Trigged Current Limiters Applications

Diunggah oleh

Víctor RojasDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Trigged Current Limiters Applications

Diunggah oleh

Víctor RojasHak Cipta:

Format Tersedia

TRIGGERED CURRENT LIMITERS FOR

CLOSING BUS TIES, BYPASSING REACTORS

AND IMPROVING POWER QUALITY

John S. Schaffer

Senior Member, IEEE

General Manager System Protection Division, G&W Electric Company

Abstract - Current limiting fuses have been commonly applied

in protective systems for decades. They are effective for

controlling peak currents and for limiting fault energy. Triggered

Current Limiters (TCLs) are higher continuous current,

electronically controlled variants of the more conventional

technology. They are applied in the traditional current limiting

fuse roles, but in addition, adapt readily to unique applications

such as bypassing (shunting) current limiting reactors and closing

system ties between adjacent buses.

Bypassing reactors with TCLs can eliminate the continual

losses and regulating voltage drop associated with current limiting

reactors. This application provides full protection during a fault

and load continuity following a fault. By closing system ties

through a TCL the user may improve switching flexibility, better

balance transformer loads, and/or start large motors with less

system voltage sag. This paper investigates the practicality, the

benefits and the limitations of TCLs in these specialized

applications. It also introduces the concept of using TCLs for

power quality enhancements on critical circuits where a bus fault

may cripple an adjacent unfaulted bus.

Key Words Fuses, current limiting, Triggered Current Limiter,

TCL, Commutating Current Limiter, CCL, bus tie, reactor, power

quality, CLiP

, PAF

, shunting, power quality

I. INTRODUCTION

Triggered Current Limiters (TCLs), sometimes referred to as

Commutating Current Limiters (CCLs), fill a unique overcurrent

protection role in the high continuous current range (up to 5000A)

of medium voltage (138kV) equipment where traditional,

meltable-element current limiting fuses reach their practical limit and

generally do not exist. For example, at 15.5kV, the meltable element

fuses are generally available to 200A continuous (but are already in a

double-barrel design) with some manufacturers reaching up to 300A

continuous (in 4-barrel designs). Heat rejection becomes a major

consideration for these traditional fuses. Also, the very high let-thru

current may be in excess of the crests of many systems. In other

words, it may not limit current to a usable range if it limits peaks at all

for the corresponding available current. They essentially reach a

practical limit in their development and usage.

The traditional means for limiting faults for higher continuous

current systems has fallen into a number of approaches:

1. Addition of a current limiting reactor to reduce fault currents

within system capabilities,

2. Open a system tie to eliminate some of the sources of fault

current,

3. Upgrade the switchgear and other overdutied equipment to higher

ratings, beyond the fault spectrum.

A. TCL Characteristics

Coming into general use during the last 2 decades, the TCLs

offer a high continuous current alternative to these techniques by

providing effective fault current limitation without the significant

losses, and without equipment upgrade or replacement. TCL energy

rejection is minimal. For example, a 15.5kV, 3000A unit rejects only

140 watts per phase. Two such Triggered Current Limiter units are

the CLiP

Current Limiting Protector and the PAF

Power Assisted

Fuse. The CLiP utilizes electronic sensing and triggering while the

PAF uses an element sensor for initiation of triggering. We will focus

on units with electronic sensing in this paper. Interrupt ratings are

40kA rms, symmetrical for all ratings with most having an optional

120kA rms, symmetrical interrupt rating. These devices have

interrupted up to 311kA rms, symmetrical at 15.7kV. The formidable

current-limiting capability at extreme fault levels adds a whole realm

of possibilities to the overcurrent protection spectrum. They are often

applied, as would a traditional current limiting fuse, to limit current

magnitude and duration from a specific source and protect one feeder

or piece of equipment. Reactor bypass and tie closure applications

and more unique to the TCL devices due to their high continuous

current capability and low losses.

B. Operation

Before a discussion of their usage, a review of their operation is

in order. Conceptually, the TCL is a high-speed switch that carries the

continuous current. Upon sensing of a fault and response by the

electronic triggering logic, the switch is opened and the current is

forced into a current-limiting fuse which interrupts the circuit. See

Fig. 1.

Figure 1. Layout of a Triggered Current Limiter

These devices are characterized by a primary conduction path,

which electrically parallels a current limiting fuse of very high energy

absorption capability and low melting I

2

t. Approximately 0.1% of the

TRIGGERING

LOGIC

CURRENT-LIMITING

SHUNT FUSE ELEMENT

CUTTING (SWITCHING)

LOCATIONS ON MAIN

CONDUCTOR

CURRENT

TRANSFORMER

POWER SUPPLY

CONNECTION

ISOLATION

STAND-OFF

INSULATOR

REPLACEABLE

INTERRUPTER

TRANSFORMER

2

continuous current flows through the shunt fuse in its normal state due

to its resistance versus that of the primary TCL current path a

busbar. Upon incident of a fault meeting the triggering criteria, the

primary current path is opened - essentially a high-speed switching

operation. This causes commutation of the fault current into the shunt

current-limiting fuse and its rapid interruption. The interrupt process

of this shunt fuse is typical of the traditional current-limiting fuse with

1/4 cycle extinction of symmetrical and 1/2 cycle extinction of

asymmetrical faults. The point of actual current limitation is often

well in advance of the time of extinction. Note that this is not at the

natural current-zero point at which most circuit breakers, switches,

reclosers and expulsion-type fuses interrupt. The one exception to

this is the reactor bypass application where the TCL is clearing

against only partial system voltage across the reactor. In this case the

clearing time is typically only a few hundred microseconds after

occurrence of the peak let-through condition. The operating

technology of TCLs has also been discussed in much greater detail

in a number of the references [1][2].

C. Coordination

From a coordination standpoint, the TCLs are catastrophic

protection devices; whereby, the lower level fault currents are

cleared by other protection devices operating within their prescribed

ratings per their standard coordination curves. It is only when the

fault capabilities of these other devices are at the point of being

exceeded that the TCL triggering logic is typically set to take over

and clear the circuit. Another factor to consider is that the continuous

current is, for all practical purposes, completely independent of the

current-limiting performance of the device. Since these are

electronically sensed and triggered units, their operating criteria is

preset and not dependent on time versus current, temperature, element

size (or melting I

2

t) or preconditions. The units described are not

dependent on rate-of-rise of fault current, but instead, are responsive

to magnitude. Specifics of fault sensing and trigger level setting as

well as the methodology of trigger level selection are topics too

lengthy for proper coverage and will not be discussed in this paper.

They are reviewed at greater length in other literature [1][4][6].

D. Energy Limitation

From a fault damage perspective, the TCLs provide a tremendous

reduction from non-current-limiting devices such as a circuit breaker.

The let-through I

2

t is approximately proportional to the fault energy

and is a common measure of damage assessment. A 5-cycle

interruption of a 40kA rms, symmetrical single-phase fault by a circuit

breaker will result in a let-through I

2

t of 133x10

6

ampere-squared

seconds. A TCL will similarly result in a maximum let-through I

2

t of

600x10

3

ampere-squared seconds a reduction to 4.5% of the

breakers [1].

The Triggered Current Limiters are useful not only as stand-

alone, but also as complementary devices to a number of the

techniques commonly employed in the protection world.

II. REACTOR BYPASS

A. Reactor Limitations

The application of reactors to a power system is a common and

effective solution to short circuit control. Unfortunately, reactors

contribute two disturbing elements to a circuit. One, they consume

substantial energy [3][7]. Two, they upset the system's voltage

regulation. Consider the regulation difficulties that a reactor

introduces into a system. Under loaded conditions, regulating voltage

drops to below 95% are not uncommon. But this 5% voltage drop can

reduce the efficiency of equipment by nearly 10% and even more in

the case of lighting systems. This is in addition to the direct energy

loss of the reactor itself. It is a substantial reduction, which may not

be tolerable. It may only be annoying, as the flicker of lights. Or

worse, it may prevent startup of large motors etc.

B. A Synergistic Effect

Bypassing the Reactor with a Triggered Current Limiter can,

however, mitigate these difficulties. The key here is that this

combination maintains the benefits of the reactor without the

operational drawbacks. It eliminates the continual energy losses

related to the resistive portion of the reactors impedance, and it

eliminates the regulating voltage across the reactor since the

impedance of the TCL is measured in micro-ohms. Furthermore, the

reactor bypass scheme eliminates the one major drawback of utilizing

the fuse by itself, specifically, that once it has operated all

downstream equipment is de-energized. The reactor is commutated

into the circuit by the TCL, during the fault, to limit current within the

breakers interrupt capability. Once the breaker clears the fault;

however, continuity to the remainder of the system is maintained

through the reactor. This is crucial to industrial facilities with critical

processes and for utilities particularly on auxiliary systems in

generating facilities. While a more costly scheme than TCLs or

reactors alone, this technique can avoid the far greater costs associated

with a complete shutdown of a process or a critical operation. Reactor

bypass applications account for approximately 30% of the TCLs.

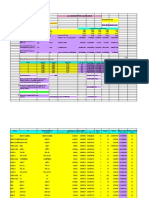

Figure 2: Example 1 and Plot 1 for Reactor Bypass

3

C. Reactor Bypass Example

Consider fig.2, a common application where the user has a circuit

breaker interrupt limitation of 20kA rms, symmetrical. The reactor is

sized to reduce the prospective fault current of 30kA down to 16kA.

The associated peak momentary current that the circuit breaker is

capable of will be approximately 2.7 times the rms, symmetrical value

of its interrupt rating. Upon occurrence of a fault, the TCL operates

and the fault current is switched from the main conduction path of the

TCL to the reactor. The reactor limits the fault magnitude to a

prospective of 16kA rms, symmetrical, within the equipment ratings

both in momentary and interrupt duty. The downstream equipment

then clears the lessened fault level. After the fault is cleared, the

reactor continues to conduct load current to the other loads on the

system, such that the critical processes of other circuits through the

reactor are not shut down or otherwise compromised. Power to other

critical loads is not lost as would happen with the TCL itself. The

bypass switches are then opened to isolate the TCL and change the

expended interrupter. Following replacement, the bypass switches are

closed to re-bypass the reactor. In the example one should note that

the peak let-through current to the system is a function of the reactor

impedance. The peak is typically not that of the TCL.

D. Application Considerations

Conditions that must be considered which are specific to applying

the TCL in parallel with a reactor are as follows:

1. The reactor circuit must be practical to begin with, in order to

be successful with the TCL.

2. Consideration must be given to single-phase and 2-phase faults.

3. Isolate the live system during fuse replacement.

4. Response of the system to reactor insertion must be reviewed.

CONDITION 1, if the circuit is not practical as a reactor circuit

alone, it will not be successful from a reactor bypass perspective. In

other words, the reactors must be of sufficient reactance value to limit

the fault currents within the equipment ratings. They must be of

sufficient fault and continuous current capability to perform their

function. In addition, the impedance must not be so high that the

voltage drop across the reactor inhibits proper system operation.

Note that there may be cases where the reactor impedance

required may be so high that its use is impractical. In these cases, the

TCL alone can usually perform the protection function, but without

the benefits of a reactor in parallel.

CONDITION 2, a major 3-phase fault will cause operation of all

three fault limiters and thereby insert all three reactor phases. The

potential user must assess the needs from the single and two-phase

fault perspective. In other words, can the system, when carrying full

load, operate without difficulty with the voltage imbalance imposed

by the insertion of only one or two reactors, while the remaining

reactors are bypassed by a TCL? More commonly, the system would

have difficulties if balance were not maintained between all three

phases. Refer to the one-line diagram in fig. 1. Note that there is an

isolation switch at each end of the TCL. If one of these is configured

with three-phase tripping and fault interrupt capability, it can be

tripped by the TCL controls to insert the remaining reactor(s). The

selection of the switch or breaker will not be discussed in detail here

but it should be noted that the duty required of this device is typically

commutating load (or limited overload) current at only the

corresponding regulating voltage imposed by that current through the

reactor. The fault will already have been cleared by either the TCL

(and current through that phase no longer exists) or by the more

immediate protection device near the fault. Some TCL users apply a

circuit breaker at one of the isolation switch locations. Others apply

lower rated devices. In order to support this function, the TCL has a

relay monitoring each individual phase of the unit. If any phase is

triggered, the relay will give a corresponding transfer. These relays

have two sets of dry form C (dpdt) contacts for customer control

interface. The response time of the relay can be as little as 2 cycles.

If the system does not have a difficulty with system imbalance, the

user has two choices. They can install the isolation switches, one

having at least loadbreak capability, and isolate the system without a

shutdown during the TCL interrupter replacement. Alternatively, they

can avoid the cost of the isolation switches by operating through the

reactors until the system can be conveniently de-energized. Users not

requiring full balance often prefer the cost savings of the latter case.

It should be noted that if all three phases of the TCL are not

triggered, that there is no need to replace the remaining untriggered

phases as is common with current limiting fuses. They are conducting

through a busbar system, not a fuse element. A fuse element alone

can be damaged or its characteristics altered by limited fault

conditions that do not melt it.

An alternative means to tripping an isolation switch should also be

noted in this paper for three-phase reactor insertion. This is the

concept of three-phase triggering of the TCL interrupters. For a single

or two-phase fault one can apply a set of pulse transformers

between phases. Thereby, for a fault with an associated operation of

any one phase, the same triggering pulse is also conducted through the

pulse transformers to the adjacent phases such that all three are

operated. This is not the preferred method for a number of reasons.

First, it is causing the non-faulted phases to attempt to be cleared by a

TCL at what may be a very modest current level. The shunt current

limiting fuse of the TCL may not melt for a low current or may take

an unacceptably long time. The shunt fuse may even attempt to clear

a current for which it is not designed, as these are typically back-up

type current limiting fuses with a minimum clear rating. This

contrasts with a known response of tripping an isolation switch.

Second, the isolation switches are generally part of the system

already. The cost of having one of the two isolation switches

configured with three phase trip and limited fault interrupt capability

is generally not a substantial cost adder when considering the overall

system. This additional cost is also mitigated by the fewer number of

interrupters used during the life of the system. One or two single or

two-phase faults may totally offset the cost of the preferred system of

operating the isolation switch.

CONDITION 3 is concerned with replacement of the triggered

interrupters. The concept here is generally that it is desirable to

replace the TCL interrupters without de-energizing the system and

shutting down critical processes. As noted in the previous section, the

system is generally configured with two isolation switches for that

purpose. Some characteristics of those switches are also discussed

there. Those performing the work to replace the interrupters should

isolate, ground and further protect the workers in full accordance with

applicable codes and practices.

CONDITION 4, a frequent question concerns the transient response

of the system during the insertion of a reactor. The exact response

falls into the realm of analysis for the systems engineer who has the

data and characteristics specific to that application. From an overall

perspective, however, one must consider that the system is already

undergoing a transient response due to the fault itself. Considering

the clearing characteristic as depicted in Fig. 2, plot 1, the reactor is

commutated into the circuit at a relatively early stage in the fault

process. The commutation at this stage is certainly of less

significance than at some later stage, at a higher current level. Over

the history of the use of TCLs in a reactor bypass application, no

disturbances specific to the insertion of a reactor have been noted.

4

III. BUS TIE CLOSURE

A. Why a Tie Closure

Often the power system engineer is facing a dilemma. It may be

a case of trying to start a large motor, or to better balance

transformer loads, or to share the output of a generator with an

adjacent bus. The overall system may possess sufficient capacity to

meet all of the needs if the tie(s) were closed. However, tie closure

results in fault currents from both buses and these may exceed the

fault ratings of the system. Extensive replacement of equipment

may be cost prohibitive. The traditional, meltable current limiting

fuse in this role is uncommon, primarily because of its low

continuous current capability. As a current limiting device capable

of very high continuous currents, the TCL excels in this role its

most common application. The tie can commonly be closed through

a TCL without replacement of equipment on either bus and without

exceeding equipment momentary or interrupt ratings [1][5].

Upon occurrence of a fault, the TCL severs the tie in a current

limiting fashion; whereby, that portion of fault current available

through it is interrupted. The magnitude is thus reduced. This

means that at some time (e.g. 2 to 5 cycles) after the TCLs

interruption, a downstream device will clear the residual fault

current, that current which was not available through the TCL.

Figure 3: Example 2 and Plot 2 for Bus Tie Application

B. Tie Closure Example

Consider the typical system in Fig. 3, Example 2. It portrays a

closed system tie. We also have a cogenerator on one side of the

tie, as is increasingly common. Assume that a fault occurs at the

location shown. We have 16kA rms, symmetrical available through

the Triggered Current Limiter for a total of 25kA. The equipment

limit is 20kA. Available currents on both sides of the tie are shown

in the plot as well as the total to the fault. Should a fault occur at

the location shown, the TCL will sense, trigger and interrupt the

available current through it. Following the TCL clearing, the buses

are separated and the downstream breaker can safely interrupt the

"residual fault," which is still supplied by the left source transformer.

It should be noted that the engineer may need to re-evaluate the

residual current contributions following the TCL clearing since both

transformers may be connected to the same source, of some finite

impedance, and the current may increase in the residual branch. While

load shedding may be necessary as a temporary measure to sustain the

left bus, critical processes or operations are commonly not dropped. It

is simply split into two systems on a temporary basis. The tie breaker

can be opened by the trip indicating relay of the TCL controls as

discussed in the Reactor Paralleling section. This would prevent a

possible single-phasing condition for those faults. Note the

disconnect switch to the right side of the TCL. Opening this and the

tie breaker will enable replacement of the expended Limiter without

de-energizing either bus.

C. Plotting the Fault Wave

Traditionally, when there are parallel sources to a fault and a

current limiting fuse protects one, an engineer will determine the

peak let-through from the fuse, via manufacturers published curves,

and add this to the peak asymmetrical crest from the other sources.

The fuse let-through from charts is a value unrelated to the angle of

fault initiation (level of asymmetry). It is a maximum value, which

may not in itself be totally accurate for that specific condition, and

does not relate to the timing of the fault wave. While this method

can be applied with TCL devices with conservative results, use of

the computer as a tool presents a clearer picture of what is

happening in the proper time perspective. Since the TCL is a

precision triggered device, the computer can project the let-through

for any specific fault magnitude, system X/R and angle of initiation

with good accuracy. This can be superimposed with other fault

current waves that are not incident through the TCL, to give a more

exacting profile, as in the associated plot. This is presently

performed for virtually all fault situations for any user. It permits

the user to visualize what is occurring without much guesswork.

Current values in the associated plot are in instantaneous terms.

This fault is depicted under fully asymmetrical conditions for a

circuit X/R of 20 (a midrange value) which will yield asymmetrical

crests of about 2.6 times the rms, symmetrical value. The upper

curve is the total prospective fault current. The shaded area depicts

the TCLs current profile. The clearing portion of the TCL plot, as

generated by the computer, is based upon the specifics of the fault

conditions combined with fuse operational characteristics. If we

add the instantaneous current of this shaded area to the "residual

current" from the faulted side of the tie (which does not flow

through the TCL), we can project the profile of the instantaneous

currents to the fault, the heavy line. Note that the system peak does

not occur at the same time as peak fuse let-thru in this example.

Also, it is not equivalent to the peak let-thru of the TCL added to the

crest of the "residual current" wave. In some other cases the peak

let-thru condition will occur at the peak let-thru point of the TCL.

Preconditions and accuracy prevent these plots with traditional

meltable-element fuses. With the aid of a computer, however, these

plots can be readily generated for virtually all TCL applications.

5

D. Application Considerations

Conditions specific to the bus tie closure application that should

be considered are as follows:

1. Rating of the TCL,

2. Single-phase fault response,

3. System response after TCL interrupt,

CONDITION 1, when selecting the TCL for a tie position, its

interrupt rating does not necessarily need to exceed the total

available fault current of the system. Only a portion of the total

available fault current will be available through the TCL. Often a

lesser rating, in excess of any foreseeable duty in the tie, will

suffice.

CONDITION 2 concerns the system response to a single-phase

or two-phase fault. Unlike the tripping of a circuit breaker that will

open all three phases and not leave a potential single-phasing

condition, interruption of a TCL, like a fuse, may be a single-phase

operation. Only the phase(s) reaching the trigger level will trigger

and interrupt. After the downstream breaker clears the residual

current, however, remaining untriggered phases of the TCL will

continue to conduct and may result in an unacceptable imbalance in

phase currents through the tie. Standard voltage sensing relay

techniques may not readily detect the difficulty since sources

reestablish full voltage at both ends of the triggered TCL after the

fault is cleared.

The TCL provides the relaying means in the user interface of its

control system for this purpose. As mentioned previously, it has a

relay monitoring each individual phase of the unit. If any phase is

triggered, the corresponding relay will transfer. These relays have

two sets of dry form C (dpdt) contacts for customer use. The

response time of the relay can be as little as 2 cycles. The user

generally configures these contacts such that any TCL operation will

cause the tie breaker to trip and thus avoid a single-phasing condition.

CONDITION 3, as mentioned prior, the current in the residual

current branch may change as the TCL interrupts. The available

fault currents may come from a variety of sources including

transformers, cogenerators, motor backfeed etc. The case that may

require an additional review concerns those sources that may have

an alternate path or means of supplying fault current after the TCL

has operated. Consider the two transformers in the prior example

(shown as impedances Z2 and Z3 in fig. 4). If they were in-turn

connected to the same source (via impedance Z1), the associated

fault current would split between Z2 and Z3 based on their values.

However, if either Z2 or Z3

becomes infinite (due to TCL

interruption of that branch), the

current in the remaining

transformer will increase.

Therefore, the residual current

also increases and the switchgear

must also be able to interrupt this

additional contribution.

Figure 4. Source Divider

IV. POWER QUALITY IMPROVEMENT

A. The Problem

Consider the system depicted in Fig. 5. It has two facilities (or

buses) supplied from the same source. Each of the facilities may

contain motors, computers, lighting systems or other critical loads.

If a fault occurs as shown, however, not only will the faulted facility

be affected, but also the unfaulted. Typical clearing times for circuit

breakers are from 3 to 5 cycles. This contrasts with lighting systems

that may drop out and require a time-consuming restart with as little

as cycle outage time. Computers may be protected by UPS

systems, but UPS systems are often not as commonly employed on

machine tools or other manufacturing equipment. Motors may fall

out of synchronism and their starters drop out by the three cycle

point. This is particularly critical in process industries where a

momentary power disturbance can result in a costly shutdown.

Figure 6: System Voltage During Fault

B. Limiting Voltage Depression

In fig.6 the system voltage is depicted for fault conditions with

and without a TCL. As can readily be noted for the upper plot, the

system voltage will be depressed during the fault period, which may

remain until the protective device clears the circuit. Explicit

percentages of depressed voltage versus operating voltage can not

be given here as they are specific to the system characteristics, fault

location and to the fault impedance. It can be noted in the lower

plot, however, that the TCL limits the time to a very short period.

Even on an asymmetrical fault, where the fault current extinction

point will be maximized for the TCL at cycle, the point of shunt

fuse melt and current limitation is typically well in advance of

current extinction. The voltage recovery of the system coincides

with the melt and subsequent clearing time. Data for the plot has

APPROXI MATI ON OF SYSTEM VOLTAGE APPROXI MATI ON OF SYSTEM VOLTAGE

PROFI LE WI THOUT AND WI TH A PROFI LE WI THOUT AND WI TH A TCL TCL

Recovered

Voltage

Fault Initiation

WI TH A TCL TCL

Depressed Voltage

Fault Initiation

WI THOUT A TCL TCL Fault Current

Recovered Voltage

Z 1

Z 2 Z 3

EXAMPLE 3 - POWER QUALITY

FAULT

LOCATION

TCL

FACILITY A FACILITY B

A fault at Facility A

will cause a temporary

undervoltage situation

at Facility B that can

cause motor starters,

computers and lighting

systems to shut down.

The TCL can also be used

to bypass reactors in this

application and maintain

continuity to the other

equipment while limiting

the voltage drop at critical

equipment.

TCL

FIGURE 5 Power Quality Example

6

been taken from a typical TCL interruption trace. It can be seen that

the condition of depressed voltage is minimal with this device.

Dropout of equipment on the adjacent bus is not expected.

What are the affects of cogenerators, or other sources in regard

to supporting voltage on the unfaulted bus? This would need to be

considered on a case by case basis by the engineer. Such factors as

the specific bus and cable impedances, cogenerator size and fault

characteristic time constants are all relevant. The application of

reactors to limit fault current, and thus support voltage on the

adjacent bus is a possibility. Again, here it is the specifics of the

system versus the reactor impedance that will determine its

practicality. The concept is to provide continuity to the faulted bus

after fault clearing. While certain equipment will be dropped, those

that can ride through the depressed voltage state will not have been

cut off by the TCL, as without the reactor. The reactor bypass

concepts are reviewed earlier in this paper.

Applications of TCLs for power quality considerations are

newer than the above topics with ones specifically dating back five

years.

V. CONCLUSIONS

The Triggered Current Limiter can be an effective tool for high

continuous current systems. It can be applied in traditional roles as

one would apply a current limiting fuse or in unique roles. Among

these are reactor bypass, tie closure and power quality applications.

Each role has its own conditions for successful application.

Likewise, each has specific benefits.

The TCL is a predictable device where its performance in the

system can be modeled by computers prior to their application.

Analysis by computer can provide a more accurate insight into the

actual conditions than by traditional analysis techniques.

REFERENCES

[1] J. Schaffer, Commutating Current-Limiters an effective

alternative for high current protection, NETA World, vol. 18,

No.4, pp. 7-18, Winter 1996-97

[2] H. M. Pflanz, et al, The development of the Current Limiting

Protector (CLP), IEEE, T-PAS, pp.3609-3619, July 1981

[3] B. E. Wharton, Application of Triggered Fault Current

Limiters in the pulp and paper industry, TAPPI Journal, vol.

75, no. 5, pp. 93-100, May 1992

[4] P. Fransen, Case history: electronically controlled fault

current limiters, IEEE-IAS Transactions, vol. 33, no. 2, pp.

319-332, March/April 1997

[5] R. J. Lawrie, High capacity cable bus updates plants

primary power, EC&M, vol. 93, no. 13, pp. 24-28, December

1994

[6] G&W Publication, Guide to the methodology of trigger level

selection for the G&W CLiP

, November 14, 1994

[7] G&W Publication, Calculating reactor losses, GW5-CLiP-

14, December 1988

BIOGRAPHY

John S. Schaffer (S73-M82-SM90) received the BSEE and

BSME degrees from Marquette University in 1974 and 1976

respectively and the MBA degree from Lewis University in 1988.

An 18 year employee of G&W Electric company, he has held

the positions of Sr. Development Engineer, Manager of Switchgear

and Fuse Engineering, and Technical Director of Project Engineering.

He has been the General Manager of its System Protection Division

since 1992. Prior to joining G&W, he was affiliated with Allis-

Chalmers Corporation for 7 years, in the engineering of high voltage

circuit breakers, motors and DC traction systems.

Mr. Schaffer is a member of the IEEE High Voltage Fuse

Subcommittee where he is active in a number of working groups on

fuse standards. He is also a member of NEMAs High Voltage Fuse

Technical Committee and other organizations.

He has authored and co-authored several technical papers on

fusing and switchgear topics and has received a number of patents in

these areas. He is a registered professional engineer in the state of

Wisconsin.

Anda mungkin juga menyukai

- AC/DC Reactor Based Solid State Fault Current Limiter: Ms. Smita A.Patil, Prof.V.R .NaphadeDokumen8 halamanAC/DC Reactor Based Solid State Fault Current Limiter: Ms. Smita A.Patil, Prof.V.R .NaphadeAnwar HossanBelum ada peringkat

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- SHORT CIRCUIT CURRENT LIMITATION TECHNIQUESDokumen13 halamanSHORT CIRCUIT CURRENT LIMITATION TECHNIQUESariefBelum ada peringkat

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesDari EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesBelum ada peringkat

- PEC006Dokumen7 halamanPEC006Ravi Kiran BBelum ada peringkat

- Jetir1712042 2Dokumen11 halamanJetir1712042 2rajeevBelum ada peringkat

- Reactive Power Compensation Using A Voltage Source GeneratorDokumen10 halamanReactive Power Compensation Using A Voltage Source GeneratorkubikBelum ada peringkat

- Basic Concepts of Superconducting Fault Current Limiter: Deeksha Sharmal and Kishan Bhushan Sahay2Dokumen5 halamanBasic Concepts of Superconducting Fault Current Limiter: Deeksha Sharmal and Kishan Bhushan Sahay2Pankaj SharmaBelum ada peringkat

- SFCLDokumen49 halamanSFCLsameerBelum ada peringkat

- Selection of ArresterRatingsDokumen3 halamanSelection of ArresterRatingshaitpmBelum ada peringkat

- Chewale2019 PDFDokumen7 halamanChewale2019 PDFOppo k 13Belum ada peringkat

- Energy Efficiency Technical Guide: How To Select and Maintain Contactors For Capacitor Banks?Dokumen16 halamanEnergy Efficiency Technical Guide: How To Select and Maintain Contactors For Capacitor Banks?SorinDanielMoisaBelum ada peringkat

- Oltc 2Dokumen4 halamanOltc 2Saravana Prakash PBelum ada peringkat

- Motor Protection Circuit Breaker Design BasicsDokumen15 halamanMotor Protection Circuit Breaker Design BasicsKI OHBelum ada peringkat

- A Lecture On Current LimiterDokumen25 halamanA Lecture On Current LimiterLavanya VallbhareddyBelum ada peringkat

- SuperConducting Fault Current LimiterDokumen25 halamanSuperConducting Fault Current LimiterLalit Kumar Verma64% (11)

- Zenergy Power mFCL Protects Electrical GridDokumen8 halamanZenergy Power mFCL Protects Electrical GridBruno SousaBelum ada peringkat

- Review of a simple adjustable power supply using linear and switching componentsDokumen4 halamanReview of a simple adjustable power supply using linear and switching componentsramesh ranjitBelum ada peringkat

- REG NO 23 (Talha Saleem)Dokumen4 halamanREG NO 23 (Talha Saleem)Talha ChaudryBelum ada peringkat

- Technical Subjective QuestionsDokumen52 halamanTechnical Subjective QuestionsEngr AHmed Ali DallBelum ada peringkat

- Current Limiting Reactor Allocation in Distribution Networks in Presence of Distributed GenerationDokumen15 halamanCurrent Limiting Reactor Allocation in Distribution Networks in Presence of Distributed GenerationarsalanhamidBelum ada peringkat

- Subject (Reg198) - Improvement of Power QualityDokumen10 halamanSubject (Reg198) - Improvement of Power QualitysorrowarBelum ada peringkat

- Five Switching Devices You Are Likely To Spot in Most of The Low Voltage SwitchgearDokumen15 halamanFive Switching Devices You Are Likely To Spot in Most of The Low Voltage SwitchgearHaris MakrigiannakisBelum ada peringkat

- Report Presentation MSETCL KalwaDokumen38 halamanReport Presentation MSETCL KalwaManish Kumar Bhardwaj100% (1)

- Application Note - Co-Ordination of Protection DeviceDokumen8 halamanApplication Note - Co-Ordination of Protection DeviceRavishankar.AzadBelum ada peringkat

- Overview of Power System ProtectionDokumen20 halamanOverview of Power System ProtectionTana AzeezBelum ada peringkat

- Enhancement of Power Quality Using DstatcomDokumen51 halamanEnhancement of Power Quality Using DstatcomKeerthi Ambati50% (2)

- Differential Protection for Power Transformers Using RelayDokumen5 halamanDifferential Protection for Power Transformers Using RelayChandan DwivediBelum ada peringkat

- Introduction To Power Systems: 1.1: A.C Transmission SystemDokumen23 halamanIntroduction To Power Systems: 1.1: A.C Transmission Systemkar1740Belum ada peringkat

- K&R Consulting 2004 TOV Limit Report SummaryDokumen8 halamanK&R Consulting 2004 TOV Limit Report Summaryhino_kaguBelum ada peringkat

- Relay Circuit Breaker ApplicationDokumen58 halamanRelay Circuit Breaker Applicationtenk_manBelum ada peringkat

- Circuit Breaker Ratings Guide for Protection EngineersDokumen13 halamanCircuit Breaker Ratings Guide for Protection EngineersAlberto José Bermúdez AriasBelum ada peringkat

- Tap ChangerDokumen6 halamanTap ChangermshahidshaukatBelum ada peringkat

- WP131001EN PDFXHRXHRDokumen8 halamanWP131001EN PDFXHRXHRbalwant_negi7520Belum ada peringkat

- BackgroundDokumen21 halamanBackgroundMaxwellBelum ada peringkat

- Power Factor ThesisDokumen5 halamanPower Factor Thesisjessicatannershreveport100% (1)

- Power Quality AssignmentDokumen6 halamanPower Quality Assignmentazzam_aliBelum ada peringkat

- Chapter One: Introduction 1.1 Background of The StudyDokumen30 halamanChapter One: Introduction 1.1 Background of The StudyUzoma FrancisBelum ada peringkat

- SBEF and REFDokumen8 halamanSBEF and REFadhyartha100% (1)

- Solid-State Circuit Breakers and Current Limiters For Medium-Voltage Systems Having Distributed Power SystemsDokumen8 halamanSolid-State Circuit Breakers and Current Limiters For Medium-Voltage Systems Having Distributed Power Systemsrazila rasheedBelum ada peringkat

- Substation Protection Devices ExplainedDokumen14 halamanSubstation Protection Devices ExplainednikcsitBelum ada peringkat

- Automated Fault Clearance Using Fault Current Limiter in Primary Distribution SystemDokumen6 halamanAutomated Fault Clearance Using Fault Current Limiter in Primary Distribution SystemIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalBelum ada peringkat

- Custom Power Applications OverviewDokumen7 halamanCustom Power Applications OverviewsunilgurubaxaniBelum ada peringkat

- Module-4 Reactive Power Compensation and Voltage ControlDokumen24 halamanModule-4 Reactive Power Compensation and Voltage ControlDeepak GowdaBelum ada peringkat

- MetalEnclosed MV SwitchgearDokumen7 halamanMetalEnclosed MV SwitchgearadauBelum ada peringkat

- Proteccion Diferencial de BarrasDokumen19 halamanProteccion Diferencial de BarrasSalvador Gutierrez CruzBelum ada peringkat

- Module-4 Reactive Power Compensation and Voltage ControlDokumen24 halamanModule-4 Reactive Power Compensation and Voltage ControlNiharikaBelum ada peringkat

- Solid State Tap Changer PresentationDokumen17 halamanSolid State Tap Changer PresentationSujit GangurdeBelum ada peringkat

- REducing ArcFlash Hazard-RELT Final-GEDokumen11 halamanREducing ArcFlash Hazard-RELT Final-GEmojsic6313Belum ada peringkat

- Implementation of Solid State Relays For Power System ProtectionDokumen6 halamanImplementation of Solid State Relays For Power System ProtectionChala DeyesaBelum ada peringkat

- GCBDokumen10 halamanGCBRavishankar.AzadBelum ada peringkat

- Different Types of Bus Bar ArrangementDokumen18 halamanDifferent Types of Bus Bar ArrangementRajeshRaman67% (3)

- Power Quality ProblemsDokumen41 halamanPower Quality ProblemsDomingo RuizBelum ada peringkat

- Power Quality Lab Manual (EE-801)Dokumen12 halamanPower Quality Lab Manual (EE-801)ASHU KBelum ada peringkat

- Assignment 2: Bee3143 - Power System AnalysisDokumen35 halamanAssignment 2: Bee3143 - Power System AnalysissalamBelum ada peringkat

- Protective Relay FundamentalsDokumen95 halamanProtective Relay FundamentalsAnirban Bandyopadhyay50% (2)

- Elements of SubstationDokumen35 halamanElements of Substationjustog_12Belum ada peringkat

- BSB Circular Ride-Through Solutions For Voltage Dip Problems in BuildingsDokumen21 halamanBSB Circular Ride-Through Solutions For Voltage Dip Problems in BuildingsYeung HofanBelum ada peringkat

- IBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECDokumen10 halamanIBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECVíctor RojasBelum ada peringkat

- Rtaa IomDokumen140 halamanRtaa IomFabian Lopez100% (1)

- Bussman - How To Size A FuseDokumen15 halamanBussman - How To Size A FuseSJS68Belum ada peringkat

- Rtaa Svx01a en - 09012005Dokumen178 halamanRtaa Svx01a en - 09012005jars03180950100% (1)

- HVAC & Refrigeration SystemDokumen22 halamanHVAC & Refrigeration SystemSivakumar NadarajaBelum ada peringkat

- Calculate Fault LevelsDokumen46 halamanCalculate Fault LevelsPichumani100% (4)

- 4 1 PDFDokumen28 halaman4 1 PDFVíctor RojasBelum ada peringkat

- Bureau of Energy EfficiencyDokumen23 halamanBureau of Energy Efficiencypbs0707Belum ada peringkat

- Wiring Diagram-Split System Air ConditionerDokumen1 halamanWiring Diagram-Split System Air ConditionerSohail Ejaz Mirza83% (12)

- 3 CH 2Dokumen20 halaman3 CH 2Mary HarrisonBelum ada peringkat

- Electrical Standard Products: Switchgear Training Centre, CoonoorDokumen20 halamanElectrical Standard Products: Switchgear Training Centre, CoonoorVíctor RojasBelum ada peringkat

- 4 4Dokumen34 halaman4 4Samir Ranjan ParidaBelum ada peringkat

- Selective Coordination EATONDokumen22 halamanSelective Coordination EATONBrenda Naranjo MorenoBelum ada peringkat

- MCC 15B CalculationV3Dokumen2 halamanMCC 15B CalculationV3Wimalasiri DissanayakeBelum ada peringkat

- Case Studies On Paralleling of TransformersDokumen7 halamanCase Studies On Paralleling of Transformersmuaz_aminu1422Belum ada peringkat

- MCC & ContactorsDokumen9 halamanMCC & ContactorsbimboawotikuBelum ada peringkat

- LT Cable Sizing Calculation SheetDokumen12 halamanLT Cable Sizing Calculation Sheet2003vinay100% (5)

- UPSDokumen63 halamanUPSgavinilaa100% (1)

- AP01200003E - Fault Current - Coordination CalculatorDokumen13 halamanAP01200003E - Fault Current - Coordination CalculatorVíctor RojasBelum ada peringkat

- Parcial 1 Distribuciones Abril-Jul 2010Dokumen12 halamanParcial 1 Distribuciones Abril-Jul 2010Víctor RojasBelum ada peringkat

- Constr Esb750Dokumen127 halamanConstr Esb750Erica MosesBelum ada peringkat

- 11 KV transformer and power system analysisDokumen18 halaman11 KV transformer and power system analysisAbdulyunus Amir100% (1)

- Cable size calculation chart for electrical installationsDokumen6 halamanCable size calculation chart for electrical installationsnicrajesh90% (10)

- Setting Calulation For Gen Tms TRF and BusbarDokumen10 halamanSetting Calulation For Gen Tms TRF and BusbarVíctor Rojas100% (1)

- Assignment SUBJECT: Industrial Power System Analysis and DesignDokumen1 halamanAssignment SUBJECT: Industrial Power System Analysis and DesignthavaselvanBelum ada peringkat

- Temp CalculationDokumen1 halamanTemp CalculationVíctor RojasBelum ada peringkat

- Short Circuit HayabusaDokumen3 halamanShort Circuit Hayabusameeng2014Belum ada peringkat

- Cable CalcDokumen7 halamanCable CalcVíctor RojasBelum ada peringkat

- Relay Setting CoordinationDokumen8 halamanRelay Setting Coordinationsmepp100% (2)

- 4.Ht Short Circuir CalculationDokumen11 halaman4.Ht Short Circuir CalculationPrabhash VermaBelum ada peringkat

- Power Electronics MCQ with AnswersDokumen3 halamanPower Electronics MCQ with AnswersSanjoy PathakBelum ada peringkat

- AMC1301 Precision, 250-mV Input, 3 - S Delay, Reinforced Isolated AmplifierDokumen36 halamanAMC1301 Precision, 250-mV Input, 3 - S Delay, Reinforced Isolated AmplifierShanon RustoffBelum ada peringkat

- Beni Suief 3rd TH Year Electrical Sheet 2 MeasuremntsDokumen5 halamanBeni Suief 3rd TH Year Electrical Sheet 2 MeasuremntsengshimaaBelum ada peringkat

- Tepper - Basic Radio Repair 1-2Dokumen224 halamanTepper - Basic Radio Repair 1-2SamKari100% (1)

- Boost Converter Design Tips: Alan MartinDokumen45 halamanBoost Converter Design Tips: Alan MartinMuhammad Abd JalilBelum ada peringkat

- Class 2 Electrical Sorted QuestionsDokumen8 halamanClass 2 Electrical Sorted QuestionsPrakhyati RautBelum ada peringkat

- Signet Advanced Troubleshooting Guide HB600 Marcação.Dokumen8 halamanSignet Advanced Troubleshooting Guide HB600 Marcação.Lucas CouraBelum ada peringkat

- Comsat S University Islamabad: Course Title: Course Name: Lab: Group MembersDokumen3 halamanComsat S University Islamabad: Course Title: Course Name: Lab: Group MembersMalik ZohaibBelum ada peringkat

- Generator Protection 7UM62Dokumen39 halamanGenerator Protection 7UM62Reji Kurian100% (1)

- Shunt ReactorDokumen6 halamanShunt ReactorvinaykumaarBelum ada peringkat

- Adafruit INA219 Current Sensor Breakout: Created by Lady AdaDokumen28 halamanAdafruit INA219 Current Sensor Breakout: Created by Lady AdamegadaveBelum ada peringkat

- Design Guide: TLP5214A Smart Gate Driver Coupler Inverter ApplicationsDokumen27 halamanDesign Guide: TLP5214A Smart Gate Driver Coupler Inverter ApplicationsMuleBelum ada peringkat

- Online Examination Internal - I - 2017 - 18.: Signature of ExaminerDokumen11 halamanOnline Examination Internal - I - 2017 - 18.: Signature of ExaminerDeepan DattaBelum ada peringkat

- Appliance DiagnosisDokumen76 halamanAppliance Diagnosisjergreen6100% (1)

- PTI RAW - Version 30 Manual PsseDokumen49 halamanPTI RAW - Version 30 Manual PssedmauriciosBelum ada peringkat

- HI 800 161 E HIMatrix F3 AIO 8 4 01Dokumen56 halamanHI 800 161 E HIMatrix F3 AIO 8 4 01M Azri ZulkipliBelum ada peringkat

- IEEE 115 Measure Shaft VoltageDokumen36 halamanIEEE 115 Measure Shaft Voltagepklake1036100% (5)

- BEE Lab Manual (2021-2022)Dokumen31 halamanBEE Lab Manual (2021-2022)Anusha KBelum ada peringkat

- 208 B InstrumentationDokumen340 halaman208 B InstrumentationRK Singh0% (2)

- 2008 Easypact CatalogueDokumen80 halaman2008 Easypact Cataloguebeckam88Belum ada peringkat

- Current transducers hall effectDokumen5 halamanCurrent transducers hall effectDaniel Rolando Gutierrez FuentesBelum ada peringkat

- Modeling of Free-Air ArcsDokumen20 halamanModeling of Free-Air Arcshalel111Belum ada peringkat

- Wonder® RGR: Retractable Bypass Conductor For Floating Roof TanksDokumen9 halamanWonder® RGR: Retractable Bypass Conductor For Floating Roof TanksrazmirarazakBelum ada peringkat

- Current-Limiting Reactors: Design, Installation and OperationDokumen12 halamanCurrent-Limiting Reactors: Design, Installation and OperationAhsn ShkBelum ada peringkat

- Cable Fault Location Manual - 2021Dokumen343 halamanCable Fault Location Manual - 2021muhd ezadBelum ada peringkat

- Circuit Breaker UvtDokumen2 halamanCircuit Breaker Uvthasbi fadliBelum ada peringkat

- Verification of Superposition TheoremDokumen2 halamanVerification of Superposition Theoremsubbu2051100% (1)

- Multiple Output Power SupplyDokumen15 halamanMultiple Output Power SupplyElvis JoelBelum ada peringkat

- IRMCS3041: Sensorless Motor Drive Platform For Appliance Based On iMOTION ChipsetDokumen11 halamanIRMCS3041: Sensorless Motor Drive Platform For Appliance Based On iMOTION ChipsetAmirBelum ada peringkat