MaKGFDS Terial Data Sheet

Diunggah oleh

ChusnadiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MaKGFDS Terial Data Sheet

Diunggah oleh

ChusnadiHak Cipta:

Format Tersedia

07.02.

2007

13:07 Uhr

Seite 1

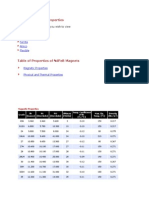

This table contains nominal or rated values. These values are subject to alteration due to

changes in the environmental conditions, processing conditions and to additives.

DIN 7728(10)

Schwartz Code

1

2

3

4

5

6

7

8

9

LAMIGAMID

LAMIGAMID

LAMIGAMID

LAMIGAMID

LAMIGAMID

LAMIGAMID

LAMIGAMID

LAMIGAMID

LAMIGAMID

10 LAMIGAMID

Material

(abbreviated)

100

200

300

307

309

310

314

317

319

320

PA 6

PA 6.6

Polyamide 6 (B) - extruded

Polyamide 6.6 (A) - extruded

PA 6 G

Cast Polyamide, resilient

PA 6 G + H

Cast Polyamide, resilient,

heat stabilised

PA 6 G + l

PA 6 G

PA 6 G + MoS2

PA 6 G + H

PA 6 G + l

PA 6 G

Cast Polyamide, resilient, oil-filled

Cast Polyamide, resilient-hard

Cast Polyamide, resilient-hard

MoS2-filled

Cast Polyamide, resilient-hard

heat-stabilised

Cast Polyamide, resilient-hard

oil-filled

Cast Polyamide hard

11 LAMIGAMID 324/327 PA 6 G + MoS2+H

Cast Polyamide, hard, MoS2-filled

heat stabilised

12 LAMIGAMID

Cast Polyamide,

elastomere-modified

Cast Polyamide, elastomere-modified, for temperatures down to -50C

400

RIM-PA 6 G

13 LAMIGAMID

410

RIM-PA 6 G

14 LAMIGAMID

510

PETP

15 LAMIGAMID

600

16 LAMIGAMID

17 LAMIGAMID

Condition

of

sample

10

11

12

13

14

15

16

g/cm3

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

kJ/m2

kJ/m2

N/mm2

N/mm2

N/mm2

dry

normal

1,14

80

42

> 50

>160

2500

1400

3200

1800

130

40

no

break

no

break

160

50

> 7 > 10,5

95

-

190

-

0,04

0,08

0,38

0,42

1,15

90

60

> 40

>150

2900

2000

3300

2000

135

60

no

break

> 3

> 15

170

100

> 8

> 12

105

-

200

-

0,02

0,08

0,35

0,42

1,13

70

50

>30

2700

2200

3200

2500

110

50

65

no

break

> 8

> 20

130

110

> 15

> 8

> 20

> 12

200

0,04... 0,35

0,42

0,08

1,13

65

45

> 25

2500

2000

3000

2300

100

40

67

no

break

> 6

> 15

130

115

> 10

> 4

> 15

> 8

200

0,04... 0,31

0,08

1,14

75

55

> 30

2700

2100

2900

2300

110

50

no

break

> 6

> 18

130

110

> 15

> 8

> 20

> 12

200

0,04... 0,14

0,20

0,08

1,15

85

65

> 25

3300

2500

3700

2800

140

60

90

no

break

> 3,5

> 15

160

125

> 20

> 12

> 24

> 16

210

0,04... 0,35

0,42

0,08

1,16

80

60

> 20

3400

2500

3500

2800

130

50

95

no

break

> 2,7

> 12

160

130

> 15

> 8

> 20

> 12

210

0,04... 0,31

0,08

1,15

80

60

> 20

3400

2500

3500

2800

130

50

91

no

break

2,7

> 12

160

130

> 15

> 8

> 20

> 12

210

0,04... 0,31

0,08

1,15

95

70

> 25

3400

2500

3500

2800

140

60

66

no

break

> 4

> 15

160

130

> 20

> 12

> 24

> 16

210

0,04... 0,14

0,20

0,08

1,15

100

80

> 15

3700

2800

3800

3000

150

70

> 2,5

> 12

175

150

> 12

> 6

> 18

> 10

210

0,04... 0,35

0,08

1,16

110

80

> 15

3700

2800

3800

3000

150

70

> 2,5

> 12

175

150

> 12

> 6

> 18

> 10

210

0,04... 0,35

0,08

dry

normal

dry

normal

dry

normal

dry

normal

dry

normal

dry

normal

dry

normal

dry

normal

dry

normal

dry

normal

dry

1,13

45-60

> 45 < 2000 > 1300

dry

1,11

40

>180

1300

Polyethylene Therephtalate

dry

1,37

74

> 50

3500

POM

Polyoxymethylen

dry

1,43

68

60

3000

700

UHMW-PE

dry

0,95

39

450

710

HMW-PE

ultrahigh molecular weight

Polyethylene (1 millon)

high density Polyethylene

(molecular weight 500.000)

dry

0,955

24

PA 12 G

Cast Polyamide, Type 12

dry

1,03

60

dry

normal

1,15

80

60

dry

1,35

dry

18 LAMIGAMID 1200

19 OPTAMID

PA 6 G

Cast Polyamide

coarsely woven cotton fabric, phenolic resin impregnated; Type 2081

finely woven cotton fabric, phenolic

resin impregnated; Type 2082

cotton fabric, phenolic resin

impregnated, MoS2 -filled; Type 2081

45

29

46

29

63

39

68

42

68

48

43

21

79

56

108

66

46

91

no

break

no

break

110

110

110

120

120

120

120

120

120

< 50

20

no

break

45

70

no

break

> 4

120

27

> 45

74

135

13

22

115

1500

18

< 100

22

23

24

25

KV/mm

cm

26

27

28

29

30

31

32

33

34

35

W

km

KJ

kg C

10 -6/K

%

10 C

220

0,23

0,1

160

-40

100 2,5-3

parts under 80 , hammer-heads,

8,5-10 machine

cup-shaped bearing shells

170

-30 2,5-3

120

7,5-9

bearing bushes, machine parts, gears, liners

180

-40

120

2,2

<7

slippers and center blocks for heavy rolling mills,

outrigger floats

180

-40

120

2,2

<7

slippers, inserts for coupling boxes

180

-40

120

1,0

slippers, inserts for coupling boxes, wear liners

180

-40

120

2,2

sheaves wheels, rollers, mandrel segments,

coupling parts, vibrator parts etc.

180

-40

120

2,2

sheaves, wheels, gear-rods, gears, sliding liners

180

-40

120

2,2

coupling parts, sealing rings, bearings

180

-40

120

1,0

sheaves and wheels without additional

bearings, sliding liners

180

-40

120

2,2

heavy-duty wheels

10

180

-40

120

2,2

heavy-duty wheels, running speed up to 3m/sec.

11

12

0,23

3,7

7,0

0,031

0,3

50

20

1015

1012

1012

1010

KA3c

KA3b

0,09

3,6

5,0

0,026

0,2

50

40

1015

1012

1012

1010

KA3c

KA3b

255

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

200220

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

215

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

200220

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

0,03

50

20

1015

1012

1012

1010

KA3c

KA3b

0,03

50

20

15

10

1012

10

1010

KA3c

KA3b

0,03

50

20

10

1012

10

1010

KA3c

KA3b

0,08

3,7

0,09

3,7

0,06

3,7

0,09

3,7

0,10

3,7

0,10

3,7

0,04

3,7

0,10

3,7

0,10

3,7

15

12

12

220

220

220

220

220

220

0,20

0,25

0,25

0,25

0,25

0,25

0,25

0,25

0,25

0,25

1,67 70-100

1,67 70-100

1,67

1,67

1,67

1,67

1,67

1,67

1,67

1,67

1,67

70-80

70-80

70-80

70-80

70-80

70-80

70-80

70-80

70-80

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

Application

210218

100150

-40

80

2,3

gear-wheels, chain-wheels, hydrocyclones,

housings, outrigger floats

205

100180

-50

60

2,3

outrigger floats, rollers

13

180

-40

100

0,4

0,6

friction bearings, wear liners

14

friction bearings, wear and sliding liners

15

0,15

3,6

0,019

90

4.1016

5.1012

Ka2

255

0,21

1,05

80

0,02... 0,32

0,08

0,90

3,7

35

10 -4

70

1015

1013

KA3b

167

0,27

1,46

100

140

-40

100

0,25

0,6

0,02... 0,29

0,08

1,0

2,3

10 -4

100

1017

1014

KA3c

136

0,33

2,30

200

120

-100

80

> 0,1

wear liners, sliding plates

16

4,5

0,02... 0,29

0,08

1,0

3,3

2 10 -4

50

1016

KA3b

130

0,14

2,30

200

120

-100

80

> 0,1

chain-guids, cutting plates, liners

17

3,5

0,04

35

1014

1012

KA3b

190

0,25

2,5

80-100

150

-40

120

0,9

1,4

sprockets, chain-wheels, pulleys, wheels,

slide and seal rings, curve disks, etc.

18

3,7

0,03

50

20

10

1012

10

1010

KA3c

KA3b

220

0,25

1,67

70-80

180

-40

120

2,2

deflection rope sheaves for elevators

19

170

5,0

0,3

108

KA1

0,29

30

150

120

100

mg

rollneck-bearings, coverts for friction rolls

20

0,02

170

5,0

0,3

108

KA1

0,29

30

150

120

100

mg

slippers, inserts for coupling boxes,

rollneck bearings

21

0,02

170

5,0

0,3

108

KA1

0,29

30

150

120

100

mg

slippers, gear-rods, bushes

22

130

150

5,0

KC100

0,30

15-30

150

125

450

mg

bearing shells and bearing collars

23

18

130

150

0,30

15-30

150

125

450

mg

bearing shells and bearing collars

24

88

95

3500

117

50

83

103

> 90

790

1100

40

16

25

32

no

break

no

break

57

3,2

>800

900

1000

31

no

break

18

36

2,8

>20

2000

2000

90

no

break

> 10

100

>25

3100

2400

3500

2700

130

55

no

break

> 3,7

> 15

150

120

50

7000

80...

100...

18

15

170

0,02

0,02

1,35

80

7000

100...

130

30

15

170

0,02

dry

1,35

50

7000

80...

100...

18

15

170

0,02

25

18

25

76

21

0,02... 0,24

0,28

0,08

56

56

20

N/mm2

160

125

38

19

m

Km

180195

no

break

> 10

17

Stre

ngt

h

Dia

lect

ric F

igur

e

Dia

lect

ric L

oss

Dia

lect

ric S

tren

gth

Pen

etra

tion

Res

ista

nce

Sur

face

Res

ista

nce

Cre

e

p

Res age

ista /leak

nce

age

Me

lting

poin

t

Technical Data

Den

sity

Synthetic Materials

Thermal Properties

Com

pre

ssiv

e

1.015

Electric Properties

Ten

sile

Stre

ngt

h

Tea

ring

Stre

ngt

h

Mo

dule

(Be

ndin of Ela

stic

g)

ity

Mo

dule

(Ten

o

sile f Ela

stic

)

ity

Bre

akin

g po

int o

nB

end

Com

ing

p

with ress

5% ive s

pre tres

ssin s

g

Com

with press

10% ive s

pre tress

ssin

Com

g

with press

20% ive s

pre tress

ssin

g

Imp

act

Res

ista

nce

(3)

Not

ch I

mp

act

Stre

ngt

h (8

Ball

)

Pre

ssu

re H

ardn

ess

Cre

(4)

1% ep Rat

Elo e St

nga res

tion s

(6)

Cre

for ep Rat

2% e S

Elo tres

nga s

tion

Hea

(6)

t

S

at 1 tab

,8 N ilisa

/mm 2 tion

(1)

Hea

at 0 t Stab

,46 ilisa

N/m tion

m2

Coe

(1)

f

f

(slid icie

withing ant of f

lubr gains rictio

icat t st n

Coe

ion) eel

(slid fficie

i

n

with g ant of f

out gain rictio

lubr st st n

icat eel

ion)

Fric

(2)

tion

We

ar

Mechanical Properties

The

rma

l Co

ndu

ctiv

ity

Spe

cific

Hea

t

Coe

Exp fficien

ans t of

ion

L

(7) inear

The

r

m

per al E

10 o xpe

nsio

C

n

Saf

e te

sho

m

rt p pera

erio ture

ds (

5) Range

Saf

e te

per

manmpera

ent ture

(5)

Ran

ge,

Mois

t

norm ure A

al a bsorp

ir co

ndit tion un

d

ion

Abs

(9) er

in w orption

ater

w

at 2 ho en im

0C

mer

sed

0107-Schwartz-Tabelle-GB.qxd

> 20

> 11

> 22

> 15

120

160

190

0,38

210

0,04... 0,35

0,42

0,08

0,09

15

12

0,1

0,1

20 LAMINEX

2000

PF-7735

21 LAMINEX

2010

PF-7735

22 LAMINEX

2040

PF-7735

23 LAMINEX

2100

PF-7708

cotton fabric, phenolic resin impregnated,

compression-moulded in moulds; Type 77

normal

1,4

60

6000

8000

80

24 LAMINEX

2140

PF-7708

cotton fabric, phenolic resin impregnated,compression-moulded in moulds filled with MoS2; Type 77

normal

1,4

60

6000

8000

80

25 LAMINEX

2101

PF

cotton fabric clips, phenolic resin

impregnated, compression moulded; Type 74

normal

1,4

40-60

7000

10000

60

> 8

> 8

130

140

6-10 (13) 0,4 (13)

20

109

108

0,30

30-40

150

125

300

mg

2,2

bearing segments and prismatic bearings

25

normal

1,4

40-60

7000

10000

60

> 8

> 8

130

140

6-10 (13) 0,4 (13)

20

109

108

0,30

30-40

150

125

300

mg

2,2

bearing segments and prismatic bearings

26

8000

180

55

0,2

320

120

bearing shells and bearing collars

28

ISO-DIS 527

DIN 53457

DIN 53457

Method

of

testing

Headquarter

USA

Schwartz GmbH

Hagdornstrae 3

D-46509 Xanten

Tel.:

+49 (0) 28 01 76 - 0

Fax:

+49 (0) 28 01 76 55

e-mail: sales@schwartz-plastic.com

http://www.schwartz-plastic.com

Schwartz Technical Plastic

US Headquarters

Bernd Nussdorfer

20 Leonberg Rd., Bldg.A

Cranberry Twn, PA 16066

phone 724-778-3310

fax

724-776-2493

e-mail: nussdorfer@schwartz-plastic.com

http://www.schwartz-plastic.com

1) tested with V-notch

2) Against hardened Steel 2162 Rough Depth Rvst=2m;

Surface pressure p = 0,05 N/mm2, v = 0,6 m/s, t = 40 C at running height

3) measured with swinging hammer 0,1 DIN 51222

4) Hc 30

5) Practice values short term - several hours,

long term - month to years

6) Stress leading to 1 - 2% stretching after 1000 h

7)

8)

9)

appr. at 20 - 100 C

ISO 180-1 valid for the materials of the lines 3-13;

all other materials acc. to DIN 53453

DIN 53473 valid for the materials of the lines 1-18;

all other materials acc. to DIN 53472

10) G, H, Oil, MoS2 , RIM, 7735 and 7708

are not abbreviations acc. to DIN 7728

11) acc. to EN 64

12) acc. to EN 63

13) at 1 kHz

ISO R 62

8000

DIN 53473

100

DIN 53472

1,45

DIN 53752

normal

DIN 52612

Type 77 - Spezial Qualitt

ISO R 1218

PF-7708

DIN 53480

HD8B

DIN 53482

28 MITELA

DIN 53482

27

DIN 53481

bearing shells and bearing collars

DIN 53483

120

DIN 53483

320

ISO 604

0,2

ISO R 75

35

ISO R 75

150

DIN 53444

7000

DIN 53444

8000

partially

70

ISO 2039

1,4

ISO 180-1A

normal

DIN 53453

Type 77 - Spezial Qualitt

DIN 53453

PF-7708

EN ISO 604

2/5 A

EN ISO 604

27 MITELA

EN ISO 604

PF

DIN 53452

2141

ISO-DIS 527

26 LAMINEX

cotton fabric clips, phenolic resin impregnated

filled with MoS2, compression moulded; Type 74

ISO R 1183

..

All information are based on our latest knowledge

and experience. It is intended to provide information about our products and possible applications. It

is not intended to guarantee specific product properties or applications.

Any patents are to be taken into consideration.

TI 0016.C.DOC Date: January 2007

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rieber Sealing in AmericaDokumen10 halamanRieber Sealing in Americaulloap*100% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Forces and Motion ActivityDokumen5 halamanForces and Motion Activityjanice alquizarBelum ada peringkat

- Tugas Metalurgi LasDokumen16 halamanTugas Metalurgi LasMizan100% (2)

- Gear BoxDokumen135 halamanGear BoxSubhendu Jana50% (2)

- Buku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase RendahDokumen240 halamanBuku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase Rendahlamenty55100% (1)

- 1 Inspection Report Dump Truck Da 1038 LaDokumen2 halaman1 Inspection Report Dump Truck Da 1038 LaChusnadiBelum ada peringkat

- Safety Engineering IIDokumen2 halamanSafety Engineering IIChusnadiBelum ada peringkat

- How To Use A Wire MeasuringDokumen2 halamanHow To Use A Wire MeasuringChusnadiBelum ada peringkat

- Behavior Theory ABC Model by Thomas KrausDokumen28 halamanBehavior Theory ABC Model by Thomas KrausChusnadiBelum ada peringkat

- Automotive Ebooks YahoooDokumen2 halamanAutomotive Ebooks YahoooChusnadiBelum ada peringkat

- Handbooks Alternatif Dari PriyatnoDokumen1 halamanHandbooks Alternatif Dari PriyatnoChusnadiBelum ada peringkat

- Magnet Materials PropertiesDokumen6 halamanMagnet Materials PropertiesChusnadiBelum ada peringkat

- Construction Risk Strategist ConferenceDokumen2 halamanConstruction Risk Strategist ConferenceChusnadiBelum ada peringkat

- 21 Juli 2014 Sub Sea Construction TestDokumen1 halaman21 Juli 2014 Sub Sea Construction TestChusnadiBelum ada peringkat

- Safety Health and Environmental EbookDokumen1 halamanSafety Health and Environmental EbookChusnadiBelum ada peringkat

- 15 Juli 2014 InspectorDokumen3 halaman15 Juli 2014 InspectorChusnadiBelum ada peringkat

- Civil Engineering BooksDokumen1 halamanCivil Engineering BooksChusnadiBelum ada peringkat

- Welding Standard For Formula StudentDokumen1 halamanWelding Standard For Formula StudentChusnadiBelum ada peringkat

- Fatality Assessment and Control EvaluationDokumen2 halamanFatality Assessment and Control EvaluationChusnadiBelum ada peringkat

- Mechanical Engineering Books 29 April 2014Dokumen1 halamanMechanical Engineering Books 29 April 2014ChusnadiBelum ada peringkat

- Marine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5Dokumen1 halamanMarine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5ChusnadiBelum ada peringkat

- Oq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceDokumen3 halamanOq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceChusnadiBelum ada peringkat

- Mechanical Inspector Course e LearningDokumen1 halamanMechanical Inspector Course e LearningChusnadiBelum ada peringkat

- Chassis Stiffness CalculationDokumen1 halamanChassis Stiffness CalculationChusnadiBelum ada peringkat

- Design GuideDokumen29 halamanDesign GuideChusnadiBelum ada peringkat

- MSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionDokumen2 halamanMSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionChusnadiBelum ada peringkat

- Code Buckling PlateDokumen6 halamanCode Buckling PlateChusnadiBelum ada peringkat

- Design of Pressure VesselDokumen137 halamanDesign of Pressure VesselAnand Bhandarkar75% (4)

- Index of Materials Science and Engineering HandbookDokumen1 halamanIndex of Materials Science and Engineering HandbookChusnadiBelum ada peringkat

- Below Hooks 19 June 2014Dokumen4 halamanBelow Hooks 19 June 2014ChusnadiBelum ada peringkat

- 95 Members: Kegiatan para Alumni SMA TRIMURTI..Dokumen1 halaman95 Members: Kegiatan para Alumni SMA TRIMURTI..ChusnadiBelum ada peringkat

- Modern Safety Management 2 Juli 2014Dokumen2 halamanModern Safety Management 2 Juli 2014ChusnadiBelum ada peringkat

- Popov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952Dokumen1 halamanPopov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952ChusnadiBelum ada peringkat

- Crystal Growth Technology: K. Byrappa T. Ohachi (Eds.)Dokumen8 halamanCrystal Growth Technology: K. Byrappa T. Ohachi (Eds.)ChusnadiBelum ada peringkat

- How To Learn, by Simon Oxenham, 15 Feb. 2013: Learning MethodsDokumen5 halamanHow To Learn, by Simon Oxenham, 15 Feb. 2013: Learning MethodsAnonymous Z1NYxC6hgYBelum ada peringkat

- 3rd - Sem-Ct-23-Chemical EngineeringDokumen3 halaman3rd - Sem-Ct-23-Chemical EngineeringJay RanjanBelum ada peringkat

- An Improved Calculation of The Mass For The Resonant Spring PendulumDokumen11 halamanAn Improved Calculation of The Mass For The Resonant Spring PendulumJuanCruzFortunattiBelum ada peringkat

- Avionics Unit 1Dokumen25 halamanAvionics Unit 1Raahini IzanaBelum ada peringkat

- Electrical TransmisionDokumen326 halamanElectrical TransmisionGermán Arias Fernández100% (4)

- On Hidden Projection of Plackett Burman Design by Yashi PalDokumen26 halamanOn Hidden Projection of Plackett Burman Design by Yashi PalyashiBelum ada peringkat

- Fluid Coupling in Belt Conveyor DrivesDokumen12 halamanFluid Coupling in Belt Conveyor Drivesnoelaroboi100% (2)

- Nota Mekanik NewtonDokumen70 halamanNota Mekanik NewtonizzuanBelum ada peringkat

- SAIC-A-2015 Rev 7Dokumen8 halamanSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- C617Dokumen5 halamanC617Rajesh KumarBelum ada peringkat

- Utilization of Ceramic Waste by Partial Replacement ofDokumen12 halamanUtilization of Ceramic Waste by Partial Replacement ofDhandapany Arun50% (2)

- Yanmar Brochure 02Dokumen2 halamanYanmar Brochure 02Fabiano OnaibafBelum ada peringkat

- Workshop 3-3: Rectangular Patch Antenna: Introduction To ANSYS Electronics DesktopDokumen21 halamanWorkshop 3-3: Rectangular Patch Antenna: Introduction To ANSYS Electronics DesktopRodrigoBelum ada peringkat

- Institute of Seismological Research, Gandhinagar: "SAR Measurements For Earthquake Studies in India"Dokumen16 halamanInstitute of Seismological Research, Gandhinagar: "SAR Measurements For Earthquake Studies in India"Santhosh Kumar BaswaBelum ada peringkat

- Spesifikasi Nikon Mikroskop Eclipse E100 PDFDokumen1 halamanSpesifikasi Nikon Mikroskop Eclipse E100 PDFHarto waldiBelum ada peringkat

- Pave RuttingDokumen440 halamanPave RuttingbloomdidoBelum ada peringkat

- Sound Isolation 2017Dokumen81 halamanSound Isolation 2017vartika guptaBelum ada peringkat

- Air Compressor Summary ListDokumen4 halamanAir Compressor Summary ListAlvin Smith100% (1)

- Soil CompactionDokumen24 halamanSoil Compactionsyah123Belum ada peringkat

- Development of A Belt Conveyor For Small Scale Industry: September 2017Dokumen6 halamanDevelopment of A Belt Conveyor For Small Scale Industry: September 2017DatBelum ada peringkat

- 2010 Aisc Steel ToolsDokumen4 halaman2010 Aisc Steel Toolsmuh2006Belum ada peringkat

- Cie - 462 - Test One.09.05.2022Dokumen2 halamanCie - 462 - Test One.09.05.2022Chris KapendaBelum ada peringkat

- 8.8 Boiler Efficiency TestDokumen17 halaman8.8 Boiler Efficiency TestRINJUBelum ada peringkat

- Fluid Mechanics Unit1Dokumen100 halamanFluid Mechanics Unit1anjuBelum ada peringkat

- Wind Energy in MalaysiaDokumen17 halamanWind Energy in MalaysiaJia Le ChowBelum ada peringkat

- Manufacturing Processes II: Fundamentals of Metal FormingDokumen17 halamanManufacturing Processes II: Fundamentals of Metal FormingMohamed Galal MekawyBelum ada peringkat