Vipu PT 8 (Compatibility Mode)

Diunggah oleh

Alexandru PoenaruDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Vipu PT 8 (Compatibility Mode)

Diunggah oleh

Alexandru PoenaruHak Cipta:

Format Tersedia

1

by

C. Vipulanandan (Vipu) Ph.D., P.E.

Professor of Civil Engineering

Director of CIGMAT & THC-IT

DFI 2012 Conference

Houston, Texas

October 16, 2012

Part 8: Specifications & Experience

I

G M

A

T

C

1994

(a) Specifications (GEC, DFI)

(b) CIGMAT/UH Project

Part 8. Specifications and Experience

2

3

Kreneck Road Bridge Project

Load Tests

Battered ACIP Piles

Load Tests and the Lessons Learned

4

Project

Location

Site Information and Conditions (contd)

Soil Profile at Krenek Road

(ACIP Pile)

Soil Profile at Runneburg Road

(Driven Pile)

Sand

Clay

Clay

Sand

Clay

Clay

Clay

42 ft

47 ft

52 ft

39 ft

40 ft

49 ft

50 ft

Sand

Sand

5

280-ft long bridge at US 90/Krenek Road

90 ft 100 ft 90 ft

16 vertical central bent

piles under 4 columns,

4-pile groups

57-ft long, 18 in piles

8 in-battered piles,

8 out-battered piles,

4:1 batter

62-ft long, 18 in piles

5 ft

7 ft

8.5 ft

43 ft

42 ft

52 ft

8 in-battered piles,

8 out-battered piles,

4:1 batter

62-foot long, 18-in piles

w/ full-length cages

16 vertical piles in 4, 4-pile groups

57-foot long, 18-in piles

w/ full-length cages

Grade Crossing: 280-foot-long

Bridge at US 90 / Krenek Road, in

Crosby, Texas

6

Basis of Design..

Simple

Design

Methods for

Ultimate

Compressive

Resistance

7

Load Testing: Both ACIP

and Driven Piles.

(for verification of capacity

estimation method)

Load- Settl e ment Cur ves f or ACI P and PC Dri ven Test

Pil es

0. 0

0. 1

0. 2

0. 3

0. 4

0. 5

0. 6

0. 7

0. 8

0. 9

1. 0

1. 1

1. 2

1. 3

1. 4

1. 5

1. 6

0 50 100 150 200 250 300

Load

t on

S

e

t

t

l

e

m

e

n

t

i

n

ACI P Pil e

215 t ons

Dri v en Pil e

165 t ons

Davi ss on' s Cri t eri a

ACI P

Davi ss on' s Cri t eri a

Dri v en Pil e

18-in. by

57 feet long

16-in by 46

feet long

8

Full-Scale Load Tests (contd)

Load transfer behavior

of ACIP pile

ACIP Pile supported by

side resistance

Almost zero end bearing

due to soil mining

(depressuring of the sand

during drilling into

waterbearing sand)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

-50 0 50 100 150 200 250

Load (tons)

D

e

p

t

h

(

f

t

)

Sand

Sand

Clay

Clay

Unit side shear resistance in clay:

driven and ACIP piles at US 90 and

Krenek/Runneberg Roads

Driven test pile: 16-in.

sq. PC by 46 feet long:

Developed shear

Available shear

() = 0.53

ACIP test pile: 18-in.

by 57 feet long:

Developed shear

Available shear

() = 0.83

Design Loads are 90 Tons w/ FS = 2

9

280-ft long bridge at US 90/Krenek Road

90 ft 100 ft 90 ft

16 vertical central bent

piles under 4 columns,

4-pile groups

57-ft long, 18 in piles

8 in-battered piles,

8 out-battered piles,

4:1 batter

62-ft long, 18 in piles

5 ft

7 ft

8.5 ft

43 ft

42 ft

52 ft

Site Information and Conditions (contd)

ACIP Pile Design Facts

TxDOT design method for drilled shafts (1972)

No. of ACIP piles =64

Abutment piles =32 (2 abutments)

Central bent piles =32 (8 columns)

Diameter of ACIP pile =18 in (0.46 m)

Length of ACIP pile

Test pile =62 ft (18.9 m)

Abutment pile=62 ft (18.9 m)

Central bent pile =57 ft (17.4 m)

10

Bridge foundation

construction

experiences

1. Drilling

ACIP piles are formed by

rotating a continuous-flight

auger (CFA) into the ground

to a predetermined tip depth.

downward

11

2. Grouting

As the auger is being

withdrawn, sand-cement

grout is injected

continuously through the

hollow stem of the auger.

Grout Mix

Truck for

Pumping

upward

Grout line

Flow Meter Pressure

Transducer

Q

Q

u

l

a

Quality Controls

12

Bullet-nosed cages

13

3. Inserting Steel Cage

Reinforcing steel cage

is inserted into the

grout after it is fully

withdrawn.

Full-length

steel cage

roller

Drilling an ACIP pile

with out-batter for an

abutment

14

PVC pipe skids

for batter pile

cages

Inserting a 62-foot

rebar cage on a

4:1 batter

15

(1) Specifications and Guidelines are available

for ACIP Piles.

(2) Real-time Monitoring of Grout Volume and

Pumping Pressure are Important.

(3) Load Tests on Site are Encouraged.

CONCLUSIONS

I

G M

A

T

C

1994

Anda mungkin juga menyukai

- Scientific American Supplement, No. 312, December 24, 1881Dari EverandScientific American Supplement, No. 312, December 24, 1881Belum ada peringkat

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Drilling With Casing PDFDokumen69 halamanDrilling With Casing PDFtibismtxBelum ada peringkat

- Girder LaunchingDokumen10 halamanGirder Launchingmitnath100% (1)

- Standard Equipment Capability EstimatesDokumen22 halamanStandard Equipment Capability EstimatesKeith Cubero67% (3)

- Wp5 Appendix C PrelimstructualdesigncalculationsDokumen62 halamanWp5 Appendix C PrelimstructualdesigncalculationsAnitha Hassan KabeerBelum ada peringkat

- Well Completion PETRONASDokumen56 halamanWell Completion PETRONASAbdul Azis Zaenal Mustopa100% (4)

- Odot - Pda IntroDokumen68 halamanOdot - Pda IntroRuBiE_CiViLBelum ada peringkat

- FAA Analysis of CC2 RigidBrill, Ricarde.10ppDokumen10 halamanFAA Analysis of CC2 RigidBrill, Ricarde.10ppTim LinBelum ada peringkat

- Method Statement of Overwatervilla and WalkwayDokumen10 halamanMethod Statement of Overwatervilla and WalkwayMuhammad Uwais100% (1)

- Recent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place PilesDokumen25 halamanRecent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place Pileszzz_monsterBelum ada peringkat

- Helical Design Theory and Applications: by Darin Willis, P.EDokumen55 halamanHelical Design Theory and Applications: by Darin Willis, P.Eahmedmohammad28Belum ada peringkat

- Horizontal DrillingDokumen36 halamanHorizontal Drillingayan100% (1)

- Slide TSP308 TSP 308 014 Metoda Dan Peralatan Konstruksi PDFDokumen59 halamanSlide TSP308 TSP 308 014 Metoda Dan Peralatan Konstruksi PDFeddyhusinBelum ada peringkat

- 0pile Load Test - 1Dokumen39 halaman0pile Load Test - 1rushikeskBelum ada peringkat

- All Type of Pile Load TestDokumen120 halamanAll Type of Pile Load TestLindsey Smith100% (17)

- Appendix F 2008Dokumen3 halamanAppendix F 2008Suhas NatuBelum ada peringkat

- Intro To Field InvestigationDokumen19 halamanIntro To Field InvestigationmlakkissBelum ada peringkat

- Casing and Cementing Preview BDokumen17 halamanCasing and Cementing Preview Bdonivald100% (1)

- 444 PDFDokumen45 halaman444 PDFfacedoneBelum ada peringkat

- Progress Presentation: Geotechnical Design of A Star Flyer Tower (Six Flags) Projected Nearby A SlopeDokumen42 halamanProgress Presentation: Geotechnical Design of A Star Flyer Tower (Six Flags) Projected Nearby A SlopeAnkur ChoudharyBelum ada peringkat

- Horizontal DrillingDokumen36 halamanHorizontal DrillingRascabuche Del InfiernoBelum ada peringkat

- West Texas - Permian BasinDokumen8 halamanWest Texas - Permian BasinPesireron RoberthBelum ada peringkat

- Geotechnical Testing Methods I - ASDokumen26 halamanGeotechnical Testing Methods I - ASSDBelum ada peringkat

- Deepwater Pipelay Capabilities: Company UpdateDokumen21 halamanDeepwater Pipelay Capabilities: Company Updatecontenido100% (1)

- Casing Drilling Baker2Dokumen34 halamanCasing Drilling Baker2Yesica Andrea GonzálezBelum ada peringkat

- Foundations and Deep BasementsDokumen76 halamanFoundations and Deep BasementsRicky Imanda100% (1)

- IESL Presentation by Ranjith12Dokumen17 halamanIESL Presentation by Ranjith12Surendra ElayathambyBelum ada peringkat

- Geotechnical Investigation 1225510757282453 9Dokumen39 halamanGeotechnical Investigation 1225510757282453 9fandhiejavanov2009Belum ada peringkat

- VST and DMTDokumen44 halamanVST and DMTRodolfo RodriguezBelum ada peringkat

- Pontoon ConstructionDokumen97 halamanPontoon ConstructionasbanjohnpiousBelum ada peringkat

- CORING (Petroleum)Dokumen64 halamanCORING (Petroleum)restofficalBelum ada peringkat

- Introduction To Bridge FoundationsDokumen39 halamanIntroduction To Bridge FoundationsTauseefBelum ada peringkat

- Foundation Design and Construction HK - Lecture SlidesDokumen20 halamanFoundation Design and Construction HK - Lecture SlidesScott DownsBelum ada peringkat

- Offshore Windfarm Design OE 5662: FoundationsDokumen46 halamanOffshore Windfarm Design OE 5662: FoundationsJpver1000Belum ada peringkat

- Cast-in-Place Piles-Installation, Design, Quality Control and Load TestingDokumen9 halamanCast-in-Place Piles-Installation, Design, Quality Control and Load TestingAlexandru PoenaruBelum ada peringkat

- Introduction To Drilling TechnologyDokumen68 halamanIntroduction To Drilling TechnologyKrupal Patel100% (1)

- Strategic Open Pit Mine Planning Course PDFDokumen1.009 halamanStrategic Open Pit Mine Planning Course PDFAnonymous IabqZQ1tk100% (1)

- LTA Ow Chun Nam PresentationDokumen46 halamanLTA Ow Chun Nam PresentationAllan Teo100% (1)

- Chapter Four Pumping Tests of WellsDokumen6 halamanChapter Four Pumping Tests of WellsMistireselassieBelum ada peringkat

- Compairing Guided Auger Boring TechniquesDokumen7 halamanCompairing Guided Auger Boring TechniquesVinita KapoorBelum ada peringkat

- Plate Load TestDokumen13 halamanPlate Load TestHumamBelum ada peringkat

- 364 PDFDokumen15 halaman364 PDFRajni SharmaBelum ada peringkat

- Bridge InvestigationDokumen183 halamanBridge Investigationgrkvani10100% (1)

- Applegate Cross Passage Excavatio FreezingDokumen60 halamanApplegate Cross Passage Excavatio FreezingSahiduj Jaman SajuBelum ada peringkat

- TAMU - Pemex Offshore Drilling: Lesson 20 Horizontal WellsDokumen54 halamanTAMU - Pemex Offshore Drilling: Lesson 20 Horizontal Wellsdriller22100% (1)

- Design of FootingsDokumen102 halamanDesign of FootingsTBCACCOUNTs100% (1)

- Lecture20 Drilled ShaftsDokumen57 halamanLecture20 Drilled ShaftsAsia WardBelum ada peringkat

- Oil and Gas OrganizedDokumen30 halamanOil and Gas OrganizedM.a.t.h T.h.e.wBelum ada peringkat

- Workover Tubing DesignDokumen120 halamanWorkover Tubing DesignMohammed IbrahimBelum ada peringkat

- Table of Content I Preface VDokumen6 halamanTable of Content I Preface VujjwalBelum ada peringkat

- Oil Well Drilling Technology-OnshoreDokumen64 halamanOil Well Drilling Technology-OnshoreAntaryami01100% (2)

- Project Work: Construction of Bridge No 352 (6 X 30.50M PSC Box Girder)Dokumen44 halamanProject Work: Construction of Bridge No 352 (6 X 30.50M PSC Box Girder)shravan38Belum ada peringkat

- The Design of Piled Foundations: Structures and Solid Body MechanicsDari EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsPenilaian: 4 dari 5 bintang4/5 (8)

- Pile Design and Construction Rules of ThumbDari EverandPile Design and Construction Rules of ThumbPenilaian: 4.5 dari 5 bintang4.5/5 (15)

- Scientific American Supplement, No. 497, July 11, 1885Dari EverandScientific American Supplement, No. 497, July 11, 1885Belum ada peringkat

- Estimator's General Construction Manhour ManualDari EverandEstimator's General Construction Manhour ManualPenilaian: 4.5 dari 5 bintang4.5/5 (20)

- Scientific American Supplement, No. 384, May 12, 1883Dari EverandScientific American Supplement, No. 384, May 12, 1883Belum ada peringkat

- HV Rede AV enDokumen7 halamanHV Rede AV enAlexandru PoenaruBelum ada peringkat

- 01-Thermal Integrity Profiler PDI USF TIPDokumen2 halaman01-Thermal Integrity Profiler PDI USF TIPAlexandru PoenaruBelum ada peringkat

- 01 ThomasDokumen39 halaman01 ThomasAlexandru PoenaruBelum ada peringkat

- C939Dokumen3 halamanC939Alexandru PoenaruBelum ada peringkat

- 02-Vibratory Driven Pile Installation Method in PermafrostDokumen8 halaman02-Vibratory Driven Pile Installation Method in PermafrostAlexandru PoenaruBelum ada peringkat

- 21 SpenceDokumen11 halaman21 SpenceAlexandru PoenaruBelum ada peringkat

- Selmon Expressway in Tampa, Florida: Case History of Drilled Shaft Design For Extreme VariabilityDokumen18 halamanSelmon Expressway in Tampa, Florida: Case History of Drilled Shaft Design For Extreme VariabilityAlexandru PoenaruBelum ada peringkat

- Cast-in-Place Piles-Installation, Design, Quality Control and Load TestingDokumen9 halamanCast-in-Place Piles-Installation, Design, Quality Control and Load TestingAlexandru PoenaruBelum ada peringkat

- Augered Piles Embedded Into Bedrock and Partially Weathered BedrockDokumen7 halamanAugered Piles Embedded Into Bedrock and Partially Weathered BedrockAlexandru PoenaruBelum ada peringkat

- Vipu PT 6 (Compatibility Mode)Dokumen17 halamanVipu PT 6 (Compatibility Mode)Alexandru PoenaruBelum ada peringkat

- Imagini JamoDokumen153 halamanImagini JamoAlexandru PoenaruBelum ada peringkat

- CE 5154 Introduction To Bridge EngineeringDokumen115 halamanCE 5154 Introduction To Bridge EngineeringDavid Gómez de la TorreBelum ada peringkat

- Computation of Interaction Diagrams For Cyclic Axial Loads in Offshore Piles Based On An Effective Stress Method.Dokumen10 halamanComputation of Interaction Diagrams For Cyclic Axial Loads in Offshore Piles Based On An Effective Stress Method.Adriana BerroteranBelum ada peringkat

- Soil Slope Stabilisation Methods: John Oliphant, Robert Mccafferty & MR Richard AptedDokumen6 halamanSoil Slope Stabilisation Methods: John Oliphant, Robert Mccafferty & MR Richard AptedRama Rama KrishnaBelum ada peringkat

- Soil ReportDokumen42 halamanSoil Reportfrog15Belum ada peringkat

- 8.0 Design For 5-Pile Group (Square Group)Dokumen1 halaman8.0 Design For 5-Pile Group (Square Group)afzal taiBelum ada peringkat

- Chapter 2 - SubstructureDokumen116 halamanChapter 2 - Substructurescribd1991Belum ada peringkat

- Arc 407 Const. DetailingDokumen15 halamanArc 407 Const. DetailingUsman UmarBelum ada peringkat

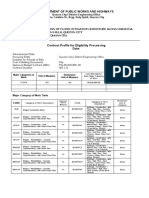

- Project Profile FormDokumen2 halamanProject Profile FormEntrepreneur WaysBelum ada peringkat

- Handout Module 06 Geotechnical InvestigationDokumen8 halamanHandout Module 06 Geotechnical InvestigationCHRISTIAN DELA CRUZBelum ada peringkat

- Soldier Pile and Lagging Caltan 1990 Tedds CalcDokumen2 halamanSoldier Pile and Lagging Caltan 1990 Tedds CalcRJSQBelum ada peringkat

- Comparison of Epoxy Coated Rebar Vs CPCC Rebar Vs CRS RebarDokumen5 halamanComparison of Epoxy Coated Rebar Vs CPCC Rebar Vs CRS RebarPritha Das100% (1)

- Asia Pile - Pda Method StatementDokumen31 halamanAsia Pile - Pda Method StatementMohd Aiman Mohd AhyakBelum ada peringkat

- FoundationDokumen48 halamanFoundationrenukaBelum ada peringkat

- Stability Analysis and Safety Factor Prediction of Excavation Supported by Inclined Piles in ClayDokumen8 halamanStability Analysis and Safety Factor Prediction of Excavation Supported by Inclined Piles in ClayPutik .jajaBelum ada peringkat

- Micropile ConstructionDokumen7 halamanMicropile Constructionyh wanBelum ada peringkat

- (Yen & Khaleghi, 2016) Design and Construction Challenges of Jointless Bridges in Seismic RegionsDokumen23 halaman(Yen & Khaleghi, 2016) Design and Construction Challenges of Jointless Bridges in Seismic RegionsAnderson UrreaBelum ada peringkat

- GB 50007-2011-EnDokumen170 halamanGB 50007-2011-Enrahman fatahBelum ada peringkat

- General Construction Notes: Bureau of DesignDokumen15 halamanGeneral Construction Notes: Bureau of DesignRicoyan YanBelum ada peringkat

- Perhitungan Tiang PancangDokumen64 halamanPerhitungan Tiang PancangibnuBelum ada peringkat

- Ground Improvement TechniquesDokumen31 halamanGround Improvement TechniquesHamadBelum ada peringkat

- 3.5xRC 21.5'X46.5' - Structural Drawing - R00Dokumen31 halaman3.5xRC 21.5'X46.5' - Structural Drawing - R00Moe Oo HtunBelum ada peringkat

- Bachelor of Engineering in Civil EngineeringDokumen19 halamanBachelor of Engineering in Civil EngineeringMritunjay kumarBelum ada peringkat

- Flood Protection HWS Brochure ENGDokumen24 halamanFlood Protection HWS Brochure ENGMark ShamaBelum ada peringkat

- AA - SPEC - 114013 - Foundations For Heavy MachineryDokumen21 halamanAA - SPEC - 114013 - Foundations For Heavy MachineryJakesBelum ada peringkat

- Suspension Bridges: Dora Mayfield CEVE 499Dokumen16 halamanSuspension Bridges: Dora Mayfield CEVE 499Cătălina Lăscoi100% (1)

- Preambles To All Trades PDFDokumen28 halamanPreambles To All Trades PDFhashim.mj100% (1)

- Wbs and Division of Work Excel Spread SheetDokumen12 halamanWbs and Division of Work Excel Spread SheetAlbertBelum ada peringkat

- Gantry Piling - MethodDokumen2 halamanGantry Piling - Methodnaseeb100% (1)

- 2012 Icee Book ListDokumen52 halaman2012 Icee Book Listbharath_vce008Belum ada peringkat

- Bill of Quantities-TenderDokumen12 halamanBill of Quantities-TenderbhartiBelum ada peringkat