API 570 Formulas

Diunggah oleh

jasminneeDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

API 570 Formulas

Diunggah oleh

jasminneeHak Cipta:

Format Tersedia

5/7/2014 API 570 Examination Formulas ~ apiXams

http://apixams.blogspot.in/2012/09/api-570-examination-formulas.html 1/2

API 570 Examination Formulas

Sl # Formula Description Formula Para/Ref. No Ref. Code

1 Soil Resistivity (ohm-cm) = 191.5 x d x R 10.10.1.4.3 API 574 2009

Edition

The number 191.5 is a constant that takes into account the mathematical equation for the mass of the Soil, and a conversion

factor to convert feet to centimeters. "d" is the distance in feet between any 0f the equally spaced pins (with all of the pins in a

straight line), "R" is a resistance factor of the voltage drop across the two inner pins divided by the induced current flow in

the earth between the two outer pins.

2 Minimum Allowable

Working Pressure (MAWP)

MAWP = 2SEt/D Table 4 API 570 2009

Edition

"S" is the allowable unit stress at the design temperature, In pounds per square inch (kilopascals), "E" is the longitudinal

quality factor.

'"t" is the corroded thickness, means actual measured thickness minus twice of calculated corrosion to next inspection period

in inches (millimeters), "P" is the internal design gauge pressure of the pipe. in pounds per square inch (kilopascals), "D" is

the OD of the pipe, in inches (millimeters)

3 Temperature Conversion Tc = 5/9 x (Tf - 32)

Tc = temperature in degrees Celsius, Tf = temperature in degrees Fahrenheit

4 Temperature Conversion Tf = 9/5 x Tc + 32

Tc = temperature in degrees Celsius, Tf = temperature in degrees Fahrenheit

5 Toe to Toe Distance Patch

Plate

=Dt 8.1.4 API 570 2009

Edition

D = Inside Diameter of Pipe, t = Thickness of Patch Plate

6 Minimum Required Pipe

Thickness

tm = t + c

t = PD/ 2(SEW + PY)

304.1.1 & 304.1.2 B31.3 2010

Edition

The minimum thickness, T, for the pipe selected, considering manufacturers minus tolerance, shall be not less than tm.

(b) The following nomenclature is used in the equations for pressure design of straight pipe:

c = sum of the mechanical allowances (thread or groove depth) plus corrosion and erosion allowances. For threaded

components, the nominal thread depth (dimension h of ASME B1.20.1 or equivalent) shall apply. For machined surfaces or

grooves where the tolerance is not specified, the tolerance shall be assumed to be 0.5 mm (0.02 in.) in addition to the specified

depth of the cut.

D = outside diameter of pipe as listed in tables of standards or specifications or as measured

d = inside diameter of pipe. For pressure design calculation, the inside diameter of the pipe is the maximum value allowable

under the purchase specification. E = quality factor from Table A-1A or A-1B, P = internal design gage pressure, S = stress

value for material from Table A-1, T = pipe wall thickness (measured or minimum in accordance with the purchase

specification), t = pressure design thickness, as calculated in accordance with para. 304.1.2 for internal pressure or as

determined in accordance with para. 304.1.3 for external pressure, tm = minimum required thickness, including mechanical,

corrosion, and erosion allowances, W = weld joint strength reduction factor in accordance with para. 302.3.5(e), Y = coefficient

from Table 304.1.1, valid for t < D/6 and for materials shown. The value of Y may be interpolated for intermediate temperatures.

For t D/6, Y = d + 2c /D + d + 2c

7 Pressure Design Thickness

(Barlow)

t = PD/2SE 11.1.2 API 574 2009

Edition

"t" is the pressure design thickness for internal pressure. in inches (millimeters), "P" is the internal design gauge pressure of

the pipe. in pounds per square inch (kilopascals), "D" is the OD of the pipe, in inches (millimeters), "S" is the allowable unit

stress at the design temperature, In pounds per square inch (kilopascals), "E" is the longitudinal quality factor.

8 Pressure Design Thickness

Valve and Flanged Fittings

tm = t + c

t = 1 .5[PD / 2(SE)]

11.2 API 574 2009

Edition

t is the pressure design thickness for internal pressure. in inches (millimetes); P is the internal design gauge pressure of the

pipe. in pounds per square inch (kilopascals); D is the OD of the pipe, in inches (millimeters); S is the allowable unit stress at

the design temperature. in pounds per square inch (kilopascals); E is the longitudinal quality factor.

9 Minimum Required

lank Thickness

tm = dg3P / 16SEW + C 304.5.3 B31.3 2010

Edition

c = sum of allowances defined in para. 304.1.1, dg = inside diameter of gasket for raised or flat face flanges, or the gasket pitch

diameter for ring joint and fully retained gasketed flanges, E = same as defined in para. 304.1.1, P = design gage pressure, S =

same as defined in para. 304.1.1, W = same as defined in para. 304.1.1

10 Hydro Test Pressure PT = 1.5 x P x Rr 345.4.2 B31.3 2010

Edition

where

P = internal design gage pressure, PT = minimum test gage pressure, Rr = ratio of ST/S for pipe or components without

established ratings, but shall not exceed 6.5,

= ratio of the component pressure rating at the test temperature to the component pressure rating at the component design

temperature for components with established ratings, but shall not exceed 6.5

S = allowable stress value at component design temperature (see Table A-1), ST = allowable stress value at test temperature

11 Flange and Flanged

Fittings Hydro Test

Pressure

PT = 1.5 x 100F (38C) rating

duration NPS 2 = 60 sec. NPS 2 8 =

120 sec. NPS 10 = 180 sec.

2.6

8.2.2

8.2.4

B16.5 2009

Edition

Rating from Table 1A and Table 2 (Test pressure round off to next higher 1 bar or 25 psi

12 Pneumatic Test Pressure PT = 1.1 x Design Pressure 345.5.4 B31.3 2010

Edition

13 Fillet Weld

Weld Size for Slip on

Flange (Xmin)

Branch Fillet weld Throat

Size (tc)

LEG = 1.414 x Throat

Throat = Leg x 0.707

Xmin = lesser of 1.4 x T or thickness of hub

tc = lesser of 0.7 x Tb or 6 mm (14 in.)

328.5.2

328.5.4

B31.3 2010

Edition

T = Thickness of pipe, Tb = Thickness of branch, tc = throat of branch fillet weld

14 Flanged Fittings

subminimum area

D = 0.35dt

m

6.1.2 B16.5 2009

Edition

15 Flanged Fittings

subminimum thickness

= 0.75 x t

m D = Diameter of

Subminimum Thickness

area

d = Inside diameter of Pipe

t

m

= Minimum Thickness

of Flanged Fittings wall

thickness from the tables.

16 Flanged Fittings

subminimum area edge to

edge distance

= 1.75dt

m

11:22 PM api Xams No comments

5/7/2014 API 570 Examination Formulas ~ apiXams

http://apixams.blogspot.in/2012/09/api-570-examination-formulas.html 2/2

17 Remaining Life RL = tactual - trequired / Cr

7.1.1

API 570

2009

Edition

18 Long-term Corrosion LT = tinitial - tactual / time (years)

19 Short-term Corrosion ST = tinitial - tactual / time (years)

RL = Remaining life Cr = Corrosion rate, LT = Long term corrosion rate, ST = Short term corrosion rate, time = time in years

between tinitial and tactual

20 Tension Test TSA = R

Sec. IX

ASME SEC. IX

2010 Edition

RSA = Width x Thickness

TS = Load/Area

Load = Area x Tensile Strength

TSA = Turned Specimen Area, TS = Tensile Strength, RSA = Reduce Specimen Area

21 PWHT BRANCH

CONNECTION (Covering

Thickness)

2 x Thickness for Given Material in Table

331.1.1 or >16mm ( in) for P1 materials

>13mm ( in) for P3, 4, 5, or 10A materials

331.1.1

331.1.3

B31.3 2010

Edition

Sketch 1

b

+ t

c

Sketch 2

h

+ t

c

Sketch 3

b

+ t

c

or + t

c

Sketch 4

h

+

r

+ t

c

Sketch 5

b

+ t

c

b = Thickness of branch, h = Thickness of header, r = Thickness of

reinforcement pad

Anda mungkin juga menyukai

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- API 570 Exam CalculationsDokumen2 halamanAPI 570 Exam Calculationssnehal.deshmukhBelum ada peringkat

- API 570 Mock Up Open Book Questions 26Dokumen13 halamanAPI 570 Mock Up Open Book Questions 26Ravindra S. Jivani100% (2)

- Code Sec.: PD C Se P Y C D Set Xcrxyrs C DDokumen1 halamanCode Sec.: PD C Se P Y C D Set Xcrxyrs C DsubhaBelum ada peringkat

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDokumen8 halamanAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinBelum ada peringkat

- API 510 PV Inspection ChecklistDokumen9 halamanAPI 510 PV Inspection ChecklistSreekumar SBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- 15 API 570 - Open Book Mockup Exam FinalDokumen12 halaman15 API 570 - Open Book Mockup Exam FinalMichael Albuquerque100% (1)

- API 510 Certification Exam Study Plan PDFDokumen3 halamanAPI 510 Certification Exam Study Plan PDFJayeshBelum ada peringkat

- API 570 Final Exam Open Book Questions 24Dokumen11 halamanAPI 570 Final Exam Open Book Questions 24Ravindra S. Jivani100% (5)

- API 570 Open BookDokumen9 halamanAPI 570 Open BookMusa ÇelikBelum ada peringkat

- Retirement ThicknessDokumen7 halamanRetirement ThicknessKamal UddinBelum ada peringkat

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDokumen8 halamanAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinBelum ada peringkat

- ASME Plant Inspector Level 1 BoK: Inspection KnowledgeDokumen5 halamanASME Plant Inspector Level 1 BoK: Inspection KnowledgeNnamdi Celestine NnamdiBelum ada peringkat

- API 570 piping classification and inspection intervalsDokumen34 halamanAPI 570 piping classification and inspection intervalsjacquesmayol0% (1)

- API 570 Responsibilities 2019Dokumen4 halamanAPI 570 Responsibilities 2019Sohn JmithBelum ada peringkat

- A) 1.7 To 4.0 B) 2.55 To 3.9 C) 2.0 To 4.0 D) None of TheseDokumen17 halamanA) 1.7 To 4.0 B) 2.55 To 3.9 C) 2.0 To 4.0 D) None of TheseAshish Patel100% (1)

- API 570 - CL Book 111122112010 R0... Mockup 3Dokumen18 halamanAPI 570 - CL Book 111122112010 R0... Mockup 3patvinderBelum ada peringkat

- API 570 Exam Prep TrainingDokumen3 halamanAPI 570 Exam Prep Trainingalouis100% (1)

- API 510 Study PlanDokumen7 halamanAPI 510 Study Plankoib789100% (2)

- API 570 - Mockup CB - Paper 2Dokumen16 halamanAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- API 510 Case Study - 7Dokumen2 halamanAPI 510 Case Study - 7Khaled FatnassiBelum ada peringkat

- Asme PCCDokumen6 halamanAsme PCCajaysharma_1009100% (2)

- API 510 QUIZ No.4Dokumen5 halamanAPI 510 QUIZ No.4Hatem RagabBelum ada peringkat

- Heat Exchanger InspectionDokumen7 halamanHeat Exchanger InspectionHamid Albashir100% (1)

- API 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsDokumen13 halamanAPI 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsShanawas Abdul Razak80% (5)

- API 510.jan 2022 (Open & Closed)Dokumen79 halamanAPI 510.jan 2022 (Open & Closed)Ali BEN YESAADBelum ada peringkat

- 177538089-API-570-Final-Exam-Questions - REALIZARDokumen26 halaman177538089-API-570-Final-Exam-Questions - REALIZARALe Infinito100% (1)

- API 570 Certification Prep CourseDokumen1 halamanAPI 570 Certification Prep Coursemcjeff32Belum ada peringkat

- API-510 IS (External) Inspection Report - ModifiedDokumen2 halamanAPI-510 IS (External) Inspection Report - ModifiedSean Lavergne100% (1)

- API 572 Study Guide: Practice QuestionsDokumen10 halamanAPI 572 Study Guide: Practice QuestionsRizwan Nazir100% (1)

- Occidental Oil and Gas pressure vessel inspectionDokumen17 halamanOccidental Oil and Gas pressure vessel inspectionedwinsazzzBelum ada peringkat

- REV 0 Material Selection Diagram MSD Blueprint IncDokumen5 halamanREV 0 Material Selection Diagram MSD Blueprint IncJohn Patrick Sanay NunezBelum ada peringkat

- Case Study - 7: Numerical in API 510 CodeDokumen4 halamanCase Study - 7: Numerical in API 510 CodeVishal BailurBelum ada peringkat

- 11.API 574 Practive QnsDokumen6 halaman11.API 574 Practive QnsvamsikrishnaBelum ada peringkat

- Api 510Dokumen4 halamanApi 510dandiar1100% (2)

- API 579 Part 5 Local Metal LossDokumen41 halamanAPI 579 Part 5 Local Metal LossAli SASSIBelum ada peringkat

- API 570 Practice Questions (Numbers Only) All Questions Are Closed BookDokumen5 halamanAPI 570 Practice Questions (Numbers Only) All Questions Are Closed BookNuwan RanaweeraBelum ada peringkat

- API-570 - Data Sheets (2018 Test)Dokumen6 halamanAPI-570 - Data Sheets (2018 Test)mahmoud alwasif100% (1)

- API 570 - Close Book Mockup Exam FinalDokumen19 halamanAPI 570 - Close Book Mockup Exam FinalHajarath AliBelum ada peringkat

- API 578 Mock QuestionDokumen4 halamanAPI 578 Mock QuestionsheikmoinBelum ada peringkat

- Guide Wave Ultrasonic Pipe Test ProcedureDokumen10 halamanGuide Wave Ultrasonic Pipe Test ProcedurejeswinBelum ada peringkat

- Rstreng PDFDokumen5 halamanRstreng PDFwellyBelum ada peringkat

- Api510 FormulasDokumen2 halamanApi510 FormulasSakthi PkBelum ada peringkat

- API 570 FormulasDokumen2 halamanAPI 570 FormulasArif Mokhtar89% (9)

- Miter B1 ADokumen55 halamanMiter B1 AFarid TataBelum ada peringkat

- A Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLDokumen14 halamanA Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedBelum ada peringkat

- Design of Piping SystemsDokumen115 halamanDesign of Piping SystemsDushyant Varshney100% (2)

- Design & Construction of Piping SystemsDokumen115 halamanDesign & Construction of Piping SystemsSuresh Babu100% (13)

- Pipe Wall Thickness CalculationDokumen8 halamanPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Design of Piping Systems by Tengku SyahdilanDokumen115 halamanDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqBelum ada peringkat

- ASME B31.3 and B31.1 Flexibility and Stress FactorsDokumen10 halamanASME B31.3 and B31.1 Flexibility and Stress FactorsSergio SmithBelum ada peringkat

- Pipping FormulaDokumen8 halamanPipping Formularajeshsabitha80Belum ada peringkat

- Retiring Wall Thickness Calculation For PipeDokumen4 halamanRetiring Wall Thickness Calculation For PipeFares JawadBelum ada peringkat

- Design of Pressure ComponentsDokumen34 halamanDesign of Pressure ComponentsYFFernando100% (1)

- Super CalculationsDokumen9 halamanSuper CalculationsNoé MarínBelum ada peringkat

- K-4b Perhitungan PipaDokumen51 halamanK-4b Perhitungan PipaIndra MaulanaBelum ada peringkat

- Asme Viii Shell & Se HeadDokumen5 halamanAsme Viii Shell & Se HeadSnr George RaczBelum ada peringkat

- Pipeextp-Asme Ug 28Dokumen1 halamanPipeextp-Asme Ug 28alvinchuanBelum ada peringkat

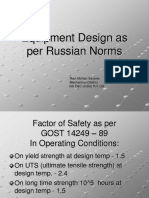

- Equipment Design As Per Russian Norms - 20090218Dokumen45 halamanEquipment Design As Per Russian Norms - 20090218vikasBelum ada peringkat

- SSPC Vis-2 PDFDokumen14 halamanSSPC Vis-2 PDFWilfredo RamirezBelum ada peringkat

- Comparison of Infrared Thermography and Heat FluxDokumen23 halamanComparison of Infrared Thermography and Heat FluxjasminneeBelum ada peringkat

- Hydrogen BakeDokumen7 halamanHydrogen BakejasminneeBelum ada peringkat

- The ABC's of Arc Welding and InspectionDokumen93 halamanThe ABC's of Arc Welding and Inspectionmichaeldtalbott100% (1)

- Norsok M001 MaterialsDokumen31 halamanNorsok M001 MaterialsbreeeeezzzzzeBelum ada peringkat

- API 571 SpreadsheetDokumen38 halamanAPI 571 Spreadsheetjasminnee100% (3)

- Improve 20selection 20and 20sizing 20of 20storage 20tanksDokumen6 halamanImprove 20selection 20and 20sizing 20of 20storage 20tanksjasminneeBelum ada peringkat

- Finite Element Method Characterization of 3D Magnetic Flux Leakage Signal of Crack Discontinuities at Multiple Liftoff ValuesDokumen8 halamanFinite Element Method Characterization of 3D Magnetic Flux Leakage Signal of Crack Discontinuities at Multiple Liftoff Valuesmangalraj900Belum ada peringkat

- 015 Emat Slofec TechniqueDokumen9 halaman015 Emat Slofec TechniquejasminneeBelum ada peringkat

- Handbook of RefractoryDokumen331 halamanHandbook of RefractoryAamirMalikBelum ada peringkat

- Storing and Redrying Electrodes-Lincoln ElectricDokumen3 halamanStoring and Redrying Electrodes-Lincoln ElectricjasminneeBelum ada peringkat

- Hydrogen BakeDokumen7 halamanHydrogen BakejasminneeBelum ada peringkat

- PT-CW3-SEODokumen6 halamanPT-CW3-SEOjasminneeBelum ada peringkat

- 1 SWI DutiesDokumen6 halaman1 SWI DutiesshrikantajitBelum ada peringkat

- Penetrant Test (PT) TerminologyDokumen4 halamanPenetrant Test (PT) TerminologyBalakumarBelum ada peringkat

- Penetrant Testing Contact ListDokumen2 halamanPenetrant Testing Contact ListjasminneeBelum ada peringkat

- UT PrinciplesDokumen26 halamanUT Principlesdzamir203Belum ada peringkat

- PT CW 1Dokumen6 halamanPT CW 1jasminneeBelum ada peringkat

- Control Checks For Penetrant TestingDokumen1 halamanControl Checks For Penetrant TestingjasminneeBelum ada peringkat

- PT 2ADokumen4 halamanPT 2AjasminneeBelum ada peringkat

- 653 Section 01 ReviewDokumen2 halaman653 Section 01 ReviewjasminneeBelum ada peringkat

- Twi Training & Certification (S.E. Asia) SDN - BHDDokumen1 halamanTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeBelum ada peringkat

- API 653 exam sample items guideDokumen3 halamanAPI 653 exam sample items guideAbdelhakim MaghnoujBelum ada peringkat

- Q PTDokumen17 halamanQ PTEzhil Vendhan PalanisamyBelum ada peringkat

- 651 Section 03 REVIEWDokumen1 halaman651 Section 03 REVIEWjasminneeBelum ada peringkat

- API Standard 607: Fire Test For Soft-Seated Quarter-Turn ValvesDokumen2 halamanAPI Standard 607: Fire Test For Soft-Seated Quarter-Turn ValvesjasminneeBelum ada peringkat

- Oceania01 PDFDokumen2 halamanOceania01 PDFjasminneeBelum ada peringkat

- Tank in Service Insp Check List VIS-653Dokumen1 halamanTank in Service Insp Check List VIS-653jasminneeBelum ada peringkat

- API 653 PC 26feb05 Question BankDokumen80 halamanAPI 653 PC 26feb05 Question Bankraobabar21Belum ada peringkat

- Api 510 Preparatory: Points To Recall - Day 1Dokumen2 halamanApi 510 Preparatory: Points To Recall - Day 1jasminneeBelum ada peringkat

- History of Computer AnimationDokumen39 halamanHistory of Computer AnimationRanzelle UrsalBelum ada peringkat

- Holacracy FinalDokumen24 halamanHolacracy FinalShakil Reddy BhimavarapuBelum ada peringkat

- TCBE - Conversation Skills TemplateDokumen10 halamanTCBE - Conversation Skills TemplateAryoma GoswamiBelum ada peringkat

- Margin Philosophy For Science Assessment Studies: EstecDokumen11 halamanMargin Philosophy For Science Assessment Studies: EstecFeyippBelum ada peringkat

- The Truth of Extinction: 7.1 Nietzsche's FableDokumen2 halamanThe Truth of Extinction: 7.1 Nietzsche's FableGraciela Barón GuiñazúBelum ada peringkat

- Develop Network Monitoring System IP Subnet CalculatorDokumen23 halamanDevelop Network Monitoring System IP Subnet CalculatorabiramanBelum ada peringkat

- 9-Lesson 5 Direct and Indirect SpeechDokumen8 halaman9-Lesson 5 Direct and Indirect Speechlaiwelyn100% (4)

- The Effects of Self-Esteem On Makeup InvolvementDokumen9 halamanThe Effects of Self-Esteem On Makeup InvolvementMichelle Nicole Tagupa SerranoBelum ada peringkat

- Stage TwoDokumen34 halamanStage TwoThar LattBelum ada peringkat

- Travel Agency ManagementDokumen47 halamanTravel Agency ManagementKatherine BarretoBelum ada peringkat

- Amber ToolsDokumen309 halamanAmber ToolshkmydreamsBelum ada peringkat

- 4.3 Structural Analysis 4.3.1 ModellingDokumen8 halaman4.3 Structural Analysis 4.3.1 Modellingdavid ROBALINOBelum ada peringkat

- Pop-Up SystemDokumen4 halamanPop-Up Systemkothat82Belum ada peringkat

- I2E: Embedding Innovation as Organizational StrategyDokumen11 halamanI2E: Embedding Innovation as Organizational StrategyDeepak PanditBelum ada peringkat

- Xiaomi Mi Drone 4K User Manual GuideDokumen47 halamanXiaomi Mi Drone 4K User Manual GuideΜιχάλης ΛαχανάςBelum ada peringkat

- An Introduction To Community DevelopmentDokumen21 halamanAn Introduction To Community DevelopmentThuyAnh NgnBelum ada peringkat

- MI 276 Rev B - Conversion of Turbochargers For Opposite Engine RotationDokumen15 halamanMI 276 Rev B - Conversion of Turbochargers For Opposite Engine RotationJesse BarnettBelum ada peringkat

- C172M QRH (VH-JZJ) v1.1Dokumen49 halamanC172M QRH (VH-JZJ) v1.1alphaBelum ada peringkat

- BA 302 Lesson 3Dokumen26 halamanBA 302 Lesson 3ピザンメルビンBelum ada peringkat

- EMI: English As A Medium of Instruction: A New Methodology To Teach English As A Foreign LanguageDokumen18 halamanEMI: English As A Medium of Instruction: A New Methodology To Teach English As A Foreign Languagepaola suarezBelum ada peringkat

- REFLEKSI KASUS PLASENTADokumen48 halamanREFLEKSI KASUS PLASENTAImelda AritonangBelum ada peringkat

- SEM 3037E Tower Piping.Dokumen52 halamanSEM 3037E Tower Piping.Kodali Naveen KumarBelum ada peringkat

- The Importance of WritingDokumen4 halamanThe Importance of WritingBogdan VasileBelum ada peringkat

- Pnas 1703856114Dokumen5 halamanPnas 1703856114pi. capricorniBelum ada peringkat

- CommunicationDokumen5 halamanCommunicationRyan TomeldenBelum ada peringkat

- DrdoDokumen2 halamanDrdoAvneet SinghBelum ada peringkat

- WORK ORDER TITLEDokumen2 halamanWORK ORDER TITLEDesign V-Tork ControlsBelum ada peringkat

- 9.tools and Equipment 1Dokumen13 halaman9.tools and Equipment 1NKH Mega GasBelum ada peringkat

- Antenna SpecificationsDokumen2 halamanAntenna SpecificationsRobertBelum ada peringkat

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDari EverandShorting the Grid: The Hidden Fragility of Our Electric GridPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Cyanide Canary: A True Story of InjusticeDari EverandThe Cyanide Canary: A True Story of InjusticePenilaian: 4 dari 5 bintang4/5 (51)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDari EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDari EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDari EverandThe Grid: The Fraying Wires Between Americans and Our Energy FuturePenilaian: 3.5 dari 5 bintang3.5/5 (48)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyDari EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyBelum ada peringkat

- Asset Integrity Management for Offshore and Onshore StructuresDari EverandAsset Integrity Management for Offshore and Onshore StructuresBelum ada peringkat

- Renewable Energy: A Very Short IntroductionDari EverandRenewable Energy: A Very Short IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDari EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionDari EverandBuild Your Own Electric Vehicle, Third EditionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Implementing an Integrated Management System (IMS): The strategic approachDari EverandImplementing an Integrated Management System (IMS): The strategic approachPenilaian: 5 dari 5 bintang5/5 (2)

- Handbook on Battery Energy Storage SystemDari EverandHandbook on Battery Energy Storage SystemPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Produced Water Treatment Field ManualDari EverandProduced Water Treatment Field ManualPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Transmission Pipeline Calculations and Simulations ManualDari EverandTransmission Pipeline Calculations and Simulations ManualPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksDari EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksBelum ada peringkat

- The Rights of Nature: A Legal Revolution That Could Save the WorldDari EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldPenilaian: 5 dari 5 bintang5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDari EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsBelum ada peringkat

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeDari EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopePenilaian: 4 dari 5 bintang4/5 (130)

- ISO 50001: A strategic guide to establishing an energy management systemDari EverandISO 50001: A strategic guide to establishing an energy management systemBelum ada peringkat

- The Rare Metals War: the dark side of clean energy and digital technologiesDari EverandThe Rare Metals War: the dark side of clean energy and digital technologiesPenilaian: 5 dari 5 bintang5/5 (2)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDari EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionPenilaian: 3 dari 5 bintang3/5 (1)