrasad PallaBelum ada peringkat

- Karthik Vickraman: Work ExperienceDokumen1 halamanKarthik Vickraman: Work ExperienceVishaal KannaBelum ada peringkat

- Smart MaterialsDokumen48 halamanSmart Materialsmjrobust05Belum ada peringkat

- Autonics TK DatasheetDokumen24 halamanAutonics TK DatasheetHoang Anh0% (1)

- Huygens' Principle, Maxwell's Displacement CurrentDokumen7 halamanHuygens' Principle, Maxwell's Displacement CurrentGalleta Galleta MetralletaBelum ada peringkat

- MCR 3U5 CPT Part 2Dokumen4 halamanMCR 3U5 CPT Part 2Ronit RoyanBelum ada peringkat

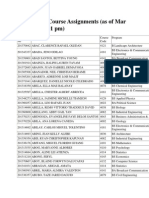

- UP Diliman Course AssignmentsDokumen82 halamanUP Diliman Course Assignmentsgamingonly_accountBelum ada peringkat

- TOP 10 PAKISTANI SCIENTISTSDokumen5 halamanTOP 10 PAKISTANI SCIENTISTSabsarBelum ada peringkat

- Introduction To Random MatricesDokumen508 halamanIntroduction To Random Matricesjorelex100% (1)

- Cooling PDFDokumen656 halamanCooling PDFTrầnNgọcCườngBelum ada peringkat

- Cat14 KDN EngDokumen76 halamanCat14 KDN EngFederico LiaudatBelum ada peringkat

- Savi TancetDokumen3 halamanSavi TancetJasmine DavidBelum ada peringkat

- Datasheet G3516 1200 RPMDokumen4 halamanDatasheet G3516 1200 RPMVerita SanjuánBelum ada peringkat

- All Ceramic Material SelectionDokumen6 halamanAll Ceramic Material SelectionERIKA BLANQUETBelum ada peringkat

- Beam StandardDokumen44 halamanBeam StandardweldmindBelum ada peringkat

- Quantum Mechanics Module NotesDokumen12 halamanQuantum Mechanics Module NotesdtrhBelum ada peringkat