Timing HTD Belt&Pulley Designation

Diunggah oleh

Machineryeng0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

55 tayangan2 halamanTiming HTD Belt&Pulley Designation

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniTiming HTD Belt&Pulley Designation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

55 tayangan2 halamanTiming HTD Belt&Pulley Designation

Diunggah oleh

MachineryengTiming HTD Belt&Pulley Designation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

A higher-performance tooth design for applications where accuracy is critical,

such as computer printers and storage equipment, robotic, and medical

diagnostic equipment.

PowerGrip GT offers:

Up to 50% greater load carrying capacity over HTD and trapezoidal timing

belt drives.

More uniform belt tooth wear.

Excellent registration.

Excellent tooth ratcheting resistance.

Minimal tooth wear, noise and vibration.

Excellent entry and exit qualities.

The Competition?

The PowerGrip GT belt has been tested against the competition, under

equivalent conditions, at speeds up to 9,000 RPM. It outlasted the competition

more than two to one. Strong fiberglass tensile cords wrapped in a durable

neoprene body give it flexibility and increased service life. A deep tooth profile

provides superior load carrying strength and greatly reduces ratcheting.

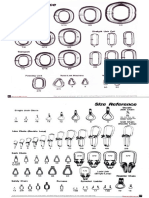

Timing Pulley Part Number Identification

B & B Manufacturing offers thousands of off-the-shelf timing pulleys. All of our stock sizes are

listing in our online catalog. Our part numbers are similar to that of other manufacturers but offer

some additional information. Below is an explanation of our numbering system.

Example 1: Trapezoidal shaped tooth minimum plain bore: 16XL037-6FA3

Number of Teeth Pitch Belt Width Construction Material Bore Size

16 XL 037 6F A 3

Example 2: Curvilinear shaped tooth minimum plain bore: 15-3M09-6CA2

Number of Teeth Pitch Belt Width Construction Material Bore Size

15 3M 09 6C A 2

Example 3: Timing pulleys bored for QD or Taper-look style bushings: TL28L050

Bushing Style Number of Teeth Pitch Belt Width

TL 28 L 050

Listed below are the codes for the various types of pulley configurations we offer.

Pitch Belt Width Belt Width Construction Material Bore Size

MP =0.080 012 =1/8 03 =3mm 6C A =Aluminum 0=3/32

LT =0.0816 187 =3/16 06 =6mm 6F S=Steel or iron 1 =1/8

XL =0.200 025 =1/4 09 =9mm 3F 2 =3/16

L =0.375 312 =5/16 10 =10mm 6 3 =1/4

H =0.500 037 =3/8 15 =15mm 6W 4 =5/16

3M =3mm 050 =1/2 16 =16mm 5 =3/8

5M =5mm 075 =3/4 20 =20mm 6 =1/2

8M =8mm 100 =1 25 =25mm 7 =5/8

2P =2mm PGGT 150 =1 1/2 30 =30mm 8 =3/4

3P =3mm PGGT 200 =2 32 =32mm 9 =7/8

T2.5 =2.5mm 300 =3 50 =50mm 10 =1

T5 =5mm 85 =85mm 11 =1 1/8

T10 =10mm

AT5 =5mm

AT10 =10mm

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDokumen53 halamanОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDokumen25 halamanHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDokumen25 halamanHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- SOP Number Insert Number: Standard Operating ProcedureDokumen2 halamanSOP Number Insert Number: Standard Operating ProcedureLawBelum ada peringkat

- Compressor MountingDokumen41 halamanCompressor MountingjmacarroBelum ada peringkat

- Lifts and Hoists Maintenance Tasks PDFDokumen19 halamanLifts and Hoists Maintenance Tasks PDFMachineryengBelum ada peringkat

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDokumen16 halamanBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengBelum ada peringkat

- RINA Rules For The Classification 2015 Part B CH 5 To 8Dokumen190 halamanRINA Rules For The Classification 2015 Part B CH 5 To 8Jorge Isaac Mendoza MarchanBelum ada peringkat

- Selection of Material Nace - H2S - Technical Paper PDFDokumen21 halamanSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009Belum ada peringkat

- Solution To Quiz 1 Fluid MechanicsDokumen7 halamanSolution To Quiz 1 Fluid MechanicsMark Augusto V. AgusBelum ada peringkat

- Piston Engine 1 2017Dokumen4 halamanPiston Engine 1 2017Training Manager SOA100% (1)

- Hsg253 The Safe Isolation of Plant and EquipmentDokumen81 halamanHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayBelum ada peringkat

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDokumen23 halamanCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengBelum ada peringkat

- LG Air Conditioner F24AHJ-NT5, F24AHJ-NT5 Service Manual PDFDokumen62 halamanLG Air Conditioner F24AHJ-NT5, F24AHJ-NT5 Service Manual PDFIoannis PerperisBelum ada peringkat

- Transmission Line Tower DesignDokumen70 halamanTransmission Line Tower DesignArgaw Tadi100% (2)

- Sulzer RTA air start valve operating principleDokumen5 halamanSulzer RTA air start valve operating principleHrishikesh More100% (1)

- Norsok ST 2001Dokumen131 halamanNorsok ST 2001mamounsdBelum ada peringkat

- Api 617 CameronDokumen31 halamanApi 617 CameronMachineryengBelum ada peringkat

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDokumen1 halamanBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraBelum ada peringkat

- UtilityDokumen8 halamanUtilityAmit JainBelum ada peringkat

- Lip Seal Installation PDFDokumen11 halamanLip Seal Installation PDFMachineryengBelum ada peringkat

- Seal Design GuideDokumen119 halamanSeal Design GuideaytepeBelum ada peringkat

- JC Gasket CranfoilDokumen2 halamanJC Gasket CranfoilMachineryengBelum ada peringkat

- Manual Best Management PortsDokumen156 halamanManual Best Management PortsAchraf DouiriBelum ada peringkat

- ESA Best Available Techniques Issue 1Dokumen4 halamanESA Best Available Techniques Issue 1vprochockyBelum ada peringkat

- SOP Templates 03Dokumen1 halamanSOP Templates 03MachineryengBelum ada peringkat

- Steam TurbinesDokumen8 halamanSteam Turbinesspalaniyandi100% (1)

- Seal Design For High Pressure Offshore-Morton & EvansDokumen10 halamanSeal Design For High Pressure Offshore-Morton & EvansMachineryengBelum ada peringkat

- Borsig BZM - 2016 - EngDokumen84 halamanBorsig BZM - 2016 - EngMachineryengBelum ada peringkat

- Pit Ot Tube Pump TechnologyDokumen12 halamanPit Ot Tube Pump TechnologymariasofiarossiBelum ada peringkat

- Creating A World That Doesnt BreakdownDokumen23 halamanCreating A World That Doesnt BreakdownmersiumBelum ada peringkat

- Lifiting Chain Size Referance PDFDokumen1 halamanLifiting Chain Size Referance PDFMachineryengBelum ada peringkat

- Compressor Turbo-Air API a4-IRDokumen12 halamanCompressor Turbo-Air API a4-IRMachineryengBelum ada peringkat

- BORSIG Valve PresentationDokumen18 halamanBORSIG Valve PresentationMachineryengBelum ada peringkat

- Perf Improv To Aches Rev 0Dokumen16 halamanPerf Improv To Aches Rev 0Poncho RmzBelum ada peringkat

- SVS.435 Steam Turbine Control UpgradesDokumen4 halamanSVS.435 Steam Turbine Control UpgradesMachineryengBelum ada peringkat

- (WM) L200 (Ka#,kb#)Dokumen1 halaman(WM) L200 (Ka#,kb#)Gabriel HreczyńskiBelum ada peringkat

- Soil Deformation Pattern Around Laterally Loaded PilesDokumen11 halamanSoil Deformation Pattern Around Laterally Loaded PilesPEdro Omar Bengochea-StaufferBelum ada peringkat

- 1618 TP-Sales Kit AMW 1618Dokumen23 halaman1618 TP-Sales Kit AMW 1618niharjyotilahonBelum ada peringkat

- Nabl 107 PDFDokumen29 halamanNabl 107 PDFGurdeep SinghBelum ada peringkat

- Prospectus 2019 PDFDokumen178 halamanProspectus 2019 PDFPratik GuptaBelum ada peringkat

- Caddy Rod LockDokumen16 halamanCaddy Rod LockcrisalevBelum ada peringkat

- Requirements of The Good Water Distribution SystemDokumen2 halamanRequirements of The Good Water Distribution SystemCassey Reign MendozaBelum ada peringkat

- Service and Maintenance Manual AFPX 513Dokumen146 halamanService and Maintenance Manual AFPX 513Cesar Fabián Padilla Garzón100% (3)

- 2.875 P110 8.70ppf PH6-TS6Dokumen1 halaman2.875 P110 8.70ppf PH6-TS6Giana KoesoemahBelum ada peringkat

- CHM 101 Lecture Note-Gas LawsDokumen11 halamanCHM 101 Lecture Note-Gas LawsMichael DanielsBelum ada peringkat

- Fluid Mechanics-Fluid Dynamics PDFDokumen3 halamanFluid Mechanics-Fluid Dynamics PDFCristian OmacBelum ada peringkat

- June 2008 QP - M1 EdexcelDokumen13 halamanJune 2008 QP - M1 EdexcelKollol KolllolBelum ada peringkat

- พอฤทัย วิริยะภาค26 3.5Dokumen2 halamanพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคBelum ada peringkat

- Activated Sludge Rheology A Critical Review On Data Collection and ModellingDokumen20 halamanActivated Sludge Rheology A Critical Review On Data Collection and ModellingZohaib Ur RehmanBelum ada peringkat

- Catalogo Medidor Gt3Dokumen12 halamanCatalogo Medidor Gt3luis_d_mBelum ada peringkat

- Technical Data PM50-6ADokumen3 halamanTechnical Data PM50-6ADodi HermawanBelum ada peringkat

- Manual Termostato Digitall t6812 FancoilDokumen4 halamanManual Termostato Digitall t6812 FancoilaarroyofBelum ada peringkat

- HPCL Syllabus 2021 All BranchDokumen8 halamanHPCL Syllabus 2021 All BranchVineeth GangaBelum ada peringkat

- An Introduction To Marine Composites: Paul H. MillerDokumen36 halamanAn Introduction To Marine Composites: Paul H. MillerGregory ChuaBelum ada peringkat

- Installation Instructions: CautionDokumen4 halamanInstallation Instructions: CautionVMBelum ada peringkat

- Addition - Toyota CamryDokumen3 halamanAddition - Toyota CamryVivek VikramBelum ada peringkat

- .Catálogo PRESSOSTATO SUCO 2Dokumen10 halaman.Catálogo PRESSOSTATO SUCO 2Fernando MoraesBelum ada peringkat

- P4. Fungsi Keadaan Dan Diferensial EksakDokumen8 halamanP4. Fungsi Keadaan Dan Diferensial EksakAnis AnisaBelum ada peringkat