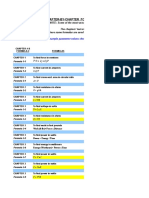

Relative Cost Analysis

Diunggah oleh

Shekhar YadavHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Relative Cost Analysis

Diunggah oleh

Shekhar YadavHak Cipta:

Format Tersedia

Relative Cost analysis Steps; 1.Focus on particular product line or services.

Typically focusses on line that overlap most with competitor Largest line Line for which cot difference matter. 2. Construction of own cost structure 3. Building up estimate of competitor current cost structure. Finding drivers of cost of each item and how rival differs in each driver. Driver of factor cost. Bargaining power over supplier Location Policy Choices Driver of Productivity Scale Capacity Utilization Experience Policy Choices 4.Use of cost analysis to conduct what if analysis.

Good habits in relative cost analyses. 1.Keep Ethics in mind. Avoid bribing, misrepresenting, 2.Triangulate Try to confirm cost estimate by multiple angles. 3.Use publicly available data with caution. Try to build up cost estimate with bottom up approach. 4. Consider marginal cost as well as total cost For some analysis marginal cost is important whereas for other total cost is important. 5.Fill the gap Make best assumption ,double check the assumption .

Do sensitivity analysis for uncertain cost item . 6.Practice Requires trial and error,iteration, guidance from experienced individuals patience and lot of practice. Competitive cost analysis Strategic application of cost modelling. It allows for a direct comparison for a company and one of its prodects or services with a direct competitor or competitive offerings. Can be used to compare supplies with one another or with an in house option. It starts with basic understanding of cost accounting elemets- raw matrial ,overhead. Cost elements vs cost driver Cost element :Material cost ,Labour cost,Overhead and profit,Transportation cost Cost Driver : Purchasing scale.Plant Location ,Process technology ,product technology,Quality yield,Plant Layout, capacity utilization,demand variability, past standardization shipping mode,delivry lead time etc. Rigorous cost driver analysis to obtain optimal footprint strategy. Booz Allen Hamiltion Cost Driver Framework.

Principle of Cost Modelling 1. Capture Cost Driver not Cost element Cost Driver generate tru insight it answers what if whereas cost elements answers what is.What drives the cost .is it controllable or relevant in the context of competitive cost analysis.

2. Avoid Generic Templates Models A standard Tempates fails to recognize the range of possible cost modelling goals.It can capture standard cost elements only thoughtful modelling can discern and differentiate the cost drivers. 3. Consider total Cost of Ownership It should consider total ownership cost including non price components like inventory carrying cost ,Customer Scrap rate etc. 4. Start simple and Add complexity as needed Build a basic cost modeller with focus on critical cost driver and then try to increase the complexity to develop different cost driver relationships, dependency and impacts. Developing an initial complex model will produce noise that would obscure the most critical cost driver relationships. 5. Traingulate the data Obtaining reliable is the key chllanges in cost driver analysis.Triangulating dat from multiple source or from same soucrce over a period of time ensures the validity of input data yielding the best insight with more accuracy. TOOLS TO ANALYZE THE Cost drivers TEAR DOWN ANALYSIS It consists of physical disassembaly and piecemeal analysis of complete product.It catalogs each part,including the type of material,the probable process employed and the weight of the component. Usefule in design driven costs. Public Data Source Source of information are : Annual Report ,10 K SEC Filing,Companies web site.Information of industry by investment banks /consultant.Trade association, Govt and other NNon profit Orgabizatin reports.

Scale Curves and Utilization Impact. Scale Curves measure production costs as a function of facility capacity. Utilization crves measures the impact within a single facility of operating at some level other than full capacity. Average unit cost = Variabel unit cost +fixed cost/quantity

Thus Utilization curve quantifies the effect of volume changes in on a facility of a given size and the Scale curve compares facilities of different sizes.

These two types of curve can be combined to provide insight on the relative importance of scale and utilization and the sensitivity to volume changes for a given facility.

Anda mungkin juga menyukai

- Simulado 5 (PREP) - BC 1Dokumen7 halamanSimulado 5 (PREP) - BC 1Maria Clara OliveiraBelum ada peringkat

- Adolph Coors (1) Group 1Dokumen8 halamanAdolph Coors (1) Group 1HaroonNasirBelum ada peringkat

- Innovation Simulation: Breaking News: HBP Product No. 8678Dokumen9 halamanInnovation Simulation: Breaking News: HBP Product No. 8678Karan ShahBelum ada peringkat

- Case 9Dokumen1 halamanCase 9Aditya KulashriBelum ada peringkat

- Industrial Organization How Is The U.S. American Fast Food Industry StructuredDokumen10 halamanIndustrial Organization How Is The U.S. American Fast Food Industry StructuredLaura SchulzBelum ada peringkat

- Financial Management E BookDokumen4 halamanFinancial Management E BookAnshul MishraBelum ada peringkat

- Ad MartDokumen10 halamanAd Martavik_bang100% (1)

- STAMYPOR MANAGEMENT OF INNOVATIONDokumen15 halamanSTAMYPOR MANAGEMENT OF INNOVATIONrockysanjitBelum ada peringkat

- Case Study: A Negotiation Between A Shopping Centre and A RetailerDokumen30 halamanCase Study: A Negotiation Between A Shopping Centre and A RetailerDheeraj MaddeBelum ada peringkat

- B2B Marketing - Jyoti - Sagar - P19052Dokumen5 halamanB2B Marketing - Jyoti - Sagar - P19052JYOTI TALUKDARBelum ada peringkat

- BOP ExpandingOpportunity+ (Fullreport) PDFDokumen324 halamanBOP ExpandingOpportunity+ (Fullreport) PDFSher Singh YadavBelum ada peringkat

- Shobhit Saxena - CSTR - Assignment IDokumen4 halamanShobhit Saxena - CSTR - Assignment IShobhit SaxenaBelum ada peringkat

- Vodafone Mannesmann Hostile TakeoverDokumen2 halamanVodafone Mannesmann Hostile Takeoverulaluca100% (1)

- Emirates Airline Success Behind Solid GrowthDokumen1 halamanEmirates Airline Success Behind Solid GrowthChRehanAliBelum ada peringkat

- John A. Quelch - Faculty & Research - Harvard Business SchoolDokumen42 halamanJohn A. Quelch - Faculty & Research - Harvard Business SchoolChristopherLalbiaknia0% (3)

- AkilAfzal ZR2001040 FinalDokumen4 halamanAkilAfzal ZR2001040 FinalAkil AfzalBelum ada peringkat

- Besanko SummaryDokumen30 halamanBesanko SummaryCindy OrangeBelum ada peringkat

- GE Medical Systems International Business AssignmentDokumen4 halamanGE Medical Systems International Business AssignmentMarissa BradleyBelum ada peringkat

- Dynamics Capabilities Modelo PPT MomoDokumen44 halamanDynamics Capabilities Modelo PPT MomoluanasimonBelum ada peringkat

- BP and The Consolidation of The Oil IndustryDokumen3 halamanBP and The Consolidation of The Oil IndustrySwati VermaBelum ada peringkat

- Learn) .: CRM Case Study EMBA 2015-2016 Soham Pradhan (Uemf15027)Dokumen2 halamanLearn) .: CRM Case Study EMBA 2015-2016 Soham Pradhan (Uemf15027)ashishBelum ada peringkat

- Vers Hire Company Study CaseDokumen11 halamanVers Hire Company Study CaseAradhysta SvarnabhumiBelum ada peringkat

- Hubspot CaseDokumen4 halamanHubspot CaseMaria NavherráizBelum ada peringkat

- MKTG Strategy Ch 1 Key Points on Orientations, Imperatives, and PrinciplesDokumen2 halamanMKTG Strategy Ch 1 Key Points on Orientations, Imperatives, and PrinciplesPrakash RanjanBelum ada peringkat

- Porter's Five Force Analysis of Industry: Rivalry Among Competitors - Attractiveness: HighDokumen5 halamanPorter's Five Force Analysis of Industry: Rivalry Among Competitors - Attractiveness: HighPrasanta MondalBelum ada peringkat

- SMMD: Practice Problem Set 3 Confidence IntervalsDokumen2 halamanSMMD: Practice Problem Set 3 Confidence Intervalsbala sanchitBelum ada peringkat

- Case Study WS MorrisonDokumen7 halamanCase Study WS Morrisonida barrieBelum ada peringkat

- AMUL-STP N SWOTDokumen9 halamanAMUL-STP N SWOTAmol Gade100% (2)

- Ashwani Gupta 2019SMF6652 Newell Case StudyDokumen3 halamanAshwani Gupta 2019SMF6652 Newell Case Studypooja guptaBelum ada peringkat

- Boise Automation Lost OrderDokumen13 halamanBoise Automation Lost OrderAntony LawrenceBelum ada peringkat

- Bayonne Packaging, Inc - Case Solution QualityDokumen19 halamanBayonne Packaging, Inc - Case Solution QualityCheenu JainBelum ada peringkat

- Marketing Decision-Product & PromotionDokumen30 halamanMarketing Decision-Product & PromotionSouvik Ghosh100% (1)

- Rationale For Unrelated Product Diversification For Indian FirmsDokumen10 halamanRationale For Unrelated Product Diversification For Indian FirmsarcherselevatorsBelum ada peringkat

- Bancolombia EosDokumen10 halamanBancolombia Eosamishaa13Belum ada peringkat

- A Practical Guide To Conjoint Analysis M-0675Dokumen9 halamanA Practical Guide To Conjoint Analysis M-0675Sriram ChepuriBelum ada peringkat

- Medicult Case Discussion QuestionsDokumen1 halamanMedicult Case Discussion QuestionsAhmad NazirBelum ada peringkat

- Maruti Suzuki India Limited HRM IIMDokumen5 halamanMaruti Suzuki India Limited HRM IIMIIMnotes100% (1)

- Piyush Sevaldasani C WAC1 1Dokumen5 halamanPiyush Sevaldasani C WAC1 1Piyush SevaldasaniBelum ada peringkat

- Tata Motors and The Automotive IndustryDokumen28 halamanTata Motors and The Automotive IndustryshyriciousBelum ada peringkat

- Product Proliferation and Preemption Strategy SupplementsDokumen22 halamanProduct Proliferation and Preemption Strategy SupplementstantanwyBelum ada peringkat

- Vora & Company case study analysisDokumen6 halamanVora & Company case study analysisPrashant NarulaBelum ada peringkat

- Program: MBA-Master in Business Administration: Student: Mislav MatijevićDokumen4 halamanProgram: MBA-Master in Business Administration: Student: Mislav MatijevićMislav MatijevićBelum ada peringkat

- Assignment 1 - Raffin CaseDokumen2 halamanAssignment 1 - Raffin CaseGaurav MundraBelum ada peringkat

- Apple Company's High Switching Cost To Enforce Customer Loyalty.Dokumen10 halamanApple Company's High Switching Cost To Enforce Customer Loyalty.Diyaree FayliBelum ada peringkat

- Case Study: Corporate New Ventures at Procter and GambleDokumen5 halamanCase Study: Corporate New Ventures at Procter and GambleVerVe LimBelum ada peringkat

- S0.0 MAACS Course Outline Mar Apr 2019Dokumen9 halamanS0.0 MAACS Course Outline Mar Apr 2019Hongwei ZhangBelum ada peringkat

- Case 2 Giovanni Buton (COMPLETE)Dokumen8 halamanCase 2 Giovanni Buton (COMPLETE)Austin Grace WeeBelum ada peringkat

- Marketing Strategies that Help Safexpress Gain DominanceDokumen6 halamanMarketing Strategies that Help Safexpress Gain DominanceArjun KatariaBelum ada peringkat

- Best Buy Co-Case AnalysisDokumen1 halamanBest Buy Co-Case Analysisgane009Belum ada peringkat

- Q1. What Are The Organizational and Operational Issues That Underlie The Problems Facing BPS?Dokumen5 halamanQ1. What Are The Organizational and Operational Issues That Underlie The Problems Facing BPS?Munsif JavedBelum ada peringkat

- The Parenting Matrix Sum UpDokumen2 halamanThe Parenting Matrix Sum Upilikesummer1234Belum ada peringkat

- Summary of Case Study A New Approach To Contracts by Oliver Hart and David FrydlingerDokumen2 halamanSummary of Case Study A New Approach To Contracts by Oliver Hart and David FrydlingerYasi Eemo100% (1)

- Appollo Case StudyDokumen1 halamanAppollo Case StudyNirmalya MukherjeeBelum ada peringkat

- Marriott CorporationDokumen8 halamanMarriott CorporationtarunBelum ada peringkat

- An Analysis of Corporate Governance Imbroglio at InfosysDokumen5 halamanAn Analysis of Corporate Governance Imbroglio at InfosysBen HiranBelum ada peringkat

- SIEMENSDokumen7 halamanSIEMENSGian Carlos Avila100% (1)

- Product Line Management A Complete Guide - 2019 EditionDari EverandProduct Line Management A Complete Guide - 2019 EditionBelum ada peringkat

- Gamification in Consumer Research A Clear and Concise ReferenceDari EverandGamification in Consumer Research A Clear and Concise ReferenceBelum ada peringkat

- Session 8Dokumen6 halamanSession 8Krunal KapadiyaBelum ada peringkat

- 8 Ways Leaders Can Motivate Employees Beyond Money - ForbesDokumen4 halaman8 Ways Leaders Can Motivate Employees Beyond Money - ForbesShekhar YadavBelum ada peringkat

- AQUALISA QUARTZ: Simply A Better ShowerDokumen44 halamanAQUALISA QUARTZ: Simply A Better ShowerFiqi Dipowicaksono87% (15)

- Aqualisa Quartz: Simply A Better ShowerDokumen40 halamanAqualisa Quartz: Simply A Better ShowerShekhar YadavBelum ada peringkat

- CapstoneDokumen28 halamanCapstonePrateek SoniBelum ada peringkat

- Achieve Investment Goals Using 'Systematic' Features of Mutual FundsDokumen4 halamanAchieve Investment Goals Using 'Systematic' Features of Mutual FundsShekhar YadavBelum ada peringkat

- Carbon FootprintsDokumen2 halamanCarbon FootprintsShekhar YadavBelum ada peringkat

- Aqualisa Quartz: Group No. 1Dokumen19 halamanAqualisa Quartz: Group No. 1Shekhar Yadav100% (1)

- MCN For GMP at Xlri PhoneticsDokumen5 halamanMCN For GMP at Xlri PhoneticsShekhar YadavBelum ada peringkat

- MBA Resume SampleDokumen1 halamanMBA Resume SampleSumanta Sarathi BiswasBelum ada peringkat

- Consulting CompaniesDokumen1 halamanConsulting CompaniesShekhar YadavBelum ada peringkat

- Energy Consulting FirmsDokumen4 halamanEnergy Consulting FirmsKatie BranchBelum ada peringkat

- Analysis of The Talbots, IncDokumen20 halamanAnalysis of The Talbots, IncShekhar YadavBelum ada peringkat

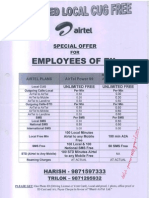

- Wffiffiwffiffiffi: Employees of EilDokumen1 halamanWffiffiwffiffiffi: Employees of EilShekhar YadavBelum ada peringkat

- Wffiffiwffiffiffi: Employees of EilDokumen1 halamanWffiffiwffiffiffi: Employees of EilShekhar YadavBelum ada peringkat

- GMAT Progress ChartDokumen4 halamanGMAT Progress ChartAbhishek BharadiyaBelum ada peringkat

- حل جميع المعادلات الكهربائيةDokumen60 halamanحل جميع المعادلات الكهربائيةGandhi HammoudBelum ada peringkat

- Waukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsDokumen6 halamanWaukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsLUISA FERNANDA TORRES MANOSALVABelum ada peringkat

- Report On Corporate Communication Strategy Analysis ofDokumen38 halamanReport On Corporate Communication Strategy Analysis ofNAFISA ISLAMBelum ada peringkat

- Data Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewDokumen14 halamanData Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewSara GuimarãesBelum ada peringkat

- Primary Mathematics Book 5Dokumen87 halamanPrimary Mathematics Book 5joseph kunikina0% (1)

- Aluminium GMAW GuideDokumen32 halamanAluminium GMAW GuideDaniel Salinas100% (2)

- INFRARED BASED VISITOR COUNTER TECHNOLOGYDokumen21 halamanINFRARED BASED VISITOR COUNTER TECHNOLOGYRahul KumarBelum ada peringkat

- Cheat SheetDokumen50 halamanCheat SheetAnubhav ChaturvediBelum ada peringkat

- Circular Tank Radius CalculationDokumen25 halamanCircular Tank Radius CalculationQamar AbbasBelum ada peringkat

- Basic Computer ConceptsDokumen77 halamanBasic Computer ConceptsJerry Mugambi100% (1)

- YEZ-Conical Brake MotorDokumen3 halamanYEZ-Conical Brake MotorMech MallBelum ada peringkat

- A134 PDFDokumen4 halamanA134 PDFJarbas MoraesBelum ada peringkat

- Scrap NFL PanipatDokumen9 halamanScrap NFL PanipatJitenderSinghBelum ada peringkat

- 0 EDEM Applications MeDokumen16 halaman0 EDEM Applications MeRuben PurcaBelum ada peringkat

- PrintedElectronics ProductOverview PDFDokumen2 halamanPrintedElectronics ProductOverview PDFanon_551622158Belum ada peringkat

- Builder's Greywater Guide Branched DrainDokumen4 halamanBuilder's Greywater Guide Branched DrainGreen Action Sustainable Technology GroupBelum ada peringkat

- Astm D-2361Dokumen4 halamanAstm D-2361Claudia Da Rolt0% (1)

- Royal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale QuotationDokumen3 halamanRoyal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale Quotationmuhammad aliBelum ada peringkat

- Jotafloor SL UniversalDokumen6 halamanJotafloor SL UniversalrogandatambunanBelum ada peringkat

- Brief Summary of The Original COCOMO ModelDokumen5 halamanBrief Summary of The Original COCOMO ModelTirthajit SinhaBelum ada peringkat

- Direct Burial Optic Fiber Cable Specification - KSD2019 PDFDokumen5 halamanDirect Burial Optic Fiber Cable Specification - KSD2019 PDFjerjyBelum ada peringkat

- Safety Training Evaluation Form: Instructor RatingDokumen1 halamanSafety Training Evaluation Form: Instructor RatingNate JamesBelum ada peringkat

- L04-L05 Parts 13-25-550 v05 42021Dokumen84 halamanL04-L05 Parts 13-25-550 v05 42021Brandi HillBelum ada peringkat

- SPW3 Manual Rev 5Dokumen713 halamanSPW3 Manual Rev 5JPYadavBelum ada peringkat

- Enclosed Product Catalogue 2012Dokumen24 halamanEnclosed Product Catalogue 2012Jon BerryBelum ada peringkat

- Nazneen Wahab CVDokumen5 halamanNazneen Wahab CVRavi MittalBelum ada peringkat

- JonWeisseBUS450 04 HPDokumen3 halamanJonWeisseBUS450 04 HPJonathan WeisseBelum ada peringkat

- Vlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyDokumen12 halamanVlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyRaghul VishnuBelum ada peringkat

- How The Draganflyer Flies: So How Does It Work?Dokumen5 halamanHow The Draganflyer Flies: So How Does It Work?sav33Belum ada peringkat

- Counter List HuaweiDokumen14 halamanCounter List Huaweiwedewe02Belum ada peringkat