Evaporation Examples

Diunggah oleh

chhinder13Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Evaporation Examples

Diunggah oleh

chhinder13Hak Cipta:

Format Tersedia

EXAMPLE 6.2.

Water chilling in a counter flow heat exchanger In a counter flow heat exchanger, water is being chilled by a sodium chloride brine. If the rate of flow of the brine is 1.8 kg s-1 and that of the water is 1.05 kg s-1, estimate the temperature to which the water is cooled if the brine enters at -8 ! and lea"es at 10 !, and if the water enters the exchanger at #$ !. If the area of the heat-transfer surface of this exchanger is 55 m $, what is the o"erall heat-transfer coefficient% &ake the specific heats to be #.#8 and '.18 k( kg -1 !-1 for the brine and the water respecti"ely. )ith heat exchangers a small sketch is often helpful*

FIG. 6.2. Diagrammatic heat exchanger

Figure 6.2 shows three temperatures are known and the fourth Tw$ can be found from the heat balance* 1.8 x #.#8 x +10 - ,-8-. / 1.05 x '.18 x ,#$ 0 Tw$&herefore Tw$ / 1 !. 2nd so T1 / +#$ - 10. / $$ ! and T$ / +1 - ,-8-. / 15 !. &herefore Tm / ,$$ - 15-3loge,$$315/ 130.#8$ / 18.# !. 4or the heat exchanger q / heat exchanged between fluids / heat passed across heat transfer surface / UATm &herefore 1.8 x #.#8 x 18 / U x 55 x 18.# U / 0.11 k( m-$ !-1 / 110 ( m-$ !-1 In some cases, heat-exchanger problems cannot be sol"ed so easily5 for example, if the heattransfer coefficients ha"e to be calculated from the basic e6uations of heat transfer which depend on flow rates and temperatures of the fluids, and the temperatures themsel"es depend on the heat-transfer coefficients. &he easiest way to proceed then is to make sensible estimates and to go through the calculations. If the final results are coherent, then the estimates were reasonable. If not, then make better estimates, on the basis of the results, and go through a new set of calculations5 and if necessary repeat again until consistent results are obtained. 4or those with multiple heat exchangers to design, computer programmes are a"ailable.

EXAMPLE .!. "ingle effect e#a$orator% &team u&age an' heat tran&fer &urface 2 single-effect e"aporator is re6uired to concentrate a solution from 107 solids to #07 solids at the rate of $50 kg of feed per hour. If the pressure in the e"aporator is 11 k8a absolute, and if steam is a"ailable at $00 k8a gauge, calculate the 6uantity of steam re6uired per hour and the area of heat transfer surface if the o"erall heat transfer coefficient is 1100 ( m -$ s-1 !-1. 2ssume that the temperature of the feed is 18 ! and that the boiling point of the solution under the pressure of 11 k8a absolute is 91 !. 2ssume, also, that the specific heat of the solution is the same as for water, that is '.18: x 10# ( kg-1 !, and the latent heat of "apori;ation of the solution is the same as that for water under the same conditions. 4rom steam tables ,2ppendix 8-, the condensing temperature of steam at $00 k8a ,g- is 1#' ! and latent heat $1:' k( kg-15 the condensing temperature at 11 k8a ,abs.- is 91 ! and latent heat is $$81 k( kg-1. Ma&& (alance ,kg h-1<olids 4eed 8roduct >"aporation $5 $5 =i6uids $$5 58 &otal $50 8# 1:1

)eat (alance ?eat a"ailable per kg of steam / latent heat @ sensible heat in cooling to 91 ! / $.1:' x 10: @ '.18: x 10#,1#' - 91/ $.1:' x 10: @ 1.8 x 105 / $.#' x 10: ( ?eat re6uired by the solution / latent heat @ sensible heat in heating from 18 ! to 91 ! / $$81 x 10# x 1:1 @ $50 x '.18: x 10# x ,91 - 18/ #.81 x 108 @ 1.: x 101 / '.51 x 108 ( Aow, heat from steam / heat re6uired by the solution, &herefore 6uantity of steam re6uired per hour / ,'.51 x 10 8-3,$.#' x 10:/ 195 kg h-1 Buantity of steam3kg of water e"aporated / 19531:1 / 1.11 kg steam3kg water. )eat*tran&fer area &emperature of condensing steam / 1#' !. &emperature difference across the e"aporator / ,1#' - 91- / '# !.

)riting the heat transfer e6uation for q in Coules3sec, q = UA T ,'.51 x 108-3#:00 / 1100 x A x '# A / 1.1' m$ 2rea of heat transfer surface / 1.1' m$ ,It has been assumed that the sensible heat in the condensed ,cooling from 1#' ! to 91 !steam is reco"ered, and this might in practice be done in a feed heater. If it is not reco"ered usefully, then the sensible heat component, about 87, should be omitted from the heat a"ailable, and the remainder of the working adCusted accordingly-.

!onsidered as a piece of process plant, the e"aporator has two principal functions, to exchange heat and to separate the "apour that is formed from the li6uid. Im$ortant $ractical con&i'eration& in e#a$orator& are the% maximum allowable temperature, which may be substantially below 100 !. promotion of circulation of the li6uid across the heat-transfer surfaces, to attain reasonably high heat transfer coefficients and to pre"ent any local o"erheating, "iscosity of the fluid which will often increase substantially as the concentration of the dissol"ed materials increases, tendency to foam which makes separation of li6uid and "apour difficult.

&?> <IAD=>->44>!& >E28FG2&FG &he typical e"aporator is made up of three functional sections* the heat exchanger, the e"aporating section, where the li6uid boils and e"aporates, and the separator in which the "apour lea"es the li6uid and passes off to the condenser or to other e6uipment. In many e"aporators, all three sections are contained in a single "ertical cylinder. In the centre of the cylinder there is a steam-heating section, with pipes passing through it in which the e"aporating li6uors rise. 2t the top of the cylinder, there are baffles, which allow the "apours to escape but check li6uid droplets that may accompany the "apours from the li6uid surface. 2 diagram of this type of e"aporator, which may be called the con"entional e"aporator, is gi"en in Fig. .!.

FIG. .! E#a$orator

In the heat exchanger section, called a calandria in this type of e"aporator, steam condenses in the Cacket and the li6uid being e"aporated boils on the inside of the tubes and in the space abo"e the upper tube plate. &he resistance to heat flow is imposed by the steam and li6uid film coefficients and by the material of the tube walls. &he circulation of the li6uid greatly affects e"aporation rates, but circulation rates and patterns are "ery difficult to predict in any detail. Ealues of o"erall heat transfer coefficients that ha"e been reported for e"aporators are of the order of 1800-5000 ( m -$ s-1 !-1 for the e"aporation of distilled water in a "ertical-tube e"aporator with heat supplied by condensing steam. ?owe"er, with dissol"ed solids in increasing 6uantities as e"aporation proceeds leading to increased "iscosity and poorer circulation, heat transfer coefficients in practice may be much lower than this. 2s e"aporation proceeds, the remaining li6uors become more concentrated and because of this the boiling temperatures rise. &he rise in the temperature of boiling reduces the a"ailable temperature drop, assuming no change in the heat source. 2nd so the total rate of heat transfer will drop accordingly. 2lso, with increasing solute concentration, the "iscosity of the li6uid will increase, often 6uite substantially, and this affects circulation and the heat-transfer coefficients leading again to lower rates of boiling. Het another complication is that measured, o"erall, heat transfer coefficients ha"e been found to "ary with the actual temperature drop, so that the design of an e"aporator on theoretical grounds is ine"itably subCect to wide margins of uncertainty. 8erhaps because of this uncertainty, many e"aporator designs ha"e tended to follow traditional patterns of which the calandria type of 4ig. 8.1 is a typical example.

+acuum E#a$oration 4or the e"aporation of li6uids that are ad"ersely affected by high temperatures, it may be necessary to reduce the temperature of boiling by operating under reduced pressure. &he relationship between "apour pressure and boiling temperature, for water, is shown in 4ig. 1.$. )hen the "apour pressure of the li6uid reaches the pressure of its surroundings, the li6uid boils. &he reduced pressures re6uired to boil the li6uor at lower temperatures are obtained by mechanical, or steam Cet eCector, "acuum pumps, combined generally with condensers for the "apours from the e"aporator. Iechanical "acuum pumps are generally cheaper in running costs but more expensi"e in terms of capital than are steam Cet eCectors. &he condensed li6uid can either be pumped from the system or discharged through a tall barometric column in which a static column of li6uid balances the atmospheric pressure. Eacuum pumps are then left to deal with the non-condensibles, which of course are much less in "olume but still ha"e to be discharged to the atmosphere.

)eat ,ran&fer in E#a$orator& ?eat transfer in e"aporators is go"erned by the e6uations for heat transfer to boiling li6uids and by the con"ection and conduction e6uations. &he heat must be pro"ided from a source at a suitable temperature and this is condensing steam in most cases. &he steam comes either directly from a boiler or from a pre"ious stage of e"aporation in another e"aporator. IaCor obCections to other forms of heating, such as direct firing or electric resistance heaters, arise because of the need to a"oid local high temperatures and because of the high costs in the case of electricity. In some cases the temperatures of condensing steam may be too high for the product and hot water may be used. =ow-pressure steam can also be used but the large "olumes create design problems. !alculations on e"aporators can be carried out combining mass and energy balances with the principles of heat transfer.

EXAMPLE .!. "ingle effect e#a$orator% &team u&age an' heat tran&fer &urface 2 single-effect e"aporator is re6uired to concentrate a solution from 107 solids to #07 solids at the rate of $50 kg of feed per hour. If the pressure in the e"aporator is 11 k8a absolute, and if steam is a"ailable at $00 k8a gauge, calculate the 6uantity of steam re6uired per hour and the area of heat transfer surface if the o"erall heat transfer coefficient is 1100 ( m-$ s-1 !-1. 2ssume that the temperature of the feed is 18 ! and that the boiling point of the solution under the pressure of 11 k8a absolute is 91 !. 2ssume, also, that the specific heat of the solution is the same as for water, that is '.18: x 10# ( kg-1 !, and the latent heat of "apori;ation of the solution is the same as that for water under the same conditions. 4rom steam tables ,2ppendix 8-, the condensing temperature of steam at $00 k8a ,g- is 1#' ! and latent heat $1:' k( kg-15 the condensing temperature at 11 k8a ,abs.- is 91 ! and latent heat is $$81 k( kg -1. Ma&& (alance ,kg h-1<olids 4eed 8roduct >"aporation $5 $5 =i6uids $$5 58 &otal $50 8# 1:1

)eat (alance ?eat a"ailable per kg of steam / latent heat @ sensible heat in cooling to 91 ! / $.1:' x 10: @ '.18: x 10#,1#' - 91/ $.1:' x 10: @ 1.8 x 105 / $.#' x 10: ( ?eat re6uired by the solution / latent heat @ sensible heat in heating from 18 ! to 91 ! / $$81 x 10# x 1:1 @ $50 x '.18: x 10# x ,91 - 18/ #.81 x 108 @ 1.: x 101 / '.51 x 108 ( Aow, heat from steam / heat re6uired by the solution, &herefore 6uantity of steam re6uired per hour / ,'.51 x 10 8-3,$.#' x 10:/ 195 kg h-1 Buantity of steam3kg of water e"aporated / 19531:1 / 1.11 kg steam3kg water. )eat*tran&fer area &emperature of condensing steam / 1#' !. &emperature difference across the e"aporator / ,1#' - 91- / '# !. )riting the heat transfer e6uation for q in Coules3sec, q = UA T ,'.51 x 108-3#:00 / 1100 x A x '# A / 1.1' m$ 2rea of heat transfer surface / 1.1' m$ ,It has been assumed that the sensible heat in the condensed ,cooling from 1#' ! to 91 !- steam is reco"ered, and this might in practice be done in a feed heater. If it is not reco"ered usefully, then the sensible heat component, about 87, should be omitted from the heat a"ailable, and the remainder of the working adCusted accordingly-.

-on'en&er& In e"aporators that are working under reduced pressure, a condenser, to remo"e the bulk of the "olume of the "apours by condensing them to a li6uid, often precedes the "acuum pump. !ondensers for the "apour may be either surface or Cet condensers. <urface condensers pro"ide sufficient heat transfer surface, pipes for example, through which the condensing "apour transfers latent heat of "apori;ation to cooling water circulating through the pipes. In a Cet condenser, the "apours are mixed with a stream of condenser water sufficient in 6uantity to transfer latent heat from the "apours.

EXAMPLE .2. Water re.uire' in a /et con'en&er for an e#a$orator ?ow much water would be re6uired in a Cet condenser to condense the "apours from an e"aporator e"aporating 5000 kg h-1 of water under a pressure of 15 cm of mercury% &he condensing water is a"ailable at 18 ! and the highest allowable temperature for water discharged from the condenser is #5 !. )eat (alance &he pressure in the e"aporator is 15 cm mercury / Zg / 0.15 x 1#.: x 1000 x 9.81 / $0 k8a. 4rom <team &ables, the condensing temperature of water under pressure of $0 k8a is :0 ! and the corresponding latent heat of "apori;ation is $#58 k( kg-1. ?eat remo"ed from condensate per kilogram / $#58 x 10# @ ,:0 - #5- x '.18: x 10# / $.': x 10: ( kg-1 ?eat taken by cooling water / ,#5 - 18- x '.18: x 10# / 1.1 x 10' ( kg-1 Buantity of heat re6uired by condensate per hour / 5000 x $.': x 10: ( &herefore 6uantity of cooling water per hour / ,5000 x $.': x 10:-31.1 x 10' / 1.1 x 105 kg

EXAMPLE .0. )eat exchange area for a &urface con'en&er for an e#a$orator )hat heat exchange area would be re6uired for a surface condenser working under the same conditions as the Cet condenser in >xample 8.$, assuming a J "alue of $$10 ( m -$ s-1 !-1, and disregarding any subcooling of the li6uid. &he temperature differences are small so that the arithmetic mean temperature can be used for the heat exchanger ,condenser-. Iean temperature difference / ,:0 - 18-3$ @ ,:0 - #5-3$ / ##.5 !. &he data are a"ailable from the pre"ious >xample, and remembering to put time in hours. Buantity of heat re6uired by condensate / UA T 5000 x $.': x 10: / $$10 x A x ##.5 x #:00 and so 2 / '5 m$ ?eat transfer area re6uired / '5 m$ &his would be a large surface condenser so that a Cet condenser is often preferred.

If li6uid is to be e"aporated in each effect, and if the boiling point of this li6uid is unaffected by the solute concentration, then writing a heat balance for the first e"aporator* q1 / U1A1,Ts - T1- / U1A1 T1 ,8.1where q1 is the rate of heat transfer, U1 is the o"erall heat transfer coefficient in e"aporator 1, A1 is the heat-transfer area in e"aporator 1, Ts is the temperature of condensing steam from the boiler, T1 is the boiling temperature of the li6uid in e"aporator 1 and T1 is the temperature difference in e"aporator 1, / ,Ts - T1-. <imilarly, in the second e"aporator, remembering that the KsteamK in the second is the "apour from the first e"aporator and that this will condense at approximately the same temperature as it boiled, since pressure changes are small, q$ / U$A$,T1 - T$- / U$A$ T$ in which the subscripts $ indicate the conditions in the second e"aporator. If the e"aporators are working in balance, then all of the "apours from the first effect are condensing and in their turn e"aporating "apours in the second effect. 2lso assuming that heat losses can be neglected, there is no appreciable boiling-point ele"ation of the more concentrated solution, and the feed is supplied at its boiling point, q1 / q$ 4urther, if the e"aporators are so constructed that A1 / A$, the foregoing e6uations can be combined. U$3J1 / T1/T2. ,8.$>6uation ,8.$- states that the temperature differences are in"ersely proportional to the o"erall heat transfer coefficients in the two effects. &his analysis may be extended to any number of effects operated in series, in the same way.

Fee'ing of Multi$le Effect E#a$orator& In a two effect e"aporator, the temperature in the steam chest is higher in the first than in the second effect. In order that the steam pro"ided by the e"aporation in the first effect will boil off li6uid in the second effect, the boiling temperature in the second effect must be lower and so that effect must be under lower pressure. !onse6uently, the pressure in the second effect must be reduced below that in the first. In some cases, the first effect may be at a pressure abo"e atmospheric5 or the first effect may be at atmospheric pressure and the second and subse6uent effects ha"e therefore to be under

increasingly lower pressures. Fften many of the later effects are under "acuum. Jnder these conditions, the li6uid feed progress is simplest if it passes from effect one to effect two, to effect three, and so on, as in these circumstances the feed will flow without pumping. &his is called forwar' fee'. It means that the most concentrated li6uids will occur in the last effect. 2lternati"ely, feed may pass in the re"erse direction, starting in the last effect and proceeding to the first, but in this case the li6uid has to be pumped from one effect to the next against the pressure drops. &his is called (ac1war' fee' and because the concentrated "iscous li6uids can be handled at the highest temperatures in the first effects it usually offers larger e"aporation capacity than forward feed systems, but it may be disad"antageous from the "iewpoint of product 6uality.

A'#antage& of Multi$le*effect E#a$orator& 2t first sight, it may seem that the multiple-effect e"aporator has all the ad"antages, the heat is used o"er and o"er again and we appear to be getting the e"aporation in the second and subse6uent effects for nothing in terms of energy costs. !loser examination shows, howe"er, that there is a price to be paid for the heat economy. In the first effect, q1 / U1A1T1 and in the second effect, q$ / U$A$T$. )e shall now consider a single-effect e"aporator, working under the same pressure as the first effect qs / UsAsTs, where subscript s indicates the single-effect e"aporator. <ince the o"erall conditions are the same, Ts / T1@ T$, as the o"erall temperature drop is between the steam-condensing temperature in the first effect and the e"aporating temperature in the second effect. >ach successi"e steam chest in the multiple-effect e"aporator condenses at the same temperature as that at which the pre"ious effect is e"aporating. Aow, consider the case in which U1 / U$ / Us, and A1 / A$. &he problem then becomes to find As for the single-effect e"aporator that will e"aporate the same 6uantity as the two effects. 4rom the gi"en conditions and from e6n. ,8.$-,

T1 / T$ and Ts/ T1 @ T$ / $T1 T1 / 0.5Ts

Aow q1 @ q$ / U1A1T1 @ U$A$T$ / U1,A1@ A$- Ts3$ but q1 @ q$ / qs and 6s / UAsTs so that ,A1 @ A$-3$ / $A13$ / As &hat is A1 / A$ / As

&he analysis shows that if the same total 6uantity is to be e"aporated, then the heat transfer surface of each of the two effects must be the same as that for a single effect e"aporator working between the same o"erall conditions. &he analysis can be extended to co"er any number of effects and leads to the same conclusions. In multiple effect e"aporators, steam economy has to be paid for by increased capital costs of the e"aporators. <ince the heat transfer areas are generally e6ual in the "arious effects and since in a sense what you are buying in an e"aporator is suitable heat transfer surface, the n effects will cost approximately n times as much as a single effect.

EXAMPLE .2. ,ri$le efect e#a$orator&% &team u&age an' heat tran&fer &urface >stimate the re6uirements of steam and heat-transfer surface, and the e"aporating temperatures in each effect, for a triple effect e"aporator e"aporating 500 kg h -1 of a 107 solution up to a #07 solution. <team is a"ailable at $00 k8a gauge and the pressure in the e"aporation space in the final effect is :0 k8a absolute. 2ssume that the o"erall heat-transfer coefficients are $$10, $000 and 1'$0 ( m-$ s-1 !-1 in the first, second and third effects respecti"ely. Aeglect sensible-heat effects and assume no boiling-point ele"ation, and e6ual heat transfer in each effect. Ma&& (alance ,kg h-1<olids 4eed 8roduct >"aporation 50 50 =i6uids '50 111 &otal 500 1:1 ###

)eat (alance 4rom steam tables, the condensing temperature of steam at $00 k8a ,g- is 1#' ! and the latent heat is $1:' k( kg -1. >"aporating temperature in final effect under pressure of :0 k8a ,abs.- is 8: !, as there is no boiling-point rise and latent heat is $$9' k( kg -1. >6uating the heat transfer in each effect* q1 / q$ / q# U1A1T1 / U$A$ T$ / U#A#T#

2nd

T1 @ T$ @ T# / ,1#' - 8:- / '8 !.

so that T1,1 @ U13U$ @ U13U#- / '8,

Aow, if A1 / A$ / A# then T$ / U1T1 3U$ and T# / U1T1 3U#

T1 x +1 @ ,$$103$000- @ ,$$1031'$0-. / '8 #.1#T1 / '8

T1

/ 1$.9 !,

and T# / T1 x ,$$1031'$0- / $0.: !

T$ / T1 x ,$$103$000- / 1'.: !

2nd so the e"aporating temperature* in first effect is ,1#' - 1$.9- / 1$1 !5 latent heat ,from <team &ables- $$00 k( kg -1. in second effect is ,1$1 - 1'.:- / 10:.5 !5 latent heat $$'0 k( kg-1 in the third effect is ,10:.5 - $0.:- / 8: !, latent heat $$9' k( kg -1 >6uating the 6uantities e"aporated in each effect and neglecting the sensible heat changes, if w 1, w$, w# are the respecti"e 6uantities e"aporated in effects 1,$ and #, and ws is the 6uantity of steam condensed per hour in effect 1, then w1 x $$00 x 10# / w$ x $$'0 x 10# / w# x $$9' x 10# / ws x $1:' x 10# &he sum of the 6uantities e"aporated in each effect must e6ual the total e"aporated in all three effects so that* w1 @ w$ @ w# / ### and sol"ing as abo"e, w1 / 11# ws / 115 w$ / 111 w# / 108

"team con&um$tion It re6uired 115 kg steam ,ws- to e"aporate a total of ### kg water, that is 0.#5kg steam3kg water e"aporated. )eat exchanger &urface. )riting a heat balance on the first effect* ,11# x $$00 x 1000-3#:00 / $$10 x A x 1$.9 A1 / $.' m$ / A$ / A# total area / A1 @ A$ @ A# / 1.$ m$. Aote that the conditions of this example are considerably simplified, in that sensible heat and feed heating effects are neglected, and no boiling-point rise occurs. &he general method remains the same in the more complicated cases, but it is often easier to sol"e the heat balance e6uations by trial and error rather than by analytical methods, refining the approximations as far as necessary.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Valve & Amplifier Design, Valve EquivalentsDokumen51 halamanValve & Amplifier Design, Valve EquivalentsValve Data80% (5)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- National Telecommunication Corporation (NTC)Dokumen40 halamanNational Telecommunication Corporation (NTC)Faheem Sajid100% (1)

- Electronic Modular Control Panel II Paralleling Emcp II P Systems Operation Troubleshooting Testing and Adjusting CaterpillarDokumen200 halamanElectronic Modular Control Panel II Paralleling Emcp II P Systems Operation Troubleshooting Testing and Adjusting CaterpillarAbdo MalkiBelum ada peringkat

- Chapter Five Decision Theories and AnalysisDokumen47 halamanChapter Five Decision Theories and AnalysisAbdela AyalewBelum ada peringkat

- New Model For Predicting Thermal Radiation From Flares and High Pressure Jet Fires For Hydrogen and SyngasDokumen15 halamanNew Model For Predicting Thermal Radiation From Flares and High Pressure Jet Fires For Hydrogen and Syngasthlim19078656Belum ada peringkat

- 04931V - 396 ToolingDokumen52 halaman04931V - 396 Toolingpiston brokeBelum ada peringkat

- UNIT1-Demand Management in Supply Chain Demand Planning and ForecastingDokumen20 halamanUNIT1-Demand Management in Supply Chain Demand Planning and Forecastingshenbha50% (2)

- Flue Gas Analysis in IndustryDokumen150 halamanFlue Gas Analysis in Industryblack_knight728Belum ada peringkat

- Read ItDokumen4 halamanRead Itchhinder13Belum ada peringkat

- Ghorhi Sithniyaan Punjabi MarriagesDokumen10 halamanGhorhi Sithniyaan Punjabi Marriageschhinder13100% (1)

- ؘ≈È≈ ⁄Û∑Áδ'Ò≈, Í«‡¡≈Ò≈ (Ùπæ'Ú≈, �Bb�¡Ízàò B@Bb) Daily Charhdikala, Patiala (Friday, 22 April, 2022)Dokumen1 halamanؘ≈È≈ ⁄Û∑Áδ'Ò≈, Í«‡¡≈Ò≈ (Ùπæ'Ú≈, �Bb�¡Ízàò B@Bb) Daily Charhdikala, Patiala (Friday, 22 April, 2022)chhinder13Belum ada peringkat

- SAP Installation GuidelinesDokumen1 halamanSAP Installation Guidelineschhinder13Belum ada peringkat

- Suhaag Ghorhiyan PunjabDokumen8 halamanSuhaag Ghorhiyan Punjabchhinder13Belum ada peringkat

- CCS (Conduct) Rules - Session 4.1 & 4.2Dokumen165 halamanCCS (Conduct) Rules - Session 4.1 & 4.2chhinder13Belum ada peringkat

- Circular.02 Dated 15.05.2013Dokumen2 halamanCircular.02 Dated 15.05.2013chhinder13Belum ada peringkat

- Story of Mulla NasrudinDokumen12 halamanStory of Mulla Nasrudinchhinder13Belum ada peringkat

- Ramayana StoryDokumen17 halamanRamayana Storychhinder13Belum ada peringkat

- Revised AISRule 100913Dokumen163 halamanRevised AISRule 100913chhinder13Belum ada peringkat

- Executive Instructions On PARDokumen14 halamanExecutive Instructions On PARchhinder13Belum ada peringkat

- Moneygram RequestDokumen2 halamanMoneygram Requestchhinder13Belum ada peringkat

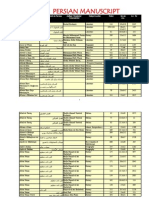

- Persian ManuscriptDokumen214 halamanPersian Manuscriptdrali508482100% (3)

- National Academy Pratibha Sangeet PDFDokumen17 halamanNational Academy Pratibha Sangeet PDFchhinder130% (1)

- All or Nothing Jay SeanDokumen7 halamanAll or Nothing Jay Seanchhinder13Belum ada peringkat

- FrecklesDokumen2 halamanFreckleschhinder13Belum ada peringkat

- Actual Face of RamdevDokumen19 halamanActual Face of Ramdevchhinder13Belum ada peringkat

- Source: Nokia C7 Video Specifications DimensionsDokumen6 halamanSource: Nokia C7 Video Specifications Dimensionschhinder13Belum ada peringkat

- Saade TyoharDokumen7 halamanSaade Tyoharchhinder13Belum ada peringkat

- R172 NTG4.5 EngineeringMenuDokumen5 halamanR172 NTG4.5 EngineeringMenualeksandar_tudzarovBelum ada peringkat

- Caliper Xy MemoryDokumen6 halamanCaliper Xy MemoryA MuBelum ada peringkat

- Efectele Pe Termen Lung Ale Alaptatului OMSDokumen74 halamanEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiBelum ada peringkat

- GGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilDokumen5 halamanGGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilAmizan AbdullahBelum ada peringkat

- Arthashastra: Citation NeededDokumen4 halamanArthashastra: Citation NeededtusharBelum ada peringkat

- Astm A106-2002Dokumen13 halamanAstm A106-2002henryBelum ada peringkat

- Vector AlgebraDokumen7 halamanVector AlgebraDeeeBelum ada peringkat

- Question & Answers: Unity Solutions Specialist Exam For Implementation EngineersDokumen6 halamanQuestion & Answers: Unity Solutions Specialist Exam For Implementation EngineersAhmad Abd-dayeemBelum ada peringkat

- Coding 3 D ShapesDokumen10 halamanCoding 3 D ShapesgmconBelum ada peringkat

- Precima Frenos FDW ATEX Operating InstructionsDokumen6 halamanPrecima Frenos FDW ATEX Operating InstructionsToni RenedoBelum ada peringkat

- Devlopment and Analysis of Natural Banana Fiber CompositeDokumen3 halamanDevlopment and Analysis of Natural Banana Fiber CompositeEditor IJRITCCBelum ada peringkat

- Pseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in ADokumen3 halamanPseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in AChristian Doson EstilloreBelum ada peringkat

- FELPRO - Tablas-de-Torque - 035Dokumen1 halamanFELPRO - Tablas-de-Torque - 035Clodoaldo BiassioBelum ada peringkat

- PDF To Image Converter v2 HOW TO USEDokumen3 halamanPDF To Image Converter v2 HOW TO USEfairfaxcyclesBelum ada peringkat

- Tugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)Dokumen4 halamanTugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)fitriani choerunnisaBelum ada peringkat

- The Mathematical Society of Serbia - 60 YearsDokumen23 halamanThe Mathematical Society of Serbia - 60 YearsBranko Ma Branko TadicBelum ada peringkat

- Ec2203-Unit IV Memory Devices Digital ElectronicsDokumen38 halamanEc2203-Unit IV Memory Devices Digital ElectronicsKarthikeyan_Go_952567% (6)

- Clipping Clamping CircuitsDokumen7 halamanClipping Clamping CircuitsPavan SaiBelum ada peringkat

- Fourier Transform: MATHS (Hons), Second YEARDokumen120 halamanFourier Transform: MATHS (Hons), Second YEARmanish chauhanBelum ada peringkat

- 1.basic Electrical Engineering Lecture Part-1Dokumen17 halaman1.basic Electrical Engineering Lecture Part-1jimvalenciaBelum ada peringkat

- Register Transfer LanguageDokumen11 halamanRegister Transfer LanguageShiva IdokBelum ada peringkat

- 2015-NBLUCK LK260 Engine Part ListDokumen16 halaman2015-NBLUCK LK260 Engine Part ListPedroBelum ada peringkat