ISO12647 CMYK Print Test Forme Colors of Indonesia

Diunggah oleh

Drakman KingHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ISO12647 CMYK Print Test Forme Colors of Indonesia

Diunggah oleh

Drakman KingHak Cipta:

Format Tersedia

700

Colorsource ISO13647-2-3-4-6-7 70x 100 cm, 50 x70 cm, and 35 x70 cm universal CMYK test forme v1.12

DO NOT REZISE THIS PDF! CROP IT AS INDICATED FOR MATCHING YOUR PRESS PAPER SIZE

700

680

A few colors of Indonesia

680

670

670

660

660

1

650 650 640 640 630 630 620 620 610 610 600 600 590 590 580 580 570 570 560 560 550 550 540 540 530 530 520 520 510 510 500 500 500

Universal Colorsource CMYK test forme ISO12647 50 x 70 cm v1.1.2

480

490

480

480

470

470

470

460

460

460

450

450

450

440

440

440

430

430

430

420

420

420

410

410

410

1

400 390 380 370 360 350 340 330 320 310 300 290 280 270 260 250 240 230 220 210 200 190 180 170 160 150

1

400 400 390 390 380 380 370 370 360 360 350 350 350

35 x 50 cm v1.1.2

1

You can use and distribute this test forme if unchanged. All pictures are subject to Colorsource Copyright.

K% CMY%

10%

20%

30%

40%

50%

60%

70%

80%

90%

95%

100%

340

330

330

320

320

310

310

300

300

290

290

280

280

270

270

260

260

250

250

Step 2: Bellow CMYK chart is to be measured as spectral data with M e a s u r eTo o l (or i1Profiler) for CMYK_Gravure application, after you have properly set your solid CMYK densities u s i n g CMYK_100% application. Please measure bellow CMYK_Gravure test chart on many good copies before you paste your spectral measurement data to be averaged by CMYK_Gravure application : 3 2 1

330

Step 3: For flexographic printing only, according to ISO 12647-6, or for building your own CMYK standard: Above chart is the i1 CMYK target 1.1: Quite enough for computing accurate CMYK ICC profiles, as long as you average measures on a few good prints! You can use it to make your own press ICC profile after you have matched your ISO12647-6 target standard using CMYK_100% (Solid inks densities) and then CMYK_Gravure applications (TVI curves for film/foil, paper or corrugated). For computing your flexographic printing configuration CMYK ICC profile, please measure above CMYK test chart on a number of good printed copies, and then average your spectral measurement data before computing your ICC profile from your averaged measurement file.

3

Check visually Cyan% are pure Check visually Magenta% are pure

1 Colorsource ISO 12647-2-3-4-6-7 Print and Proof free Color Quality control bar: Can be freely incorporated into your CMYK print and proofs, and checked using your free Colorsource CMYK_Print_and_Proof application.

320

310

300

290

280

270

260

250

240

240

240

230

230

Download Colorsource press setting software: www.iso12647solution.com/Downloads_and_links.htm

230

220

220

COLORSOURCE

Color separation are ISOcoated_v2 with 300% maximal total coverage. Gray patches for visual control are only valid on thick matte or glossy coated paper with D50 light.

220

100

210

210

210

90

70

Check visually Yellow% are pure

200

200

200

60

40

190

190

190

10

30

180

180

180

100

80

170

170

170

50

70

160

160

160

150

150

140

140

140

130

130

130

EFI 2 or o r P e hing e-On for matc y E , tions e Pro e-On e applica 6. y E e ld us -4 or sourc shou ith Color 2647-2-3 u o Y w ISO1 : 000 ES-1 resses to nload w o p r D you

20

40

150

Check visually Black% are pure

1

10 90 60 30 80 50

120 120 120

1

140 130 120

ISOcoated_v2 - D50

Neutral grays MaxK - NoK

100

20

110

110

110

110

Max K

L = 25 L = 50 L = 75

No K

Visual control: Check bellow high density and low density patches using a magnifier, in order to check small tones and maximal usable black or else ink limits to use in your CMYK ICC profiles.

10% 9 8 7 6 5 4 3 2 1 0 100 99 98 97 96 95 94 93 92 91 90% 090 100

90

100

100

100

70

090

090

090

60

40

080

080

080

080

10

30

070

070

070

Step 1: Measure one of the two CMYK charts bellow as spectral data with MeasureTool (or i1Profiler)

for CMYK_100% application. First chart is OK for setting your solid inks densities matching any ISO12647-2-3-4-6 standard and controlling your superimpositions. We recommend using the second chart when you want to establish your own CMYK standard, because it allows you monitoring your print contrast while you increase your solid inks 1 densities. Corps 9 - Corps 9

Corps 8 - Corps 8

Corps 4 - Corps 4

Corps 3 - Corps 3

Corps 2 - Corps 2 Corps 2 - Corps 2

070

Corps 3 - Corps 3

Corps 4 - Corps 4

060

060

060

0.125 0.25 0.50 0.75 1 2

Corps 7 - Corps 7 Corps 6 - Corps 6 Corps 6 - Corps 6 Corps 7 - Corps 7 Corps 5 - Corps 5

Corps 5 - Corps 5

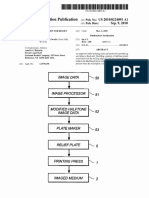

Step 0: Check and/or calibrate your printing formes. For lithographic offset plates you can

first produce only the black plate and use PLATE software:

0% 1 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 % 100 %

060

050

This is the IDEAlliance ISO12647-7 2009 control bar you can use as well on your prints and proofs and control using free Colorsource CMYK_Print_and_Proof application.

050

050

Corps 9 - Corps 9

Corps 4 - Corps 4

Corps 8 - Corps 8

050

Geometrical 50% if plate is calibrated and no gravure curve is used

040

1 2

040

Slur

1

Corps 9 - Corps 9

Corps 8 - Corps 8

Corps 4 - Corps 4

Corps 3 - Corps 3

Corps 2 - Corps 2

Corps 2 - Corps 2

Corps 3 - Corps 3

040

1

030 030

3 4 5

Corps 7 - Corps 7 Corps 6 - Corps 6 Corps 6 - Corps 6 Corps 7 - Corps 7 Corps 5 - Corps 5

Corps 5 - Corps 5

030

Corps 9 - Corps 9

Corps 8 - Corps 8

Check your 50% geometrical dot area with a magnifier or measure your offset plates model N-Factor:

040

40% 70%

030

000

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

000

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

000

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

40%

000

Anda mungkin juga menyukai

- Color Management: Understanding and Using ICC ProfilesDari EverandColor Management: Understanding and Using ICC ProfilesPhil GreenBelum ada peringkat

- ISO Graphic ArtsDokumen26 halamanISO Graphic ArtsAnonymous l6OMyp4w0% (2)

- CYMKDokumen6 halamanCYMKkzolf4522Belum ada peringkat

- Fogra Softproof Handbook PDFDokumen43 halamanFogra Softproof Handbook PDFLalo GutierrezBelum ada peringkat

- Argyll Tutorial - FCMS2010Dokumen70 halamanArgyll Tutorial - FCMS2010kiteprinterBelum ada peringkat

- Faq From IccDokumen27 halamanFaq From IccAnonymous FGY7goBelum ada peringkat

- CMYK GUIDE - Color SeparationDokumen22 halamanCMYK GUIDE - Color SeparationcarutadanBelum ada peringkat

- Device Link ProfileDokumen28 halamanDevice Link ProfileMarcos Flint0% (1)

- ICC Minor Revision For WebDokumen102 halamanICC Minor Revision For WebRolo Calfio AcostaBelum ada peringkat

- X Rite GregtagmacbethDokumen21 halamanX Rite GregtagmacbethdeepanairbalachandraBelum ada peringkat

- Vsip - Info Acro Rip Manual New PDF FreeDokumen1 halamanVsip - Info Acro Rip Manual New PDF FreeBaron SigmaBelum ada peringkat

- Understanding Paper Whiteness PDFDokumen2 halamanUnderstanding Paper Whiteness PDFSappiETCBelum ada peringkat

- Workflow - PDF OTIMODokumen56 halamanWorkflow - PDF OTIMOrafael_faria_4Belum ada peringkat

- EagleRIP4.0 User GuideDokumen175 halamanEagleRIP4.0 User GuideCarlos V.Belum ada peringkat

- Us 20100224091Dokumen12 halamanUs 20100224091Cikumunya ArsBelum ada peringkat

- Achieve G7 Master Printer Status: Improve Gray Balance and Color ConsistencyDokumen2 halamanAchieve G7 Master Printer Status: Improve Gray Balance and Color ConsistencyChenna VijayBelum ada peringkat

- Eci Grayconm I1 Fogra39Dokumen1 halamanEci Grayconm I1 Fogra39migueldemacrolabBelum ada peringkat

- BESTColor Manual EN4-1Dokumen110 halamanBESTColor Manual EN4-1vitprint22Belum ada peringkat

- Resolution, Color Management & PrintingDokumen23 halamanResolution, Color Management & PrintingCalin TrutaBelum ada peringkat

- Wasatch Quickstart SPDokumen8 halamanWasatch Quickstart SPIris AceroBelum ada peringkat

- Fogra Specification - System and Process Check For Large Format Printing Application V1.0Dokumen26 halamanFogra Specification - System and Process Check For Large Format Printing Application V1.0Carnot Junior100% (1)

- 10 BVDM Mediastandard Print 2016Dokumen78 halaman10 BVDM Mediastandard Print 2016Duy KhoaBelum ada peringkat

- EFI Vs GMG Vs CGS Is There A Clear WinnerDokumen18 halamanEFI Vs GMG Vs CGS Is There A Clear WinnersmkazmiBelum ada peringkat

- E0499 Fogra Softproof HandbookDokumen43 halamanE0499 Fogra Softproof HandbookMarcus FX100% (1)

- Full Color Screen Printing With PhotoshopDokumen7 halamanFull Color Screen Printing With Photoshopmimpi_ilusiBelum ada peringkat

- 2015 DT ImageQualityTestforms PDFDokumen21 halaman2015 DT ImageQualityTestforms PDFErinaldo FerreiraBelum ada peringkat

- Eci Offset 2009 enDokumen5 halamanEci Offset 2009 enicsoicsoBelum ada peringkat

- Measuring CMYK Halftones: The Case For Spot Color Tone Value (SCTV) FormulaDokumen24 halamanMeasuring CMYK Halftones: The Case For Spot Color Tone Value (SCTV) FormulaLong HộiBelum ada peringkat

- Icc Book1Dokumen281 halamanIcc Book1fu82Belum ada peringkat

- ONYX. Profiling Training. What S New in 7.1 Profiling Workflow Agenda Getting Started Application Settings Create A New Media Tips - RecapDokumen78 halamanONYX. Profiling Training. What S New in 7.1 Profiling Workflow Agenda Getting Started Application Settings Create A New Media Tips - RecapMaria ShiptjenkoBelum ada peringkat

- Eagle RipDokumen4 halamanEagle RippedroaraoztBelum ada peringkat

- Frequently Asked Questions (FAQ's) Pertaining To GRACoL, G7, and ISO 12647-2Dokumen6 halamanFrequently Asked Questions (FAQ's) Pertaining To GRACoL, G7, and ISO 12647-2SappiETCBelum ada peringkat

- Test ChartDokumen1 halamanTest ChartZigma ImpresionBelum ada peringkat

- ZCC+Features ListDokumen7 halamanZCC+Features ListMirjana EricBelum ada peringkat

- SWOP Proofing 17x21 Visual 1107Dokumen1 halamanSWOP Proofing 17x21 Visual 1107Vlado KamenovBelum ada peringkat

- G7 Guide FinalDokumen31 halamanG7 Guide FinalThảo PhạmBelum ada peringkat

- Understanding Working Principles Laser Printer: Click To Edit Master Subtitle StyleDokumen13 halamanUnderstanding Working Principles Laser Printer: Click To Edit Master Subtitle StyleJucia ChawBelum ada peringkat

- Gray Balance Variabile: c40 Y32 Y31 Y30 Y29 Y28 Y27Dokumen1 halamanGray Balance Variabile: c40 Y32 Y31 Y30 Y29 Y28 Y27ecdtcenterBelum ada peringkat

- Summa Bigpaint 1500 Maintenance ManualDokumen134 halamanSumma Bigpaint 1500 Maintenance ManualMo_DaviesUKBelum ada peringkat

- TN5602 HalfToningDokumen36 halamanTN5602 HalfToningSudhagarSubbiyanBelum ada peringkat

- NAA Digital Color Test Form: A A0 0A A0 0 A A0 00 00 0Dokumen1 halamanNAA Digital Color Test Form: A A0 0A A0 0 A A0 00 00 0Chenna VijayBelum ada peringkat

- HP CM Atp 0.25 StrokeDokumen1 halamanHP CM Atp 0.25 StrokeroniBelum ada peringkat

- 2012 DEER Poster Design To Print Series (Print Only) - Sep11Dokumen6 halaman2012 DEER Poster Design To Print Series (Print Only) - Sep11Sergio TellezBelum ada peringkat

- Navigator 9 User Manual PDFDokumen444 halamanNavigator 9 User Manual PDFLalo GutierrezBelum ada peringkat

- Introduction of Pixels: Fig (1.1) RGB (Red, Green, Blue)Dokumen20 halamanIntroduction of Pixels: Fig (1.1) RGB (Red, Green, Blue)Kalyan Reddy AnuguBelum ada peringkat

- Embossing and Debossing File Setup GuideDokumen2 halamanEmbossing and Debossing File Setup GuidePrintNinjaBelum ada peringkat

- Create A 60 S Psychedelic Style Concert Poster - Psdtuts+Dokumen7 halamanCreate A 60 S Psychedelic Style Concert Poster - Psdtuts+ajarmanBelum ada peringkat

- DTG Viper Error 0001001DDokumen1 halamanDTG Viper Error 0001001DjoecentroneBelum ada peringkat

- C5500 C5800 C6100 Service ManualDokumen242 halamanC5500 C5800 C6100 Service ManualBiagio BuonoBelum ada peringkat

- EX 280 - EX-i 280 ComparisonDokumen6 halamanEX 280 - EX-i 280 Comparisonlokanath BKBelum ada peringkat

- Color ManageDokumen39 halamanColor ManageZsuzsaBelum ada peringkat

- L) Screen Printing: Document 2, Health and Safety: Pages 6-7Dokumen10 halamanL) Screen Printing: Document 2, Health and Safety: Pages 6-7GeorgiaBelum ada peringkat

- Preps User Guide enDokumen232 halamanPreps User Guide enTapash Dey100% (1)

- PANTONE Color Support User GuideDokumen18 halamanPANTONE Color Support User GuideChenna VijayBelum ada peringkat

- User Manual For UV210C PDFDokumen19 halamanUser Manual For UV210C PDFAndrei SerbanBelum ada peringkat

- Color Rendering Index White Paper Ron Kubara NoritsuDokumen7 halamanColor Rendering Index White Paper Ron Kubara NoritsuelsokukabaBelum ada peringkat

- Snap Gracol Swap IsoDokumen15 halamanSnap Gracol Swap IsoKalvoBelum ada peringkat

- Theme: Discuss The Relevance of Philosophy of Religions To The Religious PersonDokumen5 halamanTheme: Discuss The Relevance of Philosophy of Religions To The Religious PersonKofi NyarkoBelum ada peringkat

- PM Furniture CatalogDokumen421 halamanPM Furniture CatalogVirgilBelum ada peringkat

- Log Horizon v04v2 - The End of The Game Part IIDokumen270 halamanLog Horizon v04v2 - The End of The Game Part IIIvan Zandonà100% (2)

- RadulescuDokumen4 halamanRadulescubigbigbig90003270100% (1)

- Jam Mengajar Guru MusikDokumen5 halamanJam Mengajar Guru MusikDafiq MauBelum ada peringkat

- Quiz de Ingles Unidad 1 2 y 3 Cambridge Touchstone Nivel 4 Contestado PDFDokumen8 halamanQuiz de Ingles Unidad 1 2 y 3 Cambridge Touchstone Nivel 4 Contestado PDFGilberto Vasquez FonsecaBelum ada peringkat

- Causeway FactsheetDokumen2 halamanCauseway FactsheetThames Discovery Programme100% (2)

- Garment CheckerDokumen29 halamanGarment Checkerzeeshan_220Belum ada peringkat

- AHAKAK TRADERS - Proposal SolutionsDokumen18 halamanAHAKAK TRADERS - Proposal SolutionsSaad JavedBelum ada peringkat

- Architecture of The PhilippinesDokumen9 halamanArchitecture of The PhilippinesShin Hye ParkBelum ada peringkat

- Transportation - Pack AnimalsDokumen41 halamanTransportation - Pack AnimalsThe 18th Century Material Culture Resource Center100% (2)

- Hatha Yoga Timeline PremodernDokumen3 halamanHatha Yoga Timeline Premodernsenthil27eceBelum ada peringkat

- PDF Download Before You Say I Do A Marriage Preparation Manual For CouplesDokumen2 halamanPDF Download Before You Say I Do A Marriage Preparation Manual For CouplesKevin EdroBelum ada peringkat

- BBC Learning English - Course - Intermediate - Unit 11 - Grammar ReferenceDokumen4 halamanBBC Learning English - Course - Intermediate - Unit 11 - Grammar ReferenceElaine Luu100% (1)

- 123 ScriptDokumen113 halaman123 ScriptGabe GirsonBelum ada peringkat

- PlayboyDokumen26 halamanPlayboyHaroolld Cast GonzalezBelum ada peringkat

- Document Cinnamon Raisin Bagels.Dokumen1 halamanDocument Cinnamon Raisin Bagels.Anthony Spinelli100% (3)

- LajwantiDokumen12 halamanLajwantilubna_rahman200288% (8)

- Astrotheology of The AncientsDokumen6 halamanAstrotheology of The AncientsDonnaveo Sherman100% (2)

- Iris Murdoch, Gender and PhilosophyDokumen5 halamanIris Murdoch, Gender and PhilosophyCoordinación General ETEPEBelum ada peringkat

- This Christmas,: No Two Homes Will Be The SameDokumen4 halamanThis Christmas,: No Two Homes Will Be The SameprimadBelum ada peringkat

- Davie504 Bass Drum Cover: Eric M. Carr and Davie 504 124Dokumen1 halamanDavie504 Bass Drum Cover: Eric M. Carr and Davie 504 124Ryker KeathBelum ada peringkat

- 1-June 4-8Dokumen3 halaman1-June 4-8Krizna Dingding DotillosBelum ada peringkat

- Dining Room OperationsDokumen35 halamanDining Room Operationsmarysue_baylongoBelum ada peringkat

- World Lit-Midterm AssignmentDokumen3 halamanWorld Lit-Midterm AssignmentMiguel LigutanBelum ada peringkat

- Verbos Irregulares en InglésDokumen6 halamanVerbos Irregulares en InglésEidorian KawaiiBelum ada peringkat

- Space Programming Des8Dokumen4 halamanSpace Programming Des8Abygail MorenoBelum ada peringkat

- ST Thomas's AnthropologyDokumen5 halamanST Thomas's AnthropologyRob Boileau100% (1)

- Resume For PortfolioDokumen1 halamanResume For Portfolioapi-548459235Belum ada peringkat

- IntroducenyourselfnGuiden1nSISTEMAS 905edec3f4a2096Dokumen9 halamanIntroducenyourselfnGuiden1nSISTEMAS 905edec3f4a2096Camilo RiveraBelum ada peringkat