Anurag

Diunggah oleh

Krishan Borwal0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

46 tayangan50 halamanAnurag

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAnurag

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

46 tayangan50 halamanAnurag

Diunggah oleh

Krishan BorwalAnurag

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 50

Project Report Submitted in Partial Fulfilment of the

Requirements for the Degree of

B.E.(Chemical with MBA)

2014

BY

ANURAG SINGH

CM10205

Dr. S. S. BHATNAGAR UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING &

TECHNOLOGY

PANJAB UNIVERSITY

CHANDIGARH-160014, INDIA

PRODUCTION OF POLYSTYRENE

CAPACITY: 200 tons/day

PANJAB UNIVERSITY, CHANDIGARH

CERTIFICATE

This is to certify that ANURAG SINGH, CM10205 a fourth year student of Dr. S. S. Bhatnagar

University Institute of Chemical Engineering & Technology, Panjab University, Chandigarh has

completed his/her project titled PRODUCTION OF POLYSTYRENE. This project report may be

accepted for evaluation as part of the requirement of B.E.(Chemical with MBA).

Signature

_____________________

Dr. Gargi Ghoshal

Dr.S.S.B.U.I.C.E.T

Panjab University

Chandigarh

ACKNOWLEDGEMENT

I would like to take this opportunity to express my sincere regards and

deep sense of gratitude to my guide Dr.Gargi Ghoshal . I am thankful to my

guide for not only guiding me for this project, but also encouraging me and

finding time for reading and commenting on manuscript.

His encouragement kept my spirit alive and lifted my moral up to very

high level of interest during the preparation of this project report.

I am highly thankful to the authorities of Prof. Sanchita Chauhan and

Prof. Anupama Thakur of Panjab University for providing valuable references

throughout the preparation of this project report. I would also like to take this

opportunity to thank all my friends without whose support I would not be able

to complete this report in time.

Finally, my grateful acknowledgements are of those who have helped me

directly or indirectly for preparing this project report.

ANURAG SINGH

B.E. (CHEMICAL)+MBA-4

TH

YEAR

ROLL NO : CM10205

YEAR : 2013-2014

Table of Contents

Title: Production of Polystyrene

1. Introduction

Properties and Uses

2 Various Polymerization Process

Choice of Process

Selection of Process

Process Description

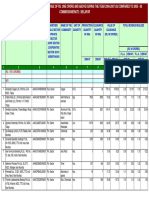

3. Material Balance 5

4. Energy Balance

5. Process and Equipment Design

Reactor

Dryer

6. Cost Estimation and economics

Estimation of Capital Investment

Estimation of Total Product Cost

Estimation of Total Income

7. Process Instrumentation Diagrams

Reactor

8. Plant Location and Site Selection 5

9. Plant Layout

10. Commissioning Start-up and Shut Down

11. Pollution Control and Safety

12. Annexure

13. Bibliography

INTRODUCTION

Ostromislensky of the Naugatuck chemical company first introduced polystyrene via

a pioneering parent in 1925. At about the same time, work by I.C. Farbenindustrie began

that resulted in the commercialization of polystyrene in Europe. The Dow Chemical

Company also began development of the polystyrene product and process in 1930.

The commercial production of polystyrene first took place at about the same time in

Germany and the US during the early 1930s; it was manufactured primarily for its good

electrical properties. The polymer was produced in the UK at about the time of the beginning

of the Second World War, when it was used not only as an electrical insulant but also as a

glass replacement in optical instruments after lenses and prisms were no longer available

from Germany.

The major stimulus to the production of styrene monomer came in 1942 in the US with

the large-scale installation of manufacturing facilities for the styrene-butadiene rubber, which

was required to replace natural rubber after the cessation of suppliers from the Far East. After

the war when natural rubber became available again, there was a large surplus production for

styrene monomer, and polystyrene became available to help meet the demand for materials,

which could be used to satisfy the shortage of consumer goods. The polymer has good

mouldability, high transparency and rigidity, which made it suitable for wide range of

applications.

Crystal polystyrene was the initial polystyrene produced was a homopolymer. It is also

known as general-purpose polystyrene and exhibits exceptional clarity with heat resistance

above that of other commodity thermoplastics. A further development was rubber modified

or impact polystyrene. Impact polystyrene is opaque and exhibits increased toughness and

ease of processing versus other commodity thermoplastics.

Another major type of polystyrene application is expandable polystyrene, which is used

mainly in lightweight insulating applications.

Polystyrene has many advantages, which include:

Lightweight: reduces transport fuel consumption and the cost of distributing products.

Performance: provides insulation and protection from contamination and impact.

Economy: usually less expensive than alternative materials resulting in savings to the

consumer.

Energy Savings: polystyrene manufacture requires less energy than alternatives resulting in

lower "greenhouse" emissions. As insulation, polystyrene foam enable enormous energy

savings in commercial installations such as cool stores.

The annual consumption of polystyrene in US comprises of 8% of the total

plastics used in the United States, making it one of the most often used types of polymers.

PROPERTIES AND USES.

Properties:

A] Processing properties:

Flow properties may be the most important properties of polystyrene processes.

There are two widely accepted industry methods for the measurement of processing

properties. These include the melt flow index and the solution viscosity.

The melt flow index is measured by ASTM method as a measure of the melt

viscosity at 200

0

C and a 5kg load. The melt flow index of polystyrene is generally

controlled by adjustment of the molecular weight of the material and by the addition of

such lubricants as mineral oil. Polystyrenes are commercially produced with melt flow

ranges of less than 1 to greater than 50, although the most widely available grades generally

have melt flows between 2.0 and 20g per 10min.

Solution viscosity is another method for measuring the molecular structure of the

polystyrene. Solution viscosity can be measured as an 8% solution in toluene and increases

with increasing molecular weight.

B] Rheological properties:

Polystyrene is a non-Newtonian fluid with viscoelastic properties. The viscosity

of polystyrene melts or solutions is defined as he ratio of shear stress to shear rate.

Generally, as the molecular weight of the polymer is increased or mineral oil is

decreased, melt viscosity increases.

C] Mechanical properties:

Crystal polystyrenes have very low impact strengths of less than 0.5ft-lb.

Commercially available impact polystyrene grades can be obtained with values of 1.0 -

4.1 ft-lb. Generally, polystyrenes are not produced with greater than 15% total rubber

because of polymerization processing constraints. Nevertheless, impact properties can be

increased substantially without additional rubber by the proper control of rubber particle

size, percentage of grafting, cross-linking, and percentage of gel.

Tensile and flexural properties are also important representation of the strength of

polystyrenes. Increasing the rubber modification of polystyrene generally leads to lower

tensile strength, crystal grades being stiff and brittle. Tensile strength is also decreased by the

addition of lubricants, such as mineral oil. Flexural strengths for polystyrenes can be obtained

from 5000 to 18000psi and are also decreased by the addition of rubber and other

additives to the polystyrene. Elongations can be obtained from 1% for crystal polystyrene to

100% for some impact polystyrene grades.

D] Thermal properties:

Annealed heat distortion is one popular method for measuring he

resistance to deformation under heat for polystyrenes. The heat distortion temperature is

decreased by the addition of rubber, mineral oil, or other additives to polystyrene.

The glass transition temperature for unmodified polystyrene is 373 K, and the

glass transition temperatures for polybutadienes are 161-205 K, subject to the cis, trans, and

vinyl content.

E] Chemical properties:

Solvent crazing of polystyrene is a commercially important phenomenon.

High impact polystyrenes are susceptible to solvent crazing at the interface between the

rubber particles and the polystyrene phase. The resistance of polystyrene to this crazing is

referred to as environmental stress crack resistance (ESCR). For food-packaging

applications, such as butter tubs and deli containers, polystyrenes with high ESCR properties

are desirable. Increasing the percentage of gel, percentage grafting, and rubber particle size

can increase stress crack resistance.

Residual levels of low molecular weight materials are also important to

polystyrene performance. Some of the chemical impurities in the polystyrene are styrene

monomer and ethyl benzene solvent. Residual levels of styrene below 200 ppm and ethyl

benzene levels below 30 ppm are obtainable for very specialized applications.

F] Optical properties:

Crystal polystyrene is a transparent and colorless polymer; high impact

polystyrene is generally opaque as a result of the rubber particles. Developmental grades of

translucent impact polystyrenes have been produced but have not gained wide acceptance.

The major optical; property for high impact polystyrene is gloss. Gloss is a

measure of the percentage of light reflected is generally controlled by the size of the

rubber particle. In general, the smaller rubber particle gives higher gloss. Values from 20

to 95% reflectance are commercially available.

High impact polystyrene is naturally white and crystal polystyrene is

naturally clear, but both can be readily colored.

G] Gas and water permeabilit y of polystyrene:

When styrene polymers are used in packaging applications, the gas and

water permeability characteristics take on an important aspect. Polystyrene itself has its

limitations and in consequence is often used with other polymers so as to achieve

different permeability properties. These properties can change dramatically as other

monomers are introduced into the molecule.

H] Weatherabilit y and ageing:

Polystyrene and the copolymers are susceptible to degradation by the

action of sunlight; the main effect being due to UV radiation in the wavelength band of

300-400nm. the action of the UV radiation is accompanied by the oxidation so that the

overall degradation reaction is one of photo oxidation. The extent of degradation varies

from location to location owing to the differences in the intensity of the radiation. This is

of considerable importance in many applications because the degradation is reflected, in

the case of transparent compositions, in a yellowing effect and generally in a loss of

mechanical properties such as a lower elongation at break and a reduced impact strength.

I] Toxicity:

Polystyrene is a low toxic product. The FDA for the food contact

applications approves almost all commercially available polystyrenes. The polymer

itself is not digestible and is not normally biodegradable.

Typical properties of the general-purpose polystyrene:

Mechanical

property

Units General purpose

polystyrene

Tensile strength MN/m

2

34.5-48.3

Elongation at break % 20-30

Modulus in tension MN/m

2

2700-3450

Impact strength J/m 37-59

Flexural strength MN/m

2

48.3-75.8

Deflection in 0.15-0.35

Hardness Rockwell scale M45-M60

Electrical and

allied property

Units GPPS

Dielectric strength V/mil 500-700

Volume resistivity -cm 10

17

-10

19

Dielectric constant cps 2.45-2.65

Power factor of

dissipation

cps 10-30*10

-8

Arc resistance S 60-135

Heat distortion 0

F

170-180

Water absorption (in 24 hrs),% 0.03-0.04

Uses:

1. 1.Extruded foam sheet of polystyrene can be thermoformed into such parts as egg

cartons or carryout food containers. Foam grade polystyrene is generally a

high- heat crystal polystyrene with a high molecular weight.

2. Another type of polystyrene foam is that produced from expandable

polystyrene beads. These beads can be molded to produce hot drink cups, ice

chests, or foam packaging. Also, the expandable beads can be molded in

very large blocks that can then be cut into sheets for thermal insulation.

Densities of as low as 1lb/ft

3

on foamed products are commercially obtainable.

3. Extruded crystal polystyrene sheet can be biaxially oriented by

mechanically pulling the extruded melt in multiple directions. The stretched

sheets is then cooled and allowed to set with the biaxially orientation frozen

into the sheet. This process produces crystal polystyrene sheet of thin gauge

wit very high strength.

Typical applications include envelope windows, cap layers for glossy sheet, or

thermoforming into food packaging applications.

4. Optical property of polystyrene is used in manufacture of unbreakable glasses for

gauges, windows and lenses, as well as in countless specialties and novelties and also

for edge lighting for the edge lighting of indicators and dials

5. Solid or liquid pigments and dies color high impact and crystal polystyrenes. This can

be accomplished in both extrusion and injection molding processes. These

colorants are added and mixed during the melting stage of both the processes.

Also, polystyrene parts are amenable to high quality printing. Labels can be printed

directly on the polystyrene part to produce attractive containers.

6. Polystyrenes are also used in furniture, packaging, appliances, automobiles,

construction, radios, televisions, toys, house ware items, and luggage.

PROCESS DESCRIPTION

Manufacturing process:

Polystyrene is manufactured by the addition polymerization of styrene monomer

unit. Dow Chemical is the world's largest producer with a total capacity of 1.8 million

metric tones in the USA, Canada, and Europe (1996 figures). The main manufacturing

route to styrene is the direct catalytic dehydrogenation of ethyl benzene:

The reaction shown above has a heat of reaction of -121 KJ/mol (endothermic).

Nearly 65% of all styrene is used to produce polystyrene.

The overall reaction describing the styrene polymerization is:

This reaction is carried out in an inert organic solvent environment, which

provides the reaction medium for this cationic polymerization reaction

The different methods available for styrene polymerization are:

1. Solution (bulk) polymerization.

2. Emulsion polymerization.

3. Suspension polymerization.

Solution (bulk) polymerization:

Solution (bulk) polymerization is commonly referred to as mass polymerization in

the industry. The vast majority of all polystyrene produced today is produced via this

technology. The common solvents used in this process are the styrene monomer itself and

ethyl benzene. The two types of mass polymerization are batch and continuous, of which

continuous mass is by far the most popular.

Batch mass polymerization consists of a polymerization section containing agitated

vessels polymerizing up to 80% conversion in a batch method. The polymerized solution is

then pumped to a batch finishing section for either devolatisation or plate and frame final

polymerization and grinding.

The most widely used process for polymerization of polystyrene today is the

continuous mass process. This solution is continuously prepared in a holding vessel and will

then be injected into the reactor system.

Typical feed to the first reactor would consist of 50 weight percent styrene monomer,

100 ppm water (based on styrene weight), 2000 ppm boron trifluoride (based on styrene

weight), with the balance being organic solvent. The polymerization reaction gives off heat

that is carried away from the reactors by jacketing them with a heat transfer

fluid. The temperature of the reactants should not vary by more than 15

0

C throughout

the reactor series. Temperature control is very important in this reaction because as the

reaction temperature increases, the average molecular weight of the polystyrene decreases.

The reaction temperature range is 40-70

0

C. Temperature can also be controlled by

intermediate shell and tube heat exchangers. Monomer conversions of up to 85wt%

polystyrene are obtainable in these reactors.

Emulsion polymerization: Emulsion polymerization is generally used for

polymerization of styrene with other monomers or polymers. It is not a generally

commercially accepted method of producing crystal polystyrene or high impact polystyrene.

Emulsion polymerization is carried out similarly to suspension polymerization except that the

monomer droplets are microscopic in size.

Suspension polymerization:

This is also called pearl polymerization. It has proved highly efficient for large-

scale production of polymers of high average molecular weight. By variation of the

polymerization condition it is possible to produce a range of polymers with different

properties and processing characteristics so that a number of grades are offered by the

manufacturers to meet the differing requirements of the conversion process and the final

product.

There are many different ways of making polystyrene using suspension process.

Most producers use a batch process, although there is no technical reasons why a continuous

process could not work. In the suspension process a number of small styrene drops 0.15-

0.50mm in diameter are suspended in water. The reaction occurs within these

drops. To aid in the formation of proper size drops a suspending agent is used, and to

keep them at that size a stabilizing agent is added. A catalyst is used to control the

reactionrate.

Suspension polymerization offers considerable advantages over the single phase

techniques in so far that heat removal control is no longer a problem but there are

disadvantages such as the need to use a dispersing agent.

Detailed process of suspension polymerization:

Suspension polymerization is a batch system popular for speciality grades of

polystyrene. It can be used to produce either crystal or high impact grades. In impact

production, the styrene and rubber solution is bulk polymerized beyond phase inversion and

is then suspended in water to create oil in water suspension utilizing soaps and suspending

agents. The suspended droplets are then polymerized to completion, utilizing initiator and a

staged heating profile. The water phase is used as a heat sink and heat transfer medium to

a temperature-controlled jacket. For the production of crystal polystyrene the styrene

monomer itself is suspended and polymerized via the same mechanism.

The requirements of polymerization are:

a] Initiator. b] Suspending agent. c] Stabilizing agent. d] Catalyst

Init iators: The initiators generally used are benzoyl peroxide and t-butylhydroperoxide.

Suspending agent: To aid in the formation of the proper size drops a suspending agent is

added. Some typical suspending agents are methylcellulose, ethyl cellulose and polyacrylic

acids. Their concentration in the suspension is between 0.01-0.5% of monomer

charged.

Stabilizing agent: To keep the drops at proper size, a stabilizing agent is added. The

stabilizing agents are often insoluble inorganic such as calcium carbonate, calcium

phosphates or bentonite clay. They are present in small amount than the suspending agents.

Catalyst: A catalyst is used to control the reaction rate. The catalysts are usually peroxides.

The most common ones are benzoyl, diacetyl, lauroyl, caproyl and tert-butyl. Their

concentration varies from 0.1-0.5% of the monomer charged. The ratio of

monomer to dispersing medium is between 10 and 40%. Polymerization temperature:

Polymerization of styrene occurs at temperature range of 90-

95

0

C.

Process description: The suspension method is carried out in large reactors equipped with

agitators, the styrene monomer being maintained in the aqueous phase as droplets with a

diameter varying between 0.4-1mm by use of a dispersing agent such as partially hydrolyzed

polyvinyl acetate, inorganic phosphates or magnesium silicates. To reduce the cycle time of

the reactors, the entering water and styrene will be preheated. The temperatures of the

input streams will be sent so as to obtain the desired reaction

temperature. The water entering the reactor will be heated to 95

0

C. The bulk of the

styrene is to be heated to 85

0

C before being charged. This is done in a vertical double pipe

heat exchanger, which is directly above the reactor. To prevent the polymerization from

occurring in the heat exchanger or piping system, there are to be no obstructions between

this heat exchanger and the reactor. The catalyst, rubber

stabilizer, and suspending agent are premixed in styrene and discharged by gravity into the

reactor. This mixture will not be preheated, since it might polymerize. Typical water to

monomer ratios is 1:1 to 3:1. A combination of two or more initiators is used with a

programmed reaction temperature to reduce the polymerization time to a minimum

for a given amount of residual styrene.

Purification steps and Extrusion: If the water can be removed using physical separation

processes, then the styrene and the other impurities dissolved in it will also be discharged.

A centrifuge with a washing step will be used to do this. The material leaving the

centrifuge has 1-5% water.

The final purification step is drying. The polystyrene leaving this unit must meet the

specifications set. (0.03% water). Then it is passed through a devolatisation extruder to

remove the volatile residues and to convert the polymer into pellets.

It was assumed that 3% of polystyrene would be removed from the process in

airveying, drying, centrifuging, transferring, or as bad as bad product. At least 95% of that

which is lost in processing must be intercepted before it leaves the plant. Most of it can be

removed and sold as off-grade material. This waste is split among the various streams

leaving the processing area.

MATERIAL BALANCE

Amount of polystyrene produced per day = 200 TPD

= 200*10

3

/24

= 8333.33 Kg/hr

The key to successful production of polystyrene is the reaction. The ratio of materials

to be used is a compromise of literature values. All the authors discussing suspension

polymerization say the reaction should be allowed to go to completion (removing and

recycling the unreacted styrene would be expensive).

It will be assumed that 99.8% of the styrene is reacted and this can be accomplished

by using an average of the temperatures and cycle time given.

Temperature of reaction = 90-95C

Cycle time of reactor=5.5hrs.

Reactor:

Input to the reactor:( unit ratios are obtained from literature):

Styrene = 1.032 kg styrene/kg polystyrene = 1.032*8333.33

= 8600 kg.

Water = 2.0 kg water/kg polystyrene = 2.0*8333.33

= 16666.67 kg.

Tricalcium phosphate = 0.005 kg tricalcium phosphate/kg polystyrene

= 0.005*8333.33

= 41.67 kg.

Dodecylbenzene sulphonate= 0.00006 kg dodecylbenzene sulphonate/kg polystyrene

= 0.00006*8333.33

= 0.5 kg.

Benzoyl peroxide = 0.0025 kg benzoyl peroxide/kg polystyrene

= 0.0025*8333.33

= 20.83 kg.

Miscellaneous = 0.004(styrene 99.6% pure)(unit ratio) = 0.004*8333.33

= 33.33 kg.

Total input to reactor = 25363 kg.

Output from the rector:(unit ratios are obtained from literature: Baasel)

Polystyrene =1.030 kg polystyrene / kg of polystyrene = 1.030*8333.33

= 8583.33 kg.

Styrene = 0.002 kg styrene/kg polystyrene = 0.002*8333.33

= 16.67 kg

Water = 2.0 kg water/kg polystyrene = 2.0*8333.33

= 16666.67 kg.

Miscellaneous = 0.0116 kg /kg polystyrene = 0.0116*8333.33

=96.67 kg.

Total output from reactor = 25363.34 kg.

Wash tank:

Output from reactor

2.0 kg water/kg

WASH TANK

0.004 kg HCl/kg

1.030 polystyrene (unit ratio)

0.002 styrene (unit ratio)

4.0 water, 0.0156 miscellaneous

Input to wash tank:

Output from reactor = (1.030+0.002+2.0+0.0116)*8333.33= 25363.34 kg.

Water =2.0 kg water/ kg polystyrene

=2.0*8333.33

=16666.67kg.

Hydrochloric acid = 0.004 kg HCl/ kg polystyrene

= 0.004*10416.67

= 33.33 kg.

Total input to wash tank = 42063.34 kg.

Output from wash tank:

Polystyrene = 1.030 kg polystyrene/ kg polystyrene desired

=1.030*8333.33 = 8583.33 kg

Styrene = 0.002 kg styrene/kg polystyrene

= 0.002*8333.33

= 16.67 kg.

Water = 4.0 kg water/ kg polystyrene

= 4.0*8333.33

= 33333.32 kg.

Miscellaneous = 0.0156 kg/kg of polystyrene

= 0.0156*8333.33

= 130 kg

Total output from wash tank = 8583.33+16.67+33333.32+130

= 42063.32 kg

Centrifuge:

Output from wash tank

0.01 kg PS/kg PS

0.002 kg styrene/kg

PS

CENTRIFUGE

1.0 kg water/kg 4.95 kg water/kg PS

0.0155 misc.

1.02 kg PS/kg PS desired

0.05 kg water/kg PS

0.0001 kg styrene/kg PS

0.0001 kg misc./kg PS

Input to the centrifuge:

Output from wash tank = 42063.32 kg

Water =1.0 kg water/kg polystyrene

=8333.33 kg water.

Output from centrifuge:

The output from centrifuge comprises of two layers. One is the desired and the

other is bad product.

Desired product composition:

Polystyrene = 1.02 kg polystyrene/kg of desired polystyrene

= 1.02*8333.33

= 8500 kg

Styrene = 0.0001 kg styrene/kg polystyrene

= 0.0001*8333.33

= 0.8333 kg.

Water = 0.05 kg water/ kg polystyrene

= 0.05*8333.33

= 416.67 kg

Miscellaneous = 0.0001 kg/ kg polystyrene

= 0.0001*8333.33

=0.8333kg

Bad product composition:

Polystyrene = 0.01kg polystyrene/kg polystyrene

= 0.01*8333.33

=83.33 kg

Styrene = 0.002 kg styrene /kg polystyrene

= 0.002*8333.33

=16.67 kg

Water = 4.95 kg water / kg polystyrene

= 4.95*8333.33

= 41250 kg

Miscellaneous = 0.0155 kg/ kg polystyrene

=0.0155*8333.33

=129.167 kg.

Dryer:

Output from centrifuge

0.015 kg PS/kg PS

0.005 kg PS/ kg PS

DRYER

0.0499 kg water/kg PS

1.0 kg polystyrene/kg polystyrene

0.0003 kg water / kg polystyrene.

Input to the dryer:

Output from the centrifuge = 11148.96kg

Output from the dryer:

Output from dryer comprises of three parts;

1. Desired polystyrene with composition:

Polystyrene =1.0 kg/kg polystyrene

= 8333.33 kg of polystyrene.

Water = 0.0003 kg/kg polystyrene

= 0.0003*8333.33

= 2.5 kg

2. Product with;

Polystyrene = 0.005 kg/kg polystyrene

= 0.005*8333.33

= 41.67 kg

Water = 0.0499kg/kg polystyrene

= 0.0499*8333.33

= 415.83 kg

3. Bad product obtained has a composition;

Polystyrene = 0.015 kg/kg polystyrene

= 0.015*8333.33

= 125kg

Extruder:

Output from dryer

EXTRUDER

1.0 Polystyrene (unit ratio)

0.0003 kg water/kg polystyrene.

Input to extruder = output from dryer

= 8333.33 kg

Output from extruder = 8333.33 kg

HEAT BALANCE

Styrene heat exchanger:

The additive feed tank must be large enough to handle all additive plus a

carrier solution of styrene. The amount of dodecylbenzene sulfonate, tricalcium

phosphate and benzoyl peroxide used per batch are:

= (0.005+0.00006+2*0.0025)*8333.33*5.5/9 = 53.2315 kg.

Assume 2kg of styrene are to be used to carry each kg of additive into the

reactor. i.e. 53.2315*2 = 102.463 kg.

When GPPS is made, all but 128.078kg of styrene are heated to 93C. For the

other products less is used. The time to charge the reactor is set as 5min. Steam at 150psi

will be used as heating medium.

Qs = msCpsTs. = Us.A. Tss ------------ (1)

Where,

Qs = rate of heat transfer.

ms = flow rate of styrene through exchanger.

= (1.032)*8333.33*5.5/9 102.463

(5/60)

= 61837.1 kg/hr.

Cps = heat capacity of styrene = 0.43BTU/lb F. = 1.799 kJ/kgC.

Ts = temperature difference of styrene entering and leaving exchanger = 93 30 =

63C.

Qs = 61837.1*1.799*63 = 7008.43*10

3

kJ/hr.

A = area of heat exchanger, m

2

.

Us= overall heat transfer co-efficient =150BTU/hr.ft

2

.F. =851.7W/m

2

K.

At 150 psi Ts=182C.

Tss = (182-30)-(182-93) = 117.7C.

ln(182-30)/(182-93)

Therefore from equation (1),

7008.43*10

3

= 851.7*117.7*A

A = 69.19m

2

.

One of the heat exchanger is needed for each reactor, because they must be

positioned vertically above the reactor. This is to prevent any hot styrene from

remaining in the exchanger or the piping where it might polymerize.

The average steam rate = msCpsTs/

= 8494.256*1.799*63 = 482.326 kg/hr.

1995.98

Where,

= latent heat of vaporization = 1995.98kJ/hr.

ms= average flow rate of styrene through exchanger.

= 1.032*(8333.33 102.463) = 8494.256 kg/hr.

Therefore maximum steam rate

=(602.908

*5.5/9)/

(5/60)

= 5787.912 kg/hr.

Air heat exchanger:

The air is to be heated to 150C using 150psi steam (182C)

The amount of energy required = Qa = maCpT.

Where,

ma = flow rate of air.

= 11239 kg/hr.

Cp = heat capacity of air entering and leaving the

exchanger = 1.0468 kJ/kgC.

T = temperature difference of air entering and leaving the

exchanger. = 150 30 = 120C.

Qa = 11239*1.0468*120

= 1.4118*10

6

kJ/hr.

This assumes a 10% heat

loss.

The area of heat exchanger A = Qa /(Ua. Tm)

Ua = overall heat transfer co-efficient.

Tm = L.M.T.D across exchanger.

= (182-30)-(182-150) = 72.015C.

ln(182-30)/(182-150)

Ua = 1 .

1/ho+1/hi

ho= h.t. co-efficient of condensing steam = 2000BTU/hr.ft

2

.F = 3461.5 kW/m

2

.C.

hi = h.t. co-efficient of air = 5BTU/hr.ft

2

.F. = 8.654 kW/ m

2

.C.

Therefore,

. = 8.632 kW/ m

2

.C.

Ua = 1

1/3461.5+1/8.654

A = 1.4118*10

6

= 2271.1m

2

of surface area.

8.632*77.015

Amount of steam required = 1.4118*10

6

= 707.32kg/hr.

1995.98

Reactor cooling system:

From reactor design,

Average energy removed per hour = 62.139*10

3

D

3

kJ/hr.

= 62.139*10

3

*(2.486)

3

.

= 265.195 kJ/s.

Inlet temperature of cooling water = 30C.

Outlet temperature of cooling water = 68C.

Let mw be the amount of cooling water required:

Q = mw.Cp. T.

mw .4.187*10

3

*(68-30) = 265.195 kJ/s

Therefore,

mw= 1.6668 kg/s in each reactor.

Therefore amount of water required in total for 9 reactors= 2.085*9 = 15.0012 kg/s.

Dryer:

Temperatures: Inlet Outlet

Polystyrene 30C. 80C.

Air 150C. 85C.

Heat required raising product to discharge temperature,

= 8494.257*1.3398*(80-30) + 2.5*4.187*(80-30).

= 5.69554*10

5

W.

Heat required removing water,

= 426.668*4.187*(80-30) + 550 + 0.45*(85-80).

= 0.8987*10

5

W.

Therefore total heat required,

= 5.69554*10

5

+ 0.8987*10

5

W.

= 6.59424*10

5

W.

Tm = (150-30)-(85-80) = 36.186C.

Ln (150-30)/(85-80)

The minimum air velocity is set by the particle size. A flow rate of 1000lb/hr.ft

2

is

adequate for 420-micron particle. This will be used. The minimum velocity is used

since it gives the smaller dryer.

The amount of air required is determined by amount of energy the 150C.

air must supply to remove the moisture from the polystyrene.

m = Qt /( Cp.T).

Where,

Cp = heat capacity of air = 0.237 BTU/lb.C.

T = difference in air temperature entering and leaving

dryer,C. Qt = heat transferred in dryer =8.23765*10

5

W.

m = mass flow rate of air.

m = 6.59424*10

5

= 10223.71kg/hr.

(0.9923*(150-85))

The amount of air is adequate. Add 10% to account for possible heat losses.

Therefore mass flow rate = 1.1* 10223.71

= 11246.08 kg/hr.

COST ESTIMATION AND ECONOMICS

Calculation of fixed capital cost:

The Chemical Engineering Plant cost Index (CEPI):

In 1969 = 119.0

In 2002 = 402.0

Let us assume that the plant is running for 325 days a year.

From literature, the capital cost for the proposed plant should range between $124 and

$253 per annual ton.

Lets take value of 1$ = Rs 60.

Lets take capital cost = $200 per annual ton.

= Rs 12000 per annual ton.

Total tones of polystyrene produced every year = 325 * 200

= 65000tones/year.

Therefore the capital cost for proposed plant in 1969 is = 65000*12000

= Rs.7.8*10

8

The fixed capital cost for the proposed plant in 2002 = 7.8*10

8

*402

119

= Rs 371.64*10

7

= Rs 371.64crores.

Estimation of Capital Investment Cost:

I. Direct Costs: material and labour involved in actual installation of complete

facility (70-90% of fixed-capital investment)

a) Equipment + installation + instrumentation + piping + electrical + insulation + painting

(50-60% of Fixed-capital investment)

1. Purchased equipment cost (PEC): (15-40% of Fixed-capital investment)

Consider purchased equipment cost = 30% of Fixed-capital investment

i.e., PEC = 30% of 371.6410

7

= 0.30 371.6410

7

= Rs. 111.4910

7

2. Installation, including insulation and painting: (25-55% of

purchased equipment cost.)

Consider the Installation cost = 35% of Purchased equipment cost

= 35% of 111.4910

7

= 0.35 111.4910

7

=Rs.39.02110

7

3. Instrumentation and controls, installed: (6-30% of

Purchased equipment cost.)

Consider the installation cost = 15% of Purchased equipment cost

= 15% of 111.4910

7

= 0.15 111.4910

7

= Rs.16.72x10

7

4. Piping installed: (10-80% of Purchased equipment cost)

Consider the piping cost = 35% Purchased equipment cost

= 35% of Purchased equipment cost

= 0.35 111.4910

7

= Rs. 39.021x10

7

5. Electrical, installed: (10-40% of Purchased equipment cost)

Consider Electrical cost = 25% of Purchased equipment cost

= 25% of 111.4910

7

= 0.25 111.4910

7

= Rs.27.8703x10

7

B. Buildings, process and Auxiliary: (10-70% of Purchased equipment cost)

Consider Buildings, process and auxiliary cost

= 30% of PEC

= 30% of 111.4910

7

= 0.30 111.4910

7

= Rs.33.447x10

7

C. Service facilities and yard improvements: (40-100% of Purchased equipment cost)

Consider the cost of service facilities and yard improvement = 50% of PEC

= 50% of 111.4910

7

= 0.50 111.4910

7

= Rs 55.745x10

7

D. Land: (1-2% of fixed capital investment or 4-8% of Purchased equipment cost)

Consider the cost of land = 6% PEC

= 6% of 111.4910

7

= 0.06 111.4910

7

= Rs. 6.689x10

7

Thus, Direct cost = Rs.330.38x10

7

----- (88.9% of FCI)

6. Indirect costs: expenses which are not directly involved with material and

labour of actual installation of complete facility (15-30% of Fixed-capital

investment)

A. Engineering and Supervision: (5-30% of direct costs)

Consider the cost of engineering and supervision = 10% of Direct costs

i.e., cost of engineering and supervision = 10% of 330.38 10

7

= 0.1330.38 10

7

= Rs 33.038 x10

7

B. Construction Expense and Contractors fee: (6-30% of direct costs)

Consider the construction expense and contractors fee = 10% of Direct costs

i.e., construction expense and contractors fee = 10% of 330.38x10

7

= 0.1 330.38 10

7

= Rs 33.038 x10

7

C. Contingency: (5-15% of Fixed-capital investment)

Consider the contingency cost = 10% of Fixed-capital investment

i.e., Contingency cost = 10% of 330.38 10

7

=Rs.33.038x10

7

Thus, Indirect Costs = Rs. 98.96x10

7

--- (26.63% of FCI)

7. Fixed Capital Investment:

Fixed capital investment = Direct costs + Indirect costs

= (330.38 10

7

) + (98.96x10

7

)

i.e., Fixed capital investment = Rs. 429.34x10

7

IV. Working Capital: (10-20% of Fixed-capital investment)

Consider the Working Capital = 15% of Fixed-capital investment

i.e., Working capital = 15% of 429.34x10

7

= 0.15 429.34x10

7

= Rs. 64.401x10

7

V. Total Capital Investment (TCI):

Total capital investment = Fixed capital investment + Working capital

= (429.34x10

7

) + (64.401x10

7

)

i.e., Total capital investment = Rs. 493.74x10

7

.

Estimation of Total Product cost:

I. Manufacturing Cost = Direct production cost + Fixed charges + Plant

overhead cost.

A. Fixed Charges: (10-20% total product cost)

i. Depreciation: (depends on life period, salvage value and method of

calculation-about 13% of FCI for machinery and equipment and 2-3%

for Building Value for Buildings)

Consider depreciation = 12%of FCI for machinery and equipment and 4%for

Building Value for Buildings)

i.e., Depreciation = (0.12111.49x10

7

)+ (0.0433.44710

7

)

= Rs. 14.7x10

7

ii. Local Taxes: (1-4% of fixed capital investment)

Consider the local taxes = 3% of fixed capital investment

i.e. Local Taxes = 0.03429.34x10

7

= Rs. 12.88x10

7

iii. Insurances: (0.4-1% of fixed capital investment)

Consider the Insurance = 0.6% of fixed capital investment

i.e. Insurance = 0.006429.34x10

7

= Rs. 2.576x10

7

iv. Rent: (8-12% of value of rented land and buildings)

Consider rent = 10% of value of rented land and buildings

= 10% of ((33.44710

7

) + (6.68910

7

))

= 0.10 ((33.44710

7

) + (6.68910

7

))

Rent = Rs. 4x10

7

Thus, Fixed Charges = Rs. 34.15610

7

B. Direct Production Cost: (about 60% of total product cost)

Now we have Fixed charges = 10-20% of total product charges (given)

Consider the Fixed charges = 15% of total product cost

Total product charge = fixed charges/15%

Total product charge = 34.15610

7

/15%

Total product charge = 34.15610

7

/0.15

Total product charge(TPC) = Rs. 227.707x10

7

i. Raw Materials: (10-50% of total product cost)

Consider the cost of raw materials = 25% of total product cost

Raw material cost = 25% of 227.707x10

7

= 0.25227.707x10

7

Raw material cost = Rs. 52.927x10

7

ii. Operating Labour (OL): (10-20% of total product cost)

Consider the cost of operating labour = 15% of total product cost

operating labour cost = 15% of 227.707x10

7

= 0.15227.707x10

7

Operating labour cost = Rs. 34.15675x10

7

iii. Direct Supervisory and Clerical Labour (DS & CL): (10-25% of OL)

Consider the cost for Direct supervisory and clerical labour = 12% of OL

Direct supervisory and clerical labour cost = 12% of 34.15675x10

7

= 0.1234.15675x10

7

Direct supervisory and clerical labour cost = Rs. 4.09872x10

7

iv. Utilities: (10-20% of total product cost)

Consider the cost of Utilities = 12% of total product cost

Utilities cost= 12% of 227.707x10

7

= 0.12227.707x10

7

Utilities cost = Rs. 27.3248x10

7

v. Maintenance and repairs (M & R): (2-10% of fixed capital investment)

Consider the maintenance and repair cost = 5% of fixed capital investment

i.e. Maintenance and repair cost = 0.05429.34x10

7

= Rs. 21.46710

7

vi. Operating Supplies: (10-20% of M & R or 0.5-1% of FCI)

Consider the cost of Operating supplies = 15% of M & R

Operating supplies cost = 15% of 21.46710

7

= 0.15 21.46710

7

Operating supplies cost = Rs. 3.22005x10

7

vii. Laboratory Charges: (10-20% of OL)

Consider the Laboratory charges = 15% of OL

Laboratory charges = 15% of 34.15675x10

7

= 0.1534.15675x10

7

Laboratory charges = Rs. 5.1234x10

7

viii. Patent and Royalties: (0-6% of total product cost)

Consider the cost of Patent and royalties = 4% of total product cost

Patent and Royalties = 4% of 227.707x10

7

= 0.04227.707x10

7

Patent and Royalties cost = Rs 9.10828x10

7

Thus, Direct Production Cost = Rs. 157.425x10

7

----- (70% of TPC)

C. Plant overhead Costs (50-70% of Operating labour, supervision, and maintenance or

5-15% of total product cost); includes for the following: general plant upkeep and

overhead, payroll overhead, packaging, medical services, safety and protection,

restaurants, recreation, salvage, laboratories, and storage facilities.

Consider the plant overhead cost = 60% of OL, DS & CL, and M & R

Plant overhead cost = 60% of ((34.15675x10

7

) + (4.09872x10

7

) + (21.46710

7

))

Plant overhead cost = 0.60 ((34.15675x10

7

) + (4.09872x10

7

) + (21.46710

7

))

Plant overhead cost = Rs. 35.833x10

7

Thus, Manufacture cost = Direct production cost + Fixed charges + Plant overhead

costs.

Manufacture cost = (157.425x10

7

) + ( 34.15610

7

) + (35.833x10

7

)

Manufacture cost = Rs. 227.414x10

7

II. General Expenses = Administrative costs + distribution and selling costs +

research and development costs

Administrative costs:(2-6% of total product cost)

Consider the Administrative costs = 5% of total product cost

Administrative costs = 0.05 227.707x10

7

Administrative costs = Rs. 11.385x10

7

A. Distribution and Selling costs: (2-20% of total product cost); includes costs for

sales offices, salesmen, shipping, and advertising.

Consider the Distribution and selling costs = 15% of total product cost

Distribution and selling costs = 15% of 227.707x10

7

Distribution and selling costs = 0.15 227.707x10

7

Distribution and Selling costs = Rs. 34.15675x10

7

B. Research and Development costs: (about 5% of total product cost)

Consider the Research and development costs = 5% of total product cost

Research and Development costs = 5% of 227.707x10

7

Research and development costs = 0.05 227.707x10

7

Research and Development costs = Rs. 11.385x10

7

C. Financing (interest): (0-10% of total capital investment)

Consider interest = 5% of total capital investment

i.e. interest = 5% of 493.74x10

7

.

= 0.05493.74x10

7

.

Interest = Rs. 24.687x10

7

Thus,

General Expenses = Rs. 81.6134x10

7

IV. Total Product cost = Manufacture cost + General Expenses

= (227.414x10

7

) + (81.6134x10

7

)

Total product cost = Rs. 309.02x10

7

V. Gross Earnings/Income:

Wholesale Selling Price of Polystyrene per ton = $1200(USD)

Let 1 USD = Rs. 60.00

Hence Wholesale Selling Price of Polystyrene per ton. =120060 = Rs 72000

Total Income = Selling price Quantity of product manufactured

= 72000 (200 T/day) (325days/year)

Total Income = Rs.4.68x10

9

Gross income = Total Income Total Product Cost

= (4.68x10

9

) (309.02x10

7

)

Gross Income = Rs. 1589.810

6

Let the Tax rate be 45% (common)

Taxes = 40% of Gross income

= 40% of 1589.810

6

= 0.401589.810

6

Taxes = Rs. 635.92 x10

6

Net Profit = Gross income - Taxes = Gross income (1- Tax rate)

Net profit = (1589.810

6

) (635.92 x10

6

) = Rs. 953.8810

6

Rate of Return:

Rate of return = Net profit100/Total Capital Investment

Rate of Return = 953.8810

6

100/ (493.74x10

7

)

Rate of Return = 19.32%

Break-even Analysis:

Data available:

Annual Direct Production Cost = Rs.119.246x10

7

Annual Fixed charges, overhead and general expenses = Rs. 1.119710

9

Total Annual sales = Rs. 4.68 x 10

9

Wholesale Selling Price of polystyrene per ton. = Rs. 72000

Direct production cost per ton of polystyrene = (119.246x10

7

)/ (4.68 x 10

9

/72000)

= Rs. 18345.554 per ton

Let n TPA be the break even production rate.

Number of tons needed for a break-even point is given by

(1.119710

9

) + (18345.554 n) = (72000n)

=> n = 39785 tons/year

n = 109 tons/day = 109 TPD

Hence, the break-even production rate is 109 TPD or 54.42% of the considered

plant capacity.

PLANT LOCATION AND LAYOUT

The Location Of The Plant Can Have A Crucial Effect On The Profitability Of A

Project, And The Scope For Future Expansion. Many Factors Must Be Considered When

Selecting A Suitable Site, And Only A Brief Review Of The Principal Factors Will Be

Given In This Section. The Principal Factors To Be Considered Are:

> Location, With Respect To The Marketing Area.

> Raw Material Supply.

> Transport Facilities.

> Availability Of Labour.

> Availability Of Utilities: Water, Fuel, Power.

> Availability Of Suitable Land.

> Environmental Impact, And Effluent Disposal.

> Local Community Considerations.

> Climate.

> Political Strategic Considerations.

Marketing Area

For Materials That Are Produced In Bulk Quantities: Such As Cement, Mineral Acids And

Fertilizers, Where The Cost Of The Product Per Ton Is Relatively Low And The Cost Of

Transport A Significant Fraction Of The Sales Price, The Plant Should Be Located Close

To The Primary Market. This Consideration Will Be Less Important For Low Volume

Production, High-Priced Products; Such As Pharmaceuticals. In An International Market,

There May Be An Advantage To Be Gained By Locating The Plant Within An Area With

Preferential Tariff.

.

Raw Materials

The Availability And Price Of Suitable Raw Materials Will Often Determine The Site

Location. Plants Producing Bulk Chemicals Are Best Located Close To The Source Of The

Major Raw Material; Where This Is Also Close To The Marketing Area.

Soda Ash Plant Should Be Located Near The Salt Lakes Or Near Sea, Where Sodium

Chloride Is Available Abundantly.

Transport

The Transport Of Materials And Products To And From Plant Will Be An Overriding

Consideration In Site Selection.

If Practicable, A Site Should Be Selected That Is Close At Least Two Major Forms Of

Transport: Road, Rail, Waterway Or A Seaport. Road Transport Is Being Increasingly

Used, And Is Suitable For Local Distribution From A Central Warehouse. Rail Transport Will

Be Cheaper For The Long-Distance Transport Of Bulk Chemicals.

Air Transport Is Convenient And Efficient For The Movement Of Personnel And Essential

Equipment And Supplies, And The Proximity Of The Site To A Major Airport Should Be

Considered.

Availability Of Labour

Labour Will Be Needed For Construction Of The Plant And Its Operation. Skilled

Construction Workers Will Usually Be Brought In From Outside The Site, But There

Should Be An Adequate Pool Of Unskilled Labour Available Locally; And Labour Suitable

For Training To Operate The Plant. Skilled Tradesmen Will Be Needed For Plant

Maintenance. Local Trade Union Customs And Restrictive Practices Will Have To Be

Considered When Assessing The Availability And Suitability Of The Labour For Recruitment

And Training.

Utilities (Services)

The Word Utilities Is Now Generally Used For The Ancillary Services Needed In The

Operation Of Any Production Process. These Services Will Normally Be Supplied From A

Central Facility; And Will Include:

Electricity: - Power Required For Electrochemical Processes, Motors,

Lightings, And General Use

Steam For Process Heating: - The Steams Required For The Process Are

Generated In The Tube Boilers Using Most Economic Fuel.

Cooling Water: - Natural And Forced Draft Cooling Towers Are Generally

Used To Provide The Cooling Water Required On Site.

Water For General Use: - The Water Required For The General Purpose Will

Be Taken From Local Water Supplies Like Rivers, Lakes And Seas. Because

Of This Reason All The Plants Located On The Banks Of River.

Dematerialized Water: - Dematerialized Water, From Which All The Minerals

Have Been Removed By Ion-Exchange Is Used Where Pure Water Is Needed

For The Process Use, In Boiler Feed Water.

Refrigeration: - Refrigeration Is Needed For The Processes, Which Require

Temperatures Below That Are Provided By The Cooling Water.

Inert-Gas Supplies.

Compressed Air: - In An Ethylene Oxide Plant Compressed Air Is One Of The

Raw Materials. It Is Also Needed For Pneumatic Controllers Etc.

Effluent Disposal Facilities: - Facilities Must Be Provided For The Effective

Disposal Of The Effluent Without Any Public Nuisance.

Environmental Impact, And Effluent Disposal

All Industrial Processes Produce Waste Products, And Full Consideration Must Be Given To

The Difficulties And Coat Of Their Disposal. The Disposal Of Toxic And Harmful

Effluents Will Be Covered By Local Regulations, And The Appropriate Authorities Must Be

Consulted During The Initial Site Survey To Determine The Standards That Must Be Met.

Local Community Considerations

The Proposed Plant Must Fit In With And Be Acceptable To The Local Community. Full

Consideration Must Be Given To The Safe Location Of The Plant So That It Does Not

Impose A Significant Additional Risk To The Community.

Land (Site Considerations)

Sufficient Suitable Land Must Be Available For The Proposed Plant And Future Expansion.

The Land Should Be Ideally Flat, Well Drained And Have Load-Bearing Characteristics. A

Full Site Evaluation Should Be Made To Determine The Need For Piling Or Other

Foundations.

Climate

Adverse Climatic Conditions At Site Will Increase Costs. Abnormally Low Temperatures Will

Require The Provision Of Additional Insulation And Special Heating For Equipment And

Piping. Stronger Locations Will Be Needed At Locations Subject To High Wind Loads Or

Earthquakes.

Political And Strategic Considerations

Capital Grants, Tax Concessions, And Other Inducements Are Often Given By

Governments To Direct New Investment To Preferred Locations; Such As Areas Of High

Unemployment. The Availability Of Such Grants Can Be The Overriding Consideration In

Site Selection.

PLANT LAY OUT

The economic construction and efficient operation of a process unit will depend on how well

the plant and equipment specified on the process flow sheet is laid out. The principal factors

are considered are:

> Economic considerations: construction and operating costs.

> The process requirements.

> Convenience of operation.

>Convenienceofmaintenance.

> Safety.

> Future expansion.

> Modular construction.

Costs

The cost of construction can be minimized by adopting a layout that gives the shortest run

of connecting pipe between equipment, and at least amount of structural steel work.

However, this will not necessarily be the best arrangement for operation and maintenance.

Process requirements

An example of the need to take into account process consideration is the need to elevate the

base of columns to provide the necessary net positive suction head to a pump or the

operating head for a thermosyphon reboiler.

Operations

Equipment that needs to have frequent attention should be located convenient to the

control room. Valves, sample points, and instruments should be located at convenient

positions and heights. Sufficient working space and headroom must be provided to allow

easy access to equipment.

Maintenance

Heat exchangers need to be sited so that the tube bundles can be easily withdrawn for

cleaning and tube replacement. Vessels that require frequent replacement of catalyst or

packing should be located on the out side of buildings. Equipment that requires dismantling

for maintenance, such as compressors and large pumps, should be places under cover.

Safety

Blast walls may be needed to isolate potentially hazardous equipment, and confine the

effects of an explosion.

At least two escape routes for operators must be provided from each level in process

buildings.

Plant expansion

Equipment should be located so that it can be conveniently tied in with any future expansion

of the process.

Space should be left on pipe alleys for future needs, and service pipes over-sized to allow for

future requirements.

Modular construction

In recent years there has been a move to assemble sections of plant at the plant

manufacturers site. These modules will include the equipment, structural steel, piping and

instrumentation. The modules are then transported to the plant site, by road or sea. The

advantages of modular construction are:

> Improved quality control.

> Reduced construction cost.

> Less need for skilled labour on site.

Some of the disadvantages are;

> Higher design costs & more structural steel work.

> More flanged constructions & Possible problems with assembly, on site.

The Plant Layout KEYWORDS

1. Raw material Storage

2. Product Storage

3. Process Site

4. Laboratories

5. Workshop

6. Canteen & Change house

7. Fire Brigade

8. Central Control Room

9. Security office

10. Administrative Building

11. Site for Expansion Project.

12. Effluent treatment plant

13. Power house

14. Emergency water storage

15. Plant utilities

A detailed plant layout is drawn and submitted with this thesis report.

Some general considerations that influenced the plans follow:

1. Space was set aside for a whole new train. His appears as dotted lines in the

figures.

2. The prevailing wind in the summer comes from the northwest and in the winter

comes from the west.

3. The blow down tank is located on the south side of the plant where winds will not

generally carry any spills over the plant.

4. The utilities and the waste treatment areas are located on the north side of the

plant where they will be upwind of the plant.

5. The styrene storage will be located on the south side of the plant 300ft from the river

and the dock. It will be 300ft from the processing area.

6. The warehouse and the bulk storage will be located on the west side, upwind from the

plant and styrene storage. They will be at least 250ft from reactor area.

7. The reactor and the feed preparation area will be on the east side of the plant 200ft

from the river.

8. The other processing areas will be between the reactor area and the warehouse.

They will be over 200ft from the reactor area.

Some specific considerations follow:

1. There must be enough headroom above the reactor to remove the agitator.

2. There must be enough room to remove the screw from the extruder.

3. Gravity feed is to be used for charging additives to the reactor, for discharging the

reactor to the hold tanks, and for feeding the dryer.

4. Each of the styrene storage tanks will have a dike around it that is capable of

containing the tanks contents when it is full.

COMMISSIONING, START-UP AND SHUT DOWN

COLUMN COMMISSIONING:

It refers to the process of preparing the column for operation. The main

objectives are:

1) Clear the system of undesirable materials.

2) Test the column and rectify potential problems.

3) Take preventive actions against performance deterioration.

Most commissioning operations are performed using readily available liquids

and gases, such as air, nitrogen, steam, water or oil. An important thing to note

is that the column and associated equipments are seldom designed to cater

specifically to commissioning operations. Therefore, they must be tailored to

suit the limitations of the available system.

START-UP:

The following steps are observed:

1. Commissioning

2. Pressure-up

3. Column heating (and/or cooling)

4. Introduction to feed

5. Introducing heating and cooling sources

6. Bring to desired operating conditions

SHUT DOWN:

1. Reducing column/unit rates.

2. Shutting down heating/cooling surfaces.

3. Stopping feed

4. Draining liquid

5. Cooling/heating the column/unit

6. Bringing the unit to atmospheric pressure

7. Eliminating undesirable materials

8. Preparing to opening to atmosphere

VARIOUS COMMISSIONING ACTIVITIES

1. LINE BLOWING:

A common pre-start up practice is to pressurize the column with air or

nitrogen. The unit then serves as vapour reservoir for blowing lines

connected to the unit to remove construction debris.

2. PRESSURIZING OR DEPRESSURIZING:

Pressurizing or depressurizing is performed during commissioning, start-ups

and shut-downs. They are used to check the columns for pressure retention

and leaks. Remove air or inert gas prior to start-up, free the column of gas

(e.g. hydrocarbon) at shut-downs or prepare the column for entry by

personnel for inspection of the column internals. Location and set pressure

of relief valves and/or bursting disks as well as major vents should be

checked.

3. PURGING:

A column needs to be purged with an inert gas prior to start-up to remove

air if it is used for separating combustible materials. The inert gas can then

be purged with process gas. The reverse steps are performed at shut-down.

Drain and vent valves must be opened intermittently so that no dead pockets

are left unpurged.

4 . STEAMING:

A unit may be steamed during commissioning to drive the air out heat the

column up, clear blockages or leak test the unit. Problem associated with it

could be creation of vacuum, water hammer, overheating etc. Steaming is

done before purging.

5. LEAK TESTING:

After purging and before introducing the process gas column is leak tested.

The most common technique is pressurizing the unit up with inert gas

(liquid N2) with all vents and drain closed.

6. WASHING:

Washing is done during start up and shut down for one or more of the

following reasons

- To remove scale, mud etc.

- To coo, the column

- To dissolve or carry away sticky deposits. Water should be drained out

after washing.

7. DRY OUT :

Water should be drained out after washing. To remove water from the

column dry out can be done using hot water or liquid.

8. BLINDING AND UNBLINDING:

Blinds and /or slip plates (spades) are usually installed in all lines which

leave or enter a unit in order to positively eliminate leakage of materials into

the unit when air is introduced. During start up, the plates are removed. The

sequence of blinding and unblinding must be carefully prepared / planned

prior to start up or shut down. A checklist of all blinds should be made.

Blinds be properly tagged, and tag ID must be reflected on checklist.

POLLUTION CONTROL AND SAFETY

Waste products that are produced during the manufacture of Polystyrene:

Polystyrene manufacture is a relatively clean process. Small volumes of liquid and

gaseous wastes are generated and these are treated within the plants. Waste polystyrene

generated during production is reprocessed or sent to a recycler. Polystyrene manufacture is a

relatively clean process. Small volumes of liquid and gaseous wastes are generated and these

are treated within the plants. Waste polystyrene generated during production is reprocessed

or sent to a recycler. This is a Most Energy-Efficient Packaging Material. Polystyrene is

Safe, Hygienic Polystyrene and the Enemy of Bacteria

Ease of disposal:

According to the U.S. Environmental Protection Agency (EPA) in the 1999 update of the

"Characterization of Municipal Solid Waste in the U.S." report, less than one percent

(about 0.6 percent) of solid waste disposed of in the U.S. is polystyrene packaging -

including both food service packaging (cups, plates, bowls, trays, clamshells, meat trays, egg

cartons, yogurt and cottage cheese containers, and cutlery) and protective packaging (shaped

end pieces used to ship electronic goods and loose fill "peanuts").

The disposal of polystyrene is managed safely and effectively through the integrated

system advocated by the U.S. EPA, which includes: Source Reduction, Reuse, Recycling,

Waste-to-Energy Recovery, and Landfilling.

Polystyrene safe to use in contact with food :

For more than 40 years, polystyrene has been in widespread use as a hygienic

material for protecting and preserving food. In fact, one-reason polystyrene single use food

containers are so widely used in hospitals and other sensitive environment is that

they are significantly more hygienic than the alternatives. Polystyrene does not harbour

bacteria, which is a major concern among health specialists.

A recent American study shows that 1 in 7 reusable dishes harbour a level of

bacteria which exceeds US health standards. In contrast, no disposable food service items

exceeded the standard.

Foam Polystyrene Presence of CFCs:

Extruded foam polystyrene produced in for meat, chicken and vegetable trays and

takeaway food containers, does not use CFC blowing agents. Producers converted away

from CFC's in 1989 and now operate on recycled carbon dioxide or hydrocarbon gases.

Expandable or bead polystyrene (EPS) such as in produce boxes has always used a

hydrocarbon blowing agent.

Reuse:

Reuse, the practice of utilizing polystyrene products in the same form, is important not only

because it delays the final disposal of a product, but also because it reduces the

manufacture and purchase of new products. As a result, reuse prevents waste. Nearly 30

percent of polystyrene loose fill (some times called "peanuts" because of its shape) is

used again, making it one of the most commonly reused packaging materials in some

retail locations. For mailing services, the reuse rate of loose fill is as high as 50 percent. The

successful application of reused loose fill polystyrene reduced the demand for virgin

polystyrene by 25 percent in 1997 alone and, to this day, continues to directly reduce

waste.

Other packaging and disposables commonly reused by the polystyrene industry include:

pallets, insulated shipping boxes, test tube trays, auto part trays, ice chests and coolers.

Recycling:

The recycling of polystyrene protective packaging and non-packaging polystyrene

materials, (such as audio/visual cassettes and agricultural nursery trays/containers) has

increased dramatically during the last decade and there has been a decrease in the amount of

polystyrene food service packaging recycled during this period. Non-food service packaging is

not contaminated with food and other wastes as is food service polystyrene packaging, and

therefore is more cost-effective to recycle. Presently, food service polystyrene packaging is

generally not recycled because it is not economically sustainable. It is important to note that

because of unfavorable economics, no other post- consumer foodservice disposable material,

including paper and paperboard, is recycled in a measurable way.

Before 1988, there was essentially no recovery of post-consumer polystyrene for

recycling, but as of 2000, just twelve years later, more than 397 million pounds of

polystyrene packaging were recycled. A portion of this material came from durable

polystyrene products such as coat hangers, compact disc "jewel cases," single-use cameras

and agricultural nursery trays.

Some companies that make protective packaging are collecting it back for recycling

through the Alliance of Foam Packaging Recyclers. In addition, some makers of loose fill

"peanuts" have set up a network of collection sites for reuse and recycling of their

polystyrene products.

Products that have incorporated recycled-content polystyrene include: foam egg

cartons, lunch trays, transport packaging, audio and videocassette cases, office supplies, and

building materials.

Waste-to-Energy Recovery:

In many overseas countries polystyrene is recycled through incineration of municipal

waste for energy recovery. The burning of polystyrene is no more hazardous than

combustion of many natural organic materials. Polystyrene consists solely of carbon and

hydrogen. When combustion is complete, water and carbon dioxide are given off, leaving

trace levels of ash, the same combustion products as from paper or wood. While some

polystyrene in medical an municipal wastes is currently incinerated in Australia, the energy

recovery option has not yet been implemented.

When incinerated, polystyrene produces energy, which compares favorably with coal

and oil. Because of its high fuel value, polystyrene in properly designed incinerators helps to

burn wet garbage more efficiently, and maintain the high burning temperatures necessary for

safe combustion.

The incineration of plastics can also generate energy and this potential is already

being harnessed in some overseas countries, particularly in Western Europe, The United

Stated and Japan.

Land filling:

While recycling and reuse continue to grow in popularity, most of the waste in this

country still goes to landfills. People assume the waste inside a landfill biodegrades. But the

fact is that very little - not paper, not polystyrene, not even food waste - degrades in a

meaningful way.

Polystyrene is effectively and safely disposed of in landfills. Modern landfills are designed

to protect the environment from the liquids and gases produced during the very slow

breakdown by reducing the exposure of garbage to air, water and sunlight - conditions

needed for degradation. Therefore, by design, modern landfills greatly retard the degradation

process to reduce the by-products that might otherwise contaminate groundwater and the air.

Preventing Litter :

The polystyrene industry cares about the environment. A widely held misconception is that

litter is a problem caused by specific materials themselves rather than aberrant consumer

behavior. The reality is that some people improperly dispose of materials by littering.

Littering is a matter of behavior; people who discard materials into the environment usually

do so because they don't think or don't care. Attributing the litter issue to one particular

packaging material does not solve the problem because another type of packaging will take

its place as litter unless behavior changes. To address concerns effectively, the polystyrene

industry supports organizations such as Keep America Beautiful, that work to prevent litter

across the country.

Anda mungkin juga menyukai

- Benzene Design 2520of 2520equipmentsDokumen60 halamanBenzene Design 2520of 2520equipmentsKrishan BorwalBelum ada peringkat

- Ammonium 2520sulphate Plant 2520Location&Layout.Dokumen5 halamanAmmonium 2520sulphate Plant 2520Location&Layout.Krishan BorwalBelum ada peringkat

- Rotary Drier DesignDokumen29 halamanRotary Drier DesignDharamvir Singh80% (5)

- Orient Paper MillsDokumen17 halamanOrient Paper MillsEr Mohneesh0% (1)

- Acrylic 2520acid Design 2520of 2520equipmentsDokumen32 halamanAcrylic 2520acid Design 2520of 2520equipmentsapi-3714811Belum ada peringkat

- Corporate RestructuringDokumen14 halamanCorporate RestructuringKrishan BorwalBelum ada peringkat

- Dividend Policy and Firm ValueDokumen10 halamanDividend Policy and Firm ValueKrishan BorwalBelum ada peringkat

- Orient Paper MillsDokumen17 halamanOrient Paper MillsEr Mohneesh0% (1)

- Lecture1&2 - Introduction To Financial ManagementDokumen6 halamanLecture1&2 - Introduction To Financial ManagementKrishan BorwalBelum ada peringkat

- Ethylene 2520oxide Cost 2520Estimation&EconomicsDokumen14 halamanEthylene 2520oxide Cost 2520Estimation&EconomicsBelema Thomson100% (1)

- Acrylic 2520acid 2520 Material 2520 BalanceDokumen6 halamanAcrylic 2520acid 2520 Material 2520 Balanceapi-3714811Belum ada peringkat

- Acrylic 2520acid Energy 2520 BalanceDokumen8 halamanAcrylic 2520acid Energy 2520 Balanceapi-3714811Belum ada peringkat

- RahulDokumen58 halamanRahulKrishan BorwalBelum ada peringkat

- First 3 PagespseomgposemgopmDokumen85 halamanFirst 3 PagespseomgposemgopmKrishan BorwalBelum ada peringkat

- Project Report On Financial Analysis of Reliance Industry LimitedDokumen107 halamanProject Report On Financial Analysis of Reliance Industry Limitedarindambarman74% (170)

- Acrylic 2520acid 2520Properties&UsesDokumen6 halamanAcrylic 2520acid 2520Properties&UsesDhaval PatelBelum ada peringkat

- RahulDokumen58 halamanRahulKrishan BorwalBelum ada peringkat

- Acrylic 2520acid Energy 2520 BalanceDokumen8 halamanAcrylic 2520acid Energy 2520 Balanceapi-3714811Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Emi Form ShieldDokumen6 halamanEmi Form ShieldwillguyBelum ada peringkat

- Factories Paying Over Rs. 1 Crore Revenue in Belapur 2006-07Dokumen7 halamanFactories Paying Over Rs. 1 Crore Revenue in Belapur 2006-07monikparmar1Belum ada peringkat

- Service Manual Rgd/Rgs Series Index Drives Models 350RGD/RGS, 500RGD/RGS & 600RGD/RGSDokumen16 halamanService Manual Rgd/Rgs Series Index Drives Models 350RGD/RGS, 500RGD/RGS & 600RGD/RGSSuhas KODREBelum ada peringkat

- Lancaster Paint Monthly Specials April-May 31, 2011Dokumen16 halamanLancaster Paint Monthly Specials April-May 31, 2011SteveBelum ada peringkat

- Architectural Fiberglass Dome InstallationDokumen5 halamanArchitectural Fiberglass Dome InstallationoscarhdefBelum ada peringkat

- Gates Belts Master Products CatalogDokumen100 halamanGates Belts Master Products CatalogpapashoBelum ada peringkat

- Mcgraw Edison Voltage Regulator Elevating Structure Instructions Mn225043enDokumen8 halamanMcgraw Edison Voltage Regulator Elevating Structure Instructions Mn225043enelmapa04Belum ada peringkat

- Goetze Faceseals FTL Seal TechnologyDokumen13 halamanGoetze Faceseals FTL Seal Technologycristobal_tl2277Belum ada peringkat

- PPI Full-Line CatalogDokumen20 halamanPPI Full-Line Catalogjrojas-1Belum ada peringkat