BW213DH-4 BVC Operation Instruction E 00804461.e07 PDF

Diunggah oleh

Herrera Salazar VisnuDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BW213DH-4 BVC Operation Instruction E 00804461.e07 PDF

Diunggah oleh

Herrera Salazar VisnuHak Cipta:

Format Tersedia

Operating instructions

Maintenance instructions

Catalogue number

008 044 61 05/2007

BW 213 DH-4 / PDH-4

BVC with attachment plates

S/N 101 583 06 ....

Single drum roller

Foreword

BOMAG 3 BW 213 DH-4/PDH-4 BVC

Foreword

BOMAG machines are products from the wide

range of BOMAG compaction equipment.

BOMAGs vast experience in connection with

state-of-the-art production and testing meth-

ods, such as lifetime tests of all important

components and highest quality demands

guarantee maximum reliability of your ma-

chine.

This manual comprises:

l Safety regulations

l Operating instructions

l Maintenance instructions

l Trouble shooting

Using these instructions will

l help you to become familiar with the machine.

l avoid malfunctions caused by unprofessional

operation.

Compliance with the maintenance instructions will

l enhance the reliability of the machine on con-

struction sites,

l prolong the lifetime of the machine,

l reduce repair costs and downtimes.

BOMAG GmbH will not assume liability for the

function of the machine

l if it is handled in a way not complying with the

usual modes of use,

l if it is used for purposes other than those men-

tioned in these instructions.

No warranty claims can be lodged in case of dam-

age resulting from

l operating errors,

l insufficient maintenance and

l wrong fuels and lubricants.

Please note!

This manual was written for operators and mainte-

nance personnel on construction sites.

Always keep this manual close at hand, e.g. in the

tool compartment of the machine or in a specially

provided container. These operating and mainte-

nance instructions are part of the machine.

You should only operate the machine after you

have been instructed and in compliance with these

instructions.

Strictly observe the safety regulations.

Please observe also the guidelines of the Civil En-

gineering Liability Association Safety Rules for

the Operation of Road Rollers and Soil Compac-

tors and all relevant accident prevention regula-

tions.

For your own personal safety you should only

use original spare parts from BOMAG.

In the course of technical development we re-

serve the right for technical modifications

without prior notification.

These operating and maintenance instructions are

also available in other languages.

Apart from that, the spare parts catalogue is avail-

able from your BOMAG dealer against the serial

number of your machine.

Your BOMAG dealer will also supply you with in-

formation about the correct use of our machines in

soil and asphalt construction.

The above notes do not constitute an extension of

the warranty and liability conditions specified in the

general terms of business of BOMAG GmbH.

We wish you successful work with your BOMAG

machine.

BOMAG GmbH

Printed in Germany

Copyright by BOMAG

Foreword

BOMAG 4 BW 213 DH-4/PDH-4 BVC

Please fill in

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine type (Fig. 1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial-number (Fig. 1 and 2)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine type (Fig. 3)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine number (Fig. 3)

i

Note

Supplement the above data together with the com-

missioning protocol.

During commissioning our organisation will in-

struct you in the operation and maintenance of the

machine.

Please observe strictly the safety regulations and

all notes on risks and dangers!

Fig. 1

Fig. 2

Fig. 3

Table of Contents

BOMAG 5 BW 213 DH-4/PDH-4 BVC

Technical Data 9

Safety regulations 13

Indicators and Controls 21

3.1 General notes 24

3.2 Description of indicators and control elements 24

3.3 Display and control elements

Variocontrol 35

3.4 Description of indicating and control elements

Variocontrol 37

3.5 Line diagram Automatic (EVIB) 39

3.6 Description of line diagram Automatic (EVIB) 41

3.7 Line diagram Manual (EVIB) 43

3.8 Description of line diagram Manual (EVIB) 45

3.9 Bar diagram (EVIB) 46

Operation 47

4.1 General notes 48

4.2 Tests before taking into operation 48

4.3 Starting the engine 49

4.4 Starting with jump wires 51

4.5 Driving the machine 52

4.6 Switching the vibration on and off 54

4.7 Operating the parking brake, stopping the machine 56

4.8 Shutting the engine down 56

4.9 Changing the LCD-display 57

4.10 Emergency exit 67

4.11 Adjusting the seat 67

4.12 Operating the hood 68

4.13 Towing in case of an engine failure 69

4.14 Transport 71

4.15 Tests before starting to operate 73

4.16 Mounting the attachment plates 73

4.17 Taking the attachment plates into service 75

4.18 Detaching the attachment plates 77

4.19 Variocontrol, selecting the operating mode 79

4.20 Measuring pass with Variocontrol 81

4.21 Finishing compaction of a track 84

4.22 Printing measuring data after completing compaction 85

4.23 Teaching distance pulses 86

4.24 Amplitude limitation (BVC only) 88

4.25 Changing the paper roll in the measuring value printer 90

4.26 Changing the printer ribbon in the measuring value printer 91

Table of Contents

BOMAG 6 BW 213 DH-4/PDH-4 BVC

Maintenance 93

5.1 General notes on maintenance 94

5.2 Fuels and lubricants 95

5.3 Table of fuels and lubricants 99

5.4 Running-in instructions 100

5.5 Maintenance chart 101

5.6 Check the engine oil level 104

5.7 Check, clean the water separator 104

5.8 Check the fuel level 105

5.9 Check the hydraulic oil level 106

5.10 Check the coolant level 106

5.11 Checking the dust separator on the oil bath air filter 107

5.12 Checking the tire pressure 108

5.13 Clean the cooling fins on engine and hydraulic oil cooler 108

5.14 Check the oil level in the drive axle 109

5.15 Checking the oil level in left/right wheel hubs 110

5.16 Check the oil level in the axle reduction gear 110

5.17 Check the oil level in the drum reduction gear 111

5.18 Checking the Vario exciter oil level 112

5.19 Changing engine oil and oil filter cartridges 113

5.20 Change the fuel filter cartridge 114

5.21 Draining the sludge from the fuel tank 115

5.22 Service the battery 116

5.23 Change the fuel pre-filter cartridge 117

5.24 Checking, replacing the refrigerant compressor V-belt 118

5.25 Service the air conditioning 119

5.26 Adjusting the valve clearance 122

5.27 Adjusting the control piston play 124

5.28 Checking / replacing the ribbed V-belt 125

5.29 Check the engine mounts 126

5.30 Change the oil in the drive axle 126

5.31 Changing the oil in the wheel hubs 127

5.32 Changing the oil in the axle reduction gear 128

5.33 Change the oil in the drum reduction gear 129

5.34 Vario exciter oil change 130

5.35 Change the oil in the exciter shaft housing of the attachment plates 131

5.36 Tightening the fastening of the axle to the frame 132

5.37 Tightening the wheel nuts 132

5.38 Check the ROPS 133

5.39 Cleaning the oil bath air filter 133

5.40 Changing hydraulic oil and breather filter 134

5.41 Changing the hydraulic oil filter 135

Table of Contents

BOMAG 7 BW 213 DH-4/PDH-4 BVC

5.42 Changing the steering oil filter 136

5.43 Changing the attachment plate oil filter 137

5.44 Change the coolant 138

5.45 Replacing the crank case ventilation valve 140

5.46 Electronic injector test EMR 141

5.47 Service the combustion air filter 142

5.48 Adjust the scrapers 144

5.49 Adjust the parking brake 145

5.50 Change the tires 146

5.51 Change the fresh air filter in the cabin 147

5.52 Tightening torques 147

5.53 Engine conservation 148

Trouble shooting 149

6.1 General notes 150

6.2 Reading out faults BVC/BTM05 150

6.3 Engine 152

Cab assembly before initial start-up 155

7.1 Preparations 157

7.2 Cabin assembly 158

7.3 Final function tests and checks 164

Table of Contents

BOMAG 8 BW 213 DH-4/PDH-4 BVC

BOMAG 9 BW 213 DH-4/PDH-4 BVC

1 Technical Data

Technical Data

BOMAG 10 BW 213 DH-4/PDH-4 BVC

Fig. 4

Dimensions in

mm

A B D H H2 K L O1 O2 S W

BW 213 DH-4

BVC/P

2960 2250 1500 2268 2972 490 5808 60 60 35 2130

*

BW 213 DH-4 BVC/P

Weights

Operating weight (CECE)

with ROPS and cabin

kg 15785

Axle load, drum (CECE) kg 7598

Axle load, wheels (CECE) kg 8187

Static linear load kg/cm 35,7

Travel characteristics

Speed km/h 0 ... 13

Max. gradability (depend-

ing on soil)

% 50

Engine

Engine manufacturer Deutz

Type TCD 2013 L04 2V

Cooling Water

Number of cylinders 4

Rated power ISO 3046 kW 119

Rated speed rpm 2200

Electrical equipment V 12

Drive system hydrostatic

Driven axles 2

Technical Data

BOMAG 11 BW 213 DH-4/PDH-4 BVC

Brakes

Service brake hydrostatic

Parking brake hydr.-mech.

Steering

Type of steering articulated

Steering operation hydrostatic

Vibration, drum

Drive system hydrostatic

Frequency Hz 28

Amplitude mm 0 ... 2,4

Vibration, attachment

plates

Drive system hydrostatic

Frequency Hz 40 ... 55

Tires

Tire size 23.1/18-26/12PR

Air pressure bar 1,8

Filling capacities

Engine Litres 15

Fuel Litres 340

Hydraulic oil Litres 60

* The right for technical modifications remains reserved

*

BW 213 DH-4 BVC/P

Technical Data

BOMAG 12 BW 213 DH-4/PDH-4 BVC

The following noise and vibration data acc. to

- EC Machine Regulation edition (98/37/EC) and

- Noise Emission Regulation 2000/14/EC

were determined at nominal speed of the drive engine and with vibration running. The machine was

standing on an elastic base.

During operation these values may vary because of the existing operating conditions.

Noise value

The sound level according to enclosure 1, paragraph 1.7.4. f of the EC-machine regulation is

sound pressure level at the work place of the operator (with cabin):

L

pA

= 76,8 dB(A)

The nose emission value for the machine according to the noise emission regulation 2000/14/EG is

guaranteed sound capacity level of the machine:

L

WA

= 111 dB(A)

These sound values were determined according to ISO 3744 for the sound capacity level (L

wA

) and ISO

11204 for sound pressure level (L

pA

) at the place of the operator.

Vibration value

The vibration values according to enclosure 1, paragraph 3. 6. 3. a of the EC-machine regulation are:

Vibration of the entire boy (drivers seat)

The weighted effective acceleration value determined in accordance with ISO 7096 is 0.5 m/sec

2

.

Hand-arm vibration values

The weighted effective acceleration value determined in accordance with EN 500/ISO 5349 , is

2.5 m/sec

2

.

BOMAG 13 BW 213 DH-4/PDH-4 BVC

2 Safety regulations

Safety regulations

BOMAG 14 BW 213 DH-4/PDH-4 BVC

General

This BOMAG machine is built in accordance

with the latest technical standard and the valid

technical rules and regulations. There is, how-

ever, a risk of danger for persons and property

if:

l the machine is used for purposes other than

those it is intended for

l the machine is operated by untrained person-

nel

l the machine is modified or converted in an un-

professional way

l the applicable safety regulations are not ob-

served.

Each person involved in operation, mainte-

nance and repair of the machine must there-

fore read and apply these safety regulations.

This should be confirmed by obtaining the sig-

natures of the customer, if necessary.

Furthermore the following regulations and instruc-

tions are obviously also valid:

l applicable accident prevention instructions

l generally acknowledged safety and road traffic

regulations

l country specific safety regulations. It is the

duty of the operator to know and observe

these regulations. This applies also for local

regulations and the regulations for various

types of manual work. If the recommendations

in this manual differ from the regulations valid

in your country, you must strictly observe the

regulations in your country.

Intended use

This machine must only be used for:

l compaction of bituminous materials, e.g. road

surface layers. (AC and AD machines only)

l medium and heavy compaction tasks in earth

work (road sub-bases)

l This machine must only be operated with fully

functional safety equipment.

l The machine should be checked by an expert

once every year.

Unintended use

Dangers may, however, arise from the machine if

it is used by untrained personnel in an unprofes-

sional way or if it is used for purposes other than

those mentioned in these instructions.

Do not work with vibration on hard concrete, on a

cured concrete layer or heavily frozen ground.

Starting and operation of the machine in an explo-

sive environment is prohibited.

Who is allowed to work with the ma-

chine?

The machine must only be operated by trained

and authorized persons which are at least 18

years of age. The responsibilities for the operation

of the machine must be clearly specified and com-

plied with.

Persons under the influence of alcohol, medica-

tion or drugs must not operate, service or repair

the machine.

Maintenance and repair tasks require specific

knowledge and must therefore only be carried out

by trained and qualified personnel.

Conversions and alterations to the ma-

chine

Unauthorized conversions to the machine are pro-

hibited for safety reasons.

Original parts and accessories have been special-

ly designed for this machine. We wish to make ex-

pressly clear that we have not tested or authorized

any original parts or special equipment not sup-

plied by us. The installation and/or use of such

products can impair the active and/or passive driv-

ing safety. The manufacturer expressly excludes

any liability for damage resulting from the use of

non-original parts or accessories.

Safety notes in the operating and main-

tenance instructions:

! Danger

Sections marked like this point out possible

dangers for persons.

Safety regulations

BOMAG 15 BW 213 DH-4/PDH-4 BVC

! Caution

Sections marked like this point out possible

dangers for the machine or for parts of the ma-

chine.

i

Note

Sections marked like this provide technical infor-

mation concerning the optimal economical use of

the machine.

Environment

Sections marked like this highlight activities

for the safe and environmental disposal of fu-

els and lubricants as well as replaced parts.

Observe all environment protection regula-

tions.

Information and safety stickers/decals

on the machine

Keep stickers/decals complete (see spare parts

catalogue) and fully legible and observe their

meaning.

Replace damaged or illegible stickers/decals im-

mediately.

Loading the machine

Use only strong and stable loading ramps. The

ramp inclination must be lower than the gradability

of the machine.

Secure the machine against turning over or slip-

ping off.

Secure the machine on the transport vehicle

against rolling off, slipping and turning over.

Persons are highly endangered if

l they step or stand under loads being lifted

l they remain in the drive range of the machine

during a demonstration or during loading.

The machine must not swing about when lifted off

the ground.

Use only safe lifting gear of sufficient load bearing

capacity.

Attach the lifting gear only to the specified lifting

points.

Towing the machine

Since the machine is not fitted with a towing hitch,

the machine cannot be towed with a tow bar.

If the machine has to be towed urgently out of the

danger zone because of other risks, this must only

be done on level ground or uphill using chains and

ropes. For this purpose towing ropes of sufficient

tensile strength must be fastened on the lifting

eyes.

After releasing the brake the machine can only be

braked by the towing vehicle.

Before releasing the brake block the machine with

chocks to prevent unintended rolling.

Checking the Roll Over Protection

Structure (ROPS)

i

Note

On machines with cabin the ROPS is an integral

part of the cabin.

The machine frame must not be distorted, bent or

cracked in the area of the ROPS fastening points.

The ROPS must not show any signs of corrosion,

damage, hairline cracks or open fractures.

The ROPS must not rattle about during driving.

This would mean that it is not properly fastened.

All bolted connections must be in accordance with

the prescribed specifications and correctly tight-

ened (observe the tightening torque values).

Screws and nuts must not be damaged, bent or

deformed.

With the cabin installed check also the condition of

the cabin mounts (rubber elements and screws).

Neither must any additional parts be welded or

bolted on, nor must any holes be drilled without the

permission of the manufacturer, since this may im-

pair the strength of the structure.

Starting the machine

Before starting

Operation of the machine is only permitted when

sitting in the operator's seat.

Use only machines which have been properly

serviced at regular intervals.

Safety regulations

BOMAG 16 BW 213 DH-4/PDH-4 BVC

Become acquainted with the equipment, the con-

trol elements, the working mode of the machine

and the area you will be working in.

Use your personal protective outfit (hard hat, safe-

ty boots etc.).

Check before mounting the machine if:

l there are persons or obstructions beside or

under the machine

l the machine is free of any oily and combustible

material

l all handrails, steps and platforms are free of

grease, oils, fuels, dirt, snow and ice

l the engine compartment hood is closed and

locked

To climb onto the machine use steps and hand-

rails.

Check before starting, whether:

l the machine shows any obvious defects

l all protective devices are properly secured in

their place

l steering, brakes, control elements, lighting

and warning horn are in order

l the seat is correctly adjusted

l the mirrors (if available) are clean and correct-

ly adjusted.

Do not start the machine if any gauges, control

lights or controls are defective.

Do not take any loose objects with you or fasten

them to the machine.

On machines with ROPS you should always wear

your seat belt!

Starting

Start and operate the machine only from the oper-

ator's seat

For starting set all control levers to "neutral posi-

tion".

Do not use any starting aids such as Start Pilot or

ether.

After starting check all gauges.

Starting with jump leads

Connect plus with plus and minus with minus

(ground cable) - always connect the ground cable

last and disconnect it first! Wrong connections

may cause severe damage in the electric system.

Never start the engine by bridging the electrical

connections on the starter, because the machine

would probably start to move immediately.

Starting in closed rooms

Exhaust gases are toxic! Always ensure an ade-

quate supply of fresh air when starting in closed

rooms!

Driving the machine

Persons in the endangered area

If the machine has turned over and the cabin door

is jammed, use the right hand cabin window as an

emergency exit.

Before starting or resuming work and especially

when driving backwards, check that there are no

persons or obstructions in the endangered area.

If necessary give warning signals. Stop work im-

mediately if persons remain in the danger area de-

spite the warning.

Do not step or stand into the articulation area of

the machine while the engine is running. Danger of

squashing!

Driving

In events of emergency actuate the emergency

stop switch immediately. Do not use the emergen-

cy stop push button as service brake.

Restart the machine only after the danger, that has

caused the actuation of the emergency stop, has

been eliminated.

If the machine has come in contact with high-volt-

age power lines:

l do not leave the operator's stand

l warn others from coming too close to the ma-

chine or touching it

l if possible drive the machine out of the danger

zone

l have the power shut off.

Operate the machine only from the operator's

seat.

Keep the cabin doors closed.

Do not adjust the seat while driving.

Do not climb onto or off the machine while driving.

Change the travel direction only while the machine

is standing.

Safety regulations

BOMAG 17 BW 213 DH-4/PDH-4 BVC

Do not use the machine to transport persons.

Stop the machine if you notice unusual noises or

the development of smoke. Investigate the cause

and have the fault corrected.

Keep a sufficient distance to excavations and em-

bankments and make sure that you work does not

impair the stability of the machine.

Do not work with vibration on hard concrete, on a

cured concrete layer or heavily frozen ground.

When passing under flyovers, bridges, tunnels,

electric power lines etc. keep a sufficient distance.

Driving on slopes and gradients

Do not drive up and down gradients, which exceed

the max. gradability of the machine.

On lopes always drive directly up or down. Change

to the lower speed range before approaching the

slope.

Wet and loose soils reduce the ground adhesion of

the machine and inclinations and slopes consider-

ably. Higher risk of accident!

Behaviour in traffic

Match the speed of the machine to the working

conditions.

Always allow loaded transport vehicles to pass.

Switch the lights on when the visibility is poor.

Keep clear of edges and embankments.

Check the effect of vibration

When compacting with vibration check the effect

of the vibration on nearby buildings and under-

ground supply lines (gas, water, sewage, electric

power supply), stop vibratory compaction if neces-

sary.

Do not work with vibration on hard (frozen, con-

crete) ground. Risk of bearing damage!

Parking the machine

Park the machine on level and firm ground.

Before leaving the machine:

l straighten the articulated joint to allow easy

access to and from the machine.

l return the travel lever to neutral position

l apply the parking brake

l shut the engine down and pull the ignition key

out.

l lock the cabin

l secure the machine against unauthorized use.

Do not jump off the machine, use access steps

and hand rails.

Always secure parked machines, which could be

in the way, with appropriate measures.

Parking on slopes and gradients

Secure the machine against rolling, place metal

chocks in front of and behind the drums.

Filling the fuel tank

Do not inhale fuel fumes.

Refuel only after shutting the engine and the aux-

iliary heater down.

Do not refuel in closed rooms.

No open fire, do not smoke.

Do not spill any fuel. Catch running out fuel, do not

let it seep into the ground.

Wipe off spilled fuel. Keep fuel free of dirt and wa-

ter.

Leaking fuel tanks can cause explosions. Ensure

tight fit of the fuel tank filling cover, replace it if nec-

essary.

Fire protection measures

Make yourself acquainted with the location and the

operation of fire extinguishers. Observe fire warn-

ing and fire fighting installations.

Maintenance work

Comply with the maintenance work described in

the operating and maintenance instructions, in-

cluding the information concerning the replace-

ment of parts.

Support the engine hood for all maintenance and

repair work in the engine compartment.

Maintenance work must only be performed by

qualified and authorized persons.

For overhead maintenance and assembly work

use the access steps and working platforms pro-

vided or other secure means. Do not use machine

parts as access steps.

Keep unauthorized persons away from the ma-

chine.

Do not perform maintenance work while the ma-

chine is driving or the engine is running.

Safety regulations

BOMAG 18 BW 213 DH-4/PDH-4 BVC

Park the machine on horizontal, level, firm ground.

Pull the key out of the ignition switch.

Secure the articulated joint with the articulation

lock.

Work on hydraulic lines

Relieve hydraulic pressures before working on hy-

draulic lines. Hydraulic oil escaping under pres-

sure can penetrate the skin and cause severe

injury. When being injured by hydraulic oil consult

a medical doctor immediately, as otherwise this

may cause severe infections.

Do not step in front of or behind the drums/wheels

when performing adjustment work in the hydraulic

system.

Do not change the setting of pressure relief valves.

Drain the hydraulic oil at operating temperature

danger of scalding!

Catch running out hydraulic oil and dispose of en-

vironmentally.

Always catch and dispose of hydraulic oils sepa-

rately.

Do not start the engine after draining the hydraulic

oil.

Once all work is completed (with the system still

depressurized!) check all connections and fittings

for leaks.

Changing hydraulic hoses

Hydraulic hoses must be visually inspected at reg-

ular intervals.

Hydraulic hoses must be immediately replaced if:

l the outer layer is damaged down to the inlay

(e.g. chafing, cuts, cracks)

l the outer layer is brittle (formation of cracks in

the hose material)

l the hose shows deformations in pressurized

and depressurized condition, which do not

comply with the genuine shape of the hydrau-

lic hose

l the hose shows deformations in bends, e.g.

squeezing, buckling, layer separation, forma-

tion of blisters

l parts of the hose are leaking.

l hoses are not correctly installed.

l the hydraulic hose has separated from the fit-

ting

l the fitting shows corrosion that impairs both

function and strength.

l hoses are mixed up by mistake.

l fittings are damaged or deformed, whereby

the function and strength of the hose/hose

connection is impaired.

Only genuine BOMAG replacement hydraulic hos-

es ensure that the correct hose type (pressure

range) is used at the right location.

Working on the engine

Shut the engine down before opening the engine

hood.

Do not work on the fuel system while the engine is

running - danger to life due to high pressures!

l Wait another minute after the engine has

stopped.

l Keep out of the danger zone during the initial

test rung.

l In case of leaks return to the workshop imme-

diately.

l Make sure that the engine cannot be started

unintentionally during service and repair work.

Drain the engine oil at operating temperature

danger of scalding!

Wipe off spilled oil, catch running out oil and dis-

pose of environmentally.

Store used filters and other oil contaminated ma-

terials in a separate, specially marked container

and dispose of environmentally.

Do not leave any tools or other objects, that could

cause damage, in the engine compartment.

The settings for idle speed and highest speed

must not be changed, since this would affect the

exhaust gas values and cause damage to engine

and power train.

Turbo chargers work with high speeds and high

temperatures. Keep hands, tools and materials

away from the intake and outlet openings of the

nturbo charger and do not touch any hot surfaces.

Check and change coolant only when the engine

is cold.

Catch coolant and dispose of environmentally.

Safety regulations

BOMAG 19 BW 213 DH-4/PDH-4 BVC

Working on electric parts of the machine

Before starting to work on electric parts of the ma-

chine disconnect the battery and cover it with insu-

lating material.

Do not use fuses with higher ampere ratings and

do not repair fuses with a piece of wire. Fire haz-

ard!

Disconnect the battery before starting welding

work on the machine.

Working on the battery

When working on the battery do not smoke, do not

use open fire!

Do not let acid come in contact with hands or

clothes! When injured by acid flush off with clear

water and seek medical advice.

Metal objects (e.g. tools, rings, watch straps) must

not come in contact with the battery poles dan-

ger of short circuit and burning!

When recharging serviceable batteries remove all

plugs, to avoid the accumulation of explosive gas-

es.

Observe the applicable instructions when starting

with an auxiliary battery.

Dispose of old batteries according to regulations.

Switch off the charging current before removing

the charging clamps.

Ensure sufficient ventilation, especially if the bat-

tery is to be charged in a closed room.

Working on the fuel system

Do not inhale any fuel fumes.

Avoid open fire, do not smoke, do not spill any fuel.

Catch running out fuel, do not let it seep into the

ground and dispose off environmentally.

Working on wheels and tires

Explosion-like bursting of tires or parts of tires and

rims can cause most severe or even deadly inju-

ries.

Assembly of tires must only be performed with ap-

propriate experience and tools. If necessary have

tires assembled in a qualified workshop.

Always ensure the correct tire pressure and do not

exceed the specified maximum pressure.

Check tires and wheels every day for specified

pressure, cuts, bulges, damaged rims, missing

wheel studs or nuts. Do not drive with damaged

tires or wheels.

Ant-sticking emulsions for tires must only consist

of water and anti-sticking agent, in a concentration

in accordance with the specifications of the manu-

facturer of the anti-sticking agent. Observe appli-

cable environmental regulations.

Cleaning work

Do not perform cleaning work while the engine is

running.

Do not use gasoline or other easily inflammable

substances for cleaning.

When cleaning with steam cleaning equipment do

not subject electrical parts and insulation material

to the direct jet of water, or cover it beforehand.

l Do not guide the water jet into the exhaust and

into the air filter.

After maintenance work

After all maintenance work is completed reinstall

all guards and safety installations.

Repair

Mark a defective machine by attaching a warning

tag to the steering wheel.

Repair work must only be performed by qualified

and authorized persons. Use our repair instruc-

tions for this work.

Exhaust gases are highly dangerous! Always en-

sure an adequate supply of fresh air when starting

in closed rooms!

Do not work on the fuel system while the engine is

running - danger to life!

The system is under high pressure! Keep away

from leakages in the high pressure system, be-

cause fuel squirting out may cause severe injury.

After shutting down the engine wait for another

minute, until the pressure has dropped to a per-

missible level. In case of leakages you should con-

tact the Service Department of the engine

manufacturer and refrain from starting the engine.

Test

The safety of compaction equipment must be

checked by a specialist as required in dependence

on the application and the operating conditions,

however at least once every year.

Safety regulations

BOMAG 20 BW 213 DH-4/PDH-4 BVC

BOMAG 21 BW 213 DH-4/PDH-4 BVC

3 Indicators and Controls

Indicators and Controls

BOMAG 22 BW 213 DH-4/PDH-4 BVC

Fig. 5

Indicators and Controls

BOMAG 23 BW 213 DH-4/PDH-4 BVC

1 Ignition switch

2 LCD display unit

3 Vent for heating and ventilation, driver

4 Vent for heating and ventilation, footwell

5 Control panel, travel lever

6 Display and control unit Variocontrol BOP

7 Rotary switch for speed range selection

8 Emergency stop push button

9 Push button for warning horn

10 Rotary switch for extension plates floating po-

sition

11 Rotary switch for extension plates vibration

frequency

12 Rotary switch vibration extension plates on/off

13 Rotary switch drum vibration on/off

14 Travel lever

15 Rotary momentary contact switch for engine

speed

16 Rotary momentary contact switch for drum vi-

bration frequency

*

17 Rotary switch for direction indicators left/right*

18 Rotary switch for hazard light system*

19 Rotary switch for lighting (StVZO)*

20 Rotary switch for working head lights*

21 Steering wheel

* Optional equipment

Indicators and Controls

BOMAG 24 BW 213 DH-4/PDH-4 BVC

3.1 General notes

Please read this section thoroughly before operat-

ing this machine if you are not yet conversant with

the indicators and control elements. All functions

are described in detail hereunder.

Paragraph 4 Operation contains only concise de-

scriptions of the individual operating steps.

3.2 Description of indicators

and control elements

Fig. 6

No. 1 = Ignition switch

Position "P"/"0" = ignition off, the key can be

pulled out, engine not running.

Position "I" = ignition on, all control and

warning lights on the fault

monitoring board light up for a

moment. The lighting can be

switched on.

i

Note

The engine can only be started when the travel le-

ver is in braking position.

The ignition switch is provided with a lock against

repetitive starting. To repeat the starting proce-

dure you must first turn the ignition switch back to

"0"-position.

Position "II" = turn further against spring

pressure, the engine starts, re-

turn the ignition key to position

"I" when the engine starts

! Caution

Run the engine warm for a short while before

starting to work. Do not let the engine run at

idling speed for longer than 10 minutes.

Do not shut the engine down all of a sudden

from full speed, but let it idle for a while for

temperature equalization.

Indicators and Controls

BOMAG 25 BW 213 DH-4/PDH-4 BVC

Fig. 7

No. 2 = LCD display unit

i

Note

With the ignition switch in position I all gauges and

instruments are switched on for 3 seconds.

Toggling between the displays is described in the

chapter "Operation".

a green = flashes when the direction indicator

switch is actuated.

b = Indication of fuel level

c = Upper display field, shows either the

time or the coolant temperature

d = Indication of travel speed and pre-se-

lected speed limitation (green ring

segment)

e red = flashes if engine oil pressure too low,

engine is shut down after 10 sec-

onds. Check engine oil level, repair

the engine if necessary.

f red = flashes if the engine overheats (oil

temperature), the warning buzzer

sounds, the engine is shut down after

2 minutes.

Switch off vibration, run engine with

idle speed or shut down engine if

necessary, clean engine oil cooler

and radiator, if necessary repair en-

gine.

g yellow = lights if combustion air filter cartridge

is soiled, clean or replace if neces-

sary.

h red = flashes when the coolant (filling) level

is too low.

Engine is shut down after 10 sec-

onds.

i yellow = lights if the hydraulic oil filter is con-

taminated, the engine is shut down

after 2 minutes.

Check hydraulic system, replace hy-

draulic oil filter.

j yellow = lights when the hydraulic oil tempera-

ture is too high

k yellow = lights when temperatures are low

(pre-heating for starting)

l yellow = Charge control light, lights if the bat-

tery is not being charged.

Check V-belt, if necessary repair the

generator.

m red = Water separator in fuel pre-cleaner.

Lights when the water proportion in

the transparent section of the fuel fil-

ter reaches the contacts.

n = Function display, set brightness of

display

o = Middle display field, can be switched

to display of operating hours or mean

fuel consumption by actuating the

"Info-button 1"

p = Bottom display field, can be switched

to display inclination, vibration fre-

quency, voltage, hydraulic oil pres-

sure, hydraulic oil temperature or

ambient temperature by actuating

"Info-button 2"

q = Hydraulic oil temperature gauge

r yellow = lights in case of problems with the air

conditioning

s yellow = lights in case of an ASC (Anti Spin

Control) failure

t red = The seat occupation monitoring sys-

tem lights when the seat is not occu-

pied. If the machine is travelling the

warning buzzer will sound, engine is

shut down after 4 seconds.

u red = Parking brake, with travel lever dis-

engaged

v red = Central warning light, lights if a fault

code is displayed

w red = Hazard light, flashes when the haz-

ard light is activated

Indicators and Controls

BOMAG 26 BW 213 DH-4/PDH-4 BVC

x = Engine speed display

No. 3 = Vents for air conditioning, heating

and ventilation, driver

No. 4 = Vents for air conditioning, heating

and ventilation, footwell

*

Fig. 8

No. 5 = Control panel, travel lever

(a) Vibration button

l Select the vibration on with the selector switch.

l Switch the vibration on or off by pressing the

push button.

(b) Push button "Plates up"

Press the push

button = Raise the plates

(c) Push button "Extend plates"

Press the push

button = The plates are extended to the

right

(d) Push button "Plates down"

Press the push

button = Lower the plates

! Caution

Do not drive backward with the plates lowered

to the ground!

(e) Push button "Retract plates"

Press the push

button = The plates are retracted

Fig. 9

Changeover of display

i

Note

The operation is described in the corresponding

chapter

Info 1 button = to toggle between operating

hours and mean consumption.

Changeover possible during

travel

Info 2 button = to toggle between display of

inclination [%], vibration fre-

quency [Hz], voltage [V], en-

gine oil pressure [bar],

hydraulic oil temperature

**

[C/

F], ambient temperature

***

[C/F]

Changeover possible during

travel

Navigation in input mode)

= Activation of input mode only

possible with the brake applied

(see chapter operation)

F2 button = Change selected field

F3 button = Select field to change

F4 button = Select field to change

F5 button = Change selected field

* Optional equipment

** Optional equipment

*** Optional equipment

Indicators and Controls

BOMAG 27 BW 213 DH-4/PDH-4 BVC

Fig. 10

No. 6 = Control unit Variocontrol BOP

i

Note

see section 3.4 display and control elements Var-

iocontrol.

Fig. 11

No. 7 = Rotary switch for final speed

Turn in direction

"Turtle" = Reduces the speed

Turn in direction

"Rabbit" = Increases the speed

Fig. 12

The adjusted travel range appears in the LCD dis-

play unit in form of a green ring segment (Fig. 12).

Fig. 13

No. 8 = Emergency stop switch

The engine will be shut down and the brake will

close.

! Danger

Danger of accident!

Operate only in emergency situations during

operation, do not use as a service brake.

The machine should only be started again after

the danger, that caused the actuation of the

emergency stop switch, has been removed.

operate = push the button completely

down, it will automatically lock

in end position.

unlock = turn the button clockwise and

release it.

to drive = move the travel lever first to

braking position, then start the

Indicators and Controls

BOMAG 28 BW 213 DH-4/PDH-4 BVC

engine and choose the travel

direction.

For safety reasons the travel system of the ma-

chine will only be enabled after the travel lever has

been shifted back to braking position.

Fig. 14

No. 9 = Push button for warning horn

Fig. 15

No. 10 = Rotary switch for attachment plates

floating position

Position left = Floating position off

Position right = Floating position on

! Danger

Danger of squashing!

Maintenance and service work must only be

performed with the attachment plates in float-

ing position. For safety reasons the extension

plates are then lowered to the ground and the

hydraulic lines depressurized.

Fig. 16

No. 11 = Rotary switch for frequency of attach-

ment plate

With this switch (potentiometer) the exciter fre-

quency can be infinitely adjusted (see technical

data).

Choose the setting in dependence on soil condi-

tion and degree of compaction.

Fig. 17

No. 12 = Rotary switch vibration attachment

plates on/off

Position left = Vibration off

Position right = Vibration on

Indicators and Controls

BOMAG 29 BW 213 DH-4/PDH-4 BVC

Fig. 18

No. 13 = Rotary switch for vibration

Position "Left" = Vibration off

Position "Right" = Vibration on

i

Note

Press additional push button on travel lever to

switch on and off.

Fig. 19

No. 14 = Travel lever

Position "mid-

dle" = Braking position service brake

Position "middle,

right" = Parking brake, to start the en-

gine

Position "I" = Forward travel

Position "II" = Backwards travel

i

Note

If the engine speed drops under load when driving

on steep gradients, take the travel lever slightly

back towards neutral. This relieves the hydraulic

system and reduces the load on the diesel engine.

Fig. 20

No. 15 = Rotary momentary contact switch for

engine speed

Electric engine speed adjustment

Position left = Idle speed position

Position middle = "ECO"-operation.

The engine speed adapts au-

tomatically to the power re-

quirements. This enables

economical operation.

Position right = Full throttle position, operating

position for driving and vibra-

tion

! Caution

Always drive and vibrate with max. engine

speed or in ECO-mode! Control the travel

speed with the travel lever.

Indicators and Controls

BOMAG 30 BW 213 DH-4/PDH-4 BVC

Fig. 21

No. 16 = Rotary momentary contact switch for

vibration frequency

*

Turn "Left" = Frequency reduction

Turn "Right" = Frequency increase

Fig. 22

No. 17 = Rotary switch for direction indicators

left / right

**

Position "mid-

dle" = Direction indicators disabled

Position "left or

right" = The front and rear direction in-

dicators for the corresponding

side of the machine light up,

control light 6 in the fault mon-

itoring board flashes

Fig. 23

No. 18 = Rotary switch for hazard light system

***

Position "left" = Hazard light switched off, con-

trol lights off.

Position "right" = Hazard light switched on, con-

trol light 7 in the fault monitor-

ing display lights up.

Fig. 24

No. 19 = Rotary switch for light system (StV-

ZO)

****

Position "left" = Light off

Position "mid-

dle" = Sidelights on, with ignition

switch in position "I" or "P"

Position "right" = Travel light on, with ignition

switch in position "I".

* Optional equipment

** Optional equipment

*** Optional equipment

**** Optional equipment

Indicators and Controls

BOMAG 31 BW 213 DH-4/PDH-4 BVC

Fig. 25

No. 20 = Rotary switch for working lights

*

Position "left" = Light off

Position "right" = Working lights on, with ignition

switch in position "I".

No. 21 = Steering wheel, electrically operated

turn = The machine steers to the cor-

responding direction

i

Note

The machine is equipped with an armrest contact

switch (safety feature).

If the armrest is raised while driving, the warning

horn is activated and the machine is decelerated

to standstill after four seconds. If the armrest is

lowered again within four seconds the machine will

continue the travel.

Lower the armrest before resuming operation, en-

gage the travel lever in "0"-position (brake posi-

tion), then operate the travel lever again to the

desired travel direction.

Fig. 26

No. 22 = Lever, swivelling of drivers seat

! Danger

Danger of accident!

Always lock the drivers seat in one of the lock-

ing positions while driving.

Do not swivel the drivers seat while driving.

swivel = Stop the machine and apply

the parking brake. Pull the le-

ver up and swivel the drivers

seat to the desired position.

i

Note

Swivelling angle max. 20 to either side.

Fig. 27

No. 23 = 2-pole socket

Current only with the ignition switch in position "I"

or when the engine is running.

* Optional equipment

Indicators and Controls

BOMAG 32 BW 213 DH-4/PDH-4 BVC

Fig. 28

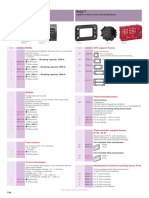

No. 24 = Fuses in electric installation box

F05, 10A = Display

F07, 15A = Hazard light

*

F08, 15A = Indicator*

F09, 10A = Parking tail light, left*

F10, 10A = Parking tail light, right*

F11, 15A = Head lights, StVZO*

F13, 30A = Starting

F18, 10A = Working head lights, relay*

F19, 15A = Working head lights, front*

F22, 15A = Working head lights, rear*

F23, 15A = Warning horn

F24, 10A = Joystick, DASA

**

, display

F39, 15A = Socket, cabin*

F67, 15A = Last ESX

***

F84, 10A = Voltage supply MESX

****

, ESX

via emergency stop

F95, 10A = EMR

*****

-control, joystick

F145, 20A = Attachment plates*

F146, 15A = Last MESX*

F148, 10A = Measuring technology*

! Danger

Fire hazard!

Do not use fuses with higher ampere ratings

and do not bridge fuses.

Fig. 29

No. 25 = Toggle switch, cabin

a = toggle switch for flashing beacon

b = toggle switch for front windscreen wiper/

washer

up = windscreen wiper moves to

end position and stops.

down = Switches on wiping of front

windscreen.

Push button = Front windscreen is sprayed

during wiping.

c = toggle switch for rear windscreen wiper/

washer

up = windscreen wiper moves to

end position and stops.

down = Switches on wiping of rear

windscreen.

Push button = Rear windscreen is sprayed

during wiping.

* Optional equipment

** DASA = Data Collector

*** ESX = BDC-remote control

**** MESX = BMU-measuring technology control

*****EMR = engine control

Indicators and Controls

BOMAG 33 BW 213 DH-4/PDH-4 BVC

d = toggle switch for rear windscreen heating

Fig. 30

No. 26 = Fuse box, cabin

! Danger

Fire hazard!

Do not use fuses with higher ampere ratings

and do not bridge fuses.

(1), 15A = (F43) wiper/washer, rear

(2), 15A = (F44) wiper/washer, front

(3), 10A = (F130) relay for rear windscreen

heating, reading light

(4), 25A = (F31) cabin fan

(5), 10A = (F41) flashing beacon

(6), 15A = (F144) cab socket

(7), 15A = (F143) rear windscreen heating

(8), 5A = (F42) potential 30, cab light

Fig. 31

No. 27 = Control panel for ventilator, air condi-

tioning, heating

e = Rotary switch for cabin ventilator

Position Off = cabin ventilator switched off.

Position 1, 2 and

3 = ventilator stages of different

strengths

f = Push button for air conditioning

*

press = air conditioning switched on.

(only with fan in stage 1, 2 or 3)

i

Note

The light above the push button lights up.

With rotary switch (g) the air conditioning unit can

be regulated within the blue range.

press again = air conditioning switched off.

i

Note

The light goes out.

g = Rotary switch for cabin heater (tempera-

ture selector switch)

Position Off = cabin heater switched off.

Position blue

range = temperature selection for air

conditioning.

Position red

range = Temperature selection for cab-

in heater.

Fig. 32

No. 28 = Cabin light

* Optional equipment

Indicators and Controls

BOMAG 34 BW 213 DH-4/PDH-4 BVC

i = reading and dashboard light

j = toggle switch for reading and dashboard

light

k = toggle switch for cabin light

l = cabin light

Fig. 33

No. 29 = Main fuse for battery

125A = (F00)

i

Note

The battery with the main fuses is located in the

engine compartment.

Indicators and Controls

BOMAG 35 BW 213 DH-4/PDH-4 BVC

3.3 Display and control ele-

ments

Variocontrol

Fig. 34

Indicators and Controls

BOMAG 36 BW 213 DH-4/PDH-4 BVC

1 E

VIB

display

2 Display for jump operation

3 Push button F5 START

4 Push button F6 STOP

5 Push button F7 PRINT

6 Push button F8 DELETE

7 Vibration frequency display

8 Rotary switch to set the nominal value (auto-

matic operation)

9 Push button F14 nominal value increase

10 Push button F13 nominal value decrease

11 Rotary switch to select operating mode (auto-

matic/manual)

12 Push button F12 automatic operation

13 Push button F11 manual operation

14 Rotary switch for manual setting of amplitude

direction

15 Push button F10 vertical effective direction

16 Push button F9 horizontal effective direction

17 Speed display

18 Amplitude display

19 Printer for measuring values

20 Fault light

21 Amplitude limitation active

Indicators and Controls

BOMAG 37 BW 213 DH-4/PDH-4 BVC

3.4 Description of indicating

and control elements

Variocontrol

No. 1 = E

VIB

-display

Display of the dynamic soil stiffness in MN/m

2

.

No. 2 = Display for jump operation

yellow

symbol = Drum jumps

red

symbol = Drum jumps excessively or

tumbles

Select a smaller amplitude, if necessary!

No. 3 = Button F5 START

press = Starts recording of measuring

values

Control field "F5" flashes green on the screen.

No. 4 = Button F6 STOP

press = Stops recording of measuring

values

The red control field "F6" on the screen lights up.

i

Note

Depending on the measuring result the green con-

trol field "F5" may stay on.

No. 5 = Button F 7 measuring value printer

To print out the measuring data saved during the

last pass press button F7 PRINT.

short actuation = Line diagram

long actuation 5

sec. = Bar chart

Control field F7 goes out and the measuring value

printer starts to print out measuring data.

i

Note

After the printing process has finished any amount

of diagrams can be printed out by pressing the

same button F7 (PRINT).

No. 6 = Button F8 DELETE

press = All stored faults are deleted.

! Caution

If the increase of the measuring value is to be

calculated on a track press button F8 DELETE

only when changing the track.

No. 7 = Frequency display (only BTM 05)

with vibration switched on this instrument shows

the frequency (rotating speed) of the exciter shaft.

No. 8 = Rotary switch P3 pre-setting of nomi-

nal values

For "Automatic" mode

In dependence on the stiffness of the soil the ef-

fective direction of the amplitude will adjust auto-

matically. The desired maximumdynamic stiffness

module E

VIB

[MN/m

2

] can be preselected in 6

stages (45, 80, 100, 120,150 and Max.).

The selected value is shown on the screen in field

"P3"

No. 9 = Button F14 increase of nominal value

With each actuation of the button the presetting is

raised by one stage.

The selected value is shown on the screen in field

"P3"

No. 10 = Button F13 reduction of nominal val-

ue

With each actuation of the button the presetting is

reduced by one stage.

The selected value is shown on the screen in field

"P3"

No. 11 = Rotary switch P2 operating mode

Position Auto-

matic E

VIB

= The machine automatically

chooses the optimal effective

direction of the amplitude in

dependence on the stiffness of

the ground and the adjusted

nominal E

VIB

-value (switch

P3).

Position E

VIB

-

Manual = The effective direction of the

amplitude is set in 6 fixed stag-

es (switch P1), when changing

the travel direction the vibra-

tion will adapt automatically

and change to other quadrant.

The selected operating mode is shown on the

screen in field "P2".

No. 12 = Button F12 automatic operation

Indicators and Controls

BOMAG 38 BW 213 DH-4/PDH-4 BVC

Pressing this button changes the operating mode

to "Automatic".

The selected operating mode is shown on the

screen in field "P2".

No. 13 = Button F11 manual operation

Pressing this button changes the operating mode

to Manual.

The selected operating mode is shown on the

screen in field "P2".

No. 14 = Rotary switch P1 manual setting of ef-

fective direction of amplitude

This switch is used to specify the vertical ampli-

tude in "Manual" mode and is only available in this

operating mode.

Position 1 (left) = Horizontal, 0 mm amplitude

Position 2 = 0,7 mm amplitude

Position 3 = 1,1 mm amplitude

Position 4 = 1,5 mm amplitude

Position 5 = 1,8 mm amplitude

Position 6

(right) = Vertical, 2,4 mm amplitude

Field P1 on the screen shows graphically with

which amplitude the machine is currently working.

i

Note

In travel lever position "0" the vibrator system re-

mains in position "horizontal" for safety reasons.

On bridges or in sensitive areas it is recommended

to use "Manual Horizontal".

No. 15 = Button F10 vertical effective direction

With each actuation of the button the effective di-

rection is changed by one step towards vertical.

The selected value is shown on the screen in field

P1

No. 16 = Button F9 horizontal effective direc-

tion

With each actuation of the button the effective di-

rection is changed by one step towards horizontal.

The selected value is shown on the screen in field

P1

No. 17 = Speed display

Shows the travel speed of the machine.

No. 18 = Amplitude display

This gauge shows the current vertical amplitude of

the machine.

No. 19 = Printer for measuring values

To print out the measuring data saved during the

last pass press button (7) "PRINT".

No. 20 = Fault light

Inform the BOMAG After Sales Service if it lights

up.

No. 21 = Amplitude limitation active

In automatic operation the amplitude limitation en-

ables a limitation of the effective amplitude.

no symbol dis-

played = Amplitude limitation inactive

Symbol shaded = Amplitude limitation active, but

inactive because of the param-

eter setting (e.g. manual

mode)

Symbol bright = Amplitude limitation active

Indicators and Controls

BOMAG 39 BW 213 DH-4/PDH-4 BVC

3.5 Line diagram Automatic

(E

VIB

)

Fig. 35

Indicators and Controls

BOMAG 40 BW 213 DH-4/PDH-4 BVC

1 Pass-No.

2 Travel direction

3 Machine equipment (BTM 05/BTM-E)

4 Software status of the measuring equipment

5 Machine number

6 Machine type

7 Operating mode

8 Setting of nominal E

VIB

value

9 Maxiumum E

VIB

value

10 Miniumum E

VIB

value

11 Mean E

VIB

-value

12 E

VIB

-change

13 Medium frequency

14 Mean travel speed

15 Track length

16 Raster division in longitudinal direction

17 Longitudinal raster line

18 Identification of nominal value line

19 Measuring value raster line

20 Diagram line

Indicators and Controls

BOMAG 41 BW 213 DH-4/PDH-4 BVC

3.6 Description of line diagram

Automatic (E

VIB

)

No. 1 = Pass

Total number of measured passes on this track.

No. 2 = Travel direction

No. 3 = Machine equipment

No. 4 = Software status of the measuring

equipment

No. 5 = Machine number

No. 6 = Machine type

No. 7 = Operating mode

Shows the setting of the operating mode (Auto)

and the presetting of nominal value (150).

No. 8 = Setting of nominal E

VIB

value

Shows the preset nominal E

VIB

-value.

No. 9 = Maximum E

VIB

value

No. 10 = Minimum E

VIB

value

No. 11 = Mean E

VIB

-value

shows the mean value of the E

VIB

-values for the

tracks driven between START and STOP.

No. 12 = E

VIB

-change

E

VIB

-change in %. They always relate to the previ-

ous pass.

No. 13 = Medium frequency

No. 14 = Mean travel speed

shows the mean value of speed driven during this

pass.

i

Note

Always shows the same travel speed in order to

avoid a falsification of the measuring results.

No. 15 = Track length

Measured track length between START and

STOP.

No. 16 = Raster division in longitudinal direc-

tion

Is used to pinpoint individual measuring values on

the measuring curve.

i

Note

The raster lines mark measuring track sections of

5 m length.

Graduation of the measuring track (track length in

printout) into fixed sections.

No. 17 = Longitudinal raster line

No. 18 = Identification of nominal value line

Show the setting of nominal value (150).

No. 19 = Measuring value raster line

No. 20 = Diagram line

Shows the E

VIB

-value at any point of the rolled

track. The raster line enables the location related

assignment of the E

VIB

-value and the location of a

fault (over or under compaction).

Indicators and Controls

BOMAG 42 BW 213 DH-4/PDH-4 BVC

Indicators and Controls

BOMAG 43 BW 213 DH-4/PDH-4 BVC

3.7 Line diagram Manual (E

VIB

)

Fig. 36

Indicators and Controls

BOMAG 44 BW 213 DH-4/PDH-4 BVC

1 Pass-No.

2 Travel direction

3 Machine equipment

4 Software status of the measuring equipment

5 Machine number

6 Machine type

7 Operating mode

8 Amplitude

9 Maxiumum E

VIB

value

10 Miniumum E

VIB

value

11 Mean E

VIB

-value

12 E

VIB

-change

13 Medium frequency

14 Mean travel speed

15 Track length

16 Raster division in longitudinal direction

17 Marking (thick line) excessive jumping, tum-

bling of the drum

18 Longitudinal raster line

19 Measuring value raster line

20 Diagram line

21 Marking (thin line) jumping of the drum

Indicators and Controls

BOMAG 45 BW 213 DH-4/PDH-4 BVC

3.8 Description of line diagram

Manual (E

VIB

)

No. 1 = Pass

Total number of measured passes on this track.

No. 2 = Travel direction

No. 3 = Machine equipment

No. 4 = Software status of the measuring

equipment

No. 5 = Machine number

No. 6 = Machine type

No. 7 = Operating mode

Shows the setting of the operating mode (Auto)

and the presetting of nominal value (150).

No. 8 = Amplitude

Shows the amplitude which was adjusted during

the E

VIB

measuring pass.

No. 9 = Maxiumum E

VIB

value

No. 10 = Miniumum E

VIB

value

No. 11 = Mean E

VIB

-value

shows the mean value of the E

VIB

-values for the

tracks driven between START and STOP.

No. 12 = E

VIB

-change

E

VIB

-change in %. They always relate to the previ-

ous pass.

No. 13 = Medium frequency

No. 14 = Mean travel speed

shows the mean value of speed driven during this

pass.

i

Note

Always shows the same travel speed in order to

avoid a falsification of the measuring results.

No. 15 = Track length

Measured track length between START and

STOP.

No. 16 = Raster division in longitudinal direc-

tion

Is used to pinpoint individual measuring values on

the measuring curve.

i

Note

The raster lines mark measuring track sections of

5 m length.

Graduation of the measuring track (track length in

printout) into fixed sections.

No. 17 = Marking of jump information

Indicates excessive jumping/tumbling of the drum

on the marked track section (thick line).

i

Note

Select a smaller amplitude, if necessary!

No. 18 = Longitudinal raster line

No. 19 = Measuring value raster line

No. 20 = Diagram line

Shows the E

VIB

-value at any point of the rolled

track. The raster line enables the location related

assignment of the E

VIB

-value and the location of a

fault (over or under compaction).

No. 21 = Marking of jump information

Indicates jumping of the drum on the marked track

section (thin line).

Indicators and Controls

BOMAG 46 BW 213 DH-4/PDH-4 BVC

3.9 Bar diagram

*

(E

VIB

)

The bar diagram differs from the line diagram only

by the graphic representation of measuring val-

ues. In the bar diagram the mean values of 5 m

sections are shown as bars. In addition, the E

VIB

changes of the individual 5 m sections are speci-

fied in percent after the second pass in the same

travel direction.

* only BTM prof

BOMAG 47 BW 213 DH-4/PDH-4 BVC

4 Operation

Operation

BOMAG 48 BW 213 DH-4/PDH-4 BVC

4.1 General notes

Please read section 3 Indicators and Control Ele-

ments thoroughly before operating the machine if

you are not yet fully familiar with the indicators and

control elements of the machine.

All indicators and control elements are described

in detail in this chapter.

4.2 Tests before taking into op-

eration

The following inspections must be carried out be-

fore each working day or before a longer working

period.

! Danger

Danger of accident!

Please observe strictly the safety regulations

in chapter 2 of this instruction manual!

l Park the machine on ground as level as possi-

ble.

Check:

l fuel tank and fuel lines for leaks

l screw joints for tight fit

l function of steering

l machine for cleanliness, damage

l presence of the appropriate operating and

maintenance instructions,

l check whether the machine has been properly

serviced.

i

Note

For a description of the following tasks refer to the

chapter "maintenance every 10 operating hours".

l Engine oil level

i

Note

In hydraulic systems filled with Panolin HLPSynth.

46 always use the same oil to top up. With other

ester based oils consult the lubrication oil service

of the respective oil manufacturer.

l Check the hydraulic oil level, top up if neces-

sary.

l Check the coolant level, top up if necessary.

! Danger

Fire hazard!

Do not refuel in closed rooms.

l Check the fuel level, top up if necessary.

Operation

BOMAG 49 BW 213 DH-4/PDH-4 BVC

l Check water separator in fuel system, drain if

necessary.

l Check the scrapers, adjust if necessary

l Check the air pressure in the tires For values

refer to the technical data.

! Caution

Ensure equal pressure in both tires.

If the machine is to be operated with padfoot

drum shell the attachment plates must be de-

coupled!

Danger of damage to the drive axle.

4.3 Starting the engine

! Danger

Danger of accident!

Always wear your seat belt.

Fig. 37

l Check, whether the travel lever (Fig. 37) is en-

gaged to the right in brake position.

Fig. 38

l Turn the rotary vibration switch (Fig. 38) to po-

sition "0", vibration off.

Operation

BOMAG 50 BW 213 DH-4/PDH-4 BVC

Fig. 39

l Check, whether the emergency stop switch

(Fig. 39) is unlocked.

Fig. 40

l Turn rotary switch (Fig. 40) to position "Min"

(idle speed).

Fig. 41

l Turn the ignition key (Fig. 41) to position "I".

Fig. 42

All control and warning lights (Fig. 42) in the fault

monitoring board light up for a moment.

The battery control (l) and brake warning lights (u)

light up, the engine oil pressure warning light (e)

flashes.

l Wait until the pre-heating light (k) has gone

out.

i

Note

The length of the pre-heating period depends on

the engine temperature.

! Caution

Perform the starting process for maximum 20

seconds without interruption and pause for a

minute between starting attempts.

If the engine has not started after two attempts

perform trouble shooting.

Operation

BOMAG 51 BW 213 DH-4/PDH-4 BVC

Fig. 43

l Turn the ignition key to position "II" (Fig. 43),

the starter cranks the engine.

l As soon as the engine ignites return the igni-

tion key to position "I".

! Caution

Do not allow the engine to run longer than 10

minutes with idle speed.

4.4 Starting with jump wires

Fig. 44

! Caution

A wrong connection will cause severe damage

in the electric system.

l Bridge the machine only with a 12 Volt auxilia-

ry battery.

l When jump starting with an external battery

connect both plus poles first.

l Then connect the ground cable first to the mi-

nus pole of the current supplying auxiliary bat-

tery and then to engine or chassis ground, as

far away from the battery as possible (Fig. 44).

l Start as described under 'Starting the engine'.

l Once the engine is running switch on a power-

ful consumer (working light, etc.).

! Caution

If no powerful consumer is switched on volt-

age peaks may occur when separating the con-

necting cables between the batteries, which

could damage electrical components.

l After starting disconnect the negative poles

(ground cable) first and the positive poles af-

ter.

l Switch off the consumer.

Operation

BOMAG 52 BW 213 DH-4/PDH-4 BVC

4.5 Driving the machine

! Danger

Danger of accident!

Wet and loose soils considerably reduce the

ground adhesion of the machine on inclina-

tions and slopes.

Soil conditions and weather influences impair

the gradability of the machine.

Do not drive up and down inclinations exceed-

ing the maximum gradability of the machine

(see technical data).

Do not drive without wearing your seat belt.

Always give way to loaded transport vehicles!

Before starting to drive make sure that the

drive range is absolutely safe.

! Caution

Always keep the cabin door closed while driv-

ing with the machine. With the door opened

and the machine fully articulated extreme os-

cillations of the machine may damage the

door.

i

Note

The machine is equipped with an armrest monitor-

ing system and a seat contact switch (safety fea-

ture).

If the armrest is raised or the driver gets up from

his seat while driving, the warning horn is activated

and the machine is decelerated to standstill after

four seconds. If the armrest is lowered again or the

driver sits down again within four seconds the ma-

chine will continue the travel.

Lower the armrest or sit down on the seat again

before resuming operation, engage the travel le-

ver in "0"-position (brake position), then operate

the travel lever again to the desired travel direc-

tion.

Fig. 45

l Close the cabin door (Fig. 45).

Fig. 46

l Sit on the driver's seat (Fig. 46) and fold down

the armrest (if applicable).

Fig. 47

l Fasten your seat belt (Fig. 47).

l "Start engine", see previous sections.

Operation

BOMAG 53 BW 213 DH-4/PDH-4 BVC

Fig. 48

l Select the desired travel speed range (Fig.

48).

The adjusted travel range appears in the LCD dis-

play unit in form of a green ring segment.

Fig. 49

l Turn the rotary switch (Fig. 49) to position

"ECO" or "MAX".

Fig. 50

l Push the travel lever (Fig. 50) to the left out of

braking position and move it slowly to the de-

sired travel direction.

i

Note

Shift the travel lever out of "0"-position slowly to

forward or reverse, the machine will drive forward

or reverse at a speed which corresponds with the

displacement of the travel lever.

Returning the travel lever towards neutral will

brake the machine and in "0"-position of the travel

lever the machine will stop.

! Danger

Danger of accident!

When stopping on inclinations and slopes pull

the travel lever to the right and lock it in brak-

ing position.

Important notes on travel operation

! Caution

When changing the travel direction hold the

travel lever for a moment in "0"-position, until

the machine has stopped, before actuating to

the new travel direction.

Do not operate jerkily!

When driving up and down inclinations move

the travel lever slowly back towards neutral to

brake the machine.

If the engine speed drops when driving up ex-

treme inclinations move the ravel lever slightly

Operation

BOMAG 54 BW 213 DH-4/PDH-4 BVC

back, if necessary change to the lower speed

range.

4.6 Switching the vibration on

and off

! Danger

Risk of damage!

When compacting with vibration you must

check the effect of nearby buildings and un-

derground supply lines (gas, water, sewage,

electric power), if necessary stop compaction

with vibration.

Do not activate the vibration on hard (frozen,

concrete) ground. Danger of bearing damage!

Fig. 51

l Pre-select the travel range for max. working

speed (Fig. 51).

The adjusted travel range appears in the LCD dis-

play unit in form of a green ring segment.

Operation

BOMAG 55 BW 213 DH-4/PDH-4 BVC

Pre-selecting the vibration

Fig. 52

l Pre-select vibration with rotary switch (Fig.

52).

Switch the vibration on

i

Note

Vibration is only possible in the range of 0 ... 8 km/

h.

Fig. 53

l Turn the rotary switch (Fig. 53) to position

"ECO" (Automatic) or "MAX" (full throttle).

! Caution

Switch the vibration on only at ECO max. en-

gine speed.

Fig. 54

l Press the push button (Fig. 54) in the travel le-

ver while driving, the drum will vibrate.

Switching the vibration off

l Press the push button again and after work

switch the rotary vibration switch to position

"0".

Operation

BOMAG 56 BW 213 DH-4/PDH-4 BVC

4.7 Operating the parking

brake, stopping the ma-

chine

Fig. 55

l Return the travel lever (Fig. 55) slowly to "neu-

tral"-position and engage it to the right parking

brake position.

The machine is automatically braked by the hydro-

static drive and parking brake closes.

i

Note

The parking brake also closes automatically when

shutting the engine down.

4.8 Shutting the engine down

! Caution

Straighten the articulated joint to provide easi-

er access to the machine.

Fig. 56

l Return the travel lever (Fig. 56) slowly to "neu-

tral"-position and engage it to the right in brak-

ing position.

Fig. 57

l Turn rotary switch (Fig. 57) to position "ECO"

or "MIN" (idle speed).

i

Note

Do not shut the engine down all of the sudden from

full speed, but let it idle for a while for temperature

equalization.

Operation

BOMAG 57 BW 213 DH-4/PDH-4 BVC

Fig. 58

l Turn the ignition switch (Fig. 58) to position "0"

or "P" and pull the ignition key out.

i

Note

The parking brake closes automatically when

shutting the engine down.

! Danger

Danger of accident!

Secure the machine against unauthorized use,

pull the ignition key out, lock the cabin door.

4.9 Changing the LCD-display

Switching the middle display over

i

Note

Switching over possible while machine is operated

Fig. 59

l Press Info-button 1 (Fig. 59) (back of travel le-

ver).

Fig. 60