Identificación de Arcillas

Diunggah oleh

leizar_death640 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

11 tayangan12 halamanDilute acetic acid is preferred over hydrochloric acid because it less likely to affect clay crystallinity. Organic matter can produce broad x-ray diffraction peaks, increase the background, and inhibit dispersions of other minerals if present in significant amounts.

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniDilute acetic acid is preferred over hydrochloric acid because it less likely to affect clay crystallinity. Organic matter can produce broad x-ray diffraction peaks, increase the background, and inhibit dispersions of other minerals if present in significant amounts.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

11 tayangan12 halamanIdentificación de Arcillas

Diunggah oleh

leizar_death64Dilute acetic acid is preferred over hydrochloric acid because it less likely to affect clay crystallinity. Organic matter can produce broad x-ray diffraction peaks, increase the background, and inhibit dispersions of other minerals if present in significant amounts.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 12

X-Ray Powder Diffraction and the identification and analysis of clay minerals

-Preparatory and Interpretive Procedures

1. Acetic acid treatment to remove carbonates

Carbonate rocks, or clastic rocks with significant carbonate contents, need to have the calcite or dolomite

removed. However, treatment with strong acids to remove carbonate can attack the structure of clay minerals

(e.g. trioctahedral minerals are often destroyed by such treatment), and even dilute acid can attack the silicate

layers via interlayer regions and exposed edges. Generally, dilute acetic acid is preferred over hydrochloric acid

because it less likely to affect clay crystallinity.

PROCEDURE FOR ACETIC ACID TREATMENT

Materials Required:

glacial acetic acid

distilled water

glass graduated cylinder

glass rod

marking pencil

300-ml glass beakers

glass pipette with rubber bulb

siphon or centrifuge

Add 1 part acid to 4 parts distilled water in the

graduated cylinder and mix throughly with the glass

rod. Caution: acetic acid can cause burns. Wear safety

goggles, plastic gloves, and an apron while working

with this chemical.

(Acetic acid 0.3 M or sodium acetate-acetic acid

solution buffer at pH 5)

Label 300-ml beakers and add sample.

Add 50-75 ml of the acetic acid solution slowly to avoid

foaming and overflow of beaker. A glass pipette may be

used to transfer the acid solution. When effervescence

subsides, add another 50-75 ml of acid. Stir and allow

to stand overnight. Repeat until suspension no longer

effervesces.

Allow the suspension to settle and carefully siphon or

pour off the supernatant liquid or wash sample by

centrifuging. Dispose of acid waste properly.

P g i n a | 2

2. Removal of organic matter with hydrogen peroxide

1

Organic matter can produce broad X-ray diffraction peaks, increase the background, and inhibit dispersal of

other minerals if present in significant amounts (a few percent). The organic matter can be removed chemically

with strong oxidizing agents. Unfortunately, with H

2

O

2

the danger is oxidizing octahedral iron and changing the

layer charge. This is most likely with chlorite and vermiculite. The general rule (if there is one) is to go ahead

with the peroxide treatment, but if you see some strange diffraction patterns that defy interpretation, suspect

that iron oxidation has occurred. This is rarely the case under normal circumstances.

PROCEDURE FOR TREATMENT WITH HYDROGEN PEROXIDE

Materials Required:

Hydrogen peroxide (3%)

glass graduated cylinder

distilled water

300-ml glass beakers

glass rod

pencil

squeeze bottle of distilled water

lab tissues

siphon

If the hydrogen peroxide is laboratory grade (30%),

prepare a dilute solution of 3% using a graduated

cylinder and distilled water. Caution: hydrogen

peroxide is a strong oxidizer that can cause severe

burns. Wear goggles, plastic gloves, and an apron while

working with this chemical.

Label the beakers with a pencil or marker. Then, place a

sample in each beaker and add about 50-100 ml of

dilute hydrogen peroxide. Stir each beaker with the

glass rod to suspend the sample. Rinse the glass rod

between each sample and dry with a lab tissue. When

bubbling stops or slows, add another 50-100 ml of

dilute hydrogen peroxide and restir the suspension.

When the addition of hydrogen peroxide to the

samples no longer causes bubbling, the organics have

been removed. Allow the suspension to settle and

carefully siphon or pour off the supernatant liquid, or

wash the sample by centrifuging.

1

Commercial bleach is NaOCl (sodium hypochlorite) and seems quicker, cheaper, and safer (for your health) than the frequently

recommended hydrogen peroxide; so the following procedure is recommended. Treat with 10 o 20 mL of NaOCl that has been adjusted to

pH 9.5 with HCl just before treatment. Heat the mixture in a boiling-water bath abour 15 min. Centrifuge at 800 rpm for 5 min and decant

and discard the supernatant. Repeat the procedure until organic material is sufficiently removed.

P g i n a | 3

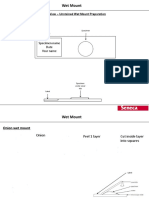

3. Randomly oriented powder mounts for x-ray powder diffraction

Bulk mineralogy of a sediment sample can be determined by X-ray diffraction with a randomly oriented powder

mount. The random orientation insures that the incident X-rays have an equal chance of diffracting off any given

crystal lattice face of the minerals in the sample. The use of a powder press to make randomly oriented powder

mounts is undesirable because excessive force could cause preferred orientation of the crystallites. Although

some orientation is inevitable (platy minerals tend toward some preferred orientation), the method described

below is sufficient for most applications.

Sample splits are commonly dried at 60 C prior to the preparation of randomly oriented powder mounts. The

mounts are typically X-rayed between the angles of 2 and 70 degrees two theta using copper K radiation at a

scanning rate of 2 degrees per minute.

PREPARATION OF RANDOMLY ORIENTED POWDER MOUNTS

Materials Required:

plastic tape and pencil

weighing paper (4"x4")

mortar and pestle

ASTM number 230 (.062 mm mesh) sieve stiff brush

spatulas

sample holders and clips

glass microscope slide

piece of glass slide cut to a size sufficient to cover

the sample holder opening

Tape the glass slide over the opening of the sample

holder. Leave tabs on each side for later removal of

this cover, but fold the extra tape against itself so that

it will not stick to other objects or the sample. Place

the holder glass side down on a piece of weighing

paper.

Grind the dried sample thoroughly so that it is easily

brushed through the sieve. The particles should be

much finer than .062 mm to avoid fractionation of the

minerals. The sieve is used only to achieve even

distribution and to ensure that the grinding is

complete.

Place a second holder over the first as a mask. This

enables the buildup of a thick enough layer of sample

for later packing, while maintaining a clean metal

surface on the final holder.

P g i n a | 4

Place the sieve over the sample holder and brush the

sample from the mortar. (Note: the sample may

become contaminated from the sieve and utensils.

These contaminants will not affect the x-ray diffraction

analysis, but do not plan to reuse this cut of the

sample for sensitive chemical analyses.)

Use the spatula to loosen any sample that has stuck to

the mortar and brush the material into the sieve.

Brush the sample through the sieve into the cavity of

the sample holder. The purpose of the brushing is to

obtain an even distribution and to minimize preferred

orientation of the particles.

Remove the sieve and mask.

Place the sample holder on a clean piece of weighing

paper, tap the powder remaining on the mask onto

the first weighing paper, and replace the mask over

the sample holder.

Pour the excess powder onto first weighing paper into

the sample holder. Distribute the powder evenly.

P g i n a | 5

Use a glass slide to pack the sample into the cavity

firmly enough so that it will not fall out, deform, or

slide, but not so firmly that preferred orientation will

be produced on the opposite surface (which will later

become the top surface). The glass slide can also be

used to scrape any sample that has flattened onto the

holder surface during packing back over the holder

opening.

Additional sample can be used as filler if necessary to

create a firm pack. This part of the sample need not be

as finely ground, as it will become the bottom surface

and will not be exposed to the X-ray beam.

Pack as above and then attach a clip to the back of the

holder. Alternately, if a generic holder is being used,

another cut glass slide can be attached with tape to

cover the holder's opening.

Turn the sample holder over and lift the tab of tape.

The glass cover is carefully lifted with a slight twisting

motion to break and surface adhesion. This will be the

surface exposed to the X-rays. It should be smooth,

uniform, and flush with the metal surface of the

holder. If not remake the mount.

Label the sample holder with the pencil.

4. Smear slide sample mounts for x-ray powder diffraction

For identifying the constituents in a bulk sample and roughly estimating the quantities, the smear technique is a

good compromise between time and skill required and the quality of the results. Done properly, phases should

be represented in their true proportions, i.e., without segregation. Although not useful for semi-quantitative

analysis, this method is useful for rapidly determining bulk mineralogy, especially if the operator knows which

mineral phases are likely present.

P g i n a | 6

PREPARATION OF SMEAR-SLIDE MOUNTS

Materials Required:

weighing paper (4"x4")

mortar and pestle

spatula

glass rod

marker pen

glass slide cut to fit the diffractometers's

sample holder

acetone in a squeeze bottle

lab tissues

diamond or carbide scribe to cut slides

Grind the dried sample thoroughly with the mortar and

pestle. The particles should be much finer than .062 mm

to avoid fractionation of the minerals. The finer the

powder the greater the opportunity for obtaining an

adequate number of particles with random orientation

and the less likely that surface roughness will reduce low-

angle intensities.

Use the spatula to loosen any sample that has stuck to

the mortar and to homogenize the powder.

Place a small amount of sample in the center of the slide

and add an amount of acetone sufficient to wet the

sample (2-3 drops). Distilled water may be used, but the

sample dries quicker with acetone.

Spread the sample into a thin layer with the glass rod.

Gently blow on the slide to rapidly evaporate the

acetone. Use the spatula or a finger to remove any excess

sample sticking to the edges of the slide. Use a lab tissue

to remove any sample stuck to the back of the slide.

P g i n a | 7

Label the slide with a marker pen. Brush the sample from

the mortar onto the weighing paper and transfer the

remaining sample back into a sample vial.

5. Oriented aggregate mounts for X-ray powder diffraction

The clay fraction can be separated from the bulk sample by centrifugation or decantation and mounted as an

oriented aggregate mount for clay-mineral identification. The oriented aggregate mounts force the clay mineral

particles, usually plate-shaped phyllosilicates, to lie flat, allowing the operator to direct the incident X-ray beam

down the z axis of the minerals and to record the diagnostic basal diffractions. It is the z axis that shows the

extent of d-spacing expansion and (or) contraction indicative of certain clay minerals during subsequent

treatments. These treatments include: air drying, glycolation with ethylene glycol, heating to 400 C, and heating

to 550 C. The material from the randomly oriented powder mount may be used for this analysis.

Commonly used substrates for oriented aggregate mounts include silver filters, ceramic tiles, and glass slides.

Silver filters tend to be expensive and react with chloride ions to form crystalline compounds that change the

mass-absorption coefficient of the mount and affect peak intensities; ceramic tiles tend to contain crystalline

material that may complicate the diffraction pattern. Glass slides cut to fit the sample holder of a diffractometer

are used in the filter-peel method described below.

PREPARATION OF ORIENTED AGGREGATE MOUNTS USING THE FILTER-PEEL TECHNIQUE

Materials Required:

glass slides cut to fit diffractometer

carbide or diamond glass scriber

lab tissues

vacuum pump

Millipore filtration apparatus vacuum tubing

Millipore HA, 47-mm, 0.45-micron

nominal pore opening cellulose filters

pipette or 20-25 cc syringe

single-edge razor or metal spatula

cylinder with a 2.5 - 5 cm outside diameter

Cut the glass slides to fit the sample holder and label

them with a scriber. Rinse and dry the slides to remove

any remaining glass shards.

P g i n a | 8

Assemble the filtration device with the cellulose filter in

place. Pour approximately 20 ml of the clay suspension

into the assembled filtration device. Exact amount will

depend on the density of the suspension, mineralogy,

presence of organics, and grain size of the particles.

If the filter clogs, use the pipette or a syringe with a

needle attached to remove the excess clay suspension

from the filtration device.

As soon as the remaining suspension has been

completely drawn into the filter, remove the glass

funnel and use a single-edge razor or metal spatula to

remove the moist filter from the filtering device.

Wrap the filter membrane tightly around the cylinder

with the clay film up and held firmly with the thumb

and forefinger.

Membrane filter and clay film are center-positioned

near the glass slide and then quickly and smoothly

lightly rolled across the slide to transfer the clay film to

the slide. Any hesitation or jerky motion during the

transfer may cause rippling of the film and disrupt the

preferred orientation.

The mounts dry in a few minutes and are then ready for

X-ray diffraction analysis. The specimens are

subsequently exposed to glycol or heat treatments.

P g i n a | 9

6. Ethylene glycol treatment

Most clay mineral samples should be analyzed in an air-dried condition, an ethylene glycol-solvated condition,

and after enough heating to collapse any expandable layers. Ethylene glycol solvation is difficult to accomplish

with random powders if they contain large amounts of smectite. Whether or not a mineral expands and the

amount of expansion can provide essential supplementary information aiding clay-mineral identification.

Swelling clays include smectites (e.g. montmorillonite, nontronite, and beidellite), some mixed-layer clays, and

vermiculite.

Two methods are presented here: a vapor treatment and a rapid method. The advantage of the vapor treatment

is fewer disturbances of the sample and less amorphous scattering of X-rays by excess liquid than in the case of

the rapid method.

ETHYLENE GLYCOL VAPOR TREATMENT

Materials Required:

ethylene glycol

oven

desiccator

desiccator shelf

Pour ethylene glycol to about 1 cm depth in base of

desiccator.

Place oriented aggregate mounts on the shelf of

desiccator. Additional shelves may be stacked if

necessary.

Place desiccator in oven at 60 to 70 C for about 4 hours

or overnight. Longer times will not hurt samples. Do not

remove mounts until they are to be run on the X-ray

diffractometer.

P g i n a | 10

ETHYLENE GLYCOL RAPID METHOD

Materials Required:

ethylene glycol

glass rod

lab tissue

Apply a drop of ethylene glycol directly to the surface

of the oriented aggregate mount with the glass rod.

Spread the ethylene glycol if necessary.

Mounts are ready to be X-rayed as soon as liquid is

uniformly absorbed. Excess ethylene glycol may be

gently mopped up with lab tissue.

7. Heat treatments for x-ray powder diffraction

Heat treatments at various temperatures are commonly used to help identify clay minerals by revealing changes

in crystal structure spacings or loss of the structure. Depending on the temperature and the mineral species,

these treatments can collapse the structure by dehydration, or in the case of other minerals destroy the crystal

structures. However, it is important for the analyst to remember that some of the changes caused by the heat

treatments may be temporary, and that partial or complete rehydration may occur during cooling.

HEAT TREATMENT

Materials Required:

furnace

tongs

wire hook

Preheat the oven to 400 C.

P g i n a | 11

Place the oriented aggregate mount in the furnace using

the tongs. Leave sample in the furnace not less than one

half hour at 400 C.

Remove mount by pulling it forward with the wire hook

until the edge of the mount can be grasped with the

tongs. Do not remove mounts until they are ready to be

run on the diffractometer.

X-ray the sample and repeat the above procedure at 550

C.

8. Final note

There is no single way to prepare materials for X-ray diffraction analysis. Preparation techniques depend on (1)

supplies and equipment available; (2) purposes of analysis, e.g., whether qualitative or quantitative

identification is the goal; (3) the material itself; and, probably most important, (4) your sense of organization

and habits, your goals and your understanding of the principles of X-ray diffraction.

Finally, when you write a report or submit a paper for publication, include the X-ray diffraction tracings in the

form in which they came off of the diffractometer, not after they have been smoothed by a draftsperson. Such

traces are data that can be reinterpreted in the future as more is learned about peak shapes, relative intensities,

and other, as yet unrecognized features.

P g i n a | 12

9. Clay Mineral Identification Flow Diagram

X-Rays of Oriented Aggregates

Treated with Electron Micrograph X-rays of randomly

Air Dried ethylene glycol Heated to 400

o

C Heated to 550

o

C if required oriented powders RESULT

~29 Expands to 31-32 with May disappear or give 24 spacing. Increase in intensity of 24 spacing Regularly interstratified

rational sequence of chlorite-montmorillonite or

higher orders cholorite-vermiculite (corrensite)

Expands but gives irrational sequence. May give irrational sequence. May give irrational sequences. May show Randomly interstratified

Peaks may be broad. increase in intensity of 12-14 peak chlorite-montmorillonite

~14 No change No change Increase in intensity 060 near 1.54 Chlorite

060 near 1.50 Dioctahedral chlorite

No change or slight increase Collapses to ~10 No change or slight additional collapse 060 near 1.54 Vermiculite

Slight collapse ~12 Additional collapse ~11 060 near 1.50 Dioctahedral vermiculite

Expands to 17 Collapses to ~10 No change or slight additional collapse 060 near 1.50 Montmorillonite

Collapses to ~10 with No change or slight additional collapse 060 near 1.52 Nontronite

very weak 5 peak 060 near 1.54 Trioctahedral montmorillonite

or vermiculite

>10 - 14 No change - rational sequence Collapses to ~10 Collapses to 10 060 near 1.54 Regularly interstratified

of higher orders illite-vermiculite

No change No change or slight increase in intensity 060 near 1.54 Regularly interstratified

illite-chlorite

No change - irrational sequence Collapses to ~10 Collapses to 10 060 near 1.54 Randomly interstratified

illite-vermiculite

No change No change or slight increase in intensity 060 near 1.54 Randomly interstratified

illite-chlorite

Expands to higher spacing Collapses to ~10 Collapses to 10 060 near 1.50 Interstratified

illite-montmorillonite

060 near 1.54 Interstratified trioctahedral

illite-montmorillonite

No change Slight collapse Further collapse 060 near 1.50 Interstratified dioctahedral

illite-vermiculite

12 - 12.5 No change Destroyed or reduced in intensity Destroyed Fibrous morphology Check hkl's against standard Sepiolite

10.5 No change Destroyed - - may survive slightly Destroyed Fibrous morphology Check hkl's against standard Palygorskite

lower temperature

~10 Symmetrical - no change No change No change 060 near 1.50; Illite (and/or mica),

check hkl's against muscovitic,

standards for polymorphs various polymorphs

060 between 1.51 - 1.52 Glauconite or celadonite

5 peak very weak (Roscoelite if V bearing)

060 near 1.54 Bictite, various polymorphs

Unsymmetrical or slight shift either way No change or slight sharpening 060 variable Interstratified illite-montmorillonite

or illite-vermiculite

Expands to ~11 Collapses to ~7 Destroyed Tubular morphology 060 near 1.49 Endellite

7 Increases in spacing or no change Collapses to 7 Destroyed Tubular morphology 060 near 1.49; Halloysite

hk bands present

No change No change No change Fibrous morphology Check hkl's against standard Chrysotile

Platy morphology Check hkl's against standard Antigorite

Destroyed Platy morphology 060 near 1.49; Disordered kaolinite

hk bands present; (fireclay)

moderately broad 001's

060 near 1.54 Chlorite

(Check increase in intensity

of 14 spacing)

060 near 1.50 Dioctahedral chlorite

(Check increase in intensity

of 14 spacing)

Hexagonal morphology hkl's resolved Kaolinite

Dickite

Nacrite

(Check against standard patterns)

Anda mungkin juga menyukai

- Humidity Calibration of Dynamic Vapor Sorption (DVS) InstrumentDokumen5 halamanHumidity Calibration of Dynamic Vapor Sorption (DVS) Instrumentleizar_death64Belum ada peringkat

- Brewster Angle Microscopy: Keith J. StineDokumen29 halamanBrewster Angle Microscopy: Keith J. Stineleizar_death64Belum ada peringkat

- Kapustin Ski IDokumen2 halamanKapustin Ski Ileizar_death64Belum ada peringkat

- Dynamic Light Scattering in Supramolecular Materials ChemistryDokumen14 halamanDynamic Light Scattering in Supramolecular Materials Chemistryleizar_death64Belum ada peringkat

- GTaC-Dover BishopDokumen160 halamanGTaC-Dover Bishopleizar_death64100% (1)

- SMC 012Dokumen14 halamanSMC 012leizar_death64Belum ada peringkat

- ASAP2020 Operator's ManualDokumen522 halamanASAP2020 Operator's ManualKim IKbeomBelum ada peringkat

- Orgunic Biologicul Chemistry: Application of The Principle of Hard and Soft Acids and Bases To Organic ChemistryDokumen1 halamanOrgunic Biologicul Chemistry: Application of The Principle of Hard and Soft Acids and Bases To Organic Chemistryleizar_death64Belum ada peringkat

- SMC 004Dokumen19 halamanSMC 004leizar_death64Belum ada peringkat

- SMC 003Dokumen16 halamanSMC 003leizar_death64Belum ada peringkat

- Capítulo 4 - Técnicas ExperimentalesDokumen53 halamanCapítulo 4 - Técnicas Experimentalesleizar_death64Belum ada peringkat

- Validation of Analytical Methods Using A Regression ProcedureDokumen4 halamanValidation of Analytical Methods Using A Regression Procedureleizar_death64Belum ada peringkat

- Quimica de Materiales-1Dokumen217 halamanQuimica de Materiales-1leizar_death64Belum ada peringkat

- Absolute Electronegativity and Absolute Hardness Lewis Acids and BasesDokumen1 halamanAbsolute Electronegativity and Absolute Hardness Lewis Acids and Basesleizar_death64Belum ada peringkat

- The Gibbs Phase Rule RevisitedDokumen3 halamanThe Gibbs Phase Rule Revisitedleizar_death640% (1)

- Titanium Alloys For Biomedical ApplicationsDokumen9 halamanTitanium Alloys For Biomedical Applicationsleizar_death64Belum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Wolkite University College of Natural and Computational Sciences Department of BiologyDokumen155 halamanWolkite University College of Natural and Computational Sciences Department of BiologyJimach Bol WieBelum ada peringkat

- Preparation TechniquesDokumen3 halamanPreparation TechniquesMarian BulatinBelum ada peringkat

- RESUMEEE JurnalDokumen6 halamanRESUMEEE JurnalnaufalarifnurrohmanBelum ada peringkat

- Tissue Procurement, Processing, and Staining TechniquesDokumen10 halamanTissue Procurement, Processing, and Staining TechniquesMuhammad JameelBelum ada peringkat

- BIO 130 Lab #3 Distribution of Tissues Within The Leaf Assessment: Measurement/Manipulation & DrawingDokumen2 halamanBIO 130 Lab #3 Distribution of Tissues Within The Leaf Assessment: Measurement/Manipulation & DrawingTaylorBelum ada peringkat

- Objectives:: Blood SmearingDokumen2 halamanObjectives:: Blood SmearingAshlyn BautistaBelum ada peringkat

- Microscopic Living Plant CellDokumen3 halamanMicroscopic Living Plant CellNiña Anrish Joy TadiaBelum ada peringkat

- 11 Bio Botany Practical Manual EM Moses SirDokumen31 halaman11 Bio Botany Practical Manual EM Moses SirMoses PackiarajBelum ada peringkat

- Observing Starch Grain in Potato ExperimentDokumen1 halamanObserving Starch Grain in Potato Experimentsadiqah mushtaqBelum ada peringkat

- Proper Use and Care of The MicroscopeDokumen5 halamanProper Use and Care of The MicroscopeNaiomi Rosario NievesBelum ada peringkat

- Immunofluorescence StainingDokumen7 halamanImmunofluorescence StainingGiovanni Aleksey GuersonBelum ada peringkat

- BIOL200L General Biology I LABDokumen4 halamanBIOL200L General Biology I LABadeeb ahmedBelum ada peringkat

- How To Prepare Golgi Staining Samples Using Paraffin Embedding MethodDokumen2 halamanHow To Prepare Golgi Staining Samples Using Paraffin Embedding MethodVlad TomaBelum ada peringkat

- Vectra 3. Quantitative Pathology Imaging System User's ManualDokumen119 halamanVectra 3. Quantitative Pathology Imaging System User's Manualjsuh00712Belum ada peringkat

- Bright-Line Hemacytometer Supplied With Two Cover Slips HemacytometersDokumen9 halamanBright-Line Hemacytometer Supplied With Two Cover Slips HemacytometersNoorsyam EffendyBelum ada peringkat

- Preservation of Specimens ObjectivesDokumen3 halamanPreservation of Specimens ObjectivesKlenn OrtezaBelum ada peringkat

- Final Histopath Notes.Dokumen19 halamanFinal Histopath Notes.anneorigmtBelum ada peringkat

- Lab 1 - The Use & Care of The MicroscopeDokumen3 halamanLab 1 - The Use & Care of The MicroscopeFatin Ahmad100% (1)

- BIO173 - Wet Mount Pre Lab 2Dokumen8 halamanBIO173 - Wet Mount Pre Lab 2Leanna FerracciBelum ada peringkat

- How To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionsDokumen2 halamanHow To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionstwinscrewcanoeBelum ada peringkat

- 71-USP-sterility TestDokumen9 halaman71-USP-sterility TestSpectre SpectreBelum ada peringkat

- Compilation of Experiments Form 4Dokumen13 halamanCompilation of Experiments Form 4Marzila MohamedBelum ada peringkat

- Lect 1 Introduction To Histo PathologyDokumen14 halamanLect 1 Introduction To Histo PathologyAbdul Hafeez100% (1)

- Microscope BasicsDokumen6 halamanMicroscope BasicsAnonymous h2EnKyDbBelum ada peringkat

- Biology Pp2 Questions 1996-2016: Whatsapp/Sms/Call at 0706 851 439 For Marking Schemes 2006-2016Dokumen73 halamanBiology Pp2 Questions 1996-2016: Whatsapp/Sms/Call at 0706 851 439 For Marking Schemes 2006-2016TudorNedelcuBelum ada peringkat

- Astm C 295-12Dokumen10 halamanAstm C 295-12jun floresBelum ada peringkat

- Microscope Lab ReportDokumen10 halamanMicroscope Lab ReportBrian Luo67% (3)

- Complete Lab ReportDokumen16 halamanComplete Lab ReportAdlina SafuraBelum ada peringkat

- Micro Lab Ex 3 NotesDokumen3 halamanMicro Lab Ex 3 NoteshmariejoyrBelum ada peringkat

- California Science Grade 5 - Activity Lab BookDokumen255 halamanCalifornia Science Grade 5 - Activity Lab BookMarina Donofrio100% (1)