Capital Budgeting

Diunggah oleh

Gtnaidu VasuHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Capital Budgeting

Diunggah oleh

Gtnaidu VasuHak Cipta:

Format Tersedia

CAPITAL BUDGETING

INTRODUCTION

An efficient allocation of capital is the most important finance function in modern

times. It involves decisions to commit firms funds to long-term assets. Such

decisions are tend to determine the value of company/firm by influencing its growth,

profitability & ris.

Investment decisions are generally nown as capital budgeting or capital e!penditure

decisions. It is clever decisions to invest current in long term assets e!pecting long-

term benefits firms investment decisions would generally include e!pansion,

ac"uisition, moderni#ation and replacement of long-term assets.

Such decisions can be investment decisions, financing decisions or operating

decisions. Investment decisions deal with investment of organi#ations resources in

$ong tern %fi!ed& Assets and / or Short term %'urrent& Assets. (ecisions pertaining to

investment in Short term Assets fall under )*oring 'apital +anagement,.

(ecisions pertaining to investment in $ong term Assets are classified as )'apital

-udgeting, decisions. 'apital budgeting decisions are related to allocation of

investible funds to different long-term assets. .hey have long-term implications and

affect the future growth and profitability of the firm.

In evaluating such investment proposals, it is important to carefully consider the

e!pected benefits of investment against the e!penses associated with it. /rgani#ations

are fre"uently faced with 'apital -udgeting decisions. Any decision that re"uires the

use of resources is a capital budgeting decisions. 'apital budgeting is more or less a

continuous process in any growing concern.

l

NEED FOR THE STUDY

.he 0ro1ect study is undertaen to analy#e and understand the 'apital

-udgeting process in edible oil manufacturing sector, which gives mean

e!posure to practical implication of theoretical nowledge.

.o now about the companys operation by using various 'apital -udgeting

techni"ues.

.o now how the company gets funds from various resources and effective

allocation of such funds %i.e. allocation between current and long term assets&

2

SCOPE OF THE STUDY

.he scope of the present study includes the following

2nderstanding the importance of capital -udgeting in 3ood, fats and

3ertili#ers 0vt $td, .adepaliigudem

4valuating of an Investment proposal of setting up 3acility at 333, for

manufacturing of 4dible /il.

3

OBJECTIVES OF THE STUDY

.o study the techni"ue of capital budgeting for decision- maing.

.o understand the practical usage of capital budgeting techni"ues

.o understand the nature of ris and uncertainty

.o mae suggestion if any for improving the financial position if the

company.

4

METHODOLOGY OF THE STUDY

.o achieve aforesaid ob1ective the following methodology has been adopted. .he

information for this report has been collected through the primary and secondary

sources.

Primary sourcs

It is also called as first handed information5 the data is collected through the

observation in the organi#ation and interview with officials. -y asing "uestions with

the accounts and other persons in the financial department

Sco!"ary sourcs

It is also collected by someone else and passed through some stastical techni"ues. .he

secondary data have been collected through the various boos, maga#ines, broachers

& websites.

3or this study collected information from company Annual 6eports.

5

LIMITATION OF THE STUDY

.hough the pro1ect is completed successfully a few limitations may be there.

Since the procedure and polices of the company will not allow to disclose

confidential financial information, the pro1ect has to be completed with the

available data given to us.

.he period of study that is 7 wees is not enough to conduct detailed study of

the pro1ect.

.he study is carried basing on the information and documents provided by the

organi#ation and based on the interaction with the various employees of the

respective departments.

$ac of nowledge. Some of the lac full-fledged nowledge of the concept

and its difficult to collect a specific opinion from them.

.ime limitation. .he duration of the pro1ect is short to collect the re"uired

information accurately

6

CHAPTERI#ATION PLAN

.he study is presented in five chapters as the following

C$a%&r'(

.his chapter deals with the introduction, need for the study, scope of the study

ob1ectives, and methodology, and limitations of the study.

C$a%&r')

.his chapter deals with the industry profile and the company profile.

C$a%&r'*

.his chapter deals with theoretical aspects of inventory management.

C$a%&r'+

.his chapter deals with data analysis and interpretation.

C$a%&r',

.his chapter deals with findings, suggestions, conclusions and bibliography

7

INDUSTRY PROFILE

In the Indian conte!t, the term 89egetable /ils is almost synonymous with

84dible /ils and land is not used as cooing media. :owever it is important to eep

this distinction in mind not all 9egetable /ils are 4dible ; Some including cater oil

are mostly non-edible and some of the edible oils lie <round =ut and 'oconut are

finding increasing industrial applications as in cosmetic, soap maing etc.

-y virtue if they are high nutritive content, 4dible oils from a ma1or source of

nutrition. .he fatty acids in 4dible /ils are re"uired by the body as a vehicle for

carrying vitamins5 provide oil caes, which are by-product of the oil e!traction

process, are important source of animal nutrition. .hese can be processed in to edible

flavors, which are rich in proteins.

/il seeds occupy an important position as the agriculture map pf and ran

second after food grains as a farm commodity crop. India accounts for a tenth of the

world out put of 9egetable /ils and fats. It is the largest produces of <round =ut,

rapeseed, mustard and sesame, second in respect of castor seeds, third in coconut,

fourth in cotton seed and fifth in line seed.

/ur country has a highly developed oil based industry. 0roviding gainful

employment to nearly >7 million persons besides another half a million engaged in

milling and processing units. It is essential a food-oil industry accounting for four

fifths of the total supply of 9egetable /ils. Soap paints and varnish industries from

the bul of non-food applications.

8

In spite of thief national importance, production of food grains has been

suffering a negative growth rate all these years. /nly during the first plan period, the

targets set for production were reali#ed after this no impressive achievement was

recorded. .he main contributory factors are two fold, first only marginal land, in rain

fed areas is being used for their cultivation resulting inevitable in low productivity,

second agriculture in India is still sub1ect to the vagaries of monsoon which maes for

erratic production. It is little wonder therefore that the annual rate5 of growth of oil-

seed production for the decade >?@7->?A@ was a mere >.B percent while that of oil

seed productivity, an e"ually dismal one percent.

9iewed in the global conte!t, India has the dubious distinction of having the

highest acreage under oil seeds and recording the highest output, and yet showing the

lowest yield, at AC@ g. Indias yield per hectare is lower than that of =igeria %>@>7.CD

Eg& 2.S.A. %?>FAF.7D Eg&, Argentina %>>7C.F? Eg& and 'hina %>>FD.77 Eg.& .he

following table would give picture of Indias placing in the world settings.

3or the year >?DG-D>, target for oil-seed production had been fi!ed at >>

million tones, actual production however lagged behind, with5 provisional estimates.

0laced at >G.B million tones. 0roduction of live ma1or oil seeds vi#./ groundnut, rare

seed mustard, sesame, line seed and castor seed and is estimated to be abound ?G

laes tones, which is about >C percent higher than the previous years production.

0roduction estimates of groundnut at 7A lae tones however show decline of AG,GGG

tones. At B lac tones castor seed production has also registered a decrease of CG,GGG

tones. 6apeseed, sesame and line seed have however, registered increased over the

previous years production levels.

.he central <overnment therefore too various measures to increase

production of oil seeds. A centrally sponsored scheme for an intensive oil seed

development programmed was operated in >F states with a coverage target FG.@ laes

hectors under a liberali#ed pattern of central, assistance.

9

:owever actual coverage was only C@ lae hectares and the short fall was

attributed to serve. (rought conditions in several states during the Eharrif season.

Short falls in production persisted in the oil year >?D>-DB as well as a result, domestic

industry could not meet the consumption needs respect of edible oils. .he total edible

and supplies from indigenous sources were estimated at about CG lae tones in >?D>-

DB %which however higher than the previous years levels of B7 laes tones&. .he gap

of >G lae tones had to be filled only though imports. 'onse"uently, the state-trading

corporation was ased to import a million tones of 4dible /ils during the oil year

>?D>-DB. .he allotment of imported 4dible /ils was also pruned in a bid to ensure

more supplies though fair price shops.

.he trend of imports in e!pected to continue in the year to come despite the best

efforts of the union agriculture ministry to raise oil seed output. .he genera-based

international trade center has pro1ected import of >C million tones of 9egetable /ils

in >?D7. As for e!ports, it is anticipated that India would e!port >7 $ae .ones of oil

e"uivalent of hand piced-selected groundnut, other nuts and castor oil by >?D7.

.he composition of our e!ports is e!pected to undergo a change palm oil and

products %palm oil and 3-( palm oil& will in further account for an increasing share

of Indian e!ports soybean oil and rapeseed oil will continue to be imported through

their combined share may fall to about one third of the total imports refined rapeseeds

oil could be the cheap oil for the li"uid maret while soybean oil is e!pected to the

supplied to the vanaspati industry. 6egarding production of oils, an increase in the

production of solvent e!tracted oils such as rice bran oil tree oils in lightly to occur

the I.' reports says that the country could mae significant investments in view of

its resource for this oil and the demand of 4dible /ils. .he report has also forecast a

rise in the de oiling of ground nuts cae and other sun caes the country could also

produce F.7 laes of tones seed oil per year.

l0

PROBLEMS-

An important feature to be taen note of in the case of seeds is that

their production facilities widely from year to due to seasonal conditions as only D

percent of the total area under oil seeds is irrigated further year substantial parts of the

verified areas under oil seeds consists of marginal lands plant population is mostly

sub-optional due to the user seed of pure "uality and wide spacing the triple alliance

of weeds, pests and pathogens cause great deals of losses both in the early state of

plant growth as also at crop maturity.

Absence of rains at critical stages also causes significant losses in yields

particularly in the case of groundnuts poor post, harvest technology including

deficiency in mareting support and storage and processing also have advice effect on

returns to grower and incentives for production.

ll

I!"ia! E"i./ Oi/ I!"us&ry

.he Indian vegetable oil economy is the worlds fourth largest after the 2S,

'hina and -ra#il, harvesting about B7 million tons of oilseeds against the world.

Since >??7, Indian share in world production of oilseeds has been around >G percent.

Although, India is a ma1or producer of oilseeds, per capita oil consumption in India is

only >G.@ g/annum which is low compared to >B.7 g/annum in 'hina, BG.D

g/annum in Hapan, B>.C g/annum in -ra#il and FD.G g/annum in 2SA.

9egetable oil consumption has increased following a rise in household

incomes and consumer demand. India imports half of its edible oil re"uirement,

maing it the worlds third-largest importer of edible oil. .he country buys soya oil

from Argentina & -ra#il and palm oil from +alaysia & Indonesia.

'urrently, India accounts for >>.B per cent of vegetable oil import and ?.C per cent of

edible oil consumption.

Ty%s o0 Oi/s commo!/y i! us i! I!"ia-

India has a wide range of oilseeds crops grown in its different agro climatic

#ones. <roundnut, mustard/rapeseed, sesame, safflower, linseed, nigerseed /

castorseed are the ma1or traditionally cultivated oilseeds. Soyabean and sunflower

have also assumed importance in recent years. <roundnut, soyabean and mustard

together contribute about D7 percent of the countrys oilseeds production. 'oconut is

most important amongst the plantation crops. 4fforts are being made to grow oil palm

in Andhra 0radesh, Earnataa, .amil =adu in addition to Eerala and Andaman &

=icobar Islands. Among the non-conventional oils, ricebran oil and cottonseed oil are

the most important. In addition, oilseeds of tree and forest origi2n, which grow

mostly in tribal inhabited areas, are also asignificant source of oils. ntil BGGB, the olive

oil sector in India was predominantly unorganised. than for cooing..

l2

INDIAN EDIBLE OILS INDUSTRY-

.he demand for edible oils in India has shown a steady growth at a 'A<6 of

F.FCI over the period from BGG> to BG>>. .he growth has been driven by

improvement in per capita consumption, which in turn is attributable to rising income

levels and living standards. :owever, the current per capita consumption levels of

India %at >C.C Eg/year for BGG?->G& are lower than global averages %BF g/year&.> .he

Indian edible oils maret continues to be underpenetrated and given the positive

macro and demographic fundamentals it has a favourable demand growth outloo

over the medium-to-long term. In terms of volumes, palm oil, soyabean oil and

mustard oil are the three largest consumed edible oils in India, with respective shares

of F@I, >@I and >FI in total oil consumption in BG>G. <iven the high price

consciousness and varied taste preferences of Indian consumers, I'6A e!pects

these three oils to continue to account for the bul of edible oil consumption in the

country.

.here has been a significant gap between demand and supply of edible oil

because of limited availability of oil seeds and shifting of acreage to other crops in the

domestic maret. .his gap has been met through imports, which account for almost

F7-7GI of the total oil consumption. In :>/JBG>G->>,B edible oil imports were

observed to be the lowest in the last three years in view of improvement in domestic

oilseed production.

=otwithstanding that, I'6A e!pects the high dependence on imported oils to

continue in the foreseeable future due to anticipated domestic supply constraints and

the high cost competitiveness of imported oils. 6efined and crude palm oil %'0/&

have accounted for the ma1or portion of edible oil imports in India %AFI in /JBGG?-

>G& mainly due to their relatively low prices and ample availability. I'6A e!pects the

dominance of palm oil in imports to continue in the near-to medium term.

> /il *orld BG>G

B /J ; /il Jear refers to the period

l3

ICRA Ra&i!1 Fa&ur I!"ia! E"i./ Oi/s I!"us&ry- 2y Tr!"s a!" Cr"i&

Im%/ica&io!s

:igh reliance on imports, domestic edible oil prices have largely been lined

to international edible oil prices. After the decline in 3JG?, international edible oil

prices remained at subdued levels during most part of 3J>G. .he prices of ma1or

edible oils rose in :B3J>> on account of anticipated higher demand for bio-fuels,

given the high crude oil prices as well as e!pected production shortfalls in palm oil

production. 0rices have, however, corrected and stabilised in recent months on

account of better-than-e!pected '0/ production from Indonesia/+alaysia during

3eb-+arch BG>>5 demand rationing due to high prices in developing countries

suffering from high levels of food inflation besides the geopolitical situation in the

+iddle 4ast and =orth Africa. .he improved pricing levels for /il Jear %/J& BG>> as

compared to /J BG>G have provided some comfort to small/medium scale domestic

solvent e!tractors and enabled relatively better capacity utilisation levels. /ver the

near term, edible oil prices are e!pected to remain firm, considering the strong

demand for alternative sources of energy lie bio-fuels in view of the continued rise in

crude oil prices.

.he Indian edible oil industry is highly fragmented, with the presence of a

large number of participants in the organised and unorganised sectors. .his has

resulted in severe competition and inherently thin profitability margins. 3urther, the

profitability of maret participants has also been vulnerable to riss emanating from

wea harvests5 commodity price volatility and fore! movements.

I'6A notes that while the share of branded oils segment has remained low

over the years, it is poised for growth in view of rising income levels5 uptrend in

urbanisation and increasing "uality consciousness of Indian consumers.

.he <overnment of India has cut down import duties on edible oil since April

BGGD. .he current duty differential between crude and refined oils stands at A.7I,

which provides protection to domestic refiners against competition from imported

refined oils. <oing forward, the industrys profitability is vulnerable to any reduction

in this duty differential.

l4

3rom a business ris perspective, I'6A considers the fle!ibility to modify

product portfolio as a ey strength in a maret characterised by commodity price

volatility. Accordingly, players with a diversified presence and e!posure to the three

ma1or categories of oil, namely, palm oil, Soya bean oil and mustard oil, would be

better positioned for growth as compared to players with single product concentration.

3urther, according to I'6A, the large-scale integrated players are better placed than

small and mid-si#ed manufacturers to withstand the challenges in the business

environment on the strength of benefits related to economies of scale such as

marginally lower cost of production and access to cheaper woring capital credit.

3rom the perspective of revenue growth and profitability, maret participants with a

high share of established branded products are better placed than participants

operating in the commoditised bul maret.

In the recent past, the Indian edible oil industry has witnessed organic and

inorganic e!pansion by some of its ma1or participants. *hile I'6A views the

increase in scale as a credit positive, the impact of these cape! activities on the capital

structure and the ability to scale up revenues and profitability to the envisaged e!tent

will be some of the variables to be closely observed from a credit perspective.

BAC2GROUND

:istorically, India has been a ma1or importer of edible oils with almost CG-

FGI of its re"uirements being imported till >?DGs. In >?D@, the <overnment of India

established the .echnology +ission on /ilseeds and 0ulses %.+/0& in order to

enhance the production of oilseeds in the country. .he .+/0 launched special

initiatives on several critical fronts such as improvement of oilseed production and

processing technology5 additional support to oilseed farmers and processors besides

enhanced customs duty on the import of edible oils. 'onse"uently, there was a

significant increase in oilseeds area, production and yields until the late->??Gs.

:owever, in order to fulfill its obligations towards various international trade

agreements and also meet the increasing demand supply deficits, India began to

reduce import restrictions on edible oils in the late >??Gs5 and it was gradually

brought under /pen <eneral $icense.

l5

.his led to a significant slump in the domestic oil seeds maret, as edible oil

prices fell sharply in line with the low international prices prevailing at that time.

Subse"uently, the duty structure was modified so as to maintain a duty differential

between crude and refined varieties in order to protect the domestic industry.

=evertheless, due to high import dependence, domestic edible oil prices remain

highly correlated to international edible oil price movement, and this has resulted in

volatility in the ey credit metrics of rated edible oil companies. At the same time,

I'6A notes that edible oil companies with benefits of large-scale integrated

operations, multi-product offerings and recogni#able branded presence in retail

marets have fared better as compared to small/medium-scale domestic oilseed

crushers.

2EY TRENDS 3 CREDIT IMPLICATIONS

Fa4ora./ "ma!" ou&/oo5 0or "i./ oi/s6 u!"r %!&ra&" mar5& o00rs

si1!i0ica!& 1ro7&$

Po&!&ia/-

.he demand for edible oils in India has shown a compounded growth of

F.7Iover the last >G years and is estimated at >@.B million tones for /il Jear%/J&

BG>G->>. India plays an important role in the global edible oil maret, accounting for

appro!. >G.BI share of consumption5 AI share of oilseed production5 7I share of

edible oil production and >C.@I share of world edible oil imports for /JBGG?->G. As

per 2S(A estimates, India is the third largest consumer of edible oils %after 'hina and

the 42-BA countries&5 and will account for >>I of global edible oil demand and >@I

of global imports in /J BG>G/>>3.

Indias annual per capita consumption has shown a steadily increasing trend

from F g in the >?AGs to>G.B g in the late >??Gs to current levels of K>C.7 - >F g.

:owever, it still rans well below the world average of around BF g %per capita

figures including consumption of bio-energy&, thereby signifying the high growth

potential of the industry. 6efer 'harts > and B for trend in domestic demand and

percapita consumption of edible oils in India.

l6

I!"us&ry rmai!s 4u/!ra./ &o &$ ris5 o0 !arro7i!1 im%or& "u&y "i00r!&ia/-

-eginning BGGA-GD, there has been a progressive reduction in import duties on

crude and refined edible oils. +ost of these policy changes have been made in order

to comply with foreign trade agreements entered by India with other countries and

associations such as AS4A= apart from meeting shortfalls in domestic supplies and

curtailing inflation. In the last round of changes in duty structure %April BGGD&, the

duty on crude palm oil was made 8nil while that on refined palm oil was made A.7I

%A.AI including education cess&, with the net duty differential being maintained at

A.7I to protect the domestic industryC. <oing forward, the reduction of import duty

differential remains a ey regulatory ris for the industry.

Bra!"" oi/ sa/s8 a/&$ou1$ curr!&/y /o7 i! I!"ia8 ar 9%c&" &o 1ro7 "u &o

r!7" &$rus& .y ma:or %/ayrs

.he share of branded product sales has remained low with most low-income

consumers opting for given the presence of a large number of unorganised

participants in the Indian edible oil maret, cheaper oils sold in loose form. As per

industry data, only about C>I of urban households and about ?I of rural households

consume branded edible oils, with the national average at >@I. <iven the low

penetration of branded oils5 increasing affluence levels and "uality consciousness of

the Indian consumers, there is a significant growth potential in the branded segment.

Amongst the ma1or edible oils consumed, palm oil is still largely traded as a

commodity and sold mostly in loose form, with pacaged sales accounting only for

>7I-BGI of total sales. Sunflower and soya oil, on the other hand, have a high

proportion of pacaged sales estimated at around AGI and 77I of total sales. .he

ma1or participants in the organised sector, namely, 6uchi Soya, Adani *ilmar

$imited %A*$& & 'argill India, have a strong presence in the branded segment, with

branded sales accounting for CDI, 7DI and @GI of total edible oil sales of these

companies respectively. +oreover, a few mid-si#ed, regional edible oil companies

such as +antora /il 0roducts $td, +odi =aturals and .ara :ealth 3oods $td have

also been striving to establish their brands.

l7

3rom a credit perspective, I'6A considers high share of branded sales as a

strength, given the favourable outloo for growth5 relatively high margins5 stability of

off tae and better pricing power as compared to the bul maret. =onetheless, since

branding activities entail high upfront outlay while sales volumes may tae time to

scale up, profitability margins of companies undertaing large-scale branding efforts

are liely to come under pressure during the interim gestation period.

Som &r!"s o0 co!so/i"a&io! 4isi./ i! &$ i!"us&ry6 /ar1'sca/ i!&1ra&"

%/ayrs /a"i!1 &$ ca%aci&y a""i&io! %rocss &$rou1$ 9%a!sio! as 7// as

ac;uisi&io!<co!so/i"a&io!

.he edible oil industry in India in the recent past has witnessed both organic as

well as inorganic e!pansion by some of the ma1or players. A*$ has added >G?G .0(

of installed capacity for refining and 7G7G .0( of installed capacity for seed

processing during 'J BG>G->> by ac"uiring five operational plants and undertaing

e!pansion at three out of its four e!isting plants. A*$ has also additionally taen

over the operations of other *ilmar associates in India %lie Acalmar /ils & 3oods

$imited& so as to consolidate its pan-India presence. Sanwaria Agro /ils $imited has

added >GGG .0( crushing capacity in BGG? through ac"uisition of two plants. ES /ils

has set up new facilities at Eota, 6atlam and <una, totaling CFGG-C@GG tpd, and

ac"uired a refining unit at :aldia. 3urther, some edible oil manufacturers have also

undertaen bacward integration to strengthen their overall business model. ES /ils

has ac"uired >,CD,GGG acres of palm plantations in Indonesia while 6uchi Soya has

access to >,A7,GGG hectares of agricultural land with palm plantations across different

Indian states.

*hile I'6A considers this consolidation and capacity e!pansion trend as a

favourable development due to the benefits associated with large scale of operations,

on the flip side, the adverse impact of such activities on the capital structure5

profitability and return metrics of the concerned companies, particularly during the

gestation period, presents a downside ris.

l8

PROJECTIONS-

India has becoming a si#able imported of 4dible /ils since the mid-seventies.

Annual reports are the order of the million tones costing around 6s.@GG cores in

foreign e!change.

It has been pro1ected that the demand edible oils will increase at the minimum

annual rates of C.7 percent. .he growth rate in oil seeds production has been then one

annual a half percent per annum in the last decade avoidably import o 4dible /ils will

be on the rise. At these assumed the levels, the annual import re"uirements will be

around >.@ millions tones by >??G. If demand grows at the higher rate, say at 7

percent, the volume of e!ports re"uired will be B.> million tones by the same year.

Imports in the range >.@ to B.> million tones will mean India rice bringing D.>G

percent of the pro1ected will e!port vegetable oil at the time. Such heavy dependence

on India to price bacs mail. .hat would be compounded in years of bad harvest. .he

foreign e!change drain on our e!change %according to *orld -an estimates& could

be us LC to F billion annually.

At the instance of the <overnment of India the =ational (airy (evelopment

-oard %=((-& has under taen the pro1ect for restructuring the pattern of production

and mareting of oil seeds and 4dible /ils. .he pro1ect has been designed to

integration production, procurement, processing and mareting of oil seeds and

vegetable oils through a two-tier co-operative structure oil seeds growers co-

operative societies at villages level and an oil seeds growers federation at the state

level.

A sum of 6s.>7G cores re"uired for pro1ect investment could come from

ploughing bac the sale proceeds of B.7 laes tones of 4dible /ils gifted to the =((-

by the co-operative league 2SA M'$2SAN =((- by co-operative union of 'anada

%'9$&. It is sought to involve @ states <u1arat, +aharashtra, .amilnadu, +adhya

0radesh, Andhra 0radesh, and /rissa in implementing the pro1ect.

l9

RICE BRAN OIL

NE= TECHNOLOGIES-

=ew technology in the 2S has proved that rice bran oil is effective in lowering

cholesterol. .his has encouraged many rice millers in the 2S to stabili#er rice bran oil

e!traction. 4dible grade rice brand oil is called 8:eart /il, in Hapan. As demand from

this oil is liely to broaden the world over and as India is the second largest producer

of rice after 'hina, the union government decision to encourage productions of this oil

is welcomed in oil "uarters. .here is great scope, to introduce modern technology in

this predominant agro-industry.

.he central <overnment has raised the e!port ceiling on de oiled rice brand

from B>@,GGG tones to CBF,GGG tones for the oil year >?D?-?G to encourage the

domestic production of brain oil and the e!port of de oiled brand. .his is a welcome

step at that time when the country is poised for it is highest level of edible imports.

It is now increasingly felt that there e!ists scope of arguments. .he and the

availability of 4dible /ils through the application of appropriate technology and the

other moderni#ation programs in the oil-milling sector of particular interest is the vast

scope of producing 4dible grade oil from rice brand.

According to study the 2nited =ations 3ood and Agricultural /rgani#ation %3A/& I=

>?D7, India is the largest producer of the rice brand oil in the world. -ut compared to

Hapan were DG percent of all rice brands are attracted for oil, only one-fourth of all

potential bran is used for oil attraction in this country.

.ill >?AA-AD, India produced about DG,GGG tones of rice brand oil, but only of

industrial grade, >?AD-A? only B,7GG tones of 4dible /ils, could be produced out of

>G>,GGG tones of rice bran oil. .he situation steadily improved since than, thans in

part to the efforts of the solvent e!tractors, Association of India %S4AI&.

20

/ut of B7G,GGG tones of the 4dible grade. 0roduction of 6I'4 -6A= /il is

liely to go up from B7G,GGG tones in >?D@-DA to C>G,GGG tones in >?DA-DD. In >?DD-

D?, the production is liely to go up CB7,GGG tones although the potential, identified

by the S4AI is of @A7,GGG tones per annum.

.he development of 6I'4 -6A= oil e!tracts illustrates how by-product

utili#ation can help argument 4dible /il supplies in the county and generate economic

activities as well.

.he thin brown layers between the hus and ernel in a grain of paddy are

called bran. .hese layers are baric barbarous in nature, indigestible, and refractory to

cooing. .hese bran layers are, therefore, indigestible, and refractory to cooing. .his

bran layers are, therefore removed by a process called polishing. About @-Egs -ran

in usually obtained from polishing one "uintal of rice.

.he bul of the oil of rice bran %7G-DG percent of the total oil& comes into bran

during its polishing. In row rice, on an average, bran contains >B->7 percent oil, while

in per ; per ; boiled rice when oil inside the grain gets deposited on the outer layer

the oil content of bran is >D-BG percent consider its fact that half of rice productive in

India is par boiled, the average oil content of rice bran could realistically be assumed

to an average of about 7G percent.

.he estimated production of paddy in the >?DD-D? was ?C million tones.

'alculated at the modest rate of 7 percent bran on each "uintal of paddy for seed

purpose, the potential output of oil comes to @>G,GGG tones out of bran of F million

tones.

-eginning in the >?AG under private suspires oil e!traction from 6I'4 -6A=

has been steadily on the increasing move ever the profession of 4dible grade 6I'4

-6A= oil to the total has gone up from more B,CGG tones during >?AA-AD to our

>GG,GGG tones in >?AA-AD. .he products of 4dible /il are closely related to the use of

this oil the 9anaspathi Industry.

2l

In spite of fluctuations in demand the use of 6I'4 -6A= oil is 9anaspathi

manufacturing has increased steadily over the year. *ith the recent decisions of the

<overnment to reduce the allocation of imported oils to the 9anaspathi Industry, it

has become more depend on indigenous oils and fats. A situation that is going to

further increase its demand for 6I'4 -6A= oil in the coming year. 9arious

<overnment policies lie e!port of de oiled bran e!ercise rebate on the use of 6I'4

-6A= oil in the 9anaspathi units, e!cise in he! an on hardened 6I'4 -6A= oil for

use so, and the levy on rice mills have contributed, towards the growth of the sector.

.he announcement of a cash compensatory support of >G percent on the 3/-

value of e!ported de oiled from cae for the C years >?D@-DA to >?DD-D? as further

boosted the processing of the rice bran.

Andhra 0radesh process the largest "uantum of rice bran, followed, 0un1ab

and 2ttar 0radesh. .his is also due to the growth in the no of solvent e!traction units.

In >?DA, out of F.D@ millions tones of solvent e!traction capacity, Andhra 0radesh had

>GCD million tones, followed by 0un1ab with D@ tones +adhya 0radesh with @ laes

and 2ttar 0radesh, with 7,DG,GGG tones. In >?D7-D@ Andhra 0radesh processed C?.7

percent of all rice bran produced accounting for 7G.C percent of total 4dible grade

6I'4 -6A= oil FG.B percent of total bran and produced AG percent of total 6I'4

-6A= oil. 7 states Andhra 0radesh, 0un1ab, 2ttar 0radesh, Earnataa and :aryana

produced D> percent of all rice bran under produced DG.F percent total 6I'4 -6A=

oil.

As a result of the encouragement given from the use of indigenous rice bran

oil particularly by the 9anaspathi Industry the processing capacity of rice bran in the

country went up from a more ?G laes tones to C.F million tones >??F and now stands

at DG million tones.

22

A number of suggestions have been put forward for augmenting the

production of 6I'4 -6A= oil. .hese includeO

>& 2niform systems of rice levy for huller and Sheller millers, so that huller

cant remain *edded their traditional technology with perpetuates wastage and would

be compelled to moderni#e. .his would also increase the availability of rice bran for

oil e!traction.

B& An increase in the e!cise rebate on using rice bran oil in 9anaspathi

manufacturing as well as fro soaps and other industries.

C& 3iscal incentives for production of refined solvent e!tracted 6I'4 -6A=

oil for direct use of cooing medium.

F& 0ermission for blending similar non-conventional oil with 6I'4 -6A= oils

for direct consumption and

7& +inimi#ing the import of 0lan oil so as to boost the price of indigenous oils

and provide an intensive to domestic producers.

(eposit all efforts to increase the production of 6I'4 -6A= oil to ma1or out

stacs, one in built in the very structure of rice milling in India and the other natural

of technology, stand in the way of the fuller development of 6I'4 -6A= oil

processing. .o tae the farmer first, largest production ; no less than half of fresh rice

bran accepts the e!traction process is together due to the problems of collection %and

stabili#ation of oil content&. .his is because no less than DG,GGG hullers scatters all

over the country, mostly in the rice producing and consuming states, produce these

brans.

.he technology constraints are closely related to the structural ones. *here as

has the hus content or rice bran in Hapan is only C percent, in India it is more than >B

percent. As a result, the oil content of 6I'4 -6A= in terms of value goes down.

3urther, when oil e!traction is done, the hus leaves a deep color in the oil, when

poses problems at the time of bleaching, another acute technological constraint arises

from the tendency of rice bran to get dehydrated as a result e!posure to the

atmosphere as a result, oil contest goes down to a great e!tent, maing it and

economical per oil e!traction.

23

.he colossal waste of paddy by production including rice bran is ingrained in

the structure of rice milling industry in India. .he number of rice mills in India

increased from F@,GGG in >??C to >GA,GGG in >?DC and >,>A,GGG in >?DA. .he number

of huller mills also increased from >?@C to DG,GGG in >?DC, before declaring to AD,CGG

in >?DA.

.he large number of huller units is a serious drawbac, not only because their

paddy out turns is low, but also because the bran obtained from huller mills is mi!ed

with hus and other foreign matter. -ecause of the low oil content, in the ran of rice

to nine percent, it becomes uneconomical to e!tract oil from this bran.

:oller mills are improved versions of hand panders mostly located in small

towns and in interior villages mostly located process BGG to 7GG tones of paddy in a

year. .hese small hullers generally involve themselves in custom milling of paddy

with fi!ed charges, in cash and in ing. .hey are e!cluded from paying the

compulsory levy imposed on larger mills, which under tae commercial milling of

paddy.

.he huller mills cater to the large number of landless laborers, sharecroppers

and poor peasants whose output is fre"uently at or below subsistence level. It has

been estimated that at treats a "uarter of the paddy produced in the country is other

land pounded or processed through huller unit custom milling. 6ice bran obtained out

of such paddy, estimate about a million tones, is neither pure enough not available in

large enough "uantities to be economically collected. .herefore, this "uantum of rice

bran is as good as not produced at all.

.here are a number of reasons why huller mills thrive in states producing rice

bran oiled vice. 3irst, huller mills are very cheap, and conveniently located in interior

areas. Second, the investment re"uirement being low, under utili#ation of huller mills

in the lean season doesnt put the owner out of business, because the can often

supplement it with other from and non from activities.

.hird, the out turn of rice is not really so low when it comes to par boiled rice.

And last but not the least, is the reason using a huller mill rather than a moderni#ed.

24

Sheller mill enables the miller to avoid mill point levy of rice and associated

problems.

Since about half of the paddy produced in India is rice bran oiled, the loss of

rice bran oil potential is colossal, particularly since the bran produced out of par

boiled rice contains three o five percent more oil that produced out of raw rice and the

oil the bran of par boiled relatively stable and doesnt degrade an account of free fatty

acid formation %33A&P

.ill such time as the huller mills are moderni#ed an intermediate short-run

solution could be applied. .his is to use a mini-rice mill or even a modified huller in

place of traditional huller, so as to improve the outturn of rice as well as to detain

purer bran.

In order to achieve the largest of moderni#ation, the 'entral <overnment runs

a huller subsidy scheme provides for 7G percent of the cost of install action to

improved rice milling e"uipment as subsidy.

3or instance, electricity heated rice bran stabili#er of various power rating and

capacities %between 7G and B7G g. 0er hour& as well as steam heated bran stabilities

have been successfully field-tested. :owever, the tests of chemical stabili#ers, which

are simple and convenient, are yet to yield sufficient results in the field.

.he <overnment of India has decided to install some of these stabilities in

research centers lie 006' to demonstrate its advantages to demonstrate its

advantages to the millers.

In American mills, rice is rubbed with leather straps instead of by emery, not

to get polished rice but also to get good e"uality. -ran in Hapan, rice mills have in

built stabili#ation units. In countries lie -elgium Hapan, *est <ermany and 2.E the

technology of continuous e!traction of oil from rice bran is used to achieve ma!imum

economic energy, labor and materials.

25

*hile most of these technologies are sophisticated, with a high degree of

efficiency of this country, because of the specific nature of the Indian rice milling

Industry, Indignation of these process, therefore is of the most importance. .here are

two ma1or stages in producing 4dible grade oil fro rice bran. .he first stage consists

of stabili#ation of bran to pressure the oil content. .he second stage involves the

processing and refining of rice bran oil.

A number of stabili#ation systems have been successfully developed in India

at the 'entral 3ood .echnological 6esearch Institute %'4.6I& +ysore, .he 0addy

0rocessing 6esearch 'enter %006'& .hiruvarur %..=&, .he 0ost harvest .echnology

'enter %0:.'& at the Indian Institute of .echnology, Eharagpur. .he stabili#ation

particularly the wet heat treatment and chemical stabili#ation particularly the wet heat

treatment and chemical stabili#ation using hydrochloric acid have opened up

enormous possibilities of producing low acid bran in the rice mills. .he rice mills can

now store and accumulated the stabili#ed bran for selling it in to the solvent

e!tractions. 4ven a trucload can be accumulated and stored for the sae of greater

economic in transport. -y the end of this century, paddy productions e!pected to

reach a level of >CG millions tones. Eeeping a side >B.7 percent of production towards

seed, the potential bran production would come to 7.A million tones, which in turn

would yield D,7G,GGG tones of 6I'4 -6A= oil. .he e!ploit this huge potential what

is needed is the right perspective and a commitment towards reali#ing the rich

possibilities in event in the agricultural by products they have conventionally been

wasted.

26

COMPANY PROFILE

PROFILE OF FOODS FATS AND FERTILI#ERS LIMITED

3oods fats and 3ertili#ers limited .adepalligudem is a family owned

organi#ation. It is well nown as 3oods & 3ats but the *est <odavari farmers call it

as a tawdu factory. .his organi#ation is professionally carrying the business activity

by )<oena, family. .he company was established in the year >?@B. It is having

branches in 'hennai, +umbai, Eainada, :yderabad, Eolata and -aroda.

:istorical bacground of foods 3ats and 3ertili#ers $imited were conceived in

>?7? born in >?@G and were on its beet by >?@B. .oday 3oods 3ats and 3ertili#ers

$.( has matured into a conglomerate of its industrial units spread over FG acres

contently bu##ing with activity and providing employment to over DGG persons.

.he wheel of fortune has turned a full circle for +r. -.E.<oena the architect

of 333 $.(, born and bred in -urma. .he <oena family established and respected

in Industry and .rade. .he rice bran from +r. <oenas mill sought as a mal feed and

wrapping papers used for sampling could this oil e!tracted.

.hese "uestions have to wait because in >?FB, the Hapanese invaded -urma

and +r. <oena has to abandon his business and return to India. -eing an optimist is

transformed the adversity into opportunity by his grit and after a brief spell in his

native land in 6a1asthan, his restless enterprising #eal brought +r. <oena to 'hennai

in >?FC. *here he is with his brother e!port of handloom fabrics in due course, he

established a te!tile business. In >?7?, +r. <oena read on article by (r. 6aghunath

0rasad of central food technological institution of +ysore that oil could be e!tracted

from bran using alcohol as a catalyst.

27

Simultaneously his brother in 6angoon informed him of plans being setup with

Hapanese and <erman technologists for e!tracting oil from rice bran +r. <oena held

deliberation with (r. 6aghunathprasad and visited -urma with him to study the

relevant technology better, he was in Hapan to study in 4urope to study the process of

:urgi of <ermany and (r. smith of -elgium.

LOCATION-

.he 'ompany is a conglomerate of various industrial units spread over FG

acres of land, with a built up area of ape!. F lac sft. $ocated in the vicinity of

.adepalligudem +andal & +unicipality in *est <odavari (istrict of Andhra

0radesh.

DEPARTMENTS IN FFFO-

0ersonnel department

0roduction department

+areting department

Accounts department

6esearch & development

MANAGEMENT-

.he manufacturing activities of the company are managed by Sri /.0.<oena

and Sri Sushil <oena at the helm of affairs as whole time (irectors at factory,

supported by team of highly educated and committed professional having wide range

of e!perience in the field of oil derivatives and allied fields.

>. =ames of (irectorsO

Sri -.E.<oena -+anaging (irector

Sri <.S.<oena -*hole .ime (irector

Sri S.-.<oena -*hole .ime (irector

Sri /.0.<oena -*hole .ime (irector

Sri -harat <oena - *hole .ime (irector

Sri Sitarama <oena -*hole .ime (irector

Sri Sushil <oena -*hole .ime (irector

Sri 9ianod umar saraogi -(irector

28

Sri Shiv Eumar 1atia -(irector

Sri Anand choradi -(irector

B. 0articulars of present collaboration if any, =o 'ollaboration %name and

address, nature of collaboration, period of collaboration etc.,&

C. =ame of chief 4!ecutive Sri -.E. <oena

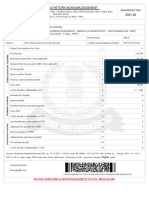

CAPITAL STRUCTURE-'

3inance is very much needed to any business so finance is as heart to the

business the company was incorporated in the year >?@G, the original share capital

subscribed is 6s. 7 lahs. .he company is a closely held industrial houses with no

public investment in the form of e"uity share capital. 3ollowing is the capital structure

as on C>.GC.G@.

Share 'apitalO %Including 6eserves& F>.@F 'rs.

$oaned fundsO %Secured $oans& A>.F? 'rs.

%2nsecured $oans& >A.7> 'rs.

TOTAL (*>?@+ Crs

BAN2ERS-'

S.A.4 -A=E /3 I=(IA M':4==AIN

S.A.4 -A=E /3 :J(46A-A( M':4==AIN

A=(:6A -A=E M.A(40A$$I(2(4+N

'4=.64$ -A=E /3 I=(IA M':4==AIN

I=(2S.6IA$ (494$/0+4=. -A=E /3 I=(IA $.( M':4==AIN

EA626 9JSJA -A=E $.( M.A(40A$$I<2(4+N

29

BRANCHES-'

+2+-AI

:J(46A-A(

EAEI=A(A

=4* (4$:I

3ood fats & fertili#ers $.( is the flagship company of the 333 group. .oday

the 333 group has matured into a conglomerate of BG industrial units spread over F7

acres constantly bu##ing with activity and providing employment to over >GGG

people.

.oday the product range of 333 $.( includes oils of ricebran, soybean,

sunflower, groundnut, sesame, palm, salseed, mangoernel, acidoils, wa!, gums,

deoiled meals Qe!tractionsR, crude distilled and hydrogenated fat for industrial use,

vanaspati, baery, shortening5 margarine, baery fats, specialty fats for manufacturing

chocolate confectionery and cosmetics, canned fruits and vegetables natural colors for

use in food and feed industry, oleo resins and herbal e!tracts. .he company also under

taes fabrication and installation of turney pro1ects for processing of vagetabel oils

and their derivatives.

MULTIFARIOUS PROGRESS-'

Starting with a solvent e!traction plant in >?@B units was continuously added

year after year to form a wide spectrum of products. 'urrent manufacturing activities

comprise of-

Solvent 4!traction 0lant > Mlurgi, <ermanyN

Solvent 4!traction 0lant B Mdesmet, -elgium/IndiaN

Solvent 4!traction 0lant C Mfabricated and installed by engineering division of 333

groupN

30

So/4!& E9&rac&io! %/a!& + A0a.rica&" a!" i!s&a//" .y oi/9 I!"ia a!"

!1i!ri!1 "i4isio! o0 FFF 1rou%B

.he above four e!traction plants provide versatility of

operation in processing different oil seeds/oil caes at the same time and hence are

highly advantageous in mareting. .he plants have facilities to process a wide variety

of oil seeds/oil caes lie rice barn, soybean, sunflower, groundnut, rapeseed, sesame,

mango, sal, =iger, etc. continuous upgradation of manufacturing process through in

house and world wide research is our hallmar.

6efinerO - Msharpels 2SA and engineering division 333 groupN

:igh "uality refining of a variety of vegetabel oils.

Fa& S%/i&&i!1 P/a!&- ' C7urs&r 3 Sa!1r USA a!" !1i!ri!1 "i4isio! o0

FFF 1rou%D

:igh pressure splitting of oil into fatty acids and sweet water.

3atty Acid (istillation 0lantO - Mluwa, Swit#erlandN

:igh "uality distillation of crude fatty acids obtained from the splitting plant.

<lycerin plantO - Mwurster & Sanger 2SAN 0rocessing of sweet water obtained from

fat splitting plant into various grades of refined glycerin.

Stearic acid plantO- Mengineering of 333 groupN

:ydrogenation of fatty acids into stearic acid flaes.

:ydrogenation plantO- M-ernardino Italy and engineering division of 333 groupN

:ydrogenation of fats and fatty acids for industrial use.

0hysical refineryO- Myoshinoi technology and engineering division of 333 groupN

6efining of high free fatty acid oils by seam distillation.

'anning divisionO- Mfabrication and installation by engineering division of 333 groupN

0rocessing of fruits into pulp 1uice and bars.

9anaspati-shortening- margarine divisionO- Mfabrication and installed by engineering

division of 333 groupN

3l

0roduction of vanaspati shortening high "uality baery fats and margarine from

refined oils

Fractionation plant:- .his division produces high "uality oleins and stearines

from various edible fats for use in manufacture of chocolate confectionery and

cosmetics. $eading manufacturers in this field of activity all over the world are our

customers.

.urney engineering divisionO- In collaboration with yoshinoi Seisausho co

$.( Hapan who have done pioneering wor in developing process and technical

now-how for refining high 33A rice bran oil, our engineering division has installed

and commissioned five plants of a total pro1ect cost of 6S. >AG million in south India.

India is the second largest producer of rice with a large potential of crude rice bran oil

to be processed and turned into a fine cooing medium t satisfy the re"uirements o fan

immense Indian maret. 333 group engineering division is e"uipped t set up any

vegetable oil and derivative processing pro1ect.

Oi/ %a/m %ro:c&-' 0lantation of oil palm to progressively cover B7GGG hectares in

Andhra 0radesh and Earnataa the southern states of India is sponsored by us.

:igh yielding variety of sprouted seeds from India and abroad is grown in our

nursery and seedlings are regularly supplied for planting to the farmers to cover the

targeted area. 2nder comprehensive e!tension services provided by us the maturing of

plantation is e!pected to be ideal mean while the group has set u plant and machinery

along with suitable infrastructure t crush the palm fruits and ernels into oil and

process the same into refined oils oleins stearines and a host of other products. .otal

pro1ect outlay is estimated to be df> billion Indian rupees.

I!&r!a&io!a/ &ra"i!1-' -esides the e!port of the manufactured products

with large warehouse for dry cargo bul storage installation for li"uid cargo at the

ports, re"uired infrastructure at our command and international trading e!perience of

over FG years the 333 group has set u high standards and achieved substantial growth

in international trading of commodities lie rice, edible oils, Industrial fats, mai#e,

tapioca, hps groundnut ernels dyes and chemicals.

32

.he group has been a pioneer in introducing various Indian products

manufactured by us to new international marets and has won awards for our

performance. :owever, a research and development new product is being done on a

continuous basis for enriching the international trading in both "uality and volumes.

Sarc$ A!" Rsarc$-' 6esearch and development is the pivot of our

activities and has made us to stand in good steady continuous up gradation of

production process with the help of a well-e"uipped 6&( laboratory at :yderabad

and diversification in new research based pro1ects in our corporation. 'ulture leading

us to a steady upward movement.

Sr4 To Soci&yO- .he 333 group is involved in a large way in social service

activities the <oena family trust runs Arts and Science college for women in Andhra

0radesh and a :igher Secondary School in 6a1asthan. It has a established a boys

college in Andhra 0radesh, a :igher Secondary School in +yanmar and a multistory

building in .amilnadu, providing accommodation to .ourists and Social functions

with a library and reading room. In addition to the above pro1ects the group has also

being regularly contributing to several educational, medical and social service

institutions.

33

ETHICSO-

.he 333 group is proud of its inherent values, which are, persuade relentlessly to

drive it towards sustainable growth. .hese values are common language that binds all

its people.

.he 333 group stands forO-

An intrinsic commitment to its people.

A culture of trust, mutual respect, opens communication and transparency of

action.

'ommitment to welfare-driven initiatives that mae a "ualitative difference to

the lives of marginali#ed people.

An environment-conscious group through its eco-friendly units.

Indian values with a global mind set.

333 groups manufacture a variety of products including vanaspati granite

readymade garments computer software etc. we have listed a few of our products

here.

TANDUL-' R0i!" ric .ra! oi/

A multi purpose-cooing medium 1udged as the safest cooing oil in the world.

'ontains tocopherol and ory#anol that reduce cholesterol. It is e!pensively used in

Hapan an evidence for the Hapanese larger living.

0acing >7g/>litre fle! pouch.

34

SUN DELITEO- 6efined sunflower oil.

Imported from Argentina and refined in the most modern refinery contains

high puff. It lowers cholesterol.. A general purpose cooing oil.

0acing, >7Eg tin/>7litre tin/7litre 1ar/>lite fle! pouch.

SURABHIO- 9anaspati

An economical vegetable fat for small-scale baeries. +ulti utility fat widely used all

over the country.

0acing, >7Eg bag-in-bi!/>7Eg tin/>7Eg 1ar.

Ba5rEs P&O- -aery shortening.

+ultipurpose baery shortening creamy white and bland in taste. A blend of specially

formulated and te!tured hydrogenated fats to provide e!cellent plasticity. .he largest

selling brand in south India for manufacturing caes beads biscuits filling cream

cooies also used for shallow and deep-frying. 0acing5 >7Eg bag-in-bo!/>7Eg

tin/>7Eg 1ar.

FFF-'Va!as%a&i

>GGI granulated vegetabel fat. A favorite of south Indian housewives for cooing and

deep-frying. A must for all festival cooing and sweet preparations. 0acing, >7Eg

tin/>7 liter tin/>lite fle! pouch/7GG,BGG and >GG ml fle! pouch.

MELLO-' +argarine.

+argarine made from the choicest of refined oils for baery industries recommended

by the best baers in the country for cae cream pastry biscuits icing and cooies.

Ideal because it is not colored and not flavored.

0acing5 >7Eg bags-in-bo!.

BISCREMEO- Ara&" .a5ry s$or&!i!1?

2niform dispersion of nitrogen gas in the fat produces a superior baery shortening

Mcontains >GI v/wt nitrogenN specially used for filling cream and icing. -est for

premium biscuits and cooies.

35

PALM DELITE-' Im%or&" E3D %a/mo/i!?

A refined bleached and deodori#ed palm oleins imported from +alaysia, 4conomical

oil supplied allover the country directly from our ports on the east and west.

0acing, >7Eg tin/> liter fle! pouch/7GG ml fle! pouch.

BA2ERS DELITEO- 0uff pastry fat, An in house development to produce a smooth

fat designed of ruse in puff pastry products. A specialty fat, which gives a flay, puff

with a good life. 0acing5 >7Eg bag-in-bo!.

GOLDEN SPREAD-' Mar1ari! 0or %u00s

Specially formulated product for puffs. .here is already a great demand for these

margarine for its superior "uality.

0acing5 >7Eg bag-in-bo!.

-A:AA6O- +ango bar

A papad made from mango pulp favorite mouth tingler for the young and the old.

0acing5 BGgms sachet.

FFF GLYCERINEO- 6efined glycerin made from sweet water obtained in fat

splitting.

<rades available---industrial white-I*

'hemically pure-'0

Indian pharmacopeia-I0

0acing5 B7Gg plastic drums.

TRIFFA-' Fa&&y aci"s<s&aric aci"s?

Standard and hardened "uality distilled fatty acids made from rice bran palm

coconut sunflower rapeseed Soya and linseed oil. 'ustom made formulations

available on order. 6aw material for cosmetic premium soap lubricants chemical

industries rubber and 09' formulations.

0acing, >>GEg in plastic carboys for li"uids 7GEg woven hdpe lined bags for

hardened "uality in flae form.

36

/.:46SO- 'rude palm, oil-bul.

6efined palms oil-bul5 contract farming by farmers. *e provide imported seedlings

after acclimati#ing now how for growing is provided to the farmers. Specialty fats5

6efined oum fat MgarceniaN

Sal stearines Mshorea 6obustaN

0roduced from forest sources. An important nontimber forest produces.

+ango stearines Mmagnifier IndiaN

Shea stearine.

'osmetic ingredients --- mango oleins

Shea oleins.

6efined rice bran oil wa!O- 2sed in various industries lie paper coating

candles water proofing floor shoe and furniture polish cosmetics carbon paper

printing ins fruit and vegetable coatings and pharmaceuticals. 6ice barn oil wa!

may substitute wa! lie carnauba.

4!porters of O- Indian rice Mnon-basmatiN

(e oiled rice barn

(e oiled saled meal- pellets non-dusty.

Importers ofO-

0alm oil and its fractions.

'rude sunflower oil

'rude soybean oil

:ave sea-worthy barges for unloading from ships when anchored near shallow

water ports. 0resence in all minor ports in India. *est coast Eochi and +angalore

east coast gopalpur Eainaa and nagapattinam

.urney pro1ect ; Supplier for double solvent refining of high 33A oils up to BGI

such as 6ice bran oil solvent e!tracted high 33A oils. .he refined oil obtained is of

e!cellent "uality as per food standards.

37

<A6+4=. 4S0/6.46SO- *e e!port woven garments to 2nited States of America,

2nited ingdom 'anada <ermany Hapan 'hile 3rance and Australia.

/ur customer span ranges from chain stores mail order bouti"ues and wholesalers

order si#es vary from >GGG to >,GG,GGG units.

<6=I.4 4S0/6.46SO- *e initially started e!porting rough blocs and have

e!panded by e!porting cut-to-si#e slabs and random slabs. $ater we shifted towards

manufacturing of finished products lie monument artifact items and fireplaces.

SOFT=ARE DEVELOPMENT-' <oena Info.ech limited provides the full range

of I. solutions and services in the following segments.

>. 'onformance services.

B. *eb gardening.

C. Software maintenance and web enabling legacy applications.

F. I. applications in power sector.

7. Smart card based solutions.

.he 7GG s"uare meters of software development center at :yderabad has been

designed to provide the state of art infrastructure for software professionals.

NE= PROJECTS-

Apart from hori#ontal e!pansion, *e have also e!panded out operations

vertically. It may be noted that the company had implemented several pro1ects during

the last 7 years which includes @+* co-generation industrial waste based power

plant, -aery shortening 0lant at 'olombo, Srilana %Hoint 9enture&.

38

I!'$ous R 3 D a!" Tc$!o/o1y Bas

As a pioneer in 4dible industry. *e have over the years built up a strong in-

house 6 & ( and technology base. Sri /m 0raash <oena, who is a 'hemical

4ngineer, with FG years of e!perience in the line, is one of the leading oil

technologists of the company and he is the bac bone for the implementation of

various pro1ects in the company.

*e had a technical collaboration agreement with Joshino Scishausho

'o.$td., Hapan, who are the pioneers in developing the technology and process now

how for refining 6ice bran /il with high 33A %3ree 3atty Acid& and maing it

suitable for edible use. /ut 4ngineering division has designed, fabricated, installed

and commissioned successfully on turn-ey basis.7 4dible /il 6efinery 0lant at a

total pro1ect cost of 6s.>AG million, based on the above technology.

) .he potential of a seed is not recognised, until one fine day we see it standing

strong, ma1estic and gigantic as a treeP So true. Its the tree that captures our

attention and not the seed from which it sproutsT,

Jet, we will fail not to recall the modest start of the C3 group with 3oods 3ats &

3ertilisers $td. Its a saga of F7 years and the 9ision of +r. -.E <oena %'hairman

and +anaging (irector& that has made the C3 group a conglomerate of BG diversified

industrial units.

Starting with edible oil e!traction and refining at 3ood 3ats and 3ertilisers $td we

branched out into multifarious vistas vis-a- vis oil palm cultivation, manufacture of

edible oils and its by-products, baery shortenings and margarine, specialty fats,

commodity trading, garments, power, etc. =otably, we have emerged as one of the

largest )-aery fat & +argarine, manufacturers in India and )*orld leaders in

Specialty fats % '-S & .echnology.,

*ith the committed team enterprise of over >GGG employees, the C3 group steered

past the Indian landscape to e!pand overseas. /ur networ and goodwill has been

vibrantly growing in countries abroad eversince.

39

/ther products manufactured at the facility are baery shortenings, fatty acids and

tailor made solvent fractionated specialty fats. .hese products find use in te!tile, soap,

3oods 3ats & 3ertilisers $td was conceived in >?7?, born in >?@G and was on its feet

by >?@B.

.oday 3oods 3ats & 3ertilisers $td was matured into a conglomerate of BG industrial

units spread over FG acres constantly bussing with activity and providing employment

to over >GGG persons .

/ur product range today includes oils of rice bran, soyabean, sunflower, groundnut ,

sesame, palm, sal seed, mango emel, acid oils, wa!, gums, deoiled meals

%e!tractions&, crude distilled and hydrogenated fatty acids, oil tractions, stearic acids,

glycerine, hydrogenated fats for industrial use, vanaspati / shortening, margarine,

canned fruits, vegetables, baery fats, speciality fats for manufacturing chocolate,

confectionery and cosmetics, natural colours for use in food and feed industry, oleo

resins and herbal e!tracts, fabrication and installation of turney pro1ects for

processing of vegetable oils and their derivatives.

40

6esearch and development is the pivot of our activities and has made us to

stand in good stead. 'ontinuous upgradation processes and diversification in new

research based pro1ects is our 'orporate culture leading us to steady upward

movement.

333 has been a ma1or player in the C3 <roup of industries for almost half a

century. 'ontinued progress in the edible oil & fats field heralded the setting up of yet

another subsidiary -the Asia 0acific 'ommodities $imited %A0'$& in +arch BGGB.

Its facilities comprises5 a modern B7G .0( (esmet physical refinement plant,

>GG .0( interesterfication plant, fatty acid distillation plant, dry fractionation plant

and state-of-art solvent fractionation plant. .hese fac cosmetics, candle, baery,

confectionery, food and chemical industries.

.he A0'$ pro1ect was implemented under .arget BGGG Scheme of <overnment

of Andhra 0radesh and hence is eligible for sales ta! e!emption/deferment. A0'$ has

clients based all over India & overseas.

+odesty <arments is one of those rare organi#ations to which success has come

naturally, since its incorporation.

Success in this highly competitive field has been the result of a devotion to

"uality, commitment to delivery schedules and a desire to always perform better.

.oday these "ualities are recogni#ed and appreciated by importers of woven

garments. .he world sees +odesty as an indispensable partner in their business,

someone who understands their needs and is able to translate that understanding into

concreteterms.

4l

Since its inception in >?DD, +odesty has grown to a turnover of 2SL >B million,

producing F.7 million garments.

=ew (elhi , India Us capital is the hub of +odestyUs operation. In addition to

manufacturing facilities, most of our support departments , shipping "uality control,

designing, sampling are also here.

+odesty <arments has a team of >7GG dedicated employees who are all a part of

oursuccess.

*e ensure that our total fabric is checed before it goes into production. 4ach

and every fabric is tested to -uyerUs re"uirements for shrinage and colour fastness.

+odesty <arments e!ports woven garments to 2nited States of America ,

2nited Eingdom , 3rance and Australia . +odestyUs customer span range from chain

stores, mail order, bouti"ues and wholesalers. /rder si#es vary from >,GGG to >,GG,GGG

units. All receive the same care and attention

.he company was established in >??G. It initially started e!porting rough

blocs to countries lie Hapan and Australia. It then e!panded its business by

e!porting cut-to-si#e slabs and random slabs to various countries lie Indonesia,

(ubai, Singapore, Saudi Arabia & =ew#ealand. .he cut-to-si#e slabs which were

e!ported to (ubai were used in the construction of famous ban called the U-an of

/manU and the ones which were e!ported to Indonesia were used in the construction

of non-alignment building in Indonesia.

$ater the company shifted its way to manufacture of finished products lie

monuments, artifacts items and fire places to countries lie -elgium, <ermany,

3rance, :olland, Scotland, =etherland, 2nitedEingdom etc.

42

Mo!um!&s-

(utch model, Irish model, -elgian model, 3rench model, 4nglish model,

<erman model, $eaves, -oos with leaves, :eart, (oppel :eart, etc.

Artefact ItemsO

3lower vases, $anterns, 2rns, -owls, -irdbaths, 3ountains, Single 0illar,

.hree piece pillar, Ashtray, -alls% >Gcms to @Gcms& and all other round items.

3ire 0lacesO

.hese are made in all designs and colours.

All these products are e!ported in Indian materials lie 0aradisom, :imalayan

blue, 9i#ag blue, Eerala green, 6uby red, Eashmir white, *iscon white, Absolute

blac, Huprana and -lac gala!y.

6ecently the company has taen up a running factory where it is

manufacturing all monuments and airfacts items. Apart from Indian materials it

started processing foreign materials lie =ero Impala from South Africa and -lue perl

from =orway and re-e!porting the same to 4uropean countries.

.he company has also got a set of silled worers and designers in both

fields of monuments and round items, which facilitates it to manufacture any product

when provided with appropriate drawings or designs.

43

VIATON INFRASTRUCTURES PVT LTD

VIATON ENERGY LTD

.he above companies are promoted by the C3 group and 'reative group.

Po7r-

0ower is a critical driver of economic growth and industrial development. India

is facing a huge gap between demand and supply year on year. .he company aims to

set up power pro1ects based on an entire gamut of generation / transmission/

distribution of power. .he company has been alloted licenses for power pro1ects

based on bio mass in 'hattisgarh, +aharashtra and 0un1ab.

Mi!or Air%or&s<Por&s<Co!&rac&ua/ Jo.s-

.he 'ompany foresees increasing infrastructure re"uirement in India, eeping in view

of the huge development phase happening - aims to build in infrastructure facilities in

the above area, in more specifically, the tier B and tier C locations.

44

*F IN OVERSEAS

'4J$/= S04'IA$I/.J 3A.S

'eylon Specialty 3ats 0vt.$td %'S3& is a subsidiary of 3oods 3ats &

3ertilisers $td.

'S3 has been established to tae advantage of Sri $anas strategic

geographic location as an international business center between 'hina, the 3ar 4ast

and countries east of the Sue#. 2nder the Indo Sri $anan 3ree .rade Agreement,

'S3 will be able to e!port its manufactured products into India duty free.

.he factory is situated in the prestigious e!port-processing #one in

-iyagama, located about C7 ms from 'olombo. .he factory is modeled on the latest

technology and is largely fabricated from imported machinery.

'S3 is e"uipped to produce >GG .0( of baery shortenings and margarine

and CG .0( of Specialty 3ats. 2nlie hydrogenation, which produces high trans fatty

acids, which are detrimental to health, 'S3 produces trans-free hard fats using the

interesterification .echnology.

'eylon Specialty 3ats will focus on maing specialty fats for the baery

and confectionery industries. .hese specialty fats will be natural ingredients to

chocolates, ice cream, pastries, biscuits, breads, and many other applications. .he

modern factory will also be able to produce table and industrial margarine that has a

growing maret both in Sri $ana and abroad.

45

*F AFRICA

.he C3 group pushes on into the remote and less accessed countries of the world

because it sees a mutual opportunity for growth and development even in far removed

nations.

C3 Africa has operations in various *est African countries such as ; <hana, -urina

3aso, -enin, +ali, .ogo, =igeria and Ivorycoast. C3 Africa is a wholly owned

subsidiary of 3oods 3ats and 3ertilisers $td., India. .he company is involved in

procurement and trading of various commodities.

.he commercial and economic activities of the company have e!tended beyond the

boundaries with various procurement centres and warehouses spread all over which

are well netted with efficient transport conduit.

/ur in-house clearing and forwarding center at the port ensures swift and efficient

foreign trade. .he African e!perience has given C3 group, the 1oy of co-operation

among developing nation.

PAR2ER INTERNATIONAL

)S+A$$ -2. 0/*4632$,

.he C3 group has always believed in the above adage. .his prompted us to set up

0arer International at Singapore - one of the worlds most prosperous countries with

strong international trading lins.

0arer International caters to the groups trading activities of Agro commodities.

46

SPECIALITY FATS

'elebrations are never complete without confectioneries. And confectioneries

are incomplete without a iss of Speciality 3ats. .he C3 <roup has been a silent

partner in sweet moments. /bscure, hidden and yet adding flavor you have relished.

/ver CG years starting from >?A7 we have grown hand in hand with the

confectionery industry providing her with e!otic fats e!tracted from Shea nuts, Sal

seeds, Eoum ernel, +ango ernel and Illipe. .hese products have been tailor-made

to suit the needs of various confectioners. 333 $td is today one of the largest sources

of specialty fats in the world.

333 $td. pioneered in India, the process of both dry fractionation and solvent

fractionation through in-house development of the process technology. *e

manufacture world-class Sal, +ango & Shea stearine using modern solvent

fractionation techni"ues. *e also have the capability to produce Illipe & oum fats

and high "uality 0alm +id 3raction %I9-CC&. .hese products find e!tensive

application in the manufacture of cocoa butter e"uivalents %'-4&, which are used in

the chocolate industry. .ailor-made '-4s have functional properties similar to cocoa

butter and are far more economical. In combination with cocoa butter it standardi#es

product "uality and enhances product shelf life. .his is made possible by use of

special types of '-4Us nown as 'ocoa -utter Improvers %'-I& which raise the

melting point of chocolate for better storage stability in tropical climates. .he

Speciality 3ats (ivision has always observed stringent "uality assurance systems in

its processes.

333 is today, one of the largest sources of speciality fats in the world.

.estimony to mar our "uality is the continued patronage we en1oy from large

manufacturers of 'ocoa -utter 4"uivalents from Hapan, +alaysia, Italy, :olland, 2E

& the Scandinavian countries.

47

OIL PALMS

.he /il 0alm (ivision %/0(& has successfully set up a complete cycle of

operation%s& and moved from the 0/' %0roof of 'oncept& stage to 6amp up stage in a

short period of time.

I! A!"$ra Pra"s$

V /perations in ? +andals of *est <odavari (ist./F +andals of 9i#ianagaram

(istrict with a potential of FGB7G ha.

V =urseries in *est <odavari and 9i#ianagaram (istricts

V >B,7GG ha area under /il 0alm

V +ultiple collection centres

V >G-BG ./hr 0alm /il +ill % Including 0roduction of 0alm Eernel /il&

V 6efinery / 3ractionation 2nit for further processing of '0/&'0E/

V A.7 +w power plant based on 0alm waste as its fuel

I! 2ar!a&a5a

V /perations in C district of Eoppal,<adag and 6aichur with a potential of CG,GGG ha.

V /ne nursery in Eoppal (istrict

V B,7GG ha area under oil palm.

V +ultiple collection centres

V 7 ->G +. 33-/ :our 0alm /il +ill coming up in Eoppal (istrict.

I! MiForam

V /perations in C district of Ai#wal,Serchhip and Saiha with a potential of BG,GGG ha.

V /ne nursery in Serchhip (istrict

V In its first year of area e!pansion covered 7GG ha under oil palm

48

I! Gu:ara&

V /perations in B distrcts of Surat and .api with a potential of >D,FGG ha.

V /ne nursery in .api (istrict

V In its first year of area e!pansion covered 7GG ha under oil palm

I! Orissa

V /perations in C distrcts of (henanal and Ha1pur with a potential of >B,GGG ha.

V /ne nursery in (henanal (istrict

V In its first year of area e!pansion covered 7GG ha under oil palm

I! Tami/!a"u

V <overnment of .amilnadu has allotted ).oothuudi, district for /il 0alm

(evelopment during

BGGD. Arrangements are being made for establishing =ursery and start related

operations

Farmrs G our %ar&!rs &o Succss

= /oo5 a& 0armrs as our %ar&!rs &o succss a!" 7 %romis

V .o give them the best "uality sapling / best e!tension practices

V .o ensure "uality plantation / best yield at field level

V .o provide training to farmers

V .o loo at intercrop in aged plantation ; increased income to farmers

V .o be a support to the farmer in his other needs.

*hat the 3uture has in Store

V A ma1or ramp up in ac"uiring a very good area coverage in the subse"uent year%s&

49

Aras o0 O%ra&io!

/0( ; A0

V =ursery - (ubacherla 9illage, *est <odavari district.

V +ill//ffice - Jernagudem village, *est <odavari district

/0( ; EA6=A.AEA