Catálogo MICO - Válvulas de Carga de Acumulador

Diunggah oleh

edgar_retuerto78100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

534 tayangan28 halamanMICO, Inc. Has attempted to present accurate information about MICO Products in its catalogs, brochures, and other printed materials. All MICO Products and service are sold and provided subject to the MICO Warranty at www.mico.com in effect on the date of sale or supply.

Deskripsi Asli:

Judul Asli

Catálogo MICO - Válvulas de Carga de Acumulador (1)

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMICO, Inc. Has attempted to present accurate information about MICO Products in its catalogs, brochures, and other printed materials. All MICO Products and service are sold and provided subject to the MICO Warranty at www.mico.com in effect on the date of sale or supply.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

534 tayangan28 halamanCatálogo MICO - Válvulas de Carga de Acumulador

Diunggah oleh

edgar_retuerto78MICO, Inc. Has attempted to present accurate information about MICO Products in its catalogs, brochures, and other printed materials. All MICO Products and service are sold and provided subject to the MICO Warranty at www.mico.com in effect on the date of sale or supply.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 28

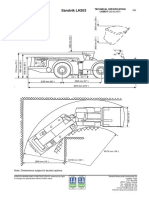

MICO, Inc. Form No.

84-463-001 Online Revised 2013-09-13 1

Innovative Braking and Controls Worldwide

Accumulator Charging Valves

single charging valves, dual charging valves,

and load sensing charging valves

Versatile, High-performance

Accumulator Charging Valves

2 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

This document is intended to provide general information about MICO Products. MICO, Inc. has attempted to present accurate information

about MICO Products in its catalogs, brochures, and other printed materials. MICO, Inc. is not responsible for errors, inaccuracies, or

inconsistencies that may exist in any catalog brochure or other printed materials or any damages arising from or related to reliance on

information in them. Materials and specifcations for MICO Products set forth in catalogs, brochures, and other printed materials are subject

to change without notice or obligation. Refer to www.mico.com for the most recent versions of our literature. If you have any questions

concerning MICO Products, please contact MICO, Inc. All MICO Products and service are sold and provided subject to the MICO Warranty at

www.mico.com in effect on the date of sale or supply.

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 3

Applications

Forestry Equipment

Agricultural Equipment

Heavy Construction

Equipment

Swing Drive Equipment

Mining Equipment

In-Plant & Warehouse

Equipment

Airport Support

Vehicles

Catalog Index

Why choose MICO ...................................................................................................4

Accumulator Charging Valve Catalog Code .............................................................5

Single Accumulator Charging Valves .....................................................................6-7

Dual Accumulator Charging Valves .......................................................................8-9

Single Accumulator Charging Valves with Relief Valve .....................................10-11

Dual Accumulator Charging Valves with Relief Valve ....................................... 12-13

Load Sensing Accumulator Charging Valves (single) ....................................... 14-15

Load Sensing Accumulator Charging Valves (dual) ......................................... 16-17

Load Sensing Accumulator Charging Valves

with Load Sense Unloading ...................................................................... 18-19

Single Accumulator Charging Valves (high fow) .............................................. 20-21

Dual Accumulator Charging Valves (high fow) ................................................. 22-23

Full Power Brake Valves ................................................................................... 24-25

Useful Formulas .....................................................................................................26

4 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Why choose MICO?

MICO, Inc. designs, manufactures and markets

hydraulic components, controls, and brake systems

primarily for off-road markets. We have manufacturing

facilities in:

North Mankato, Minnesota U.S.A.

Ontario, California U.S.A.

Empalme, Sonora, Mexico

Many of the worlds largest off-highway OEMs value

the knowledgeable staff at MICO and work with us to

make their products better. Our custom-engineered

products are designed with the customer requirements

as the primary driver. It is our intent to help custom-

ers build their systems with our expertise in hydraulic

components, braking systems and controls.

Our goal is to meet or exceed our customers

expectations in every aspect of our business.

Product lines we specialize in include:

Actuators

Brake Locks

Brakes

Controls

Cylinders

Electrohydraulics

Master Cylinders

Valves

MICO is proud to be ISO 9001 and ISO 14001 certifed

and continuously strive for improvement while remain-

ing a quality leader in our feld. We have been a suc-

cessful business for over 60 years. Privately owned,

customer driven. We look forward to working with you!

Accumulator Charging Valves

The same dependability, safety and performance that

goes into every MICO Braking System Product also

goes into our accumulator charging valves. This is an

important consideration when you select a source of

supply for your fuid power needs.

The MICO Accumulator Charging Valves presented in

this catalog are designed for vehicles that are equipped

with other hydraulic power devices in either open center,

closed center or load sensing hydraulic systems. This

design feature eliminates the need for a separate

hydraulic fuid system.

Unless specifed, all valves in this catalog are used with

mineral base hydraulic oil. Consult MICO when using

other fuids. Dimensional drawings shown may vary

slightly between similar units and are to be used for

reference purposes only.

For more information regarding brake system design

see Technical papers 80-950-073, 80-950-074, 80-950-

098, and 80-950-102 at www.mico.com.

Complete the appropriate Application Data Sheet online,

www.mico.com. The MICO, Inc. Applications Depart-

ment will analyze your specifcations and based on your

input recommend an accumulator charging valve suit-

able for your requirements.

For more information about MICO Hydraulic Brake

Valves see catalog 84-466-001.

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 5

Accumulator Charging Valve Catalog Code

Product designator

ACV = Accumulator

Charge Valve

Seal material

Blank = Nitrile

V = Fluorocarbon

Charging rate

High charging limit

A C V M

Number of accumulators

S = One

D = Two

Type of actuation

M = Hydro-mechanical

Excess fow

N = Not applicable

F11 = Flow through, maximum fow rate

in dekaliters/min is 11 (30 GPM)

F13 = Flow through, maximum fow rate

in dekaliters/min is 13 (35 GPM)

F25 = Flow through, maximum fow rate

in dekaliters/min is 25 (65 GPM)

O11 = Power beyond, maximum fow rate

in dekaliters/min is 11 (30 GPM)

O13 = Power beyond, maximum fow rate

in dekaliters/min is 13 (35 GPM)

O25 = Power beyond, maximum fow rate

in dekaliters/min is 25 (65 GPM)

MICO defnes fow through as fow that passes

through the accumulator charging valve and

returns to the reservoir.

MICO defnes power beyond as fow that may

be used to perform work at auxiliary functions.

Load sensing

Blank = Not load sensing

LS = Standard bleed down

LSB = With additional 0.4 mm diameter bleed down orifce

Relief valve

Blank = No relief valve

RV*** = Relief valve (system, full fow where *** = relief valve

setting in bar) (example: RV203)

NOTE: Not all listed code combinations are attainable.

3 L/min

4 L/min

6 L/min

8 L/min

9 L/min

10 L/min

11 L/min

13 L/min

14 L/min

15 L/min

16 L/min

17 L/min

19 L/min

Pressure setting - bar

Low charging limit

Pressure setting - bar

Unloading valve

Blank = No unloading valve

UL12 = Unloading valve (12 Vdc)

UL24 = Unloading valve (24 Vdc)

6 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Single Accumulator

Charging Valves

PRINCIPLES OF OPERATION

These MICO Single Accumulator Charging Valves are

designed for installation in an open-center hydraulic

system between the pump and its relief valve and the

downstream secondary hydraulic devices; for example,

a power steering control valve and cylinder installed in

the same hydraulic circuit.

These single accumulator charging valves supply oil to

an accumulator from an open center circuit on demand.

This is accomplished at a preset rate, L/min (GPM), at

a selected pressure and is constant within the preset

pressure limits.

The fow to the downstream secondary hydraulic

devices will be reduced when the accumulator is

charging. This does not noticeably affect the operation

of these components. Full system pressure is available

to the downstream secondary hydraulic devices at all

times provided oil delivery and pressure from the pump

and relief valve are not impeded.

The accumulator charging fow rates and upper and

lower accumulator pressure limits are set at the time of

manufacture.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Uses power developed in the main hydraulic system

z Remotely mounted from brake valves

z Snap action control section promotes positive

unloading of the pump

z Designed to improve effciency by having no

continuous drain of oil to reservoir

z Large variety of pressure ranges between high and

low limits are available in order to reduce pump cycle

time

z Designed for mobile equipment with varying pump

fows

z Flow rates to 113 L/min (30 GPM)

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 7

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) L/min (GPM) bar (PSI)

06-463-008

06-463-010

06-463-012

06-463-014

06-463-016

06-463-018

06-463-020

06-463-022

06-463-024

06-463-026

06-463-028

06-463-030

06-463-032

06-463-034

06-463-036

06-463-038

06-463-040

06-463-044

06-463-048

06-463-050

06-463-052

06-463-054

06-463-056

06-463-058

06-463-060

06-463-064

06-463-066

06-463-078

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

67

41

94

55

83

145

128

155

103

103

94

55

103

124

114

86

114

86

103

117

114

72

93

114

45

128

48

116

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

95

90

124

76

103

190

159

186

128

138

124

76

128

152

138

124

138

124

138

145

138

103

124

138

60

159

90

159

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

10

10

6

6

6

10

10

10

10

3

10

6

10

6

17

3

10

4

6

6

6

3

3

3

3

3

6

10

3.5 ( 50)

3.5 ( 50)

2.6 ( 37)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 25)

3.5 ( 50)

3.5 ( 50)

2.6 ( 37)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

1.7 ( 25)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

3.5 ( 50)

1.7 ( 25)

3.5 ( 50)

2.3 ( 0.6)

2.3 ( 0.6)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

1.9 ( 0.5)

1.1 ( 0.3)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

0.1 ( 0.25)

0.1 ( 0.25)

0.1 ( 0.25)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

Water emulsion models

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Power beyond fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 to 113 L/min (2 to 30 GPM)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8 bar at 56.8 L/min (70 PSI at 15 GPM)

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

8 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Dual Accumulator

Charging Valves

PRINCIPLES OF OPERATION

These MICO Dual Accumulator Charging Valves per-

form essentially the same functions as the single charg-

ing valves. When the dual accumulator charging valves

are used in a split hydraulic brake system each indi-

vidual axle is separately controlled. These dual charging

valves charge both accumulators. The primary advan-

tage of dual charging valves are that if half of the brake

system fails the remaining half will continue to function.

These dual charging valves charge the accumulators

from the open center circuit upon demand and within its

preset operating charge rate and maximum pressure.

Other charge rates and pressures are available upon

request.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Uses power developed in the main hydraulic system

z Remotely mounted from brake valves

z Snap action control section promotes positive

unloading of the pump

z Designed to improve effciency by having no

continuous drain of oil to reservoir

z Large variety of pressure ranges between high and

low limits are available in order to reduce pump

cycle time

z Designed for mobile equipment with varying pump

fows

z Pressure switch port senses the lower pressure of

the two accumulators

z Flow rates to 113 L/min (30 GPM)

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 9

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) bar (PSI) L/min (GPM)

06-463-200

06-463-202

06-463-204

06-463-206

06-463-208

06-463-210

06-463-212

06-463-214

06-463-216

06-463-218

06-463-222

06-463-224

06-463-226

06-463-228

06-463-230

06-463-234

06-463-250

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

128

155

114

86

117

103

86

64

93

95

148

138

86

145

114

138

148

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

159

190

138

124

145

128

103

83

114

124

179

166

103

179

138

166

179

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

10

10

10

10

10

10

10

10

3

6

10

6V

3

3

6

6

10V

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Power beyond fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 to 113 L/min (2 to 30 GPM)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8 bar at 56.8 L/min (70 PSI at 15 GPM)

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

10 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Single Accumulator Charging

Valves with Relief Valve

PRINCIPLES OF OPERATION

The MICO Single Accumulator Charging Valves with

Relief Valve incorporate a main system relief valve. This

valve was developed for installation in an open center

hydraulic system between the pump and the down-

stream

secondary hydraulic devices; for example, a power

steering control valve and cylinder installed in the same

hydraulic circuit.

These valves supply oil to the system accumulator from

an open center circuit on demand. This is accomplished

at a preset rate L/min (GPM) at a selected pressure and

is relatively constant within the preset pressure limits.

The fow to the downstream secondary hydraulic

devices will be reduced when the accumulator is charg-

ing. This does not noticeably affect the operation of

these components. Full system pressure is available

to the downstream secondary hydraulic devices at all

times provided oil delivery and pressure from the pump

is not impeded. Maximum system pressure is set by an

integral relief valve.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information

FEATURES

z Incorporated pump relief valve

z Direct acting relief valve for reliability and fast

action

z Uses power developed in the main hydraulic system

z Remotely mounted from brake valves

z Snap action control section promotes positive

unloading of the pump

z Designed to improve effciency by having no

continuous drain of oil to reservoir

z Large variety of pressure ranges between high and

low limits are available in order to reduce pump cycle

time

z Designed for mobile equipment with varying pump

fows

Typical Circuit Schematic

MICO

Single

Modulating

Valve

Single

Brake

System

A P

T

Accumulator

MICO

Pressure

Switch

MICO Single

Accumulator

Charging

Valve

Pump

Filter

To Power

Beyond

A

SW

T P O

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 11

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

Relief

Valve Setting

Tolerance

bar (PSI) bar (PSI) L/min (GPM) bar (PSI)

06-463-302

06-463-304

06-463-306

06-463-308

06-463-312

06-463-314

06-463-318

06-463-320

06-463-324

06-463-328

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

-

-

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

SMO11

-

-

-

-

-

-

-

-

-

-

RV172

RV190

RV138

RV172

RV203

RV203

RV203

RV121

RV172

RV172

-

-

-

-

-

-

-

-

-

-

86

86

83

103

153

128

128

86

128

110

-

-

-

-

-

-

-

-

-

-

124

124

103

138

186

159

159

107

159

134

-

-

-

-

-

-

-

-

-

-

6

6

6

10

10

6

17

3

3

10

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

0.1 ( 0.25)

1.9 ( 0.5)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Power beyond fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 to 113 L/min (2 to 30 GPM)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8 bar at 56.8 L/min (70 PSI at 15 GPM)

Relief valve fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 L/min (20 GPM)

Relief valve setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206.8 bar (3000 PSI) maximum

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

12 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Dual Accumulator Charging

Valves with Relief Valve

PRINCIPLES OF OPERATION

The MICO Dual Accumulator Charging Valves with

Relief Valve incorporate a main system relief valve. This

valve was developed for installation in an open center

hydraulic system between the pump and downstream

secondary hydraulic devices; for example, a power

steering control valve and cylinder installed in the same

hydraulic circuit.

These valves supply oil to the system accumulators from

an open center circuit on demand. This is accomplished

at a preset fow rate and is constant within the preset

pressure limits.

The fow to downstream secondary hydraulic devices

will be reduced for a short time when the accumulator is

charging. This does not noticeably affect the operation

of these components. Full system pressure is available

to the downstream secondary hydraulic devices at all

times provided oil delivery and pressure from the pump

is not impeded. Maximum system pressure is set by an

integral relief valve.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Incorporated pump relief valve

z Pilot operated relief valve for reliability and fast action

z Uses power developed in the main hydraulic system

z Remotely mounted from brake valves

z Snap action control section promotes positive

unloading of the pump

z Designed to improve effciency by having no

continuous drain of oil to reservoir

z Large variety of pressure ranges between high and

low limits are available in order to reduce pump cycle

time

z Designed for mobile equipment with varying pump

fows

z Flow rates to 113 L/min (30 GPM)

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 13

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

Relief

Valve Setting

Tolerance

bar (PSI) bar (PSI) L/min (GPM) bar (PSI)

06-463-415

06-463-424

06-463-425

06-463-426

06-463-432

06-463-434

06-463-440

06-463-496

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

DMO11

-

-

-

-

-

-

-

-

RV138

RV203

RV203

RV202

RV172

RV145

RV210

RV207

-

-

-

-

-

-

-

-

86

155

147

150

126

103

138

140

-

-

-

-

-

-

-

-

103

18

176

181

155

128

193

189

-

-

-

-

-

-

-

-

10

10

14

3

10

10

19

10

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

3.8 ( 1.0)

1.9 ( 0.5)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure (unless otherwise indicated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Power beyond fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 to 113 L/min (2 to 30 GPM)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8 bar at 56.8 L/min (70 PSI at 15 GPM)

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

14 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Load Sensing Accumulator

Charging Valves (single)

PRINCIPLES OF OPERATION

The MICO Load Sensing Accumulator Charging Valves

operate in a fow and pressure-on-demand system. The

control section of these valves send a pilot signal to a

pressure compensated load sense pump when fuid is

required. It maintains reserve volume and pressure in

the accumulator, allowing the pump to stand by when

there is no demand for fuid.

These charging valves are normally used in single

systems in conjunction with one accumulator and single

brake valve.

The charge rate and upper and lower accumulator pres-

sure limits are set at the time of manufacture. Various

charge rates, high and low limit settings and pressure

ranges between high and low limits are available to con-

form to specifc customer requirements.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Uses power developed in the main hydraulic system

z Remotely mounted from brake valves

z Snap action control section promotes positive

unloading of the pump

z Designed to improve effciency by having no

continuous drain of oil to reservoir

z Large variety of pressure ranges between high and

low limits are available in order to reduce pump cycle

time

Typical Circuit Schematic (Single)

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 15

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) bar (PSI) L/min (GPM)

06-463-102

06-463-106

06-463-108

06-463-110

06-463-112

06-463-114

06-463-116

06-463-136

06-463-158

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

-

SMN

SMN

SMN

SMN

SMN

SMN

SMN

SMN

SMN

-

-

-

-

-

-

-

-

-

LSB

LSB

LSB

LSB

LSB

LSB

LSB

LS

LSB

-

-

-

-

-

-

-

-

-

74

104

117

116

117

93

83

128

153

-

-

-

-

-

-

-

-

-

107

129

159

141

159

114

103

166

186

-

-

-

-

-

-

-

-

-

6

10

11

11

15

11

6

15

11

3.5 ( 50)

2.6 ( 37)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

Consult MICO Applications Department for other available models and application detail.

NOTE: Model numbers with LSB catalog code designation are designed for use in load sense systems

with pumps that do not have a bleed down orifce.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Flow through capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

16 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Load Sensing Accumulator

Charging Valves (dual)

PRINCIPLES OF OPERATION

The MICO Load Sensing Accumulator Charging Valves

operate in a fow and pressure-on-demand system. The

control section of these valves send a pilot signal to a

pressure compensated load sense pump when fuid is

required. It maintains reserve volume and pressure in

the accumulators, allowing the pump to stand by when

there is no demand for fuid.

These charging valves are used in split systems with

two or more accumulators and a tandem or dual brake

valve.

The charge rate and upper and lower accumulator pres-

sure limits are set at the time of manufacture. Various

charge rates, high and low limit settings and pressure

ranges between high and low limits are available to con-

form to specifc customer requirements.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Uses power developed in the main hydraulic system

z Remotely mounted from brake valves

z Snap action control section promotes positive

unloading of the pump

z Designed to improve effciency by having no

continuous drain of oil to reservoir

z Large variety of pressure ranges between high and

low limits are available in order to reduce pump cycle

time

z Pressure switch port senses the lower pressure of

the two accumulators

Typical Circuit Schematic (Dual)

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 17

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) bar (PSI) L/min (GPM)

06-463-100

06-463-118

06-463-122

06-463-124

06-463-126

06-463-128

06-463-148

06-463-156

06-463-162

06-463-164

06-463-166

06-463-184

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

-

-

-

-

DMN

DMN

DMN

DMN

DMN

DMN

DMN

DMN

DMN

DMN

DMN

DMN

-

-

-

-

-

-

-

-

-

-

-

-

LSB

LS

LSB

LS

LS

LS

LSB

LS

LS

LSB

LSB

LSB

-

-

-

-

-

-

-

-

-

-

-

-

55

128

119

97

86

155

86

128

145

128

166

128

-

-

-

-

-

-

-

-

-

-

-

-

78

159

145

172

114

190

114

159

176

159

186

159

-

-

-

-

-

-

-

-

-

-

-

-

6

6

11V

8V

6

16

8

13

13

13

6

13

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

2.8 ( 0.75)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Flow through capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

18 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Load Sensing Accumulator Charging

Valves with Load Sense Unloading

PRINCIPLES OF OPERATION

These are load sensing accumulator charging valves

with an integral solenoid valve to disable the load

sensing signal when energized. These high-pressure

charging valves operate in a fow and pressure on

demand system.

The control section of these valves send a pilot signal to

a load sense pump when fuid is required. They maintain

and isolate hydraulic energy in two separate accumu-

lators allowing the pump to standby when there is no

demand for fuid.

These charging valves feature a solenoid-operated

valve that can be used to unload the pilot signal from the

charging valve to the pump at startup.

Typical applications would include off-highway vehicles

with split braking systems that have two or more accu-

mulators and a tandem or dual full power brake valve.

The load sense-unloading feature is for vehicles that

require startup at low hydraulic load such as vehicles

that operate in cold climates.

FEATURES

z Solenoid feature allows machine to be started

without immediately charging accumulators

z Solenoid feature is desirable in cold start conditions

and marginal horsepower applications

z Solenoid valve could be controlled by a timer, ignition

switch, or computer system

z If solenoid stays on, accumulators will not charge

z Contact MICO for single accumulator charging valve

design

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 19

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) bar (PSI) L/min (GPM)

06-463-132

06-463-134

06-463-140

06-463-142

06-463-146

06-463-150

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

DMN

DMN

DMN

DMN

DMN

DMN

-

-

-

-

-

-

LS

LS

LS

LS

LS

LS

-

-

-

-

-

-

UL24

UL24

UL24

UL24

UL24

UL24

-

-

-

-

-

-

134

97

120

103

103

120

-

-

-

-

-

-

166

172

160

128

128

160

-

-

-

-

-

-

6V

8V

6V

3V

9V

6V

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

System pressure to 250 bar (3625 PSI)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 206.8 bar (3000 PSI)

Flow through capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

20 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Single Accumulator

Charging Valves (high fow)

PRINCIPLES OF OPERATION

The MICO Single Accumulator Charging Valves may be

used in an open center hydraulic system in conjunction

with an accumulator and a MICO Modulating Valve or

other hydraulic components.

These charging valves control the charging rate of the

accumulator and the pressure of the fuid in the accumu-

lator. These valves automatically halt the charging when

the accumulator pressure reaches its high limit.

When the accumulator pressure reaches its low limit,

these charging valves divert a small amount of fuid from

the main open center hydraulic system to charge the

accumulator.

These valves charge the accumulator from the open

center circuit upon demand and within its preset operat-

ing charge rate and maximum pressure. Other charge

rates and pressures are available upon request.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Uses power developed in the main hydraulic system

z May be remotely mounted from brake valves

z Settings are adjusted at the time of manufacture to

conform to specifc customer requirements

z Flow rates up to 246 L/min (65 GPM)

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 21

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) bar (PSI) L/min (GPM)

06-460-202

06-460-210

06-460-214

06-460-224

06-460-226

06-460-230

06-460-238

06-460-240

06-460-242

06-460-244

06-460-248

06-460-254

06-460-256

06-460-258

06-460-268

06-460-270

06-460-276

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

SMO25

SMO13

SMO13

SMO13

SMO13

SMO13

SMO25

SMO25

SMO13

SMO13

SMO13

SMO13

SMO13

SMO13

SMO13

SMO13

SMO13

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

148

117

145

131

66

124

55

131

145

83

116

83

100

97

66

110

83

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

178

145

172

159

83

152

79

159

172

103

145

103

128

121

93

138

103

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

10

3

3

10

3

10

10

10

10

3

6

6

6

3

10

6

10

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

2.3 ( 0.6)

0.1 ( 0.25)

0.1 ( 0.25)

2.3 ( 0.6)

0.1 ( 0.25)

2.3 ( 0.6)

2.3 ( 0.6)

2.3 ( 0.6)

2.3 ( 0.6)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

2.3 ( 0.6)

1.9 ( 0.5)

2.3 ( 0.6)

Pressure port and fow through port conform to SAE 1 inch split fange.

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 186.2 bar (2700 PSI)

Power beyond fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 to 246 L/min (35 to 60 GPM) (split fange models only)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 bar at 132 L/min (20 PSI at 35 GPM)

2.8 bar at 246 L/min (40 PSI at 65 GPM) (split fange models only)

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

22 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Dual Accumulator

Charging Valves (high fow)

PRINCIPLES OF OPERATION

These MICO Dual Accumulator Charging Valves

perform essentially the same functions as the single

charging valves. When the dual accumulator charging

valves are used in a split hydraulic brake system each

individual axle is controlled separately by a modulating

valve and an accumulator. These valves charge both

accumulators. The primary advantage of the dual charg-

ing valves over the single charging valves are that if half

of the brake system fails the remaining half will continue

to function.

These valves charge the accumulators from the open

center circuit upon demand and within its preset operat-

ing charge rate and maximum pressure. Other charge

rates and pressures are available upon request.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Uses power developed in the main hydraulic system

z May be remotely mounted from brake valves

z Full system pressure is available to the power

steering or secondary devices at all times

z Flow rates to 246 L/min (65 GPM)

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 23

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Catalog Code

(refer to page 5)

Low Limit

Tolerance

High Limit

Tolerance

Accumulator

Charging Rate

Tolerance

bar (PSI) bar (PSI) L/min (GPM)

06-460-216

06-460-218

06-460-222

06-460-252

06-460-264

06-460-290

06-460-292

ACV

ACV

ACV

ACV

ACV

ACV

ACV

-

-

-

-

-

-

-

DMO13

DMO13

DMO13

DMO13

DMO13

DMO13

DMO13

-

-

-

-

-

-

-

48

97

131

97

126

97

131

-

-

-

-

-

-

-

69

124

159

124

153

124

159

-

-

-

-

-

-

-

3

3

6

6

3

6

3

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

3.5 ( 50)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

1.7 ( 25)

0.1 ( 0.25)

0.1 ( 0.25)

1.9 ( 0.5)

1.9 ( 0.5)

0.1 ( 0.25)

1.9 ( 0.5)

0.1 ( 0.25)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 186.2 bar (2700 PSI)

Power beyond fow capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 to 246 L/min (35 to 65 GPM) (split fange models only)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 bar at 132 L/min (20 PSI at 35 GPM)

2.8 bar at 246 L/min (40 PSI at 65 GPM) (split fange models only)

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

24 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

Full Power Brake Valves

PRINCIPLES OF OPERATION

The MICO Full Power Power Brake Valves use the

hydraulic power developed for the power steering sys-

tem to actuate the vehicles brakes, eliminating the need

for a separate power brake unit or separate hydraulic

system fuid.

These valves control the charging rate of the accumula-

tor, the pressure of the fuid in the accumulator, and the

fow and pressure of the fuid to the brakes.

All hydraulic fuid from the hydraulic pump system fows

through the valve. When the accumulator pressure

reaches its low limit, the valve diverts a small amount

of fuid from the main open center hydraulic system to

charge the accumulator. It automatically halts the charg-

ing when accumulator pressure reaches its high limit.

Actuation of the valve provides output pressures to the

brakes in direct proportions to the pedal effort applied.

MICO also offers a complete line of hydraulic pressure

switches for your application. Contact MICO for more

information.

FEATURES

z Readily adaptable to both hydraulic and mechanical

brakes

z Uses power developed in main hydraulic system

z Brake response much faster than air brakes

z Provides limited power-off braking through pressure

and volume stored in the accumulator

Typical Circuit Schematic

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 25

Dimensions may vary slightly by model number.

millimeters

inches

Model

Number

Maximum Brake

Pressure Setting

Nominal

Accumulator

Charging Rate

Nominal

High Limit

Nominal

Low Limit

Push Rod

Force

at Maximum

Pressure

bar (PSI) L/min (GPM) bar (PSI) bar (PSI) N (lb)

06-460-800

06-460-810

06-460-814

06-460-816

06-460-820

06-460-830

06-460-832

06-460-834

06-460-838

06-460-846

06-460-848

06-460-852

06-460-854

06-460-856

06-460-858

06-460-860

06-460-870

06-460-890

06-460-894

06-460-900

06-460-950

06-460-956

06-460-958

06-460-960

44.8 3.5 (650 50)

108.6 1.7 (1575 25)

103.4 3.5 (1500 50)

108.6 1.7 (1575 25)

44.8 3.5 (650 50)

98.3 5.2 (1425 75)

65.5 3.5 (950 50)

82.7 3.5 (1200 50)

106.9 5.2 (1550 75)

108.6 1.7 (1575 25)

70.7 1.7 (1025 25)

98.3 5.2 (1425 75)

103.4 3.5 (1500 50)

98.3 5.2 (1425 75)

117.2 3.5 (1700 50)

75.8 5.2 (1100 75)

69.0 5.2 (1000 75)

25.9 1.7 (375 25)

22.4 1.0 (325 15)

18.6 1.0 (270 15)

134.4 3.5 (1950 50)

25.9 1.7 (375 25)

34.5 3.5 (500 50)

41.4 3.5 (600 50)

6.4 1.9 (1.7 0.5)

9.8 2.3 (2.6 0.6)

6.4 1.9 (1.7 0.5)

9.8 2.3 (2.6 0.6)

9.8 2.3 (2.6 0.6)

6.4 1.9 (1.7 0.5)

6.4 1.9 (1.7 0.5)

9.8 2.3 (2.6 0.6)

6.4 1.9 (1.7 0.5)

9.8 2.3 (2.6 0.6)

6.4 1.9 (1.7 0.5)

2.8 0.1 (0.75 0.25)

2.8 0.1 (0.75 0.25)

6.4 1.9 (1.7 0.5)

6.4 1.9 (1.7 0.5)

9.8 2.3 (2.6 0.6)

2.8 0.1 (0.75 0.25)

9.8 2.3 (2.6 0.6)

9.8 2.3 (2.6 0.6)

9.8 2.3 (2.6 0.6)

6.4 1.9 (1.7 0.5)

2.8 0.1 (0.75 0.25)

6.4 1.9 (1.7 0.5)

9.8 2.3 (2.6 0.6)

89.6 1.7 (1300 25)

124.1 1.7 (1800 25)

131.0 1.7 (1900 25)

124.1 1.7 (1800 25)

89.6 1.7 (1300 25)

103.4 1.7 (1500 25)

103.4 1.7 (1500 25)

103.4 1.7 (1500 25)

148.2 5.2 (2150 75)

120.7 1.7 (1750 25)

113.8 1.7 (1650 25)

103.4 1.7 (1500 25)

134.4 3.5 (1950 50)

110.3 1.7 (1600 25)

153.4 1.7 (2225 25)

93.1 1.7 (1350 25)

70.7 1.7 (1025 25)

89.6 1.7 (1300 25)

89.6 1.7 (1300 25)

89.6 1.7 (1300 25)

165.5 3.5 (2400 50)

89.6 1.7 (1300 25)

89.6 1.7 (1300 25)

120.7 3.5 (1750 50)

41.4 3.5 (600 50)

96.5 3.5 (1400 50)

106.9 1.7 (1550 25)

96.5 3.5 (1400 50)

41.4 3.5 (600 50)

82.7 3.5 (1200 50)

82.7 3.5 (1200 50)

82.7 3.5 (1200 50)

110.3 3.5 (1600 50)

96.5 3.5 (1400 50)

93.1 3.5 (1350 50)

82.7 3.5 (1200 50)

106.9 3.5 (1550 50)

89.6 3.5 (1300 50)

124.1 3.5 (1800 50)

75.8 3.5 (1100 50)

57.9 3.5 (840 50)

41.4 3.5 (600 50)

41.4 3.5 (600 50)

41.4 3.5 (600 50)

134.5 3.5 (1950 50)

43.1 1.7 (625 25)

60.3 3.5 (875 50)

56.9 3.5 (825 50)

1690 (380)

3692 (830)

3514 (790)

3692 (830)

1690 (380)

3514 (790)

2358 (530)

2811 (632)

3514 (790)

3559 (800)

2624 (590)

1335 (300)

1335 (300)

3514 (790)

3514 (790)

2669 (600)

2491 (560)

956 (215)

1601 (360)

712 (160)

1335 (300)

1890 (425)

1335 (300)

2825 (635)

Consult MICO Applications Department for other available models and application detail.

SPECIFICATIONS

Typical Valve

PERFORMANCE DATA

Flow through capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .to 137 L/min to 246 L/min (35 to 65 GPM) (split fange models only)

Flow through pressure drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 bar at 132 L/min (20 PSI at 35 GPM)

2.8 bar at 246 L/min (40 PSI at 65 GPM) (split fange models only)

Accumulator pressure, maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to 189.6 bar (2750 PSI)

Accumulator charging rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 to 12.1 L/min at 69.0 bar (0.5 to 3.2 GPM at 1000 PSI) in three ranges

Actuating push rod stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.56 mm to 10.67 mm (0.219 in to 0.420 in) depending on model number

Accumulator capacity is determined from brake line pressure, displacement and number of power-off emergency brake applications.

26 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

USEFUL FORMULAS

Piston Area (in

2

) = (3.1416) x r

2

(in)

Area (in

2

)

Piston Radius (in) =

(3.1416)

Force (lb) = Piston Area (in

2

) x Line Pressure (PSI)

Force (lb)

Piston Area (in

2

) =

Line Pressure (PSI)

Force (lb)

Line Pressure (PSI) =

Piston Area (in

2

)

Volume (in

3

) = Piston Area (in

2

) x Stroke (in)

Volume (in

3

)

Piston Area (in

2

) =

Stroke (in)

Volume (in

3

)

Stroke (in) =

Piston Area (in

2

)

Volume (gallons) = Flow Rate (GPM) x Time (min)

Volume (gallons)

Flow Rate (GPM) =

Time (min)

Volume (gallons)

Time (min) =

Flow Rate (GPM

Pump Displacement (cir) x Pump RPM

Flow Rate (GPM) =

231

Flow Rate (GPM) x 231

Pump displacement (cir) =

Pump RPM

Flow Rate (GPM) x 231

Pump RPM =

Pump Displacement (cir)

PTO/Pump RPM = PTO % Engine Speed x Engine RPM

PTO/Pump RPM

PTO % Engine Speed =

Engine RPM

PTO/Pump RPM

Engine RPM =

PTO % Engine Speed

Flow Rate (GPM) x Line Pressure (PSI)

Horsepower =

1714 x % Pump Effciency

Torque (lbft) x RPM

Horsepower =

5252

Horsepower x 5252

Torque (lbft) =

RPM

Horsepower x 5252

RPM =

Torque (lbft)

cir = cubic inches per revolution

231 cubic inches = 1 U.S. gallon

MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13 27

28 MICO, Inc. Form No. 84-463-001 Online Revised 2013-09-13

MICO, Incorporated

1911 Lee Boulevard

North Mankato, MN U.S.A. 56003-2507

Tel: +1 507 625 6426 Fax: +1 507 625 3212

Web Site: www.mico.com

MICO is a trademark and registered trademark of

MICO, Inc. MICO is registered in the U.S. Patent and

Trademark Offce as well as in Australia, Canada,

Indonesia, Japan, Peoples Republic of China, South

Korea, and the European Community.

PRODUCT LINE:

Brakes

Caliper Disc Brakes

Multiple Disc Brakes

Brake Locks

Electric

Mechanical

Controls

Electronic Controls

Hydraulic Throttle Controls

Pedal Controls

Switches

Transducers/Sensors

Cylinders

Drive Axle Brake Actuators

Slave Cylinders

Wheel Cylinders

Master Cylinders

Boosted Cylinders

Hydraulically and Air Actuated

Straight Bore Cylinders

Two-Stage Cylinders

Valves

Accumulator Charging

Electrohydraulic Brake

Park Brake

Pressure Modulating

Miscellaneous Components

In-line Residual Check Valves

Pump with Integrated Valves

Reservoirs

Form No. 84-463-001 Online Revised 2013-09-13 Printed in U.S.A.

Anda mungkin juga menyukai

- 8 Tren de Potencia Toro 006Dokumen120 halaman8 Tren de Potencia Toro 006Juan Antonio Montoya0% (1)

- Manual de Partes Toro 0010 No.8Dokumen76 halamanManual de Partes Toro 0010 No.8cacoman93100% (1)

- Transmicion R1600Dokumen31 halamanTransmicion R1600Anonymous SxvgPDoEpBelum ada peringkat

- Guide To Ejc 417 Hydraulic SystemDokumen50 halamanGuide To Ejc 417 Hydraulic SystemAnonymous VCvIxKBelum ada peringkat

- Operation Manual - Manual de Operación HC 109Dokumen39 halamanOperation Manual - Manual de Operación HC 109Cesar Gajardo Gonzalez Horacio0% (1)

- Mti LT 210 Ser 13-4448 Lt-210 - Parts BookDokumen322 halamanMti LT 210 Ser 13-4448 Lt-210 - Parts BookJuan david100% (1)

- Spare Parts Gatalogue Getman Parte 1Dokumen310 halamanSpare Parts Gatalogue Getman Parte 1EFREN SANCHEZ ROBLESBelum ada peringkat

- Cop 1838Dokumen13 halamanCop 1838francks123100% (1)

- lt17 PDFDokumen12 halamanlt17 PDFMehdi MansourianBelum ada peringkat

- Martillo SB 202 PartsDokumen2 halamanMartillo SB 202 PartsRene Ramos MenesesBelum ada peringkat

- 8991 3816 00 Diagrams Boltec 235HDokumen57 halaman8991 3816 00 Diagrams Boltec 235HAngel Sanchez Vilca100% (1)

- Martillo List Parts, SB 302Dokumen24 halamanMartillo List Parts, SB 302ctorres_505746100% (1)

- Brake Systems r1600Dokumen21 halamanBrake Systems r1600RubenJosefina100% (2)

- Planos Electrcos Ehidraulicos Jumbo s1dDokumen116 halamanPlanos Electrcos Ehidraulicos Jumbo s1dseverinoBelum ada peringkat

- S06-1 THC560 DL331 (@)Dokumen122 halamanS06-1 THC560 DL331 (@)SERMAT REKLAMBelum ada peringkat

- Power Extractors For Rock DrillsDokumen2 halamanPower Extractors For Rock DrillsMax RojasBelum ada peringkat

- Manuel Partes ElectricoDokumen28 halamanManuel Partes ElectricoAndersonBelum ada peringkat

- 6991 1274 01a APCDokumen15 halaman6991 1274 01a APCpeter_157608700Belum ada peringkat

- Montabert HC109Dokumen14 halamanMontabert HC109Yiğit Erpak100% (2)

- Manual de Servicio - ConvertidorDokumen37 halamanManual de Servicio - ConvertidorJuan Carlos Inga Vasquez100% (1)

- Hydraulic Drifter: Innovative DesignDokumen2 halamanHydraulic Drifter: Innovative DesignEsty50% (2)

- 11 - Perforadora Montabert Hc50Dokumen12 halaman11 - Perforadora Montabert Hc50Raphael Ruiz RamosBelum ada peringkat

- Manual de Reparación Ingles SB 102Dokumen36 halamanManual de Reparación Ingles SB 102Capces Frostmoore100% (2)

- Ervice Arts IST: 16D2149 P T D S LCB 13150 P S F CDokumen16 halamanErvice Arts IST: 16D2149 P T D S LCB 13150 P S F Cjasmin selimić100% (3)

- S03 Pressure Accumulator For HydraulicDokumen18 halamanS03 Pressure Accumulator For HydraulicjoseBelum ada peringkat

- HydraulicsDokumen46 halamanHydraulicsA Ramos GabyBelum ada peringkat

- Sandvik LH203-3 PDFDokumen3 halamanSandvik LH203-3 PDFjuan carlos0% (1)

- Service Parts List: Converter C2122-47 4266128Dokumen40 halamanService Parts List: Converter C2122-47 4266128ayman akrabBelum ada peringkat

- Bomba Serie 42 SauerDokumen190 halamanBomba Serie 42 SauerOscar Navarro100% (2)

- Front Axle Technical DocumentationDokumen11 halamanFront Axle Technical Documentationmario pastranaBelum ada peringkat

- Datos Tecnicos LH202Dokumen8 halamanDatos Tecnicos LH202Roel Aroni CuaresmaBelum ada peringkat

- ST 2D PDFDokumen257 halamanST 2D PDFsaul75% (4)

- Diagramas Boomer s2Dokumen156 halamanDiagramas Boomer s2Sebastián Rojas Martínez100% (1)

- 8Dokumen90 halaman8Dixon Javier Cortes TapiaBelum ada peringkat

- Clark 14D Planetary Drive Axle PDFDokumen61 halamanClark 14D Planetary Drive Axle PDFIvanBelum ada peringkat

- 16 kW Rock Drill Technical OverviewDokumen52 halaman16 kW Rock Drill Technical OverviewDavis Paredes100% (1)

- Underground Mining Vehicles: Innovative Drivetrain SolutionsDokumen8 halamanUnderground Mining Vehicles: Innovative Drivetrain SolutionsSales Aydinkaya100% (1)

- Partes Mti DT-1304Dokumen308 halamanPartes Mti DT-1304Ricardo Ramirez EstrelloBelum ada peringkat

- 09-3916 - Parts ManualDokumen316 halaman09-3916 - Parts ManualRicardo Ramirez EstrelloBelum ada peringkat

- Operators Guide ST7 and ST7LPDokumen86 halamanOperators Guide ST7 and ST7LPRichard J. Castañeda Estrella100% (1)

- Epiroc SB 202 Manual de Partes - Desde BES051618 PDFDokumen36 halamanEpiroc SB 202 Manual de Partes - Desde BES051618 PDFDiego Egoávil MéndezBelum ada peringkat

- Transmission 5800 - 16800 8-Speed ManualDokumen65 halamanTransmission 5800 - 16800 8-Speed ManualMauro Perez100% (1)

- S06 - 1 THC560 DD311Dokumen128 halamanS06 - 1 THC560 DD311Canchari Pariona Jhon AngelBelum ada peringkat

- Parts Catalogue For TM25XH With TB830XDokumen150 halamanParts Catalogue For TM25XH With TB830XSergey SlomchinskiyBelum ada peringkat

- Sistema Hidráulico 1Dokumen114 halamanSistema Hidráulico 1Jhoel Torres OnofreBelum ada peringkat

- S08 Diesel Power PackDokumen142 halamanS08 Diesel Power PackKarthii AjuBelum ada peringkat

- Clark 19D Planetary Drive Axle PDFDokumen104 halamanClark 19D Planetary Drive Axle PDFEdgarRetuerto100% (3)

- LF70PQ 2011 Thru CurrentDokumen268 halamanLF70PQ 2011 Thru CurrentNelson David Botero Baena100% (1)

- CMX Catalogo TecnicoDokumen74 halamanCMX Catalogo TecnicoMauricio Ariel H. OrellanaBelum ada peringkat

- Sandvik 5 range tramming with electric brake parts manualDokumen86 halamanSandvik 5 range tramming with electric brake parts manualanthonycc1200100% (2)

- 7Dokumen34 halaman7Dixon Javier Cortes Tapia100% (1)

- Small Scoop Spare PartsDokumen10 halamanSmall Scoop Spare PartsMartinBelum ada peringkat

- Circuit DiagramsDokumen143 halamanCircuit DiagramsRebeca Santos100% (1)

- Rammer 1533 Parts ManualDokumen32 halamanRammer 1533 Parts ManualSerkanAlBelum ada peringkat

- Manual Rock Scaler CompletoDokumen122 halamanManual Rock Scaler CompletoNelson GonzalezBelum ada peringkat

- Drive TrainDokumen90 halamanDrive TrainJuan Carlos RBelum ada peringkat

- Accumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesDokumen27 halamanAccumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesPedro MendozaBelum ada peringkat

- Accuulator Charging PDFDokumen28 halamanAccuulator Charging PDFChrissz NoxdBelum ada peringkat

- AquaSentry 025G Bund Water Control Unit User Manual REV D NewDokumen30 halamanAquaSentry 025G Bund Water Control Unit User Manual REV D NewMAJones89Belum ada peringkat

- Valve Maintenance PDFDokumen30 halamanValve Maintenance PDFNazim Saleh100% (2)

- Engineering SpecsDokumen146 halamanEngineering Specssercopetrol100% (2)

- 330C Excavator Hydraulic SystemDokumen8 halaman330C Excavator Hydraulic Systemjohn ayengah100% (1)

- GE Water Heater ManualDokumen28 halamanGE Water Heater ManualSteven LyBelum ada peringkat

- Hazop & Check ListDokumen39 halamanHazop & Check ListgarciaolinadBelum ada peringkat

- SPGP003vikingpump kk125Dokumen16 halamanSPGP003vikingpump kk125Hector_Cornejo_5673Belum ada peringkat

- CNR Sample Pump OperationDokumen38 halamanCNR Sample Pump OperationDiego Nicolás FERNANDEZBelum ada peringkat

- Technical Service Manual: Model Number ChartDokumen19 halamanTechnical Service Manual: Model Number ChartIván NavarroBelum ada peringkat

- JW Proline Xe Power Vent English jwpv100 - 0217rev 2 - CompressedDokumen2 halamanJW Proline Xe Power Vent English jwpv100 - 0217rev 2 - Compressedbuisson-21Belum ada peringkat

- Valvula de Control Trans. 140HDokumen13 halamanValvula de Control Trans. 140HRCA09100% (6)

- Segment Survivability Analysis Theory 1 3Dokumen77 halamanSegment Survivability Analysis Theory 1 3Thái Xuân QuangBelum ada peringkat

- Where To Locate The PSV Inlet NozzleDokumen2 halamanWhere To Locate The PSV Inlet NozzleDiego1980bBelum ada peringkat

- Jos e ManualDokumen29 halamanJos e ManualbonifaceBelum ada peringkat

- Applicable Valve StandardsDokumen21 halamanApplicable Valve StandardsMatthew KuttikadBelum ada peringkat

- RegO Pop-Action ValveDokumen1 halamanRegO Pop-Action ValveSwapnil JawaleBelum ada peringkat

- Relief ValvesDokumen59 halamanRelief ValvesAli Naveed Farooki100% (2)

- Intro To Pneumatics PDFDokumen30 halamanIntro To Pneumatics PDFTEUKUBelum ada peringkat

- Pressure Relief SystemDokumen33 halamanPressure Relief SystemRanchojiBelum ada peringkat

- P&ID Preparation ProcedureDokumen38 halamanP&ID Preparation ProcedureNguyen Anh Tung100% (1)

- Process Safety Beacon - LPG TragedyDokumen1 halamanProcess Safety Beacon - LPG TragedyRodrigo RattoBelum ada peringkat

- Pressure Relief AplicationsDokumen3 halamanPressure Relief AplicationsAndres PerezBelum ada peringkat

- Design Requirements For Pressure Safety Relief Valves: Codes: Structure & ComparisonDokumen5 halamanDesign Requirements For Pressure Safety Relief Valves: Codes: Structure & Comparisontss1372350% (2)

- Appendix 8 Part1 Basic Design DocumentDokumen23 halamanAppendix 8 Part1 Basic Design DocumentpavanBelum ada peringkat

- PZ SeriesDokumen28 halamanPZ SeriesSomiar TradingBelum ada peringkat

- Fire Nfpa 20Dokumen25 halamanFire Nfpa 20BRANDON100% (2)

- Evo Duo Manual Us Lit91127us 05.2018Dokumen67 halamanEvo Duo Manual Us Lit91127us 05.2018Ronal SolisBelum ada peringkat

- Engine Fire Detection SystemsDokumen47 halamanEngine Fire Detection SystemsSThaneasMur100% (2)

- Big Blaster® PDFDokumen20 halamanBig Blaster® PDFZahir KhiraBelum ada peringkat

- 2S 5S 11D 22T 32T 31Q Multiplex Plunger Pumps ManualDokumen59 halaman2S 5S 11D 22T 32T 31Q Multiplex Plunger Pumps ManualLakshmi KishoreBelum ada peringkat

- Lecture 6Dokumen33 halamanLecture 6tommy6700Belum ada peringkat