Total Dissolved Solid

Diunggah oleh

vanilivanili0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

159 tayangan18 halamanElsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniElsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

159 tayangan18 halamanTotal Dissolved Solid

Diunggah oleh

vanilivaniliElsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 18

Desalination, 12 (1989) 275-292

Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands

215

Electrical Conductivity and Total Dissolved

Solids-What is Their Precise Relationship?

N.R.G. WALTON

Hydrogeochemical Engineer & R.O. Consultant, 25, Eric Lock Road, Shrewsbury SY3 OHQ

(U.K.), Tel.: 0743-723771

(Received J uly 25,1988)

SUMMARY

The ability of RO plants to consistently produce water within the usual 500

mg/l WHO guidelines is a major factor in determining the longer term success

of the plant, and is a principal criterion for guarantee and contractural obli-

gations. However, since total dissolved solids (TDS) is not easily measured,

except under controlled conditions in reputable laboratories, a common alter-

native method is to utilise the simple permeate electrical conductivity (EC)

reading and multiply by a standard correction factor (typically 0.7) to obtain

the required TDS result. This paper demonstrates the considerable problems,

both theoretical and practical, associated (but generally not appreciated) with

these apparently simple measurements and shows that just one simple linear

conversion factor cannot be suitable throughout the range of waters encoun-

tered in the desalination industry, but that several different K factors ranging

from 0.50 to 0.75 need to be used for increasingly saline waters. The apparent

simplicity of the TDS and EC measurements are shown to be illusory and much

care is needed before taking contractural actions based upon these results.

Keywords: desalination, reverse osmosis, distillate, permeate, water quality, quality measurement,

electrical conductivity, total dissolved solids, water chemistry.

I NTRODUCTI ON

Much confusion exists throughout the water industry over this very simple

but important question. I t may come as a surprise to some workers in the de-

salination industry to find that there is unfortunately no simple precise rela-

tionship between these two parameters although workers in every field of water

studies from physical chemistry through electrochemistry, hydrochemistry, soil

and irrigation science, hydrology, geochemistry to marine chemistry each claim

to have the best approximation.

What they are actually using is a tolerable empirical approximation which

appears to hold good within the range of ion concentrations and salinities that

OOll-9164/89/$03.50 0 1989 Elsevier Science Publishers B.V.

276

their particular subject deals with. Thus the theoretical chemists continue to

build on the pioneering works of the early physical chemists, Arrhenius, Ost-

wald, Debye and Hiickel, Onsager, Kohlrausche et al. from early in this century

using ideal solutions and infinite dilutions to formulate absolute definitions

for individual ion behaviors, whilst soil and irrigation scientists get more in-

volved with ionic strength effects due to their interest in the balance between

monovalent and divalent ions, and engineers - preferring a simple on-site rule

of thumb - often simply take the factor of 0.7 so often found on the fixed

scales of commercial electrical conductivity-total dissolved solids (EC-TDS)

meters and think little more about it.

This factor of 0.7 is typically used as the fixed K factor in the well-known

expression

TDS=K.EC

where TDS is in mg/l and EC is in @/cm at 25 C. However there is no fixed

factor and no linear relationship of the above type which is applicable through-

out the water industry for the reasons which will be demonstrated in this paper.

Nevertheless, what can be usefully and practically employed are a few well-

chosen linear K factors to represent distilled waters, natural waters, brackish

waters and seawaters accordingly. A range of K factors is especially required

in the desalination industry because, by definition, the complete range of water

types is dealt with from distilled and fresh natural waters through natural

brackish waters to seawaters and reject brines. The consistent use of just one

K factor (typically 0.7)) even though this is the average value between possible

extremes of 0.5 to 0.9, can lead to errors of up to 30% in TDS estimation from

just this one theoretical simplification alone. This paper goes on to discuss the

many problems and sources of both random and systematic errors associated

with the theory and measurement of both EC and TDS values, which will dem-

onstrate that the simplicity generally associated with these two parameters in

the desalination industry is merely a facade covering a multitude of simplifi-

cations, assumptions, and approximations which have been conveniently over-

looked in the search for the simple K factor.

WHY LI FT THE LI D FROM THI S PARTI CULAR CAN OF WORMS?

The need for greater accuracy in estimating TDS from EC results rather

than using one simple factor to cover all cases is becoming increasingly impor-

tant due to:

(i) Tighter new plant design criteria and specifications.

(ii ) Plant operation efficiency calculations.

(iii ) Contractural specification and guarantee requirements.

(iv) WHO and local health requirements for potable quality water.

The increasing use of RO and ED desalination systems makes this review of

the EC-TDS relationship more pertinent due to the reliance of both plant

design and membrane performance and guarantees upon good product EC-

TDS results - especially when dealing with brackish water desalination. Fur-

thermore, the almost universal reliance on a current WHO limit of 500 mg/l

TDS for potable water, brings the manufacturers of one-pass seawater RO

desalination plants close to the limits, since at typically 99% membrane salt

rejection rates, standard seawater RO permeate will contain around 330 mg/l

TDS and Arabian Gulf seawater around 450 mg/l TDS. Reliance upon EC-

TDS conversion factors then becomes critically important for performance

guarantee evaluation, since the direct measurement of TDS is not easily and

accurately carried out without controlled laboratory conditions and skilled

technicians.

The need for a quick and simple conversion from EC to TDS arises from the

dichotomy between design standards and operational utility. All standard val-

ues for the degree of mineralisation of waters are expressed in the absolute

terms of TDS, which is not a parameter which is readily measurable. The re-

lated value of EC is however simply and conveniently measured by on-line

variable resistance devices which can be coupled to recorders and alarms etc.

for continuous monitoring of plant performance. The difficulty is to find a

simple relationship between these two related measurements without gross

oversimplification making the chosen factor or expression too erroneous.

This paper will demonstrate that the true precise relationship between these

two parameters throughout the range of natural water salinities is almost im-

possibly complicated, whilst at the other extreme the use of just one simple K

factor is a gross oversimplification which leads to potentially large errors. It is

however possible to compromise by defining several K factors which can be

applied in the correct circumstances to give a very good approximation of TDS

from an EC result, thereby maintaining the operational simplicity and utility

of EC readings.

TOTAL DI SSOLVED SOLI DS (TDS) -DEFI NI TI ON AND MEASUREMENT

What is TDS?

Superficially this question appears to be self evident, but this hides a number

of important points both theoretical and practical. The question of what is

dissolved and what is not has long been a difficult question in the water

industry, since particles, ions and molecules exist throughout an entire size

spectrum both individually and in larger polymeric agglomerations, through

colloidal suspensions to visible particulate matter. The dividing line between

what is truly dissolved and what is in colloidal suspension or agglomeration

can only be drawn by reference to a specific filter mesh size.

Since micron-sized colloidal particles are evident under a simple microscope,

the line had to be drawn at the sub-micron size and the figure of 0.45 pm has

tended to become the internationally accepted standard in the water industry

for deciding what is in true solution or dissolved matter and what is partic-

ulate matter. This dividing line came about largely arbitrarily as a matter of

practical necessity since 0.45 pm was the smallest pore-size filter paper com-

mercially available in the 1960s and early 1970s when these matters were being

deliberated internationally.

Sampling problems

Having defined dissolved, what about the practical difficulties associated

with collecting a 0.45 pm filtered water sample?

I t is very often not practicable to filter the sample on site, so any filtration

(if carried out at all) generally takes place in the laboratory after many hours

or days later. I n this time interval, a whole range of physical, chemical and

biological activities can take place in the sample bottle, e.g.

(i) Oxygenation of sample can lead to precipitation of previously dissolved

species like iron and sulphide.

(ii) Degassing of CO, can give a raised pH which will upset the carbonate

equilibria and may precipitate CaCO,.

(iii) Biological decay of dissolved NO; ions which may subsequently degas

as volatile NH3 or N2 gases.

(iv) Biological utilisation of COz, dissolved organic matter and PO:- ion

uptake.

(v) Agglomeration of micro-colloids originally smaller than 0.45 pm.

Many of these biological changes can be slowed down to relative insignific-

ance by storing the sample in the cold and dark immediately after collection

and prior to analysis. However, the overall error potential is such that samples

should ideally be filtered in situ at the time of collection, then kept in a refrig-

erator prior to analysis, which should ideally be within 24 h of sample collection

and filtration.

Analytical problems

The standard TDS measurement is normally carried out by evaporating an

accurately weighed water sample in a platinum crucible to dryness at lBOC,

followed by cooling in a dessicator and weighing the residue to constant weight.

Theoretical problems associated with this are:

(i) The bicarbonate equilibrium is upset by the rise in temperature, and 50%

of the original bicarbonate ion dissolved in the water is lost as CO, gas when

CaCO, scale precipitates viz.

2HCO,-CO;- +CO,+H,O

219

Since bicarbonate is often a dominant ion in most fresh natural waters, this

can be the source of very large errors unless corrected for.

(ii) Upon precipitation of the dissolved salts during evaporation, some water

of crystallisation can be incorporated into the crystal structure, which will then

be weighed as solid material. Using a temperature of 180 C rather than the

originally lower temperature of 110C helps to minimise this problem, but

when significant quantities of sulphate salts are present, as in brackish waters

and seawater, the calcium and magnesium sulphates tend to retain some water

of crystallisation, even at 180 C.

(iii) Heating to 180 C can partially decompose organic matter and will drive

off any volatile material present, although these effects are likely to be small.

Practical problems associated with the TDS measurement include:

(i) The common substitution of a porcelain or other dish/crucible due to the

expense of platinum. This can result in errors due to precipitation of salts

within the pores of the porcelain which become difficult to remove, and the

hydration-dehydration cycle of the porcelain itself gives weighing errors at

different temperatures.

(ii) The common substitution of loo-105 C instead of 180 C as the final

evaporating temperature due to the general availability of water-baths but not

such ready availability of controlled heating mantles for the higher tempera-

tures. The increased presence of water of crystallisation, especially in sulphate

salts, will cause errors in TDS weighings.

(iii) Sputtering of water sample during heating allows carry-over of salts

with the water and into aerosols.

(iv) For low TDS samples, the accuracy in weighing, even with a good elec-

tronic balance will lead to significant errors, e.g. a lo-mg/l TDS water sample

will involve the weighing of just 1 mg of dried residue from the standard 100

ml sample; an error of up to 30% is quite conceivable here, just in the weighing

alone. Of course larger samples can be evaporated, but time can then become

a difficult problem for the laboratory.

(v) The availability of good laboratory facilities and skilled analysts will

have an important effect on the final TDS result, with error potentials up to

40% not uncommon on the lower TDS waters. Even finger-marks on the dish

can add a significant sweat-film at the sub-mg level and the inclusion of dust

particles is always a constant problem unless the greatest care is taken.

(vi) Actual TDS evaporation measurements are not always carried out, es-

pecially if a full chemical analysis is required at the same time; the TDS is then

often calculated by adding together all the major cations:

Na++K++Ca2++Mg2+, and major anions: HCO; + SO:- + Cl- + NO, in

mg/l. Minor ions like Sr+, F-, Br-, I -, Fe2+ are rarely included but, except

for Br- in seawater, their omission is usually insignificant. However, neutral

dissolved solids like Si02 and organic material can be a significant source of

error in low TDS waters if they are not analysed for and included in the total

analysed ions.

280

Sometimes a TDS evaporation measurement is included alongside a full water

analysis. I n such cases it is interesting to compare the measured value with the

calculated value of TDS. Differences of the order of 50% are not uncommon in

potable waters. This gives some idea of the error magnitude that can be asso-

ciated with individual TDS results due to a combination of some or all of the

three theoretical and six practical problems listed above, and possibly others

not listed here.

Thus using an actual TDS measurement as an absolute standard against

which to judge an EC reading, is not always superior or beneficial. There are

often times when the use of a good EC reading multiplied by the appropriate

K factor is a better way of obtaining the TDS than by analysing for it. The

important thing here is to use the correct K factor, since using the common 0.7

factor will generally not give a better result than the TDS evaporation method.

ELECTRI CAL CONDUCTI VI TY (EC) - DEFI NI TI ON, THEORY AND

MEASUREMENT

Background and definition

Theories of electrical conductivity of ions in solution were developed to-

wards the end of the last century, building upon the pioneering works of Ohm

and Faraday to formulate expressions for the electrical conductance of solu-

tions, analogous to those developed in the electrical industry for electrical re-

sistivity of solid matter. Hence the term specific conductance (or conductiv-

ity) of a solution was developed as the simple reciprocal of specific electrical

resistance (or resistivity ) . This involves an expression relating the resistance

or conductance of a specific item within fixed dimensions.

Specific electrical conductance (SEC) was the originally accepted term, but

often became shortened to electrical conductance, which implies an incorrect

inverse connection with electrical resistance, rather than resistivity. Thus con-

ductivity or electrical conductivity (EC) is now the generally accepted term

for this measurement, although specific conductance is still used by the more

academic workers.

Electrical conductivity (EC), as its name implies, is a measure of the ability

of a conductor to carry an electric current. The EC of an electrolyte or aqueous

solution is a summation of the current-carrying ability of every ion present and

is dependent upon the number of ions per unit volume of solution and the

mobilities with which each ion is able to move under the influence of the ap-

plied electrical potential. Since the temperature dependence of EC is critical

(about 2% per 1 C), either the exact temperature of measurement or, more

commonly, the EC result corrected to the standard thermodynamic reference

temperature of 25 o C must be quoted. This is conveniently written as EC,,.

The absolute units for EC are mhos/cm, although for practical purposes

pmhos/cm are commonly used. However, the mho (or reciprocal ohm) has now

281

TABLE I

Typical EC,, values of natural waters

Water type Approximate

EC @S/cm)

at 25C

Ultra-pure water 0.05-0.5

Distilled waters l-10

Rain waters 5-50

Potable waters 50-1000

Brackish waters 2000-20,000

Saline waters 20,000-40,000

Seawaters 40,000-60,000

Brines 60,000+

been directly replaced by the Siemens, thus @/cm are now the usual units for

the expression of EC, with natural waters having the typical values as illus-

trated in Table I .

Theoretical background

The measurement of EC,, always involves the combined measurement of

two or more ions. To express conductivity as an absolute property of individual

ions, use is made of a parameter called the equivalent (or molar) conductance

(A) of each ion, which is defined as

A= 1000% in S cm/equiv. (or mol)

where EC,, is expressed in its absolute units of S/cm at 25 C and C is the

concentration of the ion in chemical equivalents per litre or mol per litre.

Since chemical normalities and equivalents are now being phased-out in the

current mood for international standardisation of units, the concentration

nowadays is expressed by mol/l.

Thus, the A value becomes molar conductance rather than equivalent con-

ductance as in the past. Molar conductivities approach a limiting upper value

with increasing dilution, so that a parameter A, -the molar conductance at

infinite dilution - can be defined for each individual ion. I n practice, infinite

dilution is approached at around 10m4 M for many simple salt solutions, with

corresponding EC& values around 10 ,&/cm.

Tables of A, values can be found in any high school physical chemistry text

book, but a few relevant examples are listed in Table I I . From such tables of

A, values, theoretical results for the conductivity of dilute solutions can be

directly calculated as follows:

282

TABLE II

Examples of typical molar conductances of common ions

Ion Molar conductance

(S cm*/mol) at

25C (/i,)

K+ 73.5

Na+ 50.1

H+ 349.8

Cl- 76.3

OH- 198.0

HCO, 45.4

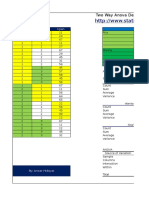

TABLE III

Calculated and measured values for ECzs of a range of concentrations of standard KC1 solutions,

illustrating the change in K value for more concentrated solutions

KC1 solution concentration

mdl

Molarity

Electrical conductivity

Calculated Measured

W/cm) W/cm)

TDS/EC

(K)

7.455 1O-4 14.98 16.8 0.503

74.55 10-3 149.8 146.9 0.507

745.5 10-2 1498.0 1408.9 0.529

7455 10-l 14,980 12,856 0.580

74,550 1.0 149,800 111,342 0.670

For example, the approximate EC of a 10 A3 A4 standard KC1 solution can be

calculated from the data in Table I I , as follows:

EC& = (73.5+76.3)~106~1/1000~10-3=149.8 @S/cm

Similarly a 10m4 M KC1 solution would have EC,, =14.98 @/cm, and so on.

Actually measured standard values for these solutions are however slightly

different as illustrated in Table I I I .

Theoretical relationship with TDS

Table I I I clearly shows the non-linearity of the TDS-EC relationship even

for a series of standard single salt KC1 solutions, where concentrations greater

than 10m3 M show increasingly large deviations reaching 26% at 1 M concen-

tration. Similar results are obtained using other single salt electrolyte solu-

tions. However, natural waters contain a mixture of various different salts and

the depression of EC& with increasing total salt concentration then becomes

283

even greater due to both physical and electrical ionic interactions. The bicar-

bonate ion in particular has a rather low molar conductance, and since it is

often a dominant ion in natural (fresh) water systems, it often exerts a marked

depressive effect on the conductivity of fresh water, so that the TDS/EC re-

lationship (K value) increases dramatically.

For example, to take an extreme case, a 10V3 M solution of NaHC03 will

have an approximate EC,, calculated from the data in Table I I of

(50.1+45.4)~106~1/1000~10-3=95.5$3/cm

and since the TDS of such a solution is 84 mg/l, the TDS/EC relationship or

K value =0.88, which is the upper extreme value for any natural water system.

Thus, it can be clearly seen that both increasing concentration and different

ionic composition, even in single salt solutions, can have a marked effect on

the TDS-EC relationship. Consequently, the relationship or K value cannot

be considered to be either fixed or linear, although the natural mix of ions in

natural water systems allows the extreme values of single-salt solutions to be

neglected.

Temperature effects

The main physical effect of temperature is to increase ionic mobility at higher

temperatures through decreasing the viscosity of the solution.

The well known approximation of the effect of temperature upon EC of about

2% per 1 o C is a very general average which is reasonable enough when used

on a mixed-ion natural water at approx. I fr 15 C from the international stan-

dard of 25 C. However, each individual ion has its own often very different

temperature coefficient, which varies with both concentration and absolute

temperature, with especially large departures (up to ten times) from the 2%

approximation evident in very cold and very hot water, where viscosity changes

and dissolved CO, ionisation rates change rapidly.

Many workers have attempted to fit empirical cubic and quartic equations

to describe the observed variations in EC with temperatures. However, in prac-

tice, general agreement suggests that the simple linear equation:

EC,,

=EC,[1+0.022(25-t)]

i.e., a 2.2% per 1 C temperature change is the most useful practical application

for temperature correction within ambient natural temperatures for most

mixed-ion natural waters.

I t should be noted that most commercially available EC meters make use of

this simple relationship to electronically correct for temperature deviations

from the standard 25 C by applying an automatic 2% per 1 C correction. How-

ever, one should beware of older meters which may temperature-correct to the

previous 20 C standard temperature which will give an immediate 10% error

284

to the EC reading if this fact is not noticed. The writer came across an inter-

esting example in one Middle-Eastern country where alarm was occasioned by

the latest annual country-wide wellwater salinity (EC) survey which indicated

a 10% rise in virtually all water well EC readings. I t was sometime before this

universal EC rise was attributed to the change from an old 20 C standard

temperature meter to a new 25 C standard meter.

pH effects

Pure water itself is not a conductor of electricity, since it exists in a molec-

ular rather than ionic structure. However, there is always a very slight ioni-

sation tendency in water as given by the ionic product of water K,= lo-l4 at

25C. i.e.,

H,O=H++OH-:

K _ [H+I [OH+ I = lo-14 mol/]

,+.- FL01

This gives an EC of about 0.05 @/cm, an exceptionally low value. However,

at especially high ( >9) or low ( <5) pH values, the EC of water becomes

significant. e.g., at pH 5, H+=10m5 M. Now since An+ =349.8 mho cm/mol

(Table I I I ), which is about five times higher than the molar conductance of

other cations, due to its very small size and high mobility, its EC contribution

would be

Similarly at high pH values, say pH 9, ( [H+ ] =lo- M), since K, =10-14,

[H+] [OH-] =10-14, therefore [OH-] =10-14/10-g=10-5 M and non- is

similarly several times larger than other anions at 198.0 mho cm2/mol (see

Table I I I ), then the EC of pH 9 water at 25 C can be calculated as

198.0. 106/103. 10m5M =1.98 @/cm

However, since virtually all waters used and produced within the desalination

industry normally lie within the natural water pH range of 5-9, the contribu-

tion to EC measurements of non-neutral, ionised water molecules is evidently

very small and generally negligible.

Undesirable electrical effects

Polarisation

The inevitable polarisation problems associated with passing electric cur-

rents through aqueous solutions of electrolytes are largely overcome by the use

of alternating currents (AC) of moderate frequency, typically 1000 Hz.

285

AC frequency

The typical moderate AC frequencies (1000 Hz) used in many ordinary com-

mercial EC meters is necessarily a compromise between the need to minimise

polarisation in high EC waters and reduce the capacitance effects which be-

come increasingly significant in low EC waters. Higher AC frequencies (2000-

4000 Hz) are often used in salinometers for oceanographic work to minimise

polarisation potential, whilst EC meters especially designed for use with dis-

tilled, de-ionised and high purity waters typically operate at 60-100 Hz to min-

imise capacitance errors. At very high frequencies (co. 10,000 Hz) however,

the inter-ionic forces break down and conductivity again approaches the high

assymptotal values reached at infinite dilution.

Capacitance

The capacitance effect is directly related to the frequency of measurement

and the length of cable between measuring cell and meter. Thus for broad-

spectrum EC meters with a fixed frequency of around 1000 Hz, it is advisable

to keep cable lengths to less than about 20-30 m to minimise capacitance prob-

lems. More sophisticated broad ranging instruments include a variable null-

balancing capacitor to allow for increased accuracy especially at low ( < 100

@/cm) conductivities, where capacitance errors can reduce the measured con-

ductance by up to 10%.

I mpedance

Boundary layer impedance is set up on the surface of the measuring elec-

trodes due to polarisation effects. This can either be reduced by using an ap-

propriate measuring frequency for the salinity of the water to be measured or

more practicably, by changing the size and material of the cell electrodes. De-

positing platinum-black on the surface of platinum electrodes or using spe-

cially prepared graphite-carbon electrodes with a cell of the appropriate size,

can significantly reduce impedance and reactance effects on conductivity

measurements.

An additional impedance (and capacitance) effect is associated with long

cable lengths, especially in highly conductive waters where the cable resistance

then becomes of a similar magnitude to the electrolyte resistance being mea-

sured. I n this instance an increase in measuring cell dimensions (see below)

is required to increase the measured electrolyte resistance and thereby de-

crease the significance of the cable resistance.

Overall electrical effects

There are inevitably interactive effects between the electrical factors of fre-

quency, capacitance, impedance and reactance, although it is only really nec-

essary to take account of these factors at very low or very high conductivities,

where the compromise electronics built into the standard broad-spectrum EC

286

meter designed to give good results at economic prices, start to give increasing

error potential. For accurate measurement of EC at <50 @/cm or >50,000

@/cm it is advisable to use measuring systems dedicated to these extreme

values since they will incorporate the different frequencies, capacitance cor-

rection, change in cell size, etc., which is necessary to maintain accuracy at

these extremes. For instance, marine chemists and oceanographers often use

specially designed EC measuring systems called salinometers. Apart from

reading directly in resistance (ohms) and salinity (ppm NaCl) these operate

at higher frequencies, utilise larger measuring cells and contain a more accu-

rate non-linear temperature correction facility to enable more accurate con-

ductivity readings to be obtained in seawater.

Measuring cell dimensions

The usual measuring (1.0 cm) cell contains electrodes of a fixed size and

arrangement, so that the electric current is passing through exactly 1.0 cm3 of

water. Any slight deviations from this rigidly fixed volume are compensated

for by a factor known as the cell constant, which for a 1.0 cm3 cell, normally

has a factor of between 0.85 and 1.15 depending upon manufacturing toler-

ances. This factor is usually marked onto the measuring cell itself, for manual

correction or on some meters it can be corrected for by an internal compen-

sation resistor which, when set to the value of the cell constant, will automat-

ically correct the EC reading.

Each new cell will have its own individual cell constant, as determined by

the manufacturer from its EC& readings in a series of standard solutions.

This cell constant correction facility present on some EC meters can be used

as a standardisation control for recalibration when fouling or abrasion may

have altered the effective cell constant, although great care is needed during

any restandardisation procedure due to the possibility of contamination of the

standardising solutions, even with distilled water.

The use of a l.O-cm measuring cell, although common, is not universal. Once

again it is an operational compromise. The measurement of low EC ( <100

@/cm) waters is more accurately obtainedusing a O.l-cm cell, whilst the mea-

surement of high EC water ( >20,000 @/cm) requires the use of a 10.0 cm cell

for greater precision and accuracy. This is due to the fact that an error in the

typical Wheatstone bridge resistance measurement is set up if the measured

resistance strays too far from any standard value, since the added resistance

of very dilute solutions effectively occurs as the reciprocal effect of parallel

resistors rather than the additive effect of series resistors. Changing the size

of the measuring cell can help to maintain a similar resistance over very large

changes in salinity, with a consequent reduction in measurement error.

281

Other practical problems with EC measurements

(i) The simple trapping of an air-bubble between the measuring electrodes

is a surprisingly common cause of erroneously low EC results, since the air

bubble occupies a portion of the fixed volume of the EC cell, thereby reducing

the measured conductivity.

(ii) Fouling of the electrode surface - particularly in on-line measurement

cells - also commonly leads to decreasing EC values with time. Small amounts

of filmy organic substances like oils or surfactants are often the cause of sim-

ple, cleanable fouling incidents. Longer term damage can be done by erosion

and corrosion of the electrode surfaces, or even poisoning as when sulphides

contact platinum electrodes and lead to serious electrode malfunctions with

time.

(iii) Range-switching innacuracies are particularly frustrating in most av-

eragely-priced EC meters, with over- or under-reading of typically up to 10%

when switching from one decade-range resistor to another. The answer to this

is to recalibrate with the appropriate KC1 standard solution each time the dec-

ade range is changed, although this is often impractical. However, process con-

trol instrumentation rarely requires range-switching once correctly set, so this

problem afflicts mainly the laboratory and other multi-purpose and portable

meters.

(iv) Some meters are fitted with very loose calibration or cell-constant

switches which are too easily knocked or moved during use and necessitate

recalibration, which may be very difficult if in isolated field locations.

(v) The presence (or absence) of the important temperature compensation

facility is often incorrectly understood. I t is sometimes thought that one must

set the dial to the temperature at which one wishes to report the result, i.e.

25 C, instead of the actual water temperature. This obviously can lead to very

large errors at the rate of about 2% per lo C.

(vi) The use of older meters which have their internal temperature compen-

sation fixed on the old British standard water temperature of 2OC, leads to

an immediate 10% error on all readings reported or understood to be standar-

dised at the international standard of 25 C.

SUMMARY OF EC AND TDS MEASUREMENT PROBLEMS

Having read the article so far, the reader may never feel quite the same about

the once ever-so-simple dip and read EC result and may look a little more

closely at any given TDS result. However, the writer intends only to point out

the degree of potential errors due to both theory and practice inherent in any

given EC or TDS result, so that a little operational tolerance and flexibility is

obtained between clients, consultants and contractors over their sometimes

288

fixed attitudes towards stated limits for plant operational guarantees and per-

formance certification.

For example, the writer has been involved in several instances when reverse

osmosis product waters appeared to lie outside the almost universal WHO limit

of 500 mg/l TDS within the guaranteed lifetime of the membranes. I n each

case, the plants were relatively small <500 m3/d and so had no on-site labo-

ratory. On-line EC meters, corroborated with hand-held portable EC meters,

gave readings of around 800-900 (us/cm which was reading 560-630 mg/l on

the lower TDS scale of the same meters.

These meters had a fixed scale conversion of TDS =0.7 x EC which is a fairly

common, but terribly misleading, facet of many commercial EC meters.

Arguments ensued between clients, consultants and contractors over guar-

anteed performance etc., etc., and even external analysis for TDS did not ini-

tially resolve the matter due to conflicting results obtained from different

laboratories.

I f the EC meters are all correctly standardised, and can all agree on an EC

reading -t 5%, then by using the correct conversion K factor of 0.55 for RO

permeate waters, the correct TDS results of 440-495 could then be realised

and hopefully agreed upon by all concerned.

RELATI ONSHI P OF EC WI TH TDS FOR THE DESALI NATI ON I NDUSTRY

Having now carefully defined both EC and TDS and outlined the many the-

oretical and practical problems associated with their measurement, the need

to define a good simple working relationship between EC and TDS is still re-

quired to be able to reconcile the plant TDS design and international standard

requirements with the EC operational readings obtained.

Since there is definitely no simple relationship between these parameters

across the range of waters encountered in the desalination industry, and since

complicated mathematical predictions which suit academics, theoreticians and

computers are of little use to the majority of workers in the industry, the best

alternative is to produce a series of K values for different ranges of salinities.

The correct way to do this is to take a series of samples of the water in

question to a reputable laboratory and measure the EC and TDS a number of

times until good precision and accuracy are statistically achieved, and then to

take the ratio of the average values to obtain a best possible K factor. Of

course, all the precautions such as filtration and bicarbonate correction for

TDS measurements, and calibration and standarisation of EC measurements

as listed in this paper need to be adhered to, to be sure of getting good, accurate

results. Only then can the actual K factor for that particular ionic-mix water

be relied upon.

However, since most desalination plants utilise fairly predictable water types,

the K factors can be approximated in advance as shown in Table I V.

TABLE I V

Suggested K factors for use with different desalination water types

Water type Typical EC&

(@J /cm )

K factor

Distillate l-10 0.50

RO permeate 300-800 0.55

Seawater 45,000-60,000 0.70

Reject brines 65,000-85,000 0.75

The reason for the predictability of the TDS-EC relationship for these water

types is due to the overwhelming predominance (cu. 90% ) of just two ions in

all these waters, namely Na+ and Cl-, and the increasingK factor with salinity

reflects the hindrance of ionic mobility by the crowding effect of these ions at

higher concentrations.

The major variability of EC with TDS comes with fresh, potable and brack-

ish waters which contain a variety of dissolved salts, sometimes with

Mg (HCO, )2 or Ca (HCO, )z predominant and sometimes CaS04, NaHCO, or

NaCl as the dominant salt present. The complex ion-pairing and physical (size )

and electrical (charge) interactions which take place in solutions of these salts

make any simple TDS-EC relationship impossible. However, many natural

waters do contain a fairly well-balanced blend of the eight major ions, and so

extremes of interaction due to large size or high charge effects are often bal-

anced down so that most natural waters have K values which vary between

0.55 and 0.85. This of course is where the much used value of 0.70 comes in as

simply the average between these two extremes.

However, from the desalination point of view, it is generally brackish waters

with EC ranging from 2000-20,000 @/ cm which are of interest and these waters

rarely have a K factor below 0.60 or above 0.67 due to the chemical evolutionary

sequence of most brackish ground waters. Consequently, a good average K value

of 0.63 has been found to satisfy most brackish Middle East groundwaters with

salinities in the range of 2000-20,000 mg/l as TDS.

Fig. 1 gives a generalised view of the change in K factor with increasing

salinities for different water types. The dominant HCO, ion concentration of

many fresh waters gives the very steep rise in K value at low concentrations,

whilst the increasing importance of SOi- in brackish waters maintains K val-

ues well-above the single mono-valent KC1 standard line, whereas the fall-off

in Kvalue between 1000 to 10,000 mg/l TDS is due to the dominance of inter-

ion interference causing reduced EC values at higher TDS values. I t is in this

region where K factors can have the highest variability due to the opposing

effects of increased physical resistance and ionic interactions at higher con-

centrations, and the disproportionate ratio of divalent to monovalent ions.

290

0.4

loo lb

I

IO2

I

IO

I

IO

I

IO5

TOS (mdl)

Fig. 1. Plot of TDS against K values showing fields of dominance for different water types.

Fig. 1 also shows that the waters important to the desalination industry

occupy very limited fields on the diagram and generally follow the exponential

trend of the NaCl line. Their limited positions on this field diagram clearly

illustrate the progressive increase in K values for increasing salinity waters,

but within very limited ranges, which indicates the proposed use of the four

different K values for the four different desalination water types.

CONCLUSI ONS

(i) The measurement of both TDS and EC has been shown to be neither

theoretically as simple nor operationally as straightforward as is often assumed.

(ii) Both results contain a host of simplifications, assumptions and poten-

tial errors that can easily give rise to total error factors in excess of 30% unless

the most careful background investigations, calibrations and cross-checkings

are carried out within reputable laboratories.

(iii) The relationship between EC and TDS has been shown to be neither

simple nor linear although because of the actual complexity of the precise re-

lationship a practical compromise has been suggested utilising four different

K factors - one for each water type encountered in the desalination industry.

291

(iv) The use of just one K factor for all water types cannot be justified since

errors of up to 25% can be introduced from just this one approximation alone.

(v) The common use of a standard K factor of 0.7, which is chosen as an

average between the possible extremes of 0.5 and 0.9, and is often to be found

in the direct transformation of EC readings to TDS results on the face of many

commercial EC meters, is very misleading and, particularly in the product water

side of desalination plants where it is most important, will give immediate

errors of some 25%.

(vi) The non-recognition of the large error inherent in this direct transfor-

mation of EC to TDS, can be the cause of contractural arguments as specifi-

cations and guarantees can appear to be broken when the normal (WHO) 500

mg/l product TDS limit is apparently breached at an EC& value of only 715

@/cm instead of the more realistic value of 910 $S/cm.

(vii) The many other factors involved in obtaining good EC and TDS re-

sults, particularly electronic simplifications and compromises within commer-

cial EC meters and analytical errors in TDS results, have been described to

give an overall appreciation of the problems and errors inherent in each of

these results, suggesting that a more cautious approach to result-interpreta-

tion should be pursued.

(viii) The temperature effect on EC has been shown to be different for each

individual ion present, although it is concluded that the use of the standard

approximation of 2.2% per 1 C is good enough for most mixed-ion waters within

+15 C of the 25 C standard reference temperature. However, the correct use

of the temperature compensator and the awareness of older meters internally

compensating to the old standard of 20 C has been pointed out as an important

source of often unnoticed error.

(ix) The theoretical basis for the recommended substitution of four individ-

ual K factors for use in different stages of desalination plants has been pre-

sented, and is considered to be the simplest and most practically useful method

of obtaining a TDS estimation from an EC result. These factors can be pre-

sented with some certainty in the desalination industry, because the water

types involved are generally very predictable and are overwhelmingly com-

posed of the two simple ions of Na+ and Cl- even in the distillate-permeate

product waters.

(x) The recommended appropriate K factors are:

Distillates, with EC,, of l-10 @/cm, K=0.50

Permeates, with EC,, of 300-800 pS/cm, K= 0.55

Seawaters, with EC& of 45-60 mS/cm, K= 0.70

Brines, with ECz5 of 65-85 mS/cm, K~0.75

(xi) Thus the linear formula

292

with TDS in mg/l and EC&, in @S/cm can still be used for estimating TDS

from EC by substituting the appropriate K factor, and the result can then often

be more accurate than the error-prone direct TDS measurement.

(xii) For the WHO limit of 500 mg/l TDS, the corresponding limiting EC&

reading for permeate waters will be 500/0.55 =910 @/cm which is some 27%

higher than the figure of 715 @/cm obtained by straightforward conversion

using the standard K= 0.7 single factor.

Anda mungkin juga menyukai

- Total Dissolved Solids Vs Total Dissolved Salts ("TDS") : Methods Used For TDS AreDokumen2 halamanTotal Dissolved Solids Vs Total Dissolved Salts ("TDS") : Methods Used For TDS AreWaqas ButtBelum ada peringkat

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionDari EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionBelum ada peringkat

- Standardizing Electrocoagulation Reactor Design - Iron Electrodes For NOM RemovalDokumen6 halamanStandardizing Electrocoagulation Reactor Design - Iron Electrodes For NOM RemovalCUEVA VASQUEZ BRYAN ALBERTOBelum ada peringkat

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationDari EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationBelum ada peringkat

- Electrol Condct TheryDokumen0 halamanElectrol Condct TheryBogdan BulgariuBelum ada peringkat

- Laboratory Scale Water Circuit Including A Photocatalytic ReactorDokumen8 halamanLaboratory Scale Water Circuit Including A Photocatalytic ReactorPatrick_NickelsBelum ada peringkat

- Standard methods for the examination of water and sewageDari EverandStandard methods for the examination of water and sewageBelum ada peringkat

- Study of The Production of Hydrogen Bubbles at Low Current Densities For Electroflotation ProcessesDokumen6 halamanStudy of The Production of Hydrogen Bubbles at Low Current Densities For Electroflotation ProcessesFrancisco CampbellBelum ada peringkat

- Electrochemical Water Treatment Methods: Fundamentals, Methods and Full Scale ApplicationsDari EverandElectrochemical Water Treatment Methods: Fundamentals, Methods and Full Scale ApplicationsPenilaian: 3.5 dari 5 bintang3.5/5 (4)

- Water and Beyond Expanding The Spectrum of Large Scale Energy Efficient Separation ProcessesDokumen10 halamanWater and Beyond Expanding The Spectrum of Large Scale Energy Efficient Separation Processesehtisham zaibBelum ada peringkat

- Dynamics of Glass-Forming Liquids. IX. Structural Versus Dielectric Relaxation in Monohydroxy AlcoholsDokumen7 halamanDynamics of Glass-Forming Liquids. IX. Structural Versus Dielectric Relaxation in Monohydroxy AlcoholsRaghava ParitalaBelum ada peringkat

- Advancements in The Industry - Determining Cellulose Degradation in Transformers Using Indirect TestsDokumen13 halamanAdvancements in The Industry - Determining Cellulose Degradation in Transformers Using Indirect TestsMuhammad RasyidiBelum ada peringkat

- Environmental Engineering Laboratory ManualDokumen58 halamanEnvironmental Engineering Laboratory ManualFi Fa50% (2)

- Heavy Metal Removal by Means of Electrocoagulation Using Aluminum Electrodes For Drinking Water PurificationDokumen9 halamanHeavy Metal Removal by Means of Electrocoagulation Using Aluminum Electrodes For Drinking Water PurificationazerfazBelum ada peringkat

- Establishing A Conversion Factor Between Electrical Conductivity and Total Dissolved Solids in South African Mine WatersDokumen11 halamanEstablishing A Conversion Factor Between Electrical Conductivity and Total Dissolved Solids in South African Mine WatersRceL AutomationBelum ada peringkat

- TDS MeterDokumen18 halamanTDS MeterTushar SainiBelum ada peringkat

- Section 3.3 - Carbonaceous DeoxygenationDokumen53 halamanSection 3.3 - Carbonaceous DeoxygenationThanh LanBelum ada peringkat

- 1 s2.0 S0011916411009155 MainDokumen7 halaman1 s2.0 S0011916411009155 MaintfemilianBelum ada peringkat

- Help Reduce Water Consumption: Llsing Conductivity Meters CanDokumen2 halamanHelp Reduce Water Consumption: Llsing Conductivity Meters Canandy175Belum ada peringkat

- Feasibility Assessment of Electrocoagulation Towards A New Sustainable Wastewater TreatmentDokumen6 halamanFeasibility Assessment of Electrocoagulation Towards A New Sustainable Wastewater TreatmentJherson Denys Contreras RamosBelum ada peringkat

- Flux Enhancement of RO Desalination ProcessesDokumen5 halamanFlux Enhancement of RO Desalination ProcessesMohammed A. HelalBelum ada peringkat

- Wp01179cen 0122Dokumen6 halamanWp01179cen 0122Eduardo AlvarezBelum ada peringkat

- Mho/cm. This Procedure Automatically Adjusts Cell ConDokumen3 halamanMho/cm. This Procedure Automatically Adjusts Cell ConRonald Figo Torres EcheBelum ada peringkat

- Mohd Nasrullah Et Al., (2020) Crecimiento Del FlocDokumen11 halamanMohd Nasrullah Et Al., (2020) Crecimiento Del FlocAndrea Carolina Cubillos OnateBelum ada peringkat

- On Line Water Chemistry Measurements For Power PlantsDokumen10 halamanOn Line Water Chemistry Measurements For Power PlantsĐặng Trung AnhBelum ada peringkat

- Orion DO Theory: Oxygen ElectrodesDokumen2 halamanOrion DO Theory: Oxygen ElectrodesSyv Consultores AsociadosBelum ada peringkat

- Eutech Conductivity TDS and Salinity PDFDokumen18 halamanEutech Conductivity TDS and Salinity PDFhariprem26Belum ada peringkat

- Purification of Brackish Water Using Hybrid CDI-EDI TechnologyDokumen30 halamanPurification of Brackish Water Using Hybrid CDI-EDI TechnologyamtBelum ada peringkat

- BAE820 - 10 Fate and Transport of Pollutants in WaterDokumen23 halamanBAE820 - 10 Fate and Transport of Pollutants in WaterArcher PlaysBelum ada peringkat

- Managing Chemistry To Mitigate Flow Accelerated CorrosionDokumen12 halamanManaging Chemistry To Mitigate Flow Accelerated Corrosiongochi bestBelum ada peringkat

- Correlation Between Conductivity and Total Dissolved Solid in Various Type of Water: A ReviewDokumen6 halamanCorrelation Between Conductivity and Total Dissolved Solid in Various Type of Water: A ReviewJose CharpentierBelum ada peringkat

- Electrodeionization Versus Electrodialysis: A Clean-Up of Produced Water in Hydraulic FracturingDokumen45 halamanElectrodeionization Versus Electrodialysis: A Clean-Up of Produced Water in Hydraulic FracturingARYAN_FATHONI_AMRIBelum ada peringkat

- Hofs BSep Pur Tech 201179365Dokumen11 halamanHofs BSep Pur Tech 201179365pinitBelum ada peringkat

- Electro CoalescenciaDokumen7 halamanElectro CoalescenciaiqubaldoBelum ada peringkat

- 116CH0120 RP ReportDokumen12 halaman116CH0120 RP ReportAscender ZeusBelum ada peringkat

- F Electro CoagulationDokumen8 halamanF Electro CoagulationBaskaraLaksamanaBelum ada peringkat

- Alan 1-S2.0-S1572665718301085-MainDokumen15 halamanAlan 1-S2.0-S1572665718301085-MainLizeth Lopez GarciaBelum ada peringkat

- 1 s2.0 S2211285520311198 MainDokumen14 halaman1 s2.0 S2211285520311198 MainCB Dong SuwonBelum ada peringkat

- 10 1016@j Desal 2006 09 007 PDFDokumen6 halaman10 1016@j Desal 2006 09 007 PDFMimi TanBelum ada peringkat

- A Miller Heavy WaterDokumen14 halamanA Miller Heavy Waterioan_vBelum ada peringkat

- Journal of Water Process Engineering: SciencedirectDokumen8 halamanJournal of Water Process Engineering: SciencedirectEricke Nandita MaharaniBelum ada peringkat

- White Paper - ConductivityDokumen10 halamanWhite Paper - ConductivityWalid FattahBelum ada peringkat

- Prediction of Semiconductor Band Edge Positions in Aqueous Environments From First PrinciplesDokumen8 halamanPrediction of Semiconductor Band Edge Positions in Aqueous Environments From First PrinciplesDibyajyoti GhoshBelum ada peringkat

- 1 s2.0 S0011916421003556 MainDokumen9 halaman1 s2.0 S0011916421003556 Mainagus sutiawanBelum ada peringkat

- A Case Study On The Relationship Between Conductivity and Dissolved Solids To Evaluate The Potential For Reuse of Reclaimed Industrial WastewaterDokumen7 halamanA Case Study On The Relationship Between Conductivity and Dissolved Solids To Evaluate The Potential For Reuse of Reclaimed Industrial WastewaterAinaBelum ada peringkat

- Electrocoagulation As A Pretreatment For Reverse Osmosi 2024 Water ResourcesDokumen11 halamanElectrocoagulation As A Pretreatment For Reverse Osmosi 2024 Water ResourcesMajidJgrBelum ada peringkat

- Smeww 2510-B 2005Dokumen9 halamanSmeww 2510-B 2005tatiekpurbawatiBelum ada peringkat

- NETA World Determining Cellulose Degradation in Transformers Using Indirect Tests LewandKoehler Fall 2021Dokumen11 halamanNETA World Determining Cellulose Degradation in Transformers Using Indirect Tests LewandKoehler Fall 2021benlahnecheBelum ada peringkat

- 1999 Hydraulics of WetlandsDokumen10 halaman1999 Hydraulics of WetlandsVahid MohammadianBelum ada peringkat

- Chloride 2Dokumen7 halamanChloride 2Prof-Zakaria Al-QodahBelum ada peringkat

- Mousavi 2013Dokumen7 halamanMousavi 2013Edgar HornusBelum ada peringkat

- PH Measurement and ControlDokumen8 halamanPH Measurement and ControlAnonymous 1zdRSWskhgBelum ada peringkat

- Rusydi 2018 IOP Conf. Ser. Earth Environ. Sci. 118 012019Dokumen7 halamanRusydi 2018 IOP Conf. Ser. Earth Environ. Sci. 118 012019Pina MeilindaBelum ada peringkat

- Capacitive Deionization Process With Decoupled Charging and Discharging Flow SchemesDokumen8 halamanCapacitive Deionization Process With Decoupled Charging and Discharging Flow SchemesbuildmetBelum ada peringkat

- Solder Flux Residues and Humidity-Related Failures in Electronics: Relative Effects of Weak Organic Acids Used in No-Clean Flux SystemsDokumen13 halamanSolder Flux Residues and Humidity-Related Failures in Electronics: Relative Effects of Weak Organic Acids Used in No-Clean Flux SystemsSergei OssifBelum ada peringkat

- Warwick Thesis WrapDokumen8 halamanWarwick Thesis Wrapafknoaabc100% (2)

- Boilers & Cooling Towers: Application BulletinDokumen2 halamanBoilers & Cooling Towers: Application BulletinashrvincentBelum ada peringkat

- 1 s2.0 S0003267007012500 MainDokumen5 halaman1 s2.0 S0003267007012500 Mainrahmon_nsBelum ada peringkat

- UBJOM Indramayu2017-03-14 19 - 52 - 26Dokumen1 halamanUBJOM Indramayu2017-03-14 19 - 52 - 26vanilivaniliBelum ada peringkat

- Ipcb Full PaperDokumen5 halamanIpcb Full PapervanilivaniliBelum ada peringkat

- CW Pump HouseDokumen3 halamanCW Pump HousevanilivaniliBelum ada peringkat

- CW Pump HouseDokumen3 halamanCW Pump HousevanilivaniliBelum ada peringkat

- Two Way AnovaDokumen2 halamanTwo Way AnovavanilivaniliBelum ada peringkat

- Hitungan Di Lab BahanDokumen5 halamanHitungan Di Lab BahanvanilivaniliBelum ada peringkat

- Thornthwaite Water Balance MethodDokumen3 halamanThornthwaite Water Balance MethodvanilivaniliBelum ada peringkat

- Module 4 (3) Collection, Transport, TransferDokumen32 halamanModule 4 (3) Collection, Transport, TransfervanilivaniliBelum ada peringkat

- Tdissue Thermal DesorpDokumen8 halamanTdissue Thermal DesorpvanilivaniliBelum ada peringkat

- Layout Tpa PDFDokumen1 halamanLayout Tpa PDFvanilivaniliBelum ada peringkat

- Edi MulyadiDokumen5 halamanEdi MulyadiImam HidayatBelum ada peringkat

- Antizar Et Al. (2004) Bioremediation of Polycyclic Aromatic Hydrocarbon (PAH) - Contaminated Waste Using Composting ApproachesDokumen41 halamanAntizar Et Al. (2004) Bioremediation of Polycyclic Aromatic Hydrocarbon (PAH) - Contaminated Waste Using Composting ApproachesvanilivaniliBelum ada peringkat

- Solids Inventory Control For Waste Water Treatment Plant Optimization enDokumen48 halamanSolids Inventory Control For Waste Water Treatment Plant Optimization enArife UstaBelum ada peringkat

- Ipi 147102Dokumen6 halamanIpi 147102vanilivaniliBelum ada peringkat

- Solids Inventory Control For Waste Water Treatment Plant Optimization enDokumen48 halamanSolids Inventory Control For Waste Water Treatment Plant Optimization enArife UstaBelum ada peringkat

- 10 Chap 16 MolluscaDokumen29 halaman10 Chap 16 MolluscaFaridh RoniantoBelum ada peringkat

- Tugas Biologi Soal-SoalDokumen3 halamanTugas Biologi Soal-SoalvanilivaniliBelum ada peringkat

- WaterSecure Factsheet Ultraviolet Light WebDokumen2 halamanWaterSecure Factsheet Ultraviolet Light WebvanilivaniliBelum ada peringkat

- What Is Soil WashingDokumen3 halamanWhat Is Soil WashingvanilivaniliBelum ada peringkat

- Total Dissolved SolidDokumen18 halamanTotal Dissolved SolidvanilivaniliBelum ada peringkat

- Verbs Followed by Gerunds and InfinitivesDokumen11 halamanVerbs Followed by Gerunds and InfinitivesCynthia Sánchez FigueroaBelum ada peringkat

- Verbs Followed by Gerunds and InfinitivesDokumen11 halamanVerbs Followed by Gerunds and InfinitivesCynthia Sánchez FigueroaBelum ada peringkat

- Mol UsscaDokumen20 halamanMol UsscavanilivaniliBelum ada peringkat

- Asian Journal of ForestryDokumen3 halamanAsian Journal of ForestryTeguh MuslimBelum ada peringkat

- Chemiphase Oilfield Demulsifier Testing ProcedureDokumen4 halamanChemiphase Oilfield Demulsifier Testing ProcedureBen Wiggins100% (1)

- Gothic Revival ArchitectureDokumen19 halamanGothic Revival ArchitectureAlexandra Maria NeaguBelum ada peringkat

- Final Paper IN MAJOR 14 EL 116 Life and Death: Fear Reflected in John Green's The Fault in Our StarsDokumen12 halamanFinal Paper IN MAJOR 14 EL 116 Life and Death: Fear Reflected in John Green's The Fault in Our StarsMary Rose FragaBelum ada peringkat

- Rediscovering The True Self Through TheDokumen20 halamanRediscovering The True Self Through TheManuel Ortiz100% (1)

- Brain Imaging TechniquesDokumen6 halamanBrain Imaging TechniquesIlika Guha MajumdarBelum ada peringkat

- Fascinating Numbers: Some Numbers of 3 Digits or More Exhibit A Very Interesting PropertyDokumen2 halamanFascinating Numbers: Some Numbers of 3 Digits or More Exhibit A Very Interesting PropertyAnonymous JGW0KRl6Belum ada peringkat

- Articles 62 & 63: Presented By: Muhammad Saad Umar FROM: BS (ACF) - B 2K20Dokumen10 halamanArticles 62 & 63: Presented By: Muhammad Saad Umar FROM: BS (ACF) - B 2K20Muhammad Saad UmarBelum ada peringkat

- Social Consequences of UnemploymentDokumen3 halamanSocial Consequences of UnemploymentvillafuerteviBelum ada peringkat

- Endocrine System Unit ExamDokumen3 halamanEndocrine System Unit ExamCHRISTINE JULIANEBelum ada peringkat

- Bug Tracking System AbstractDokumen3 halamanBug Tracking System AbstractTelika Ramu86% (7)

- Epic Story of IbalonDokumen30 halamanEpic Story of IbalonKi Ko100% (3)

- Challenges Faced by Freight Forwarders in Their Operations in Chennai City, Tamil NaduDokumen3 halamanChallenges Faced by Freight Forwarders in Their Operations in Chennai City, Tamil NaduNiraj KasbeBelum ada peringkat

- Argumentative Essay Project DescriptionDokumen5 halamanArgumentative Essay Project DescriptionKaren Jh MoncayoBelum ada peringkat

- RA 9344 As Amended by RA 10630 - HandoutsDokumen9 halamanRA 9344 As Amended by RA 10630 - HandoutsJan Re Espina CadeleñaBelum ada peringkat

- Ang Tibay Vs CADokumen2 halamanAng Tibay Vs CAEarl LarroderBelum ada peringkat

- Middle Grades ReportDokumen138 halamanMiddle Grades ReportcraignewmanBelum ada peringkat

- International Conference On Basic Science (ICBS)Dokumen22 halamanInternational Conference On Basic Science (ICBS)repositoryIPBBelum ada peringkat

- Amtek Auto Analysis AnuragDokumen4 halamanAmtek Auto Analysis AnuraganuragBelum ada peringkat

- (Kre?Imir Petkovi?) Discourses On Violence andDokumen610 halaman(Kre?Imir Petkovi?) Discourses On Violence andGelazul100% (1)

- Marriage Practices Among The Gidda Oromo, Northern Wollega, EthiopiaDokumen2 halamanMarriage Practices Among The Gidda Oromo, Northern Wollega, Ethiopiajoseph mathewBelum ada peringkat

- Arsu and AzizoDokumen123 halamanArsu and AzizoZebu BlackBelum ada peringkat

- Sale Deed Document Rajyalakshmi, 2222222Dokumen3 halamanSale Deed Document Rajyalakshmi, 2222222Madhav Reddy100% (2)

- 1929 Davos DisputationDokumen20 halaman1929 Davos DisputationEstevao Cruz100% (1)

- Soal Midtest + Kunci JawabanDokumen28 halamanSoal Midtest + Kunci JawabanYuyun RasulongBelum ada peringkat

- Chapter Three: Research MethodologyDokumen3 halamanChapter Three: Research MethodologyEng Abdulkadir MahamedBelum ada peringkat

- Entity-Level Controls Fraud QuestionnaireDokumen8 halamanEntity-Level Controls Fraud QuestionnaireKirby C. LoberizaBelum ada peringkat

- Su Jok, Twist Therapy AND Smile MeditationDokumen7 halamanSu Jok, Twist Therapy AND Smile MeditationprateekBelum ada peringkat

- Grade 5 Forces Acting On Structures and Mechanisms CirriculumDokumen3 halamanGrade 5 Forces Acting On Structures and Mechanisms Cirriculumapi-2072021750% (1)

- Reaction PaperDokumen3 halamanReaction PaperCecille Robles San JoseBelum ada peringkat

- Process Plant Equipment: Operation, Control, and ReliabilityDari EverandProcess Plant Equipment: Operation, Control, and ReliabilityPenilaian: 5 dari 5 bintang5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDari EverandSodium Bicarbonate: Nature's Unique First Aid RemedyPenilaian: 5 dari 5 bintang5/5 (21)

- Water-Based Paint Formulations, Vol. 3Dari EverandWater-Based Paint Formulations, Vol. 3Penilaian: 4.5 dari 5 bintang4.5/5 (6)

- Guidelines for Chemical Process Quantitative Risk AnalysisDari EverandGuidelines for Chemical Process Quantitative Risk AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDari EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlPenilaian: 4 dari 5 bintang4/5 (4)

- Understanding Process Equipment for Operators and EngineersDari EverandUnderstanding Process Equipment for Operators and EngineersPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookDari EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookBelum ada peringkat

- Phase Equilibria in Chemical EngineeringDari EverandPhase Equilibria in Chemical EngineeringPenilaian: 4 dari 5 bintang4/5 (11)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesDari EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesBelum ada peringkat

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDari EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookBelum ada peringkat

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDari EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsBelum ada peringkat

- Bow Ties in Risk Management: A Concept Book for Process SafetyDari EverandBow Ties in Risk Management: A Concept Book for Process SafetyBelum ada peringkat

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDari EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsBelum ada peringkat

- Distillation Design and Control Using Aspen SimulationDari EverandDistillation Design and Control Using Aspen SimulationPenilaian: 5 dari 5 bintang5/5 (2)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDari EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDari EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesBelum ada peringkat

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDari EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksBelum ada peringkat

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Dari EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Belum ada peringkat

- Physical and Chemical Equilibrium for Chemical EngineersDari EverandPhysical and Chemical Equilibrium for Chemical EngineersPenilaian: 5 dari 5 bintang5/5 (1)