Form Work

Diunggah oleh

aditya2053Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Form Work

Diunggah oleh

aditya2053Hak Cipta:

Format Tersedia

Formwork is the term given to either temporary or permanent molds into which concrete or similar

materials are poured. In the context of concrete construction, the falsework supports the shuttering

moulds.

Contents

[hide]

1 Formwork and concrete form types

2 Slab formwork (deck formwork)

o 2.1 History

o 2.2 Timber beam slab formwork

o 2.3 Traditional slab formwork

o 2.4 Metal beam slab formwork

o 2.5 Modular slab formwork

o 2.6 Table or flying form systems

2.6.1 Structure

2.6.2 Support

2.6.3 Size

o 2.7 Tunnel forms

o 2.8 Cassette formwork

3 Usage

4 Gallery

5 See also

6 Literature

7 References

8 External links

Formwork and concrete form types[edit]

Formwork comes in several types:

1. Traditional timber formwork. The formwork is built on site out of timber and plywood or

moisture-resistant particleboard. It is easy to produce but time-consuming for larger

structures, and the plywood facing has a relatively short lifespan. It is still used extensively

where the labour costs are lower than the costs for procuring reusable formwork. It is also

the most flexible type of formwork, so even where other systems are in use, complicated

sections may use it.

2. Engineered Formwork System. This formwork is built out of prefabricated modules with a

metal frame (usually steel or aluminium) and covered on the application (concrete) side with

material having the wanted surface structure (steel, aluminum, timber, etc.). The two major

advantages of formwork systems, compared to traditional timber formwork, are speed of

construction (modular systems pin, clip, or screw together quickly) and lower life-cycle costs

(barring major force, the frame is almost indestructible, while the covering if made of wood;

may have to be replaced after a few - or a few dozen - uses, but if the covering is made with

steel or aluminium the form can achieve up to two thousand uses depending on care and

the applications).

3. Re-usable plastic formwork. These interlocking and modular systems are used to build

widely variable, but relatively simple, concrete structures. The panels are lightweight and

very robust. They are especially suited for low-cost, mass housing schemes.

4. Permanent Insulated Formwork. This formwork is assembled on site, usually out of insulating

concrete forms (ICF). The formwork stays in place after the concrete has cured, and may

provide advantages in terms of speed, strength, superior thermal and acousticinsulation,

space to run utilities within the EPS layer, and integrated furring strip for cladding finishes.

5. Coffor is a structural stay-in-place formwork system to build constructions in concrete. It is

composed of two filtering grids reinforced by vertical stiffeners and linked by articulated

connectors that can be folded for transport. A standard panel 1.10 m x 2.70 m (3' 8 x 9)

weighs 32.7 kg (72 lbs) and can be carried by hand. After Coffor is placed, concrete is

poured between the grids: excess water of concrete is eliminated by gravity and air is also

eliminated. Coffor remains in the construction after concrete is poured and acts as

reinforcement. Any type of construction can be built with Coffor: individual houses, multi-

story buildings including high-rise buildings, industrial , commercial or administrative

buildings. Several types of civil works can be done with Coffor. Coffor is delivered

completely assembled from the factory. No assembly is necessary on the construction site.

6. Stay-In-Place structural formwork systems. This formwork is assembled on site, usually out

of prefabricated fiber-reinforced plasticforms. These are in the shape of hollow tubes, and

are usually used for columns and piers. The formwork stays in place after the concrete has

cured and acts as axial and shear reinforcement, as well as serving to confine the concrete

and prevent against environmental effects, such as corrosion and freeze-thaw cycles.

Slab formwork (deck formwork)[edit]

Pantheon dome

Schematic sketch of traditional formwork

Modular formwork with deck for housing project in Chile

Steel and plywood formwork for poured in place concrete foundation

History[edit]

Some of the earliest examples of concrete slabs were built by Roman engineers. Because concrete

is quite strong in resisting compressive loads, but has relatively poor tensile or torsional strength,

these early structures consisted of arches, vaults and domes. The most notable concrete structure

from this period is the Pantheon in Rome. To mould this structure, temporary scaffolding and

formwork or falsework was built in the future shape of the structure. These building techniques were

not isolated to pouring concrete, but were and are widely used inmasonry. Because of the

complexity and the limited production capacity of the building material, concretes rise as a favored

building material did not occur until the invention of Portland cement (and developments by

the Edison Portland Cement Company) and reinforced concrete.

Timber beam slab formwork[edit]

Similar to the traditional method, but stringers and joist are replaced with engineered wood beams

and supports are replaced with metal props. This makes this method more systematic and reusable.

Traditional slab formwork[edit]

Traditional timber formwork on a jetty in Bangkok

On the dawn of the rival of concrete in slab structures, building techniques for the temporary

structures were derived again from masonry and carpentry. The traditional slab formwork technique

consists of supports out of lumber or young tree trunks, that support rows of stringers assembled

roughly 3 to 6 feet or 1 to 2 metres apart, depending on thickness of slab. Between these stringers,

joists are positioned roughly 12 inches, 30 centimeters apart upon which boards or plywood are

placed. The stringers and joists are usually 4 by 4 inch or 4 by 6 inch lumber. The most common

imperial plywood thickness is inch and the most common metric thickness is 18 mm.

Metal beam slab formwork[edit]

Similar to the traditional method, but stringers and joist are replaced with aluminium forming systems

or steel beams and supports are replaced with metal props. This also makes this method more

systematic and reusable. Aluminum beams are fabricated as telescoping units which allows them to

span supports that are located at varying distances apart. Telescoping aluminium beams can be

used and reused in the construction of structures of varying size.

Hand setting modular aluminum deck formwork

Handset modular aluminum formwork

Modular slab formwork[edit]

These systems consist of prefabricated timber, steel or aluminum beams and formwork modules.

Modules are often no larger than 3 to 6 feet or 1 to 2 metres in size. The beams and formwork are

typically set by hand and pinned, clipped, or screwed together. The advantages of a modular system

are: does not require a crane to place the formwork, speed of construction with unskilled labor,

formwork modules can be removed after concrete sets leaving only beams in place prior to

achieving design strength.

Table or flying form systems[edit]

United States Patent 4036466.

These systems consist of slab formwork "tables" that are reused on multiple stories of a building

without being dismantled. The assembled sections are either lifted per elevator or "flown" by crane

from one story to the next. Once in position the gaps between the tables or table and wall are filled

with "fillers". They vary in shape and size as well as their building material. The use of these systems

can greatly reduce the time and manual labor involved in setting and striking the formwork. Their

advantages are best utilized by large area and simple structures. It is also common for architects

and engineers to design building around one of these systems.

Flying formwork tables with aluminium and timber joists. The tables are supported by shoes attached to previously

poured columns and walls

Structure[edit]

A table is built pretty much the same way as a beam formwork but the single parts of this system are

connected together in a way that makes them transportable. The most common sheathing

isplywood, but steel and fiberglass are also in use. The joists are either made from timber, wood I-

beams, aluminium or steel. The stringers are sometimes made of wood I-beams but usually from

steel channels. These are fastened together (screwed, weld or bolted) to become a "deck". These

decks are usually rectangular but can also be other shapes.

Support[edit]

All support systems have to be height adjustable to allow the formwork to be placed at the correct

height and to be removed after the concrete is cured. Normally adjustable metal props similar to (or

the same as) those used by beam slab formwork are used to support these systems. Some systems

combine stringers and supports into steel or aluminum trusses. Yet other systems use metal frame

shoring towers, which the decks are attached to. Another common method is to attach the formwork

decks to previously cast walls or columns,thus eradicating the use of vertical props altogether. In this

method, adjustable support shoes are bolted through holes (sometimes tie holes) or attached to cast

anchors.

Size[edit]

The size of these tables can vary from 70 to 1,500 square feet (6.5 to 139.4 m

2

). There are two

general approaches in this system:

1. Crane handled: this approach consists of assembling or producing the tables with a large

formwork area that can only be moved up a level by crane. Typical widths can be 15, 18 or

20 ft. or 5 to 7 metres but their width can be limited, so that it is possible to transport them

assembled, without having to pay for an oversize load. The length might vary and can be up

to 100 ft. (or more) depending on the crane capacity. After the concrete is cured,

the decks are lowered and moved with rollers or trolleys to the edge of the building. From

then on the protruding side of the table is lifted by crane while the rest of the table is rolled

out of the building. After the centre of gravity is outside of the building the table is attached

to another crane and flown to the next level or position.

This technique is fairly common in the United States and east Asian countries. The advantages of

this approach are the further reduction of manual labour time and cost per unit area of slab and a

simple and systematic building technique. The disadvantages of this approach are the necessary

high lifting capacity of building site cranes, additional expensive crane time, higher material costs

and little flexibility.

1. Crane fork or elevator handled:

Formwork tables in use at a building site with more complicated structural features

By this approach the tables are limited in size and weight. Typical widths are between 6 to 10 ft or 2

to 3 meters, typical lengths are between 12 and 20 ft or 4 to 7 metres, though table sizes may vary in

size and form. The major distinction of this approach is that the tables are lifted either with a crane

transport fork or by material platform elevators attached to the side of the building. They are usually

transported horizontally to the elevator or crane lifting platform singlehandedly with shifting trolleys

depending on their size and construction. Final positioning adjustments can be made by trolley. This

technique enjoys popularity in the US, Europe and generally in high labor cost countries. The

advantages of this approach in comparison to beam formwork or modular formwork is a further

reduction of labor time and cost. Smaller tables are generally easier to customize around

geometrically complicated buildings, (round or non rectangular) or to form around columns in

comparison to their large counterparts. The disadvantages of this approach are the higher material

costs and increased crane time (if lifted with crane fork).

Tunnel forms[edit]

Tunnel forms are large, room size forms that allows walls and floors to be cast in a single pour. With

multiple forms, the entire floor of a building can be done in a single pour. Tunnel forms require

sufficient space exterior to the building for the entire form to be slipped out and hoisted up to the

next level. A section of the walls is left uncasted to remove the forms. Typically castings are done

with a frequency of 4 days. Tunnel forms are most suited for buildings that have the same or similar

cells to allow re-use of the forms within the floor and from one floor to the next, in regions which

have high labor prices.

Cassette formwork[edit]

See structural coffer.

Usage[edit]

For removable forms, once the concrete has been poured into formwork and has set (or cured), the

formwork is struck or stripped (removed) to expose the finished concrete. The time between pouring

and formwork stripping depends on the job specifications, the cure required, and whether the form is

supporting any weight, but is usually at least 24 hours after the pour is completed. For example,

the California Department of Transportation requires the forms to be in place for 17 days after

pouring,

[1]

while the Washington State Department of Transportation requires the forms to stay in

place for 3 days with a damp blanket on the outside.

[2]

Formwork stripped exposing the set concrete

Spectacular accidents have occurred when the forms were either removed too soon or had been

under-designed to carry the load imposed by the weight of the uncured concrete. Less critical and

much more common (though no less embarrassing and often costly) are those cases in which

under-designed formwork bends or breaks during the filling process (especially if filled with a high-

pressure concrete pump). This then results in fresh concrete escaping out of the formwork in a form

blowout, often in large quantities.

Concrete exerts less pressure against the forms as it hardens, so forms are usually designed to

withstand a number of feet per hour of pour rate to give the concrete at the bottom time to firm up.

For example, wall or column forms are commonly designed for a pour rate between 48 ft/hr.

[citation

needed]

The hardening is an asymptotic process, meaning that most of the final strength will be

achieved after a short time, though some further hardening can occur depending on the cement type

and admixtures.

Wet concrete also applies hydrostatic pressure to formwork. The pressure at the bottom of the form

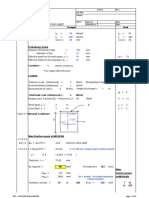

is therefore greater than at the top. In the illustration of the column formwork to the right, the 'column

clamps' are closer together at the bottom. Note that the column is braced with steel adjustable

'formwork props' and uses 20 mm 'through bolts' to further support the long side of the column.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Fielders PurlinsGirts ManualDokumen104 halamanFielders PurlinsGirts ManualthailanBelum ada peringkat

- AECOM Construction Cost Guide 20202021Dokumen28 halamanAECOM Construction Cost Guide 20202021Yacoubou ATTYBelum ada peringkat

- DUDBC Engineers Training Manual Volume 1 8Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 8aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 9Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 9aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 8Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 8aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 6Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 6aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 4Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 4aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 2Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 2aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 9Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 9aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 2Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 2aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 4Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 4aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 6Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 6aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 1Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 1aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 5Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 5aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 3Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 3aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 6Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 6aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 3Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 3aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 4Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 4aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 5Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 5aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 6Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 6aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 5Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 5aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 4Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 4aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 2Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 2aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 1Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 1aditya2053Belum ada peringkat

- DUDBC Engineers Training Manual Volume 1 3Dokumen1 halamanDUDBC Engineers Training Manual Volume 1 3aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 6Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 6aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 5Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 5aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 6Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 6aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 3Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 3aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 2Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 2aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 5Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 5aditya2053Belum ada peringkat

- SciAm SpacePhysics - Aug-Sep20 4Dokumen1 halamanSciAm SpacePhysics - Aug-Sep20 4aditya2053Belum ada peringkat

- Deflection of Simply-Supported Beams: Title of The ExperimentDokumen21 halamanDeflection of Simply-Supported Beams: Title of The Experimentopeyemi71Belum ada peringkat

- MMC-Finishes Schedule-R2 220519Dokumen5 halamanMMC-Finishes Schedule-R2 220519Sandip PaulBelum ada peringkat

- Zarges UK LTD Professional Ladder Frame Instruction ManualDokumen7 halamanZarges UK LTD Professional Ladder Frame Instruction ManualviksofBelum ada peringkat

- Unit I DTS - Journal BearingDokumen19 halamanUnit I DTS - Journal BearingsathiaBelum ada peringkat

- The Edge Amsterdam NetherlandsDokumen4 halamanThe Edge Amsterdam NetherlandsKaeBelum ada peringkat

- KTPH LocationsDokumen17 halamanKTPH LocationsMahesh GonuguntlaBelum ada peringkat

- Find Study Resources: Answered Step-By-StepDokumen5 halamanFind Study Resources: Answered Step-By-StepJAHNELLA XYRINE PERITOBelum ada peringkat

- Pcadmin, 235Dokumen8 halamanPcadmin, 235Katrine Visitacion Dela CruzBelum ada peringkat

- ED & HJ W.H.HagerDokumen9 halamanED & HJ W.H.Hagerjamjam75Belum ada peringkat

- Document Transmittal To Black Cat - Dn80Dokumen2 halamanDocument Transmittal To Black Cat - Dn80Joseph PerezBelum ada peringkat

- EPC Schedule-B1Dokumen56 halamanEPC Schedule-B1sujeetBelum ada peringkat

- Structural Design Analysis Using STAAD - ProDokumen4 halamanStructural Design Analysis Using STAAD - ProvijaykumarzBelum ada peringkat

- Passive Design: Strategies in ArchitectureDokumen9 halamanPassive Design: Strategies in ArchitectureUmang KayasthaBelum ada peringkat

- Pipelines Leak RepairDokumen6 halamanPipelines Leak Repairathar_abbas_1100% (2)

- Carillo Rod Bolts Tech InfoDokumen1 halamanCarillo Rod Bolts Tech Infoagrandi12Belum ada peringkat

- UAP Doc 301Dokumen3 halamanUAP Doc 301MaeDaphneYap50% (2)

- Beam Reactions (And Their Calculation)Dokumen20 halamanBeam Reactions (And Their Calculation)Sanghaar BhuttoBelum ada peringkat

- Dr. Fixit Raincoat Waterproof CoatingDokumen3 halamanDr. Fixit Raincoat Waterproof CoatingsudhakarrrrrrBelum ada peringkat

- Drawings - 37163, 37164Dokumen23 halamanDrawings - 37163, 37164intecBelum ada peringkat

- BS 8110 Data Given: Calculation SheetDokumen10 halamanBS 8110 Data Given: Calculation SheetLee See VoonBelum ada peringkat

- Patan Reoprt (Gujarat)Dokumen26 halamanPatan Reoprt (Gujarat)Himanshu PanchalBelum ada peringkat

- Ajiya - 2017 - Catalogue A - Rev41 (Final Copy)Dokumen12 halamanAjiya - 2017 - Catalogue A - Rev41 (Final Copy)pincer-pincerBelum ada peringkat

- Jiffy Model J-2000Dokumen6 halamanJiffy Model J-2000arturoBelum ada peringkat

- Internal CoilDokumen2 halamanInternal CoilwhngomjBelum ada peringkat

- Tablas Weldolets, ThredoletsDokumen44 halamanTablas Weldolets, ThredoletsIng TelloBelum ada peringkat

- Leonhardt Cable StayDokumen29 halamanLeonhardt Cable StayTarun Kant GoyalBelum ada peringkat

- Chow & Tan (Design & Construction of Bored Pile Foundation - 2003)Dokumen74 halamanChow & Tan (Design & Construction of Bored Pile Foundation - 2003)Donny B TampubolonBelum ada peringkat

- Electrical Engineer (CV+Application) SAMPLEDokumen6 halamanElectrical Engineer (CV+Application) SAMPLESufi Shah Hamid JalaliBelum ada peringkat