Final Report

Diunggah oleh

group2sd1314Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Final Report

Diunggah oleh

group2sd1314Hak Cipta:

Format Tersedia

FINAL REPORT

KEADUE WWTP UPGRADE WORKS

KMCF ENGINEERING DUBLIN ROAD ATHLONE

2014

Table of Contents 1.0 Project Brief ......................................................................................................................... 1 2.0 Background to Site ............................................................................................................... 2 2.1 Environmental constraints in Keadue .............................................................................. 2 2.1.1 Subsoil Database........................................................................................................ 3 2.1.2 Natural Heritage Area ................................................................................................ 4 2.1.3 Other Relevant Maps ................................................................................................. 6 3.0 Feasibility Study ................................................................................................................... 6 4.0 Scheduling ............................................................................................................................ 7 4.1 Construction Schedule ..................................................................................................... 7 4.2 Work Schedule ................................................................................................................. 7 5.0 Monitoring System............................................................................................................... 7 5.1 Earned Value Management.............................................................................................. 8 5.2 Function to allow for delay in project .............................................................................. 8 5.2.1 Programme Contingency/ Extension of Time............................................................ 8 5.2.2 Adjustment to contract sum...................................................................................... 9 5.3 Automated Report Generator .......................................................................................... 9 Appendices............................................................................................................................... 10

List of Figures

Figure 1: County and Province Map which the red mark is where the location of sample is taken .......................................................................................................................................... 3 Figure 2: Kilronan Mountain Bog (NHA) in yellow colour.......................................................... 5 Figure 3: Corrigeenroe Marsh conservation area in yellow colour. .......................................... 5

List of Table

Table 1: Geo Chemical Information present on the samples: ................................................... 4

1.0 Project Brief KMCF are the Tendering Team working for a Small Civil Engineering contracting organisation. Tendering Manager has requested to prepare a submission for senior management documenting that the company approach to selecting a tender design for use in a design and build works proposal which is Upgrade Works of Keadue Waste Water Treatment Plant (WWTP) and project team is to develop a generic tender selection system which is applicable to all future work for Keadue development. In addition, the company are also requested to document how the KMCF Project Team could handle the proposal, in the tender format provided, and develop a schedule and cost performance system for use during the contract phase. The KMCF team shall prepare the requisite quality and management systems necessary to perform the following: Responsibility Assignment Matrix A feasibility assessment system on two design options for the planned development of the existing WWTP. The system is used as the basis for the development of a generic system. A construction and works schedule tailored to the development requirements of the chosen WWTP tender. The project team shall host all information on a WordPress intranet for ease of access by both middle and senior management. Video presentations shall be prepared for the project. Tender Documentation should consider the following: FTS4 Tender and Schedule Scope of the Works Schedule of Prices Contract Drawings

2.0 Background to Site Keadue, Co. Roscommon has been chosen as the trial site for the incorporation of this tendering and performance monitoring system. The site is located close to Ballyfarnon 6 miles North of Boyle. It is on the location of the existing treatment works for the village. The effluent flows by gravity through the existing works. The current treatment system existed on site is Traditional type system which can serve approximately 300 PE and it consists of the following elements: 1 no. Split flow chamber and screens 1 no. Imhoff tank 1 no. Rotary Filter 1 no. Humus Tank 3 no. Sludge drying beds 1 no. Outlet inspection chamber 1 no. Reed bed

Lough Meelagh will be the location where the final effluent will be discharged, which is in close proximity to the proposed site. The site is located off R284 from where the works are easily accessible. It is proposed to incorporate a treatment plant into the existing works and to utilise as much of the existing works if possible. The age of plant is almost 25 years old and upgrade works are necessary to meet the current and future demand as well as to improve the quality of effluents produced. According to (Roscommon County Council, 2008-2014), it is estimated about 5% and 45% of high population growth in rural development increases over 6 years.

2.1 Environmental constraints in Keadue

A full Environmental Impact Assessment (EIA) and quite possibly Environmental Impact Statement (EIS) would normally be conducted as discussed in this section. 2

2.1.1 Subsoil Database Based on research conducted by National Soils Database which can be accessed in EPA website, samples are taken approximately 0.48 km distance away from Keadue as shown in Figure 1.

Figure 1: County and Province Map which the red mark is where the location of sample is taken. Sandstone is the type of rock present in the samples having acidic pH 5.4. Table 1 below is the geo chemical result produced by the collected samples which possibly would drive the elements to the WWTP in Keadue.

Table 1: Geo Chemical Information present on the samples.

pH 5.4 Available Phosphorus 6.17 Available Magnesium 295 Aluminium (Al) % 4.49 Barium (Ba) mg/kg 198.9 Cadmium (Cd) mg/kg 0.989% Cobalt (Co)mg/kg 8.3 Copper (Cu) mg/kg 48.4 Gallium (Ga) mg/kg 12.63 mg/kg Mercury (Hg) mg/kg 0.115 mg/kg Lanthanum (La) mg/kg 19.7 mg/kg Magnesium (Mg) % 0.277% Molybdenum (Mo) mg/kg 14.36 mg/kg Niobium (Nb) mg/kg 7.55 mg/kg Phosphorus (P) % 0.176% Rubidium (Rb) mg/kg 52.4 mg/kg Antimony (Sb) mg/kg 1.41 mg/kg Selenium (Se) mg/kg 1.88 mg/kg Strontium (Sr) mg/kg 61.9 mg/kg Thorium (Th) mg/kg 4.42 mg/kg Thallium (Tl) mg/kg 0.938 mg/kg Vanadium (V) mg/kg 155.4 mg/kg Yttrium (Y) mg/kg 7.89 mg/kg Soil Organic Carbon (SOC) 7.07% Available Potassium 132.85 Arsenic (As) mg/kg 11.69 Calcium (Ca)% 0.453 Cerium (Ce)mg/kg 37.2 Chromium (Cr)mg/kg 62.1 Iron (Fe) % 2.6% Germanium (Ge) mg/kg 1.37 mg/kg Potassium (K) % 0.53% Lithium (Li) mg/kg 37.8 mg/kg Manganese (Mn) mg/kg 1155 mg/kg Sodium (Na) % 0.202% Nickel (Ni) mg/kg 21.1 mg/kg Lead (Pb) mg/kg 38.9 mg/kg Sulphur (S) % 0.085% Scandium (Sc) mg/kg 6.05 mg/kg Tin (Sn) mg/kg 2.82 mg/kg Tantalum (Ta) mg/kg 0.54 mg/kg Titanium (Ti) mg/kg 2177 mg/kg Uranium (U) mg/kg 5.19 mg/kg Tungsten (W) mg/kg 0.76 mg/kg Zinc (Z) mg/kg 88.6 mg/kg

2.1.2 Natural Heritage Area Kilronan Mountain Bog (NHA) is the conservation area for upland blanket bog habitat including Purple Moor-grass (Molinia caerulea), Hares-tail Cottongrass (Eriophorum vaginatum) and Ling Heather (Calluna vulgaris). This mountain is a protected area near to Keadue WWTP as shown in Figure 2.

Location of Site

Figure 2: Kilronan Mountain Bog (NHA) in yellow colour.

There are two others proposed Natural Heritage Area including Lough Allen and Corrigeenroe Marsh that exists further away from Keadue WWTP as shown in Figure 3.

Location of Site

Figure 3: Corrigeenroe Marsh conservation area in yellow colour.

According to (Natural Heritage Area, 2005), any works will be constructed within this area and the surrounding, must be specified for the purposes under section 19 (1) of the Act.

2.1.3 Other Relevant Maps The following are relevant maps that also being considered in conjunction to the location of the Keadue WWTP: Aquifer Data (refer Appendix A) Bedrock - Structural Linework & Solid Geology (refer Appendix B) Bedrock - Generalised Map (refer Appendix C) Groundwater Well Data (refer Appendix D) Karst Features (refer Appendix E) Recharge Data (refer Appendix F) River Basin District Boundaries & Groundwater Bodies (refer Appendix G) Source Protection Area Data (refer Appendix H) Teagasc Subsoil Data (refer Appendix I) Vulnerability Data (refer Appendix J)

This project is purely a desktop study and therefore those components cannot be completed. In addition, due to Environmental constraints and insufficient of information, the BMS package with 20/30 quality effluent was chosen. The proposed system on site will be discussed under the feasibility study section.

3.0 Feasibility Study IT package was developed to compare 10 various package systems and a conventional treatment system. Initial comparisons consideration: PE (current and future demand) Size of plant Biochemical Oxygen Demand (BOD) SS (Suspended Solids) 6

Final comparisons consideration (Narrowed to the two best packages): Ease of construction Economical use of land Time for completion Ecological footprint

Furthermore, this section also included alterations to compare different type of systems. For instance larger systems could be compared for bigger sites.

4.0 Scheduling Developed in a generic fashion to allow for the schedule to be altered for different sites or the use of a conventional system.

4.1 Construction Schedule

Construction Scheduling is a process of breaking down a project into smaller activities and the durations of time each will take, then organizing them into an order of actions to be taken to finish the job. The contractor will have Start dates and finish dates for every task and main goal is to determine a total duration of the project.

4.2 Work Schedule

A schedule of works as used in the construction industry refers to a schedule that is a basic timeline of how the site should run. This should show the start and set up of the site to the completion and handover of the finished works, with all the various procedures and works shown on the task scheduler in between.

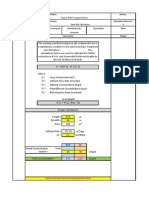

5.0 Monitoring System KMCF need to develop an automated system design for the upgrade works at Keadue Wastewater Treatment Plant (WWTP). The monitoring system for the upgrade works of Keadue WWTP will have the following components: 1. Earned Value Management 2. Function to allow for delays in Project 3. Automated report generator 7

5.1 Earned Value Management

Earned Value Management (EVM) helps project managers to measure project performance. It is a regular project management process used to find variances in projects based on the comparison of worked performed and work planned. EVM technique used to track the progress and status of the project and forecast the likely future performance of the project. EVM integrates the scope, schedule and cost of the project. EVM can be used to show past performance of the project, current performance of the project and also show the future performance of the project. Good planning coupled with effective use of the EVM technique will reduce a large amount of issues arising out of schedule and cost overruns. Once the contractor's EVM System is considered and implemented on a project, there are significant benefits to the contractors. Contractor benefits make it easier to meet project schedule, cost and technical objectives. The Contractors internal systems must be able to provide: Planned value Earned Value Actual cost of work performed Budget at completion Estimate at completion Cost variance Schedule variance Variance at completion

5.2 Function to allow for delay in project It should automatically update construction schedule costs and duration to allow for delay events. It documents cause of delay and updates all EVM information accordingly. It documents delay event into the Project status Report. 5.2.1 Programme Contingency/ Extension of Time The programme should all for Extension in the time required to complete an activity. In our programme it can be taken into account by, activating a Programme Contingency, if one

exists in accordance with Public Works Contractor for Civil Engineers Designed by Contractor or if none exists by entering the delay. 5.2.2 Adjustment to contract sum This is completed in accordance with Public Works Contractor for Civil Engineers Designed by Contractor which can be completed by, taking existing prices off original Bill of Quantities or altering existing prices in original Bill of Quantities or recalculating cost for the activity taking into account, labour, materials, plant and design.

5.3 Automated Report Generator

The automated report generator is capable of updating automatically as the project progress. As per the standard format of a Project Status Report, the document includes the following: Work planned for last month Work completed last week Work planned for next week Open issues Open risks Current status of milestones Key Performance Indicators

All of the above information will update automatically in real-time. This will allow for all delays and issues to documented easily and provide a clear picture of the projects progression and current status. This inclusion of this function with the monitoring system will allow the project manager in charge to regularly print of copies of this report as normal but will remove all effort required in this process, allowing him/her to focus on the task at hand. This document may also be presented to the client, either in person or via the online communication system our team have developed. This will provide the client with all the necessary information to gain an insight into their project progress.

Appendices

10

Appendix A

11

12

Appendix B

13

14

Appendix C

15

16

Appendix D

17

18

Appendix E

19

20

Appendix F

21

22

Appendix G

23

24

Appendix H

25

26

Appendix I

27

28

Appendix J

29

30

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Method Statement (RC Slab)Dokumen3 halamanMethod Statement (RC Slab)group2sd131486% (7)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Reed Bed CalculationsDokumen1 halamanReed Bed Calculationsgroup2sd1314Belum ada peringkat

- Feasibility ReportDokumen21 halamanFeasibility Reportgroup2sd1314100% (2)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Cost Index For ManufacturingDokumen6 halamanCost Index For ManufacturingSari OctavianiBelum ada peringkat

- ASTM - G82 Corrosion Galvanica PDFDokumen7 halamanASTM - G82 Corrosion Galvanica PDFDanny Milton Silva VasquezBelum ada peringkat

- Construction ScheduleDokumen3 halamanConstruction Schedulegroup2sd1314100% (1)

- Construction ScheduleDokumen3 halamanConstruction Schedulegroup2sd1314100% (1)

- Method Statement (Roadways)Dokumen3 halamanMethod Statement (Roadways)group2sd1314Belum ada peringkat

- Delay & Extension TimeDokumen10 halamanDelay & Extension Timegroup2sd1314Belum ada peringkat

- Delay & Extension of TimeDokumen10 halamanDelay & Extension of Timegroup2sd13140% (1)

- Keadue Gantt ChartDokumen21 halamanKeadue Gantt Chartgroup2sd131433% (3)

- Cost Benefit Analysis Template: Results Calculation PageDokumen1 halamanCost Benefit Analysis Template: Results Calculation Pagegroup2sd1314Belum ada peringkat

- Risk RegisterDokumen3 halamanRisk Registergroup2sd1314100% (1)

- Statement of WorkDokumen7 halamanStatement of Workgroup2sd1314Belum ada peringkat

- Cost Benefit Analysis: GroundworksDokumen1 halamanCost Benefit Analysis: Groundworksgroup2sd1314Belum ada peringkat

- CBA (Benefits)Dokumen1 halamanCBA (Benefits)group2sd1314Belum ada peringkat

- Construction ScheduleDokumen4 halamanConstruction Schedulegroup2sd1314100% (1)

- CBA (Instructions)Dokumen1 halamanCBA (Instructions)group2sd1314Belum ada peringkat

- Pipe SizingDokumen2 halamanPipe Sizinggroup2sd1314Belum ada peringkat

- Slab DesignDokumen1 halamanSlab Designgroup2sd1314Belum ada peringkat

- Works ScheduleDokumen1 halamanWorks Schedulegroup2sd1314Belum ada peringkat

- MilestoneDokumen1 halamanMilestonegroup2sd1314Belum ada peringkat

- Project Status ReportDokumen1 halamanProject Status Reportgroup2sd1314Belum ada peringkat

- Pump SelectionDokumen2 halamanPump Selectiongroup2sd1314100% (1)

- Delay & Extension of TimeDokumen10 halamanDelay & Extension of Timegroup2sd1314Belum ada peringkat

- ClarifierDokumen1 halamanClarifiergroup2sd1314Belum ada peringkat

- Population Estimate & FlowDokumen1 halamanPopulation Estimate & Flowgroup2sd1314Belum ada peringkat

- Health and SafetyDokumen15 halamanHealth and Safetygroup2sd1314Belum ada peringkat

- Package WWTP DataDokumen1 halamanPackage WWTP Datagroup2sd1314Belum ada peringkat

- 1 Unit Achieves 2 Units in Parallel Achieve: Company Name: Model NameDokumen1 halaman1 Unit Achieves 2 Units in Parallel Achieve: Company Name: Model Namegroup2sd1314Belum ada peringkat

- Comparison of TwoDokumen1 halamanComparison of Twogroup2sd1314Belum ada peringkat

- Meeting MinutesDokumen21 halamanMeeting Minutesgroup2sd1314Belum ada peringkat

- Actlabs - Schedule of Services - Canada 2016 (03-02)Dokumen44 halamanActlabs - Schedule of Services - Canada 2016 (03-02)Anonymous iq67rN8A150% (2)

- The Consortium Cataclysm Shuffler - Instructions Found Here (Clicky)Dokumen13 halamanThe Consortium Cataclysm Shuffler - Instructions Found Here (Clicky)iPikselBelum ada peringkat

- Introduction To Metal CastingDokumen73 halamanIntroduction To Metal CastingVineeth ShankarBelum ada peringkat

- TB Grinding EnglishDokumen20 halamanTB Grinding EnglishVk PrabakranBelum ada peringkat

- 3.05 A. Welding Specification of Carbon Steel & Alloy SteelDokumen40 halaman3.05 A. Welding Specification of Carbon Steel & Alloy SteelVivek Patil100% (1)

- Foundry DefectsDokumen12 halamanFoundry DefectsVirendra Gupta100% (1)

- Awwa Water Pipe Deposit AnalysisDokumen25 halamanAwwa Water Pipe Deposit AnalysisAntoine LiaboeufBelum ada peringkat

- Standared SamplesDokumen26 halamanStandared SamplesHazem DiabBelum ada peringkat

- Alloy 030Dokumen2 halamanAlloy 030Nookang SeaSunBelum ada peringkat

- A314-15 Standard Specification For Stainless Steel Billets and Bars For ForgingDokumen3 halamanA314-15 Standard Specification For Stainless Steel Billets and Bars For Forgingtjt4779Belum ada peringkat

- MSRIT Muralidhara.M.K MechDokumen7 halamanMSRIT Muralidhara.M.K Mechசெல்வ குமார்Belum ada peringkat

- Uranium in North East India Atomic Minerals Division India Economic GeologyDokumen4 halamanUranium in North East India Atomic Minerals Division India Economic GeologyS.Alec KnowleBelum ada peringkat

- Sa 6 PDFDokumen56 halamanSa 6 PDFadvantage025Belum ada peringkat

- Fire ClayDokumen6 halamanFire ClayAndi NoraBelum ada peringkat

- ISCAR Cutting Tools - Metal Working Tools - Grade - IC907 CNGG 432-PPDokumen2 halamanISCAR Cutting Tools - Metal Working Tools - Grade - IC907 CNGG 432-PPqdarioBelum ada peringkat

- A 890 - A 890M - 99 Qtg5mc05oq - PDFDokumen4 halamanA 890 - A 890M - 99 Qtg5mc05oq - PDFMung Duong XuanBelum ada peringkat

- Outokumpu Stainless Steel Wall Chart PDFDokumen1 halamanOutokumpu Stainless Steel Wall Chart PDFcnaren67Belum ada peringkat

- Recovery of Gallium From Bayer LiquorDokumen10 halamanRecovery of Gallium From Bayer LiquorBen Duncan Málaga Espichán100% (1)

- Is 3930Dokumen19 halamanIs 3930IPSITBelum ada peringkat

- 3935 A722-43007 - Rev00 - 01Dokumen55 halaman3935 A722-43007 - Rev00 - 01Elena CucerBelum ada peringkat

- 13MET KIN A Gas Purging System For Metallurgic 152995Dokumen15 halaman13MET KIN A Gas Purging System For Metallurgic 152995Carlos Ortega JonesBelum ada peringkat

- Exercise Chp9Dokumen4 halamanExercise Chp9Siti NorhayatiBelum ada peringkat

- A540A540M-11 Standard Specification For Alloy-Steel Bolting For Special ApplicationsDokumen8 halamanA540A540M-11 Standard Specification For Alloy-Steel Bolting For Special ApplicationsChuthaBelum ada peringkat

- Aalco Metals LTD Aluminium Alloy 5754 H22 Sheet and Plate 153Dokumen2 halamanAalco Metals LTD Aluminium Alloy 5754 H22 Sheet and Plate 153a1528347Belum ada peringkat

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Dokumen2 halamanWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200kashyap_structuralBelum ada peringkat

- Cathodic Protection Rev2Dokumen19 halamanCathodic Protection Rev2Muhammad ShafeeqBelum ada peringkat

- Nickel and HT Alloys For Petrochemical Applications PDFDokumen39 halamanNickel and HT Alloys For Petrochemical Applications PDFganeshBelum ada peringkat

- Kaolin Densities PDFDokumen4 halamanKaolin Densities PDFalenocitoBelum ada peringkat