Fire Relief Dynamic Study

Diunggah oleh

lutfi awnHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fire Relief Dynamic Study

Diunggah oleh

lutfi awnHak Cipta:

Format Tersedia

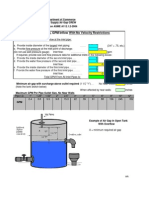

Name : Fire Relief Rate Study (Semi-Dynamic Approach)

Version: 1.3

Description This spreadsheet uses sequential flashing results from commercial simulation

software to calculate relief valve flow rate during external fire. This calculation is

done for wetted vertical and horizontal vessels when flow through relief valve

orifice is sonic (critical) based on API and other published articles

Producer: Saeid Rahimi M.

Publishing Date: 28-Feb-2013

Publisher: www.chemwork.org

No of sheets: 2

Content:

About

Fire Relief Study based on Sequential Flashing Method

Reference:

Relief Rate Calculation; External Fire (Part-2), Published on www.chemwork.org

Sizing, Selection, and Installation of Pressure Relieving Devices in Refineries,

API-520, 8th Edition, Dec 2008

Pressure-relieving and Depressuring Systems, API-521, 5th Edition, Jan 2000

Revision History :

Version Description of Changes Date

1.0 Produced for personal library 15-Aug-2007

1.1 Revised by adding different vessel orientations 23-Oct-2009

1.2 Modified for publishing on web 9-Sep-2011

1.3 Revised according to the users feedbacks 28-Feb-2013

Contact:

Please visit www.linkedin.com/groups/chemwork-3822450 should you have any comment,

question or feedback or feel free to contact s.rahimi@gmail.com.

This spreadsheet is copyright 2011, The Chemwork Spreadsheet Page,

www.chermwork.org. The information contained herein may not be retransmitted, copied,

or electronically posted without the expressed written consent of its owner. You may use

this spreadsheet for personal or professional use only.

DATE :

BY :

REV :

DOC NO.:

psig

%

Total Backpressure psig

---

---

---

Btu/hr ft2

---

----

Vessel Head Cap type ----

m

m

m

psia

Critical Pressure psia

Vessel Cylinder Volume m3

Calculation Validity Cehck ---

Vap

(wt% )

r

(kg/m3)

l

(btu/lb)

V

(m3)

Mass

(kg)

A

(m2)

Q

(btu/hr)

w

(lb/hr)

W

(kg/hr)

Z

(--)

T

(F)

M

(--)

Cp/Cv

(--)

C

(--)

A

orifice

(in2)

0 508.5 157.6 0.79 399 4.45 500829 3178 1444 0.8025 451.6 89.8 1.094 326.6 0.1249

5 500.2 147.7 0.76 379 4.34 490875 3323 1511 0.7888 469.1 95.2 1.094 326.6 0.1269

10 492.6 138.8 0.73 359 4.22 480151 3459 1572 0.7751 484.8 100.3 1.095 326.7 0.1286

15 485.8 131.0 0.70 339 4.10 468604 3577 1626 0.7621 498.6 105.0 1.097 326.9 0.1298

20 479.6 124.0 0.67 319 3.97 456349 3680 1673 0.7495 511.1 109.3 1.099 327.1 0.1305

25 474.1 117.8 0.63 299 3.83 443342 3764 1711 0.7378 522.3 113.3 1.101 327.3 0.1307

30 469.1 112.2 0.60 279 3.69 429700 3830 1741 0.7267 532.6 117.0 1.104 327.6 0.1305

35 464.5 107.1 0.56 259 3.54 415480 3879 1763 0.7163 541.9 120.5 1.107 327.9 0.1298

40 460.3 102.5 0.52 240 3.39 400689 3909 1777 0.7063 550.6 123.7 1.110 328.3 0.1286

Maximum Relief Valve Size in

2

0.1307

Valid

Vessel Length

Liquid Level Height

228.1 Relieving Pressure

Calculaion Results

2.36

133.7

Vessel Dimesnsion

Vertical

Relief Valve Set Pressure 176.4

21.0

0.975

Insulation Factor 1.000

20.0

Combination Corr. Factor (Kc)

1.0

3.0

1.0

Vessel Diameter

Overpressure

Effective Discharge Coe (Kd)

Backpressure Coefficient (Kb)

Vessel Orientation

Elliptical

1.000

Fire Heat Input Rate 21000

1.000

Fire Relief Rate Study for Wetted Vessels (Sequaential Flashing Method)

Input Data

S.Rahimi

0-Jan-00

UNIT :

PROJECT :

PROJ. NO.:

CLIENT :

0.1240

0.1250

0.1260

0.1270

0.1280

0.1290

0.1300

0.1310

0.1320

0 10 20 30 40 50

A

O

r

i

f

i

c

e

A

r

e

a

(

i

n

2

)

Liquid Vaporized (wt%)

Anda mungkin juga menyukai

- Liquid Pressure DropDokumen8 halamanLiquid Pressure Droplutfi awnBelum ada peringkat

- Energy conversion factors and density ranges for petroleum productsDokumen2 halamanEnergy conversion factors and density ranges for petroleum productslutfi awnBelum ada peringkat

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDokumen11 halamanHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnBelum ada peringkat

- E10 Blending Study Final ReportDokumen107 halamanE10 Blending Study Final Reportlutfi awnBelum ada peringkat

- Conversion of Milligrams Per Cubic Meter To PPMDokumen2 halamanConversion of Milligrams Per Cubic Meter To PPMlutfi awnBelum ada peringkat

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDokumen8 halamanVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanBelum ada peringkat

- Air Compressor Curve ToolDokumen14 halamanAir Compressor Curve Toollutfi awnBelum ada peringkat

- Bitumen Upgrading Shell Canada LimitedDokumen301 halamanBitumen Upgrading Shell Canada Limitedlutfi awnBelum ada peringkat

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Dokumen30 halamanLiquid and Gas Velocity Gas Compressibility and Renolds Number.lutfi awnBelum ada peringkat

- Lubricating Oils: Test Methods Test MethodsDokumen32 halamanLubricating Oils: Test Methods Test MethodsCorina StanculescuBelum ada peringkat

- Astm D 86Dokumen8 halamanAstm D 86lutfi awnBelum ada peringkat

- H2S RiskDokumen6 halamanH2S Risklutfi awnBelum ada peringkat

- Hydraulic Calculations MKIIDokumen8 halamanHydraulic Calculations MKIIlutfi awnBelum ada peringkat

- Air Compressor Tools APODokumen7 halamanAir Compressor Tools APOlutfi awnBelum ada peringkat

- Mixer Tank Jet Pumps Gea - tcm11 34889Dokumen4 halamanMixer Tank Jet Pumps Gea - tcm11 34889Venodaren VelusamyBelum ada peringkat

- 04 Jet Mixing Design ApplicationsDokumen6 halaman04 Jet Mixing Design Applicationslutfi awnBelum ada peringkat

- Fonds Bombes - Surface MouilleeDokumen3 halamanFonds Bombes - Surface MouilleesegunoyesBelum ada peringkat

- 2011 Chaudhuri U R Fundamentals of Petroleum and PetrochDokumen33 halaman2011 Chaudhuri U R Fundamentals of Petroleum and Petrochlutfi awnBelum ada peringkat

- PumpDokumen31 halamanPumpkajale_shrikant2325Belum ada peringkat

- Valve Sizing Worksheet InstructionsDokumen11 halamanValve Sizing Worksheet Instructionslutfi awnBelum ada peringkat

- Water Demand Calculation 1Dokumen2 halamanWater Demand Calculation 1lutfi awnBelum ada peringkat

- Calculation ExampelDokumen21 halamanCalculation Exampellutfi awnBelum ada peringkat

- Molecular Sieve Dehydration OptimizationDokumen24 halamanMolecular Sieve Dehydration Optimizationlutfi awn100% (1)

- Line sizing for gas flow from PCV to flare headerDokumen2 halamanLine sizing for gas flow from PCV to flare headerlutfi awnBelum ada peringkat

- Gas ReservesDokumen8 halamanGas Reserveslutfi awnBelum ada peringkat

- Plumbing H 2 Osu Pair Gap CalculatorDokumen9 halamanPlumbing H 2 Osu Pair Gap Calculatorlutfi awnBelum ada peringkat

- Gas TurbDokumen10 halamanGas Turblutfi awnBelum ada peringkat

- Centrifugalcompressorpower Si UnitsDokumen4 halamanCentrifugalcompressorpower Si UnitsJoshi DhvanitBelum ada peringkat

- GOR Vs GVFDokumen8 halamanGOR Vs GVFlutfi awnBelum ada peringkat

- ZM KV Idag eDokumen6 halamanZM KV Idag elutfi awnBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Electronics HubDokumen9 halamanElectronics HubKumaran SgBelum ada peringkat

- How To Install Windows XP From Pen Drive Step by Step GuideDokumen3 halamanHow To Install Windows XP From Pen Drive Step by Step GuideJithendra Kumar MBelum ada peringkat

- J-Garlic in CheeseDokumen12 halamanJ-Garlic in CheeseMary GinetaBelum ada peringkat

- Preparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimDokumen9 halamanPreparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimslightlyguiltyBelum ada peringkat

- MBA 2020: Research on Online Shopping in IndiaDokumen4 halamanMBA 2020: Research on Online Shopping in Indiaprayas sarkarBelum ada peringkat

- LM385Dokumen14 halamanLM385vandocardosoBelum ada peringkat

- Business Ethics Concepts & Cases: Manuel G. VelasquezDokumen19 halamanBusiness Ethics Concepts & Cases: Manuel G. VelasquezRaffi MouradianBelum ada peringkat

- Math-149 MatricesDokumen26 halamanMath-149 MatricesKurl Vincent GamboaBelum ada peringkat

- RA 5921 and RA 10918Dokumen32 halamanRA 5921 and RA 10918Hani Loveres100% (1)

- S 212 Pre Course WorkDokumen5 halamanS 212 Pre Course Workafiwierot100% (2)

- Organizing and Delivering A Memorized SpeechDokumen9 halamanOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- De Thi HK 2 Tieng Anh 9 de 2Dokumen17 halamanDe Thi HK 2 Tieng Anh 9 de 2Lê Thu HiềnBelum ada peringkat

- Project Report VajDokumen15 halamanProject Report VajTamil SelvanBelum ada peringkat

- ANAPHYDokumen23 halamanANAPHYYu, Denise Kyla BernadetteBelum ada peringkat

- Powers of Central Govt under Environment Protection ActDokumen13 halamanPowers of Central Govt under Environment Protection Actsirajudeen IBelum ada peringkat

- YSUUSYs NiCd Battery RepairDokumen6 halamanYSUUSYs NiCd Battery Repairrwesseldyk50% (2)

- Acid content in fruitsDokumen2 halamanAcid content in fruitsbone fire100% (1)

- Silicone Bonding BrochureDokumen4 halamanSilicone Bonding BrochureAmir ShahzadBelum ada peringkat

- EMarketer Time Spent With Media SnapshotDokumen13 halamanEMarketer Time Spent With Media SnapshotWei ShingBelum ada peringkat

- Active Disturbance Rejection Control For Nonlinear SystemsDokumen8 halamanActive Disturbance Rejection Control For Nonlinear SystemsTrần Việt CườngBelum ada peringkat

- Reasons Why Coca Cola Has A Large Market Share in Kenya and The WorldDokumen9 halamanReasons Why Coca Cola Has A Large Market Share in Kenya and The WorldAludahBelum ada peringkat

- 740 (Q50, V40, Awa 4Dokumen10 halaman740 (Q50, V40, Awa 4rawat2583Belum ada peringkat

- Tutorial Backpropagation Neural NetworkDokumen10 halamanTutorial Backpropagation Neural NetworkHeru PraBelum ada peringkat

- Magnets Catalog 2001Dokumen20 halamanMagnets Catalog 2001geckx100% (2)

- Leks Concise Guide To Trademark Law in IndonesiaDokumen16 halamanLeks Concise Guide To Trademark Law in IndonesiaRahmadhini RialiBelum ada peringkat

- Project Planning and Management Unit 1Dokumen13 halamanProject Planning and Management Unit 1Savant100% (1)

- Professional Builder - Agosto 2014Dokumen32 halamanProfessional Builder - Agosto 2014ValBelum ada peringkat

- The Diary of Anne Frank PacketDokumen24 halamanThe Diary of Anne Frank Packetcnakazaki1957Belum ada peringkat

- Unitisation of Legal Methodsalsdkgh GHNJFKL A SDFG LKJH Asdfgf Lkjhasdfg LKKJ Asdfg LKJH A Slkjfs Aaaaaaaaaaaaslkdfj Asldkjf SLDKFJDokumen3 halamanUnitisation of Legal Methodsalsdkgh GHNJFKL A SDFG LKJH Asdfgf Lkjhasdfg LKKJ Asdfg LKJH A Slkjfs Aaaaaaaaaaaaslkdfj Asldkjf SLDKFJKailashnath Reddy AjjuguttuBelum ada peringkat

- Axel LeijonhufvudDokumen7 halamanAxel LeijonhufvudDario CoceresBelum ada peringkat