Betta Flo Iom Jet Pump

Diunggah oleh

marpadanDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Betta Flo Iom Jet Pump

Diunggah oleh

marpadanHak Cipta:

Format Tersedia

JET PUMP

INSTALLATION MANUAL

SHALLOW WELL JET PUMPS

STEP 1 Make sure the well is pumped clean and that sand and grit are absent. STEP 2 Before installing a shallow well or centrifugal pump make sure the total suction lift does not exceed 25 feet. STEP 3 For convertible jet pumps attach the ejector to the pump housing, making sure that the 1 1/4 and 1 tapped holes in the ejector match up with the 1 1/4 and 1 tapped holes in the pump housing. STEP 4 Install a 1 1/4 foot valve on the bottom of the suction pipe, on driven wells, where the well casing is used as suction pipe, install a 1 1/4 horizonal line check valve. STEP 5 Install a sanitary well seal onto the top of the 1 1/4 suction pipe to fit well diameter. Use 1 1/4 tee and a 1 1/4 plug at the top of the well seal to support suction pipe in the well. Install 1 1/4 union between well and 1 pressure pipe that will rest on the well seal to support the pipes and ejector or jet in well. A 1 1/4 tee or elbow can be used on the top of the 1 1/4 suction pipe which needs to be slightly higher than the 1 pressure pipe to make the connection to the pump housing. Install a compression coupling on both suction & pressure pipes staggering them apart from each other. Install 1 1/4 pipe into the 1 1/4 tap in the pump housing. Install 1 pipe in to the 1 tap in the pump housing. Join together with

SHALLOW WELL JET PUMPS CONT.

two unions between the pump and the well. If vertical pump is being used, adapt the 1 1/4 and 1 pipes directly into the 1 1/4 and 1 taps in the pump housing and adapt some type of supports or legs from the foundation to brackets on the pump housing to support the weight of the pipes, ejector or jet in the well. STEP 6 Prime pump by pouring water into the discharge of the pump housing or automatic regulator that is mounted on the discharge of pump. STEP 7 Make sure pump is off! Check motor decal and make sure motor is wired for voltage being used. Make your wire connections in the pressure switch. STEP 8 Adjust regulator to maximum pressure, and start the pump. When pressure builds up on the pressure guage, start opening regulator slowly. The pump will start discharging water and the pressure will decrease. Continue to slowly open up regulator until pump starts to charge tones or pump starts to lose prime. At this point determine what your operating pressure is by the reading on the pressure guage. Adjust regulator back up about 5 pounds above this tone or prime loss pressure. Put a jam nut on regulator to secure adjustment. STEP 9 Make connection on the discharge of pump to the water tank. This connection can be made with galvanized or pvc pipe.

STEP 3 Connect foot valve to bottom of jet with 1 1/4 galvanized nipple or full length of 1 1/4 galvanized pipe. Connect 1 1/4 galvanized pipe to 1 1/4 tap in ejector or jet body. Connect 1 pipe to the 1 tap in ejector or jet body. Keep adding pipes until you reach the desired depth. As each pipe is added fill each with water after lowering in well. STEP 4 Install a double pipe sanitary well seal at the top of the well to keep out contamination and to support the pipe and ejector or jet in well. STEP 5 Use 1 galvanized elbow on top of pump. Connect suction pipe into tapped hole in housing or ejector. Pump needs to be installed at an uphill slope from the well with no dips or low spots to eliminate the possibility of air pockets. Pump needs to be mounted onto the foundation for smoother and quieter operation and prolonged motor life. STEP 6 Prime the pump! Be sure the suction pipe and pump housing are full of water with no trapped air pocket in suction line. STEP 7 Make sure power is off! Check motor decal and make sure motor is wired for voltage being used. Connect power voltage wire to terminals marked line voltage in pressure switch. Connect ground wire to ground terminal on pressure switch. STEP 8 Start pump! If pressure does not build after a reasonable time, stop the pump. Reprime and start again. Allow pump to operate briefly to purge air from the system. This procedure may have to be repeated until pump builds up pressure. STEP 9 Make connection on discharge of pump to water tank. This connection can be made with galvanized or pvc pipe.

DEEP WELL JET PUMP DOUBLE PIPE

STEP 1 Make sure the well is pumped clean and that sand and grit are absent. STEP 2 Deep well pumps are always installed with the ejector or jet attached to the bottom of the suction and pressure pipe in the well. A foot valve must be used if the ejector does not have a built in check valve. A tail pipe may be used beneath the ejector with the foot valve at the bottom of the tail pipe.

DEEP WELL JET PUMP SINGLE PIPE

STEP 1 Make sure the well is pumped clean and that sand and grit are absent. STEP 2 Deep well pumps are always installed with the ejectors or jet attached to the bottom of the suction pipe in the well. A foot valve must be used if the ejector or jet does not have a built in check valve. A tail pipe may be used beneath the ejector or jet with the foot valve mounted on the bottom of the tail pipe.

STEP 3 Install foot valve to the bottom of the jet or on the bottom of the tail pipe, if the tail pipe is being used. Stretch leather cup washer to open up leathers for a better seal in the well casing. Connect the ejector or jet to 1 1/4 pipe and lower into the well. Keep adding pipes and lowering the ejector or jet into the well to the desired depth. Fill suction pipe with water as it is lowered into the well. Fill the well casing with water as each suction pipe is added. STEP 4 Install casing adapter onto 1 1/4 suction pipe, lossen the three flange bolts on the adapter and lower adapter onto the well casing, being careful not to damage the rubber gasket. Make sure the well adapter is all the way around. Tighten the three bolts, each evenly until tight. Fill the well adapter with water making sure both the 1 and 1 1/4 holes are full of water. STEP 5 Mount the pump onto the well adapter with gaskets and bolts, making sure that the 1 1/4 and 1 holes in pump line up with the holes in the adapter.

STEP 6 Prime the pump by pouring water into the discharge of the pump housing or automatic regulator mounted in discharge of the pump on some models. STEP 7 Make sure the power is off! Check motor decal and make sure the motor is wired for the voltage being used. Make your wire connections in the pressure switch. STEP 8 Adjust the regulator to maximum pressure, start the pump when the pressure builds up on the pressure guage start opening the regulator slowly. The pump will start discharging water and the pressure will start decreasing as the discharge flow increases. Continue to slowly open up the regulator until pump starts to change tones or pump starts to loose its prime. At this point determine what your operating pressure is by reading the pressure guage. Adjust the regulator back up about 5 pounds above this tone or prime lost pressure. Use a jam nut on regulator to secure this adjustment. STEP 9 Make connection on discharge of pump to water tank. This connection can be made with galvanized or pvc pipe.

TROUBLE SHOOTING

A. PUMP WONT RUN

CAUSE OF TROUBLE

1. Blown fuse. 2. Low in voltage

HOW TO CHECK

Check to see if fuse is ok Use voltmeter to check pressure switch or terminals nearest pump

HOW TO CORRECT

If blown, replace with fuse of proper size. If voltage is under recommended minimum, check the size of wiring from main switch on property. If ok, contact power company. Rewire any incorrect circuits. Tighten connections, replace defective wires.

3. Loose, broken or incorrect wiring.

4. Defective Motor 5. Defective pressure switch 6. Tubing to pressure switch clogged

Check wiring circuit against diagram. See that all connections are tight and that no short circuits exist because of worn insulation, crossed wire, etc. Check to see that switch is closed Check switch setting. Examine switch contacts for dirt or excessive wear. Remove tubing and blow through it.

Repair or take to motor shop. Adjust switch settings. Clean contacts with emory cloth if dirty. Clean and replace if plugged.

TROUBLE SHOOTING CONT.

A. PUMP WONT RUN CONT..

CAUSE OF TROUBLE

7. Impeller or seal 8. Defective start capacitor

HOW TO CHECK

Turn off power, then use screwdriver to turn impeller or motor. Use an omhmmeter to check resistance across capacitor. Needle should jump when contact is made. No movement means an open capacitor, no resistance means capacitor is shorted. If fuse blows when pump is started ( and external wiring is ok) motor is shorted.

HOW TO CORRECT

If impeller wont turn, remove turn housing and locate source of binding. Replace capacitor or take motor to a service station.

9. Motor shorted out

Replace Motor

B. MOTOR OVERHEATS AND OVERLOAD TRIPS OUT . 1. Incorrect line voltage

Use voltmeter to check at pressure switch or terminals nearest pump If voltage under recommended minimum, check size of wiring from main switch on property. If ok, contact power company. Reconnect for proper voltage as per wiring diagram. Provide adequate ventilation or move pump. Install globe valve on dicharge line and throttle to increase pressure

2. Motor wired incorrectly 3. inadequate ventilation

Check motor wiring diagram Check air temperature where pump is located. Iif over 100 degrees F overload may be tripped out on external head Continuous operation at very low pressure places heavy overload on pump. This can cause overload protection to trip.

4. Prolonged low pressure delivery

C. PUMP STARTS AND STOPS TOO OFTEN

1. Leak in the pressure tank Apply soapy water to entire surface above water line. If bubbles appear, air is leaking from the tank. This will lead to a waterlogged tank. Make sure control is operating properly. If not, remove and examine for plugging. Make sure all fixtures in plumbing system are shut off. Then check all units (especially ballcocks) for leaks. Listen for noise of water running. On shallow well units, install pressure guage on suction side. On deep well systems, attach a pressure guage to the pump. Close the discharge line valve. Then using a bicycle pump or air compressor, apply about 30 psi pressure to the system. If the system will not hold this pressure when the compressor is shut off, there is a leak on the suction side. Pull piping and examine foot valve Repair leaks or repair tank.

2. Defective air volume control

Adjust switch settings. Clean with emory cloth if dirty. Repair leaks as necessary.

3. Leak on discharge side of system

4. Leak on suction side of system

Make sure above ground connections are tight. Repeat test. If necessary, pull piping and repair leaks.

5. Leak in foot valve.

Repair or replace defective valve

TROUBLE SHOOTING CONT.

D- PUMP WONT SHUT OFF

CAUSE OF TROUBLE

1. Wrong pressure switch setting or setting drift. 2. Defective pressure switch

HOW TO CHECK

Lower switch setting. If pump shuts off this was the trouble. Arcing may have caused switch contacts to weld together in closed position. Examine points and other parts of switch for defects. Remove tubing and blow through it. When no water is delivered check prime of pump and well piping. Check well depth against pump performance table to make sure pump and ejector are properly sized. Remove ejector and inspect

HOW TO CORRECT

Adjust switch to the proper setting. Replace switch if defective.

3. Tubing to pressure switch clogged 4. Loss of prime 5. Low well level

Clean and replace if plugged. Reprime if necessary If undersized, replace pump or ejector.

6. Plugged ejector

Clean and reinstall if dirty

E - PUMP OPERATES BUT DELIVERS LITTLE OR NO WATER

1. Low line voltage Use voltmeter to check at pressure switch or terminals nearest the pump. When no water is delivered, check prime of pump and well piping. Check horizontal piping between well and pump. If it does not pitch upward from the well to pump, an air lock may form. If system delivery is low, the discharge piping and/or plumbing lines may be undersized. Refigure friction loss. Disconnect air volume control tubing at pump and plug hole. If capacity increases, a leak exist in the tubing of control. Check valve setting, inspect valve for defects. On shallow well units, install pressure guage on suction side. On deep well systems, attach a pressure guage to the pump. Close the discharge line valve. Then using a bicycle pump or air compressor apply about 30 psi pressure to the system. If the system will not hold this pressure when the compressor is shut off, there is a leak in the suction side. Check well depth against pump performance table to make sure pump and ejector are sized correctly. Check pump and ejector models against manufactures performance tables. Tighten all fittings and replace control if necessary. Reset, clean, or replace valve as needed. Make sure above ground connections are tight. Repeat test if necessary, pull piping and repair leaks. If voltage under recommended minimum, check size to see if wiring from main switch on property. If ok contact power company. Reprime if necessary. Rearrange piping to eliminate air lock.

2. System incompletely primed 3. Air lock in suction line.

4. Undersized piping.

5. Leak in volume control or tubing

6. Pressure regulating wire stuck or incorrectly set. (Deep well only) 7. Leak on suction side of system

8. Low well level

If undersized, replace pump or ejector.

9. Wrong pump-ejector combination.

Replace ejector if wrong model is being used.

TROUBLE SHOOTING CONT.

E - PUMP OPERATES BUT DELIVERS LITTLE OR NO WATER CONT...

10. Low water level in well. Shut off pump and allow well to recover. Restart pump and note whether delivery drops after continuos operation. Remove ejector and inspect. Pull foot valve and inspect. Partial clogging will reduce delivery. Complete clogging will result in no water flow. A defective foot valve may cause pump to loose its prime, resulting in no delivery. Low delivery may result from wear or impeller or other pump parts. Disassemble and inspect. If well is weak lower ejector (deep well pumps) use a tall pipe, or switch from shallow well to deep well equipment. Clean, and reinstall if dirty. Clean, repair or replace if needed.

11. Plugged ejector. 12. Defective or plugged foot valve and/or strainer.

13. Worn or defective pump parts or plugged impeller.

Replace worn parts on entire pump. Clean parts if required.

Anda mungkin juga menyukai

- ANSI Codes PDFDokumen3 halamanANSI Codes PDFelectrical_1012000100% (2)

- 5.weir TankDokumen87 halaman5.weir TankmarpadanBelum ada peringkat

- Sname CoriolisDokumen17 halamanSname CoriolismarpadanBelum ada peringkat

- ICEE BrochureDokumen4 halamanICEE BrochuremarpadanBelum ada peringkat

- Crude Palm OilDokumen19 halamanCrude Palm OilmarpadanBelum ada peringkat

- ANSI Codes PDFDokumen3 halamanANSI Codes PDFelectrical_1012000100% (2)

- Catalogue of ValvesDokumen52 halamanCatalogue of ValvesMarlon TurnerBelum ada peringkat

- 1 SMDokumen12 halaman1 SMAfryanBelum ada peringkat

- Tank MaintenanceDokumen17 halamanTank MaintenancetoanvmpetrologxBelum ada peringkat

- TU-Connections in Steel Structures V-2004 PDFDokumen498 halamanTU-Connections in Steel Structures V-2004 PDFmarpadanBelum ada peringkat

- Tank MaintenanceDokumen17 halamanTank MaintenancetoanvmpetrologxBelum ada peringkat

- Bill of Materials 11: Valve ViewDokumen1 halamanBill of Materials 11: Valve ViewmarpadanBelum ada peringkat

- Catalogue of ValvesDokumen52 halamanCatalogue of ValvesMarlon TurnerBelum ada peringkat

- Flanged Standard Bore Ball Valves: ANSI CLASS 150 & 300Dokumen8 halamanFlanged Standard Bore Ball Valves: ANSI CLASS 150 & 300marpadanBelum ada peringkat

- Temp 1 PDFDokumen15 halamanTemp 1 PDFmaddukuri jagadeesh babuBelum ada peringkat

- Media 111415 enDokumen30 halamanMedia 111415 enhenryjwrBelum ada peringkat

- c311 0Dokumen7 halamanc311 0ambition1340cnBelum ada peringkat

- Shaft AlignmentDokumen8 halamanShaft AlignmentTarek MohamedBelum ada peringkat

- Specific Heat Capacity of Crude Palm OilDokumen5 halamanSpecific Heat Capacity of Crude Palm OilmarpadanBelum ada peringkat

- HDD BroschDokumen24 halamanHDD BroschRomany AllamBelum ada peringkat

- HDDDokumen42 halamanHDDwaseemiqbal133Belum ada peringkat

- 3-Way Mixing Valve en LQDokumen8 halaman3-Way Mixing Valve en LQhaseebamerBelum ada peringkat

- Engine Exhaust Flow Rate CalculationDokumen8 halamanEngine Exhaust Flow Rate CalculationMani Kumar50% (2)

- Technical Note Comparison of 4pole and 2pole Designs For Large Motors and Generators en 052011Dokumen2 halamanTechnical Note Comparison of 4pole and 2pole Designs For Large Motors and Generators en 052011marpadanBelum ada peringkat

- OGP 434-3 Storage Incident FrequenciesDokumen23 halamanOGP 434-3 Storage Incident FrequenciesJose QuinteroBelum ada peringkat

- Engine Exhaust Flow Rate CalculationDokumen8 halamanEngine Exhaust Flow Rate CalculationMani Kumar50% (2)

- Ap14 00564 Id Tech Data Item 1 Ac Ups 10kvaDokumen6 halamanAp14 00564 Id Tech Data Item 1 Ac Ups 10kvamarpadanBelum ada peringkat

- Density of Moist AirDokumen4 halamanDensity of Moist AirChristian MavarezBelum ada peringkat

- Philips Industry Lighting BrochureDokumen39 halamanPhilips Industry Lighting Brochureuriquil006Belum ada peringkat

- Cobem2005 0150Dokumen8 halamanCobem2005 0150marpadanBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- P30series (메뉴얼)Dokumen72 halamanP30series (메뉴얼)Luân ThànhBelum ada peringkat

- WPT 2 e 33Dokumen4 halamanWPT 2 e 33Julio Juarez RodriguezBelum ada peringkat

- Ofc LedDokumen6 halamanOfc LedVignesh DevanBelum ada peringkat

- HCPL-7800A: Isolation AmplifierDokumen9 halamanHCPL-7800A: Isolation AmplifierkarkonBelum ada peringkat

- gp2000 ProfaceDokumen7 halamangp2000 ProfacedombanBelum ada peringkat

- Thermogravimetry (TG) : 1. Isothermal Thermogravimetry 2. Quasi-Isothermal Thermogravimetry 3. Thermogravimetry DynamicDokumen19 halamanThermogravimetry (TG) : 1. Isothermal Thermogravimetry 2. Quasi-Isothermal Thermogravimetry 3. Thermogravimetry DynamicZUL KAMARUDDIN100% (1)

- Smart Office Automation SystemDokumen6 halamanSmart Office Automation SystemInternational Journal of Application or Innovation in Engineering & Management100% (1)

- SFTPreal10 Cat7 6x4p Loom 900MHz AWG23Dokumen2 halamanSFTPreal10 Cat7 6x4p Loom 900MHz AWG23Slobodan ĐenićBelum ada peringkat

- Moscap5mar 2020Dokumen2 halamanMoscap5mar 2020Omkar KatkarBelum ada peringkat

- Bengkel Perkongsian Teknik Menjawab Kertas 3 SPM SMKRDDokumen17 halamanBengkel Perkongsian Teknik Menjawab Kertas 3 SPM SMKRDMThana BalanBelum ada peringkat

- Updates To ANSI-EASA AR100 2015 0Dokumen3 halamanUpdates To ANSI-EASA AR100 2015 0VILLANUEVA_DANIEL2064Belum ada peringkat

- Leonova Diamond TD Sheet 2Dokumen10 halamanLeonova Diamond TD Sheet 2Ahmed Mohamed HassanBelum ada peringkat

- Vibration TesterDokumen7 halamanVibration Tester07Andhika IqbalBelum ada peringkat

- A History of The Invention of The Transistor and Where It Will Lead UsDokumen9 halamanA History of The Invention of The Transistor and Where It Will Lead UstthenryBelum ada peringkat

- Nema SB 50-2008Dokumen32 halamanNema SB 50-2008Irwin CastroBelum ada peringkat

- Grounding Rod Catalog Socome PDFDokumen3 halamanGrounding Rod Catalog Socome PDFedy yusufBelum ada peringkat

- EdforaDokumen4 halamanEdforaJayNsteinBelum ada peringkat

- HISIC450 Overheight Detectors: Reliable Overheight Detection of VehiclesDokumen8 halamanHISIC450 Overheight Detectors: Reliable Overheight Detection of Vehiclesazer NadingaBelum ada peringkat

- PG 3 ZYBO - SCHDokumen13 halamanPG 3 ZYBO - SCHanuptonemeBelum ada peringkat

- Гусеничный экскаватор Hidromek HMK 370 LC HDDokumen2 halamanГусеничный экскаватор Hidromek HMK 370 LC HDdicon100% (1)

- Zoom Player: Operation ManualDokumen16 halamanZoom Player: Operation ManualCris TuxêBelum ada peringkat

- Original Drivers and Sadassdafor VPCCW1 Series (Windows 7 64 Bit) - Download - Sony Asia PacificDokumen6 halamanOriginal Drivers and Sadassdafor VPCCW1 Series (Windows 7 64 Bit) - Download - Sony Asia PacificAnthony FoeBelum ada peringkat

- Aftron - Split AC Unit SpecDokumen2 halamanAftron - Split AC Unit Specjhay rarezaBelum ada peringkat

- The Learner Demonstrates Understanding of Media and Information Literacy (MIL) and MIL Related ConceptsDokumen4 halamanThe Learner Demonstrates Understanding of Media and Information Literacy (MIL) and MIL Related ConceptsJules MarcoBelum ada peringkat

- Mitsubishi E500 ManualDokumen202 halamanMitsubishi E500 ManualChaitanya TrivediBelum ada peringkat

- Mpeg-2 Video Compression Technique PresentationDokumen12 halamanMpeg-2 Video Compression Technique PresentationPrateek Raj GautamBelum ada peringkat

- Zetta - 8GB eMMC and 8Gb 2 X 4Gb LPDDR3 MCP - DatasheetDokumen9 halamanZetta - 8GB eMMC and 8Gb 2 X 4Gb LPDDR3 MCP - DatasheetAmzil Emmc UfsBelum ada peringkat

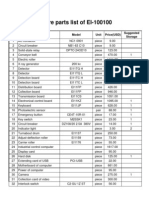

- Ei 100100Dokumen2 halamanEi 100100Tabassum BanuBelum ada peringkat

- Pdvsa: Engineering Design ManualDokumen6 halamanPdvsa: Engineering Design Manual20jose12luisBelum ada peringkat

- Katalog MHPPDokumen51 halamanKatalog MHPPDina ButkovićBelum ada peringkat