ACKROYD - Simplified Frame Design of Type PR Construction

Diunggah oleh

Valentin Vergara GonsagaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ACKROYD - Simplified Frame Design of Type PR Construction

Diunggah oleh

Valentin Vergara GonsagaHak Cipta:

Format Tersedia

Simplified Frame Design of

Type PR Construction

MICHAEL H. ACKROYD

Design of unbraced building frames using simple connections

between beams and columns has been based historically on

Type 2 Construction assumptions. Extensive research on the

performance of this type of frame has led to the

recommendation that Type 2 Construction should be limited

to frames less than 10 stories tall, when the lateral load is

resisted entirely by the unbraced frame.

1

Moreover, it was shown that the governing limit state in

such frames is overall frame instability under combined wind

and gravity loads, initiated by extensive plastification of the

leeward column stack (Fig. 1). Two common features of this

limit state are that girders are loaded to about half their

bending capacity and the exterior columns are heavily

overloaded in bending. The reason for this inappropriate

apportionment of steel to the girders and exterior columns is

that the simple connections do possess rotational stiffness

and tend to decrease the in-span girder gravity moments by

developing a fraction of the fixed-end moments, referred to

herein as flexible-end moments.

This paper describes a more appropriate model for

gravity analysis of frames with flexible beam-to-column

connections that enables a simplified design procedure for

Type PR Construction.

Behavior of Type PR Frames

Extensive analytical studies of the fully nonlinear response of

flexibly connected frames indicates the overall frame

deformations are well explained as a superposition of the two

deformed shapes (Fig. 2). The deformations induced by wind

are well predicted by the portal method of analysis. The

deformations induced by gravity consist of beam bending

Michael H. Ackroyd, Ph.D, P.E., is Vice President of applications

development, Techtrol, Ltd., Montreal, Canada.

and reverse curvatures of exterior columns due to the one-

sided flexible-end moment from the girders.

Simplified Models for Frame Behavior

While the portal method is suitable for computing member

forces due to wind, one needs to devise a more appropriate

model for predicting member forces due to gravity. If one

assumes inflection points at mid-heights of exterior columns

and no flexure of interior columns (Fig. 3), then one can

model interior girders as beams connected through rotational

springs into fixed supports. One can model exterior girders as

beams connected through a rotational spring to a fixed

support at interior ends and to the column stack segment at

exterior ends. Note, we only need to develop a math model

for the latter subassemblage, because in the limit as we let

the columns become infinitely stiff, we obtain the support

conditions of the interior girder.

Fig. 1. Typical limit-state mode for simply connected frames

FOURTH QUARTER / 1987 141

Fig. 2. Component deformed shapes

Fig. 3. Flexibly connected girder models

Flexible-end Moment Calculations

Analysis of the exterior girder model for symmetric gravity

loads on the girder

1,5

leads to simple expressions for the

flexible-end moments at the interior end of the girder M

i

and

at the exterior end M

e

as a fraction of the usual fixed end

moment M

f

:

M

M

C

i

f

i

M

M

C

e

f

e

where the coefficients C

i

and C

e

depend on connection

stiffness k on the bending stiffness of the girder EI

g

/l and on

the relative flexibility of the girder to the columns

(I

g

/l)/(I

c

/h):

C a

g

g a

C a

g a

a

i

e

+

+ +

+ +

+

+

( )

( )

( )

( )

( )

1 2

3 1 6

1 2

2 1 3

3 1 6

and the parameters, a and g are defined as:

Connection flexibility parameter a

EI

kl

g

Relative flexibility factor g

I l

I h

g

c

/

/

The above expressions are easily automated on a

programmable calculator. Alternatively, Fig. 4 gives a design

aid for obtaining values for C

i

and C

e

for realistic frame

configurations.

Fig. 4. Flexible end-moment coefficients

142 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

SIMPLIFIED DESIGN OF

FLEXIBLY-CONNECTED FRAMES

The above method for calculating flexible end moments can

be used to predict gravity moments in a frame design if

appropriate accounting of connection nonlinearity and

column second-order effects can be made, based on

observations of these nonlinear effects from analytic

studies.

1,5

Appropriate Connection Stiffness Values

Close study of the results of extensive analyses of frames

with nonlinear connections indicate the secant stiffnesses of

beam-to-column connections near ultimate frame capacity

were typically 20% of the initial stiffness k

i

at leeward ends

of girders and 80% of k

i

at the windward ends of girders,

when combined gravity and wind loading was applied. So, it

is reasonable to assume an average connection stiffness of,

say, 0.5 k

i

when computing the flexible end moments for

design.

Fig. 5. Simplified PR design procedure

For frames with elastic-plastic connections, it is more

appropriate to use the calculated value of k

i

directly in the

flexible end moment computations. If this moment exceeds

the plastic capacity of the connection M

p

, then simply use M

p

as the flexible-end moment.

Appropriate Effective Length Factors

for Column Design

From the extensive analytic studies,

1,2,5

all frame failures

were in an overall frame sway mode of instability, caused by

plastification of the leeward column stack. No frames failed

in the classical story shear mode presumed in the popular

Jackson-and-Moreland nomographs. Therefore, based on

engineering judgment, it is recommended to use an effective

length factor of 1.5 for in-plane buckling effects. Use of the

nomographs is not recommended. The value of 1.5

recommended here has been tested by analyzing a full range

of buildings based on these design assumptions and the

ensuing design procedure: all buildings attained their

intended load factors without failure.

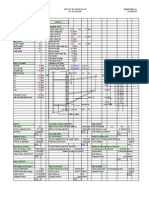

Proposed Design Procedure

The proposed design procedure starts with the same steps

used in a Type 2 design, improves the estimates of moments

due to gravity as influenced by connection stiffness and

results typically in frames with lighter girders but heavier

exterior columns. The steps are outlined in Fig. 5. A detailed

example follows:

Detailed Example

An example frame is designed here to illustrate the

application of the proposed Design Procedure.

Step 1: Frame Definition

The frame to be designed is three stories tall, with 14 ft per

story. It has three bays, with 39 ft per bay. The frame is

assumed to be a Type 2 wind bent with 30-ft tributary width

of building.

Step 2: Loading Definition

Gravity loading is assumed to be a total deck load of 125 psf

with a curtain wall load of 30 psf, vertical area. Wind loads

are assumed to be 33 psf uniform over the height of the

building.

Step 3: Assumptions

For design, it is assumed girders are braced sufficiently

against lateral torsional buckling that allowable bending

stress is F

b

= 0.6 F

y

. A36 steel is to be used throughout.

Effective length factor of columns for in-plane, second-order

effects is taken as K

x

= 1.5. Out-of-plane bracing of columns

is assumed, so that K

y

= 1.0. Only W14 series rolled shapes

will be considered for design.

Step 4: Analysis

The portal method for wind analysis is summarized below.

FOURTH QUARTER / 1987 143

Simple framing assumptions are used for the initial gravity

analysis:

Girders:

P = (125 psf) (30') (19.5') = 73,125 lb. = R

M (@ mid-span) = Pl/4 = 712,969 ft-lb.

Curtain Walls:

P (concentrated) = (30 psf) (30') (14')

= 12,600 lb.

Exterior Columns:

at each story,

P = R + P (curtain wall)

= 12,600 + 73,125

= 85,725 lb.

story P (gravity)

3 85,725 lb.

2 171,450

1 257,175

Interior Columns:

at each story,

P = 2R = 146,250 lb.

story P (gravity)

3 146,250 lb.

2 292,500

1 438,750

Step 5: Design

The design resulted in the member sizes shown below, based

on AISC Specifications, Part 1.

4

Initial Type 2 Design

Flange plate connections were used for beam-to-column

connections. It was decided to use the same plate size

throughout all W33 beams, to carry a design wind moment of

363.8 in.-kips:

Axial load in plate = 363.8 in.-k/(33.09 + t) in.

Compression plate, (governs plate area)

assume width, b < 11 in. (W33 130 has b

f

= 11.5)

assume length, l = 1.5 width

< 16.5 in.

r= sqrt (I/A) and assume K = 1.0

then Kl/r = 1.5 sqrt(12) b/t

Try b = 8 in., t = 0.25 in.

Then P = 10.9 kips

Kl/r = 167,

F

a

= 5.35 ksi,

allow. P = 10.7 kips o.k.

Detail calculations for connections, welds, etc. are not shown

here for conciseness.

Step 6: Gravity Re-Analysis

Connection calculations (see Appendix for derivations)

Stiffness

k

Etd

+

2 2

3

29 000 0 25 3309

3

( , )( . .)( . ) ksi in .25 in.

=2.686 E06 in.-kip/rad.

Moment capacity of flange plates

M

p

= b t F

y

d

= (8")(.25")(35 ksi)(33")

= 2,376 in.-kips

= 198 ft-kips

Connection flexibility parameter

a EI kl

k

g

/

( , )( , )

( . )( )

29 000 6 710

2 686 06 39 12

4

kip in.

E in. in.

=0.155

Relative flexibility factors

story 3 =

story 2

story

,

( , / )

( / )

.

,

( . / )

/ / )

.

,

( , / )

( / / )

.

g

g

g

+

6 710 39

291 14

8277

6710 39

291 14 428 14

3350

1

6 710 39

428 14 640 14

2 255

Flexible-end moments

interior girders, C

i

= C

e

= 1 + 2a = 1.310

exterior girders, C

i

C

e

story 3 1.039 5.499

story 2 1.098 3.005

story 1 1.130 2.451

Girder reference moments

fixed-end moments,

M

f

= Pl/8 = (0.125 ksf)(30')(0.5 39')(39')/8

= 356.5 ft-kips

simple, mid-span moment,

M

ss

= Pl/4 = 713.0 ft-kips

144 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

M

i

and M

e

values are shown directly on the sketch. Note,

though, the amount of flexible end moment that could be

generated at all interior connections was limited to the upper

bound of M

p

of the flange plate capacity M

p

= 198 ft-k.

Adjusted moment diagrams also shown directly on sketch.

Distribution of Moments Accounting

for Connection Stiffness

These new moment diagrams are now combined with the

original portal analysis results to re-design members with

changes in applied forces. The table summarizes the cycles of

Steps 5 and 6 for this example. As can be seen, interior

columns are not affected in this re-design, interior girders

achieve the greatest gains in economy, the uppermost exterior

girder does not benefit as much as the other girders because

it receives the least rotational restraint from the exterior top

column and exterior columns need to be increased in capacity

because quite long girders are framed in from one side only,

resulting in non-trivial gravity moments.

For these design cycles, the total weight of the frame

decreased from one iteration to the next. But essentially all of

the economy was achieved in the first re-design cycle, as

shown in this table:

Total Weight of Framing Members, Lbs.

(numbers in parentheses are ratios to Type 2)

Type 2 Cycle-1 Cycle-2 Cycle-3

Ext. Cols. 3,752 5,432 6,300 6,300

(1.000) (1.448) (1.679) (1.679)

Int. Cols. 5,432 5,432 5,432 5,432

(1.000) (1.000) (1.000) (1.000)

Girders 45,630 39,156 38,220 38,220

(1.000) (0.858) (0.838) (0.838)

Total 54,814 50,020 49,952 49,952

(1.000) (0.913) (0.911) (0.911)

Difference 0 4,790 4,862 4,862

Total weight reduction for this frame was 4,862 pounds, or

8.9%. Note, this represents a true savings, since the

connection designs did not change at all. Weight reductions

in the range of 4% to 11% have been found for typical

building configurations.

1,5

PR Frames with Composite Girders

When considering the overall sway stability of a frame, one

would anticipate that by designing girders as composite

girders the overall capacity would be increased because of

the increases in girder stiffnesses. A study of a range of Type

2 frame designs was made to assess this possibility.

7

Results

showed, however, that while the Elg of the girders did

increase girder stiffnesses initially, two nonlinear phenomena

negated the potential benefits. First, because partial

composite construction was used, slip along the concrete-

steel interface resulted in a gradual softening of the girders.

Second, and more pronounced, because the depth of the steel

beam in the composite beam was significantly smaller than

the depth of its all-steel counterpart, the steel-beam-to-

column connection was significantly smaller than the

connection in the all-steel counterpart. The net effect was

that the stiffening tendency of the composite girder was

nullified essentially by the reduction in connection stiffness.

Unless one takes explicit steps to increase the connection

stiffness in composite construction, one cannot expect to

improve the load-carrying capacity of PR frames using

composite girders over that of their all-steel counterparts.

REFERENCES

1. Ackroyd, M. H. Design of Flexibly-Connected Steel Building

Frames Final Research Report to American Iron and Steel

Institute, Project No. 333, November 1985.

2. Ackroyd, M. H. Limit States of Type 2 Steel Building Frames

Research Report to American Iron and Steel Institute, Project

No. 311, August 1981.

FOURTH QUARTER / 1987 145

3. Altman, W. G., Jr., A. Azizinamini, J. H. Bradburn and J. B.

Radziminski Moment-Rotation Characteristics of Semi-Rigid

Steel Beam-Column Connections Report to NSF for Grant No.

PFR-7923520, University of South Carolina, June 1982,

Columbia, S.C.

4. American Institute of Steel Construction, Inc. Specification for

the Design, Fabrication, and Erection of Structural Steel

Buildings Effective Nov. 1, 1978.

5. Cronembold, J. Evaluation and Design of Type 2 Steel Building

Frames Master of Architecture Thesis, Rensselaer Polytechnic

Institute, May 1986, Troy, N.Y.

6. Richard, R. M. and B. J. Abbott Versatile Elastic-Plastic Stress-

Strain Formula ASCE Journal of the Engineering Mechanics

Division, Vol. 101, No. EM4, August 1975 (pp. 511-515).

7. Zaremba, C. J. Limit State Analysis of Partial Composite Girders

and Application to Building Frames Master of Science Thesis,

Rensselaer Polytechnic Institute, August 1986, Troy, N.Y.

APPENDIX

The model used for top and seat angle wind connections was

that proposed by Altman, et al.,

3

which used a Fryeand-

Morris polynomial moment-rotation curve, as summarized:

P g

e

2

K = t

f

1128 .

d

1.287

t

c

0 4145 .

l

0.6941

P

e

1 35 .

= 0.2234 10

4

(KM)

+ 0.18507 10

7

(KM)

3

+ 0.318898 10

11

(KM)

5

k

i

= .22324 10

4 1 128

t

f

.

d

1.287

t

c

.4145

l

.6941

P

e

1 35 .

The model used for flange plate connections was derived

from strength of materials considerations as shown below,

neglecting any rotational stiffness contributed by the shear

clip on the web. The resulting elastic-plastic moment-

rotation curve was then represented by the Richard-Abbot

formulation

6

using n = 15.5.

k

M Ebtd

l

i

2

2

if l b k

Etd

i

15

3

2

. ,

M

y

= (btd)F

y

Richard-Abbott Equation: M

k

k

M

i

i

y

_

,

1

]

1

1

1

15 5

1 15 5

.

/ .

146 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Anda mungkin juga menyukai

- Steel Beam Column With Braced FrameDokumen21 halamanSteel Beam Column With Braced Framearno assassinBelum ada peringkat

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDari EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsBelum ada peringkat

- Lateral Support For Tier Building FramesDokumen4 halamanLateral Support For Tier Building Framesuhu_plus6482Belum ada peringkat

- Reinforced Concrete Buildings: Behavior and DesignDari EverandReinforced Concrete Buildings: Behavior and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Combined axial and bending strength of RC columnsDokumen21 halamanCombined axial and bending strength of RC columnsMiski45Belum ada peringkat

- Gusset Plate Stability Using Variable Stress TrajectoriesDokumen6 halamanGusset Plate Stability Using Variable Stress TrajectoriestmaBelum ada peringkat

- Chapter 1 - Introduction To Steel SectionDokumen24 halamanChapter 1 - Introduction To Steel SectionAhmad Ubaidillah Abdul RaniBelum ada peringkat

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- COLUMN EFFECTIVE LENGTH - Yura1971q2Dokumen6 halamanCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Dari EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Penilaian: 4 dari 5 bintang4/5 (10)

- Steel - 10-Prof. Zahid Siddiqi PDFDokumen71 halamanSteel - 10-Prof. Zahid Siddiqi PDFMuhammad AhmedBelum ada peringkat

- Beams and Framed Structures: Structures and Solid Body MechanicsDari EverandBeams and Framed Structures: Structures and Solid Body MechanicsPenilaian: 3 dari 5 bintang3/5 (2)

- Steel - 05-Prof. Zahid Siddiqi PDFDokumen39 halamanSteel - 05-Prof. Zahid Siddiqi PDFMuhammad AhmedBelum ada peringkat

- Transverse Plate-To-squarerectangular Hss ConnectionsDokumen7 halamanTransverse Plate-To-squarerectangular Hss Connectionsdeepak_dce_meBelum ada peringkat

- RISA Wood Design Training ManualDokumen352 halamanRISA Wood Design Training ManualГеорги ЦвятковBelum ada peringkat

- Design of Vertical Bracing Connections For High Seismic DriftDokumen12 halamanDesign of Vertical Bracing Connections For High Seismic DriftvBelum ada peringkat

- Engineering For Steel ConstructionDokumen2 halamanEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- SWD-CSA-A23.3-04 Shear Wall Design ManualDokumen82 halamanSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimBelum ada peringkat

- Steelwise PDFDokumen3 halamanSteelwise PDFFourHorsemenBelum ada peringkat

- Guide to Design of Post-Installed Anchor Bolt Systems in Hong KongDokumen87 halamanGuide to Design of Post-Installed Anchor Bolt Systems in Hong KongAhsan SattarBelum ada peringkat

- Introduction to Structural Steel DesignDokumen10 halamanIntroduction to Structural Steel DesignGail Nathalie LiraBelum ada peringkat

- Column Design CalculationDokumen1 halamanColumn Design CalculationD SRINIVASBelum ada peringkat

- Stiffner Design For Beam Column ConnectionsDokumen84 halamanStiffner Design For Beam Column ConnectionsfabnameBelum ada peringkat

- Portal Frame Practice ProblemsDokumen10 halamanPortal Frame Practice ProblemsBoyzz ChinBelum ada peringkat

- Shearwall DesignDokumen72 halamanShearwall DesignRemembr EmilzBelum ada peringkat

- Designing anchor reinforcement for seismic shear loadsDokumen38 halamanDesigning anchor reinforcement for seismic shear loadsSarah Perez100% (1)

- Anchor Bolts in Masonry Under Combined Tension and Shear - 2002Dokumen18 halamanAnchor Bolts in Masonry Under Combined Tension and Shear - 2002sethhoffman85Belum ada peringkat

- Reinforced Concrete Design 2: Frame AnalysisDokumen100 halamanReinforced Concrete Design 2: Frame AnalysisAhmad Ubaidillah Abdul Rani67% (3)

- Hilti HIT System - Rebar ApplicationDokumen34 halamanHilti HIT System - Rebar ApplicationTerence CheeBelum ada peringkat

- Structural Steel Column DesignDokumen54 halamanStructural Steel Column DesignAhmad Salih100% (1)

- Bending Moment and Shear Force Diagrams ExplainedDokumen11 halamanBending Moment and Shear Force Diagrams Explainedhardik5818100% (1)

- Application of AISC Design Provisions For Tapered Members PDFDokumen13 halamanApplication of AISC Design Provisions For Tapered Members PDFclam2014Belum ada peringkat

- Single Plate Framing Connection Design PDFDokumen83 halamanSingle Plate Framing Connection Design PDFlaiju p b100% (1)

- Steel ConnectionsDokumen29 halamanSteel ConnectionsSHRADDHA KADAM100% (1)

- Chapter 1 - Introduction To Structural Steel DesignDokumen44 halamanChapter 1 - Introduction To Structural Steel DesignKhaled Khafagy100% (1)

- 3.design of Steel StructuresDokumen13 halaman3.design of Steel Structuresarju21Belum ada peringkat

- Flexural Strength of Reinforced and Prestressed Concrete T-Beams PDFDokumen29 halamanFlexural Strength of Reinforced and Prestressed Concrete T-Beams PDFmotahareshBelum ada peringkat

- Truss ExampleDokumen8 halamanTruss Exampledixn__Belum ada peringkat

- Reinforced Shear Wall GuideDokumen25 halamanReinforced Shear Wall GuideGerald MagingaBelum ada peringkat

- Corrosion Protection and Connection Design: Choosing the Right SystemDokumen3 halamanCorrosion Protection and Connection Design: Choosing the Right Systemdimitris22Belum ada peringkat

- Distribution of Lateral ForcesDokumen2 halamanDistribution of Lateral ForcesGerald OrtizBelum ada peringkat

- Simplified Design of Reinforced Concrete Buildings - PDF - Strwength of Materials - Framing (Construction)Dokumen6 halamanSimplified Design of Reinforced Concrete Buildings - PDF - Strwength of Materials - Framing (Construction)chondroc11Belum ada peringkat

- Simple Shear Connections SteelwiseDokumen4 halamanSimple Shear Connections SteelwiseAnil K Vishwa100% (1)

- Analysis of Effects of Openings On RCC BeamDokumen20 halamanAnalysis of Effects of Openings On RCC BeamNilesh Saksena100% (1)

- Footing Soil Pressure From Biaxial LoadingDokumen18 halamanFooting Soil Pressure From Biaxial LoadingSon NguyenBelum ada peringkat

- Wind LoadDokumen2 halamanWind LoadMac KYBelum ada peringkat

- Cross Bracing Design PDFDokumen5 halamanCross Bracing Design PDFVictor Miranda AcuñaBelum ada peringkat

- Factors Affecting Strength of Epoxy Repaired TimberDokumen15 halamanFactors Affecting Strength of Epoxy Repaired TimberJosé PeBelum ada peringkat

- 2013 Masonry Shear WallDokumen4 halaman2013 Masonry Shear WallMohamed TabetBelum ada peringkat

- Steel Framed FloorsDokumen12 halamanSteel Framed Floorsyoki_triwahyudi50% (2)

- 16WS05 Chicago Wind Workshops Hour 3 Shearwalls and DiaphragmsDokumen86 halaman16WS05 Chicago Wind Workshops Hour 3 Shearwalls and DiaphragmsVengatesh HariBelum ada peringkat

- Limit Analysi of Reinforced Concrete SlabsDokumen122 halamanLimit Analysi of Reinforced Concrete Slabssebastian9033100% (1)

- 00 FormulasDokumen86 halaman00 FormulasKory EstesBelum ada peringkat

- Strengthening Design Limitation of Column PDFDokumen9 halamanStrengthening Design Limitation of Column PDFSushil DhunganaBelum ada peringkat

- 612c (Uas 2019)Dokumen37 halaman612c (Uas 2019)jawarta simamoraBelum ada peringkat

- Basics Design and Installation of Post Installed Rebars PDFDokumen39 halamanBasics Design and Installation of Post Installed Rebars PDFPatrick LaoBelum ada peringkat

- Temprorary Structure Design 30-07-2020Dokumen15 halamanTemprorary Structure Design 30-07-2020Ankush SharmaBelum ada peringkat

- Moren - MODULE 3 - Beams-ColumnDokumen18 halamanMoren - MODULE 3 - Beams-ColumnJoshua Espanto MorenBelum ada peringkat

- Full CalculationDokumen8 halamanFull CalculationkprabishBelum ada peringkat

- 11 03ChapGereDokumen14 halaman11 03ChapGereAfoldoBelum ada peringkat

- Retrofitting Transmission Tower Angle Legs to Increase Load CapacityDokumen247 halamanRetrofitting Transmission Tower Angle Legs to Increase Load CapacityLuis Horacio Martínez MartínezBelum ada peringkat

- Product Submittal Sheet: 1400S200-68 (50ksi, CP60) P - PunchedDokumen1 halamanProduct Submittal Sheet: 1400S200-68 (50ksi, CP60) P - PunchedAdnan QuaziBelum ada peringkat

- Buckling of Frames Theory of Elastic StabilityDokumen10 halamanBuckling of Frames Theory of Elastic StabilityNaturinda SarahBelum ada peringkat

- Discussion - A Technical Note - Derivation of The LRFD Column Design EquationsDokumen2 halamanDiscussion - A Technical Note - Derivation of The LRFD Column Design EquationsgigingBelum ada peringkat

- SyllabusDokumen38 halamanSyllabusVishalSelvanBelum ada peringkat

- Aircraft Structures For Engineering StudDokumen3 halamanAircraft Structures For Engineering StudMyname SmaBelum ada peringkat

- DESIGN OF NEW SHED AT RUSYAL MB PETROLIUMDokumen8 halamanDESIGN OF NEW SHED AT RUSYAL MB PETROLIUMamachmouchiBelum ada peringkat

- Ansys TipsDokumen79 halamanAnsys TipsMuhammad AliBelum ada peringkat

- Thickness CalculationsDokumen6 halamanThickness Calculationsvijayunity100% (1)

- Design of Gantry GirderDokumen46 halamanDesign of Gantry GirderGOVINDARAJU SBelum ada peringkat

- Stability Analysis and Design of Steel-Concrete Composite ColumnsDokumen19 halamanStability Analysis and Design of Steel-Concrete Composite ColumnsDarsHan MoHanBelum ada peringkat

- Stabilit Y of ColumnsDokumen45 halamanStabilit Y of ColumnsAnonymous POUAc3zBelum ada peringkat

- D. Study About AnsysDokumen6 halamanD. Study About AnsysLaxmi RaoBelum ada peringkat

- Subsea Concrete CylindersDokumen89 halamanSubsea Concrete CylindersSteven SebastianBelum ada peringkat

- Bracing Connection RefDokumen5 halamanBracing Connection Refsukarma acharyaBelum ada peringkat

- 5-Eigenvalue Buckling PredictionDokumen4 halaman5-Eigenvalue Buckling PredictionMaurizio FalconieriBelum ada peringkat

- Perea Et Al. - Slender CFT Experiments - Interaction Behavior - JSE 2014Dokumen12 halamanPerea Et Al. - Slender CFT Experiments - Interaction Behavior - JSE 2014prisciliano1Belum ada peringkat

- Offshore Fixed Platform Design In-Place Analysis: Pbt750@mun - CaDokumen60 halamanOffshore Fixed Platform Design In-Place Analysis: Pbt750@mun - CaJOSE LUIS GUTIERREZ GARCIABelum ada peringkat

- Experiment-5: Southwell Method To Study Flexural Instability of ColumnDokumen8 halamanExperiment-5: Southwell Method To Study Flexural Instability of ColumnRahul RoyBelum ada peringkat

- Nist GCR 16-917-38Dokumen56 halamanNist GCR 16-917-38Victor Vargas100% (1)

- Jicable 2019 Remote FreeFloatingDokumen6 halamanJicable 2019 Remote FreeFloatingAleksa SaricBelum ada peringkat

- SP 8004 - Panel FlutterDokumen51 halamanSP 8004 - Panel FlutterElumalai SrinivasanBelum ada peringkat

- ES5101 Week 3 Critique Writing Assignment OutlineDokumen4 halamanES5101 Week 3 Critique Writing Assignment Outlinekoksoon chongBelum ada peringkat

- Unit I Introduction To Limit State What Is Limit State?Dokumen15 halamanUnit I Introduction To Limit State What Is Limit State?rajBelum ada peringkat

- Structural AnalysisDokumen12 halamanStructural Analysisabhishek5810Belum ada peringkat

- ColumnsDokumen66 halamanColumnsArchana GSBelum ada peringkat

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (137)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBelum ada peringkat

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDari EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationPenilaian: 4 dari 5 bintang4/5 (18)

- AutoCAD Civil 3D - Roads Design: 2Dari EverandAutoCAD Civil 3D - Roads Design: 2Penilaian: 3.5 dari 5 bintang3.5/5 (2)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaDari EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaBelum ada peringkat

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Summary of Neil Postman's Amusing Ourselves to DeathDari EverandSummary of Neil Postman's Amusing Ourselves to DeathPenilaian: 4 dari 5 bintang4/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDari EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgePenilaian: 4.5 dari 5 bintang4.5/5 (59)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDari EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Matrix Methods of Structural AnalysisDari EverandMatrix Methods of Structural AnalysisPenilaian: 4.5 dari 5 bintang4.5/5 (8)

- Cable Supported Bridges: Concept and DesignDari EverandCable Supported Bridges: Concept and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Transportation Engineering: Theory, Practice, and ModelingDari EverandTransportation Engineering: Theory, Practice, and ModelingBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shallow Foundations: Discussions and Problem SolvingDari EverandShallow Foundations: Discussions and Problem SolvingPenilaian: 5 dari 5 bintang5/5 (1)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDari EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingBelum ada peringkat

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookDari EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookBelum ada peringkat

- Water 4.0: The Past, Present, and Future of the World's Most Vital ResourceDari EverandWater 4.0: The Past, Present, and Future of the World's Most Vital ResourcePenilaian: 3.5 dari 5 bintang3.5/5 (9)