WS2000 Datasheet

Diunggah oleh

Vega47Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

WS2000 Datasheet

Diunggah oleh

Vega47Hak Cipta:

Format Tersedia

WS2000 welding control

data sheet

www.bfentron.co.uk

typical systems

Proven features and flexibility

The WS2000 welding control is based on a high-performance 16-bit

microcontroller and uses cost effective construction techniques to produce a

low-cost, high-specification system that is easy to use and maintain. The

standard configuration is as a fully integrated controller that includes SCR,

power supply, circuit breaker and welding timer in a single compact package.

The WS2000 is suitable for most types of resistance welding application

including automotive, manual, projection and seam equipment.

features benefits

single/dual gun flexible

16 welding programs versatile

three-interval welding

sequence

suitable for coated materials

constant current or phase

angle control modes

quality welding

programmable digital outputs easy to interface with other equipment

stepping and counting quality welding

network or local programming for large or small installations

analogue pressure control can be used with proportional valves

data card option for backups and monitoring

extensive monitoring and

diagnostics

pinpoint most welding problems

options

CMU2/Starchive PC software for programming and monitoring

RS232 (printer) or RS485 (network) adapters

two-hand start

medium frequency adapter

3-phase drive card

data card

welding cable monitor

configurations

WS2000 + data card

CMU network system

WS2000 custom case

SCRs from 63 A to 250 A circuit breakers from 63 A to 600 A ELR

BF ENTRON Ltd Castle Mill Works Dudley West Midlands DY1 4DA UK

( +44 (0)1384 455401 +44 (0)1384 455551 8 sales@bfentron.co.uk

WS2000 welding control

data sheet

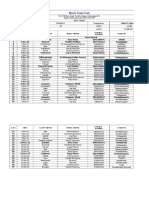

welding programs x 16 SCR options

3-interval weld sequence with phase angle/constant current control SCR type kVA

spot/repeat/seam with long/short weld sequences TC50/1WS 50

slope control TC150/1WS 150

single/dual gun TC500/1WS 500

pulsation all SCRs are water cooled

electrode stick detection

analogue pressure control circuit breakers

automatic retry type rating breaking capacity

programmable digital outputs 63AS 63 A 25 kA

63AH 63 A 45 kA

monitoring programs x 16 125AS 125 A 25 kA

low/pre/high limits for each weld interval 125AH 125 A 45 kA

fail counter 225AS 225 A 25 kA

225AH 225 A 45 kA

electrode programs 1 schedule per gun 400AS 400 A 25 kA

maximum steps 5 400AH 400 A 45 kA

welds per step 0..999 600AS 600 A 25 kA

change per step -50..+200 % heat/current 600AH 600 A 45 kA

automatic interpolation between steps all circuit breakers are available with an optional ELR

optional stop at end of stepping

optional output at end of stepping environmental

prewarning on last step temperature

reset via input/programmer/CMU2 - operating -5 to +60C

- storage -25 to +70C

counter 1 per gun humidity

components 0..65000 - operating up to 90% (relative)

welds per component 1..99 - storage up to 90%

optional stop at end of count

optional output at end of count

reset via input/programmer/CMU2

i/o ratings

4 outputs 1 A @ 24 V dc/110 V ac each

8 outputs 500 mA @ 24 V dc/110 V ac each

14 inputs 10 mA @ 24 V dc each (max)

power/synchronisation requirements

voltage 50VA @ 380/400/420/440 V ac

line frequency 50/60 Hz 1Hz

Information in the document is subject to change without notice.

91-10-00-00-24 rev. 1 2003 BF ENTRON Ltd.

BF ENTRON Ltd Castle Mill Works Dudley West Midlands DY1 4DA UK

( +44 (0)1384 455401 +44 (0)1384 455551 8 sales@bfentron.co.uk

Anda mungkin juga menyukai

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDari EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsPenilaian: 3.5 dari 5 bintang3.5/5 (6)

- DocumentDokumen96 halamanDocumentKatie Hui TongBelum ada peringkat

- SCR/SCRF Series: Industry's First Choice For Time-Tested Proven ReliabilityDokumen8 halamanSCR/SCRF Series: Industry's First Choice For Time-Tested Proven ReliabilityAdrian M FahriBelum ada peringkat

- ESS reporting & analysis toolDokumen9 halamanESS reporting & analysis toolHemavathi Hema100% (1)

- ABB Substation Automation Under/Over Voltage Relay VHXm FeaturesDokumen6 halamanABB Substation Automation Under/Over Voltage Relay VHXm FeaturesAmit KumarBelum ada peringkat

- Application Structure and Files-R14Dokumen23 halamanApplication Structure and Files-R14Developer T24Belum ada peringkat

- Ergonomic Analysis of Motor VehiclesDokumen14 halamanErgonomic Analysis of Motor VehiclesdeyeBelum ada peringkat

- User Manual Sepam 20-1Dokumen78 halamanUser Manual Sepam 20-1Ursula JohnsonBelum ada peringkat

- LandisGyr ZXG300 TechData EN1Dokumen6 halamanLandisGyr ZXG300 TechData EN1Atok Lukmanul KhakimBelum ada peringkat

- KAM CatalogDokumen34 halamanKAM Catalog08Dhanushka100% (1)

- ATV32HD15N4Dokumen12 halamanATV32HD15N4gasm22Belum ada peringkat

- Modicon M221 TM221C16RDokumen11 halamanModicon M221 TM221C16RBrian Parado LeonBelum ada peringkat

- PIECAL 535 10-50ma 4-20 Ma - V Calibrator Datasheet 535-9001 REV GDokumen4 halamanPIECAL 535 10-50ma 4-20 Ma - V Calibrator Datasheet 535-9001 REV GHan ArifBelum ada peringkat

- Protect 7VH60 High-Impedance Busbar RelayDokumen7 halamanProtect 7VH60 High-Impedance Busbar RelayMohamed TalebBelum ada peringkat

- ATV32 variable speed drive 7.5 kW data sheetDokumen11 halamanATV32 variable speed drive 7.5 kW data sheetbmshivakumarBelum ada peringkat

- Microprocessor-Based Scrpowercontroller Designed Fo R ApplicationflexibilityDokumen4 halamanMicroprocessor-Based Scrpowercontroller Designed Fo R ApplicationflexibilityCamilo MartinezBelum ada peringkat

- 06 Pomocni Sklopnici I RelejiDokumen55 halaman06 Pomocni Sklopnici I Relejiaksiom007Belum ada peringkat

- IEC-Compliant Electricity Meter Technical SpecsDokumen6 halamanIEC-Compliant Electricity Meter Technical Specsroadkill7Belum ada peringkat

- Công Tơ ZMG 400Dokumen6 halamanCông Tơ ZMG 400vietbkfetBelum ada peringkat

- Zelio Control RM35LM33MWDokumen6 halamanZelio Control RM35LM33MWOgreson OgreBelum ada peringkat

- Duplicator Power Source 102050 - 01 - enDokumen11 halamanDuplicator Power Source 102050 - 01 - enCarlos AlbertoBelum ada peringkat

- TM221CE40R: Product Data SheetDokumen12 halamanTM221CE40R: Product Data SheetGiles HarperBelum ada peringkat

- Trivector MeterDokumen2 halamanTrivector MeterTarun AhujaBelum ada peringkat

- TM221CE24R: Product DatasheetDokumen9 halamanTM221CE24R: Product DatasheetNuttakan AsapaviriyaBelum ada peringkat

- Air Circuit Breaker: Catalogue 2012Dokumen20 halamanAir Circuit Breaker: Catalogue 2012Addin Galih PrakosoBelum ada peringkat

- 4-20 Milliamp Loop Calibrator: Model 530Dokumen4 halaman4-20 Milliamp Loop Calibrator: Model 530mahuzierBelum ada peringkat

- Airpax PDFDokumen46 halamanAirpax PDFvjBelum ada peringkat

- ACB MitsubishiDokumen64 halamanACB MitsubishiAlHadiPutroBelum ada peringkat

- Solid State Contactor: DRC SeriesDokumen11 halamanSolid State Contactor: DRC SeriesloritocomBelum ada peringkat

- ZIEGLER EM 3490 SS Energy Meter RS485 SpecsDokumen6 halamanZIEGLER EM 3490 SS Energy Meter RS485 SpecsmaheshBelum ada peringkat

- Meter ZxD-300 XT (7102000134 - En)Dokumen4 halamanMeter ZxD-300 XT (7102000134 - En)dikox1x2Belum ada peringkat

- Easy to operate general-purpose instrument that's as easy to affordDokumen5 halamanEasy to operate general-purpose instrument that's as easy to affordakv_303Belum ada peringkat

- DC/DC Converters: FeaturesDokumen4 halamanDC/DC Converters: FeatureskhoshnamaBelum ada peringkat

- Datasheet ATV61EXS5C63N4Dokumen8 halamanDatasheet ATV61EXS5C63N4flake03Belum ada peringkat

- ATV61HD30N4Dokumen4 halamanATV61HD30N4BlAdE 12Belum ada peringkat

- CET Power - Datasheet BRAVO 230vac - 2014 v1Dokumen2 halamanCET Power - Datasheet BRAVO 230vac - 2014 v1Micah WilsonBelum ada peringkat

- ATV312HU75N4: Product Data SheetDokumen3 halamanATV312HU75N4: Product Data Sheetkfd2Belum ada peringkat

- Drts 33: The New Generation of Advanced Test Equipments For Relays, Energy Meters, Transducers and Power Quality MetersDokumen8 halamanDrts 33: The New Generation of Advanced Test Equipments For Relays, Energy Meters, Transducers and Power Quality MetersHameed Ahmed Khas KheliBelum ada peringkat

- Charger US-AT10 Order FormDokumen6 halamanCharger US-AT10 Order Formwjames007Belum ada peringkat

- ATV31HU55N4A: Variable Speed Drive ATV31 - 5.5kW - 500V 3-Phase Supply - EMC Filter - IP20Dokumen3 halamanATV31HU55N4A: Variable Speed Drive ATV31 - 5.5kW - 500V 3-Phase Supply - EMC Filter - IP20Lê HiệpBelum ada peringkat

- Ca3kn22bd Telemecanique - Unit5.relayDokumen8 halamanCa3kn22bd Telemecanique - Unit5.relaykapenziBelum ada peringkat

- 230-400/24VDC - Max 10% Ripple: Type SUSL-KDokumen1 halaman230-400/24VDC - Max 10% Ripple: Type SUSL-KToroid Do BrasilBelum ada peringkat

- Atr243 Rev GDokumen50 halamanAtr243 Rev GSamir HimedBelum ada peringkat

- RISH Energy Measures AllDokumen8 halamanRISH Energy Measures AllDevin Carlos100% (1)

- Em 6400Dokumen6 halamanEm 6400chetanmahulkar755374Belum ada peringkat

- RCB600 :: ROAL Living EnergyDokumen10 halamanRCB600 :: ROAL Living EnergyroalscribdBelum ada peringkat

- Variable speed drive data sheetDokumen13 halamanVariable speed drive data sheetMutu DanielBelum ada peringkat

- E6000 Catalog v23Dokumen6 halamanE6000 Catalog v23rommel76Belum ada peringkat

- PRODUCT ATV71HD15N4ZDokumen4 halamanPRODUCT ATV71HD15N4ZSilas SilvaBelum ada peringkat

- Altivar 71 ATV71HD11N4Dokumen13 halamanAltivar 71 ATV71HD11N4Dagostino GigiBelum ada peringkat

- 3gen 400-600Dokumen4 halaman3gen 400-600Alexandre BatistaBelum ada peringkat

- PSTN and Leased Line Modem Technical SpecificationsDokumen4 halamanPSTN and Leased Line Modem Technical Specificationsdevdas_atherBelum ada peringkat

- 8300/8400/8500 Power Meter: Intelligent Revenue MetersDokumen5 halaman8300/8400/8500 Power Meter: Intelligent Revenue MetersaleruedamxBelum ada peringkat

- DRTS 64 - 2014Dokumen8 halamanDRTS 64 - 2014Dulmar MamaniBelum ada peringkat

- 2ucd180000e002 - B Statcom Technical CatalogueDokumen20 halaman2ucd180000e002 - B Statcom Technical Cataloguehey_frindBelum ada peringkat

- CVMk2 enDokumen4 halamanCVMk2 enSphagneBelum ada peringkat

- ATV71H075N4: Product Data SheetDokumen4 halamanATV71H075N4: Product Data SheetOtto AcnBelum ada peringkat

- ATV71HC20N4 DocumentDokumen8 halamanATV71HC20N4 DocumentToth VasileBelum ada peringkat

- DC High Voltage Capacitor Chargers 2.5-5kJDokumen3 halamanDC High Voltage Capacitor Chargers 2.5-5kJsantosh_babar_26Belum ada peringkat

- Altivar ATV61HU55N4 CatalogueDokumen4 halamanAltivar ATV61HU55N4 CatalogueEugen Marius BadescuBelum ada peringkat

- Altivar 71 ATV71HU75N4Dokumen4 halamanAltivar 71 ATV71HU75N4electrosysro8560Belum ada peringkat

- VP210 En002Dokumen22 halamanVP210 En002Nikhil SinghBelum ada peringkat

- Reliable test devices for electric power systemsDokumen6 halamanReliable test devices for electric power systemsCoty62Belum ada peringkat

- Visual C++ NET TutorialsDokumen39 halamanVisual C++ NET Tutorialspgoyal10Belum ada peringkat

- Инструкция терминала IND310Dokumen52 halamanИнструкция терминала IND310ДенисBelum ada peringkat

- C6925 0000 Komputer Przemysłowy Beckhoff Manual PDFDokumen152 halamanC6925 0000 Komputer Przemysłowy Beckhoff Manual PDFThưởng Văn LêBelum ada peringkat

- Lecture 9 2 5g by Rab Nawaz Jadoon PDFDokumen13 halamanLecture 9 2 5g by Rab Nawaz Jadoon PDFShahbaz JadoonBelum ada peringkat

- Data Sheet: FeaturesDokumen16 halamanData Sheet: FeatureschristianBelum ada peringkat

- Transportation ModelDokumen41 halamanTransportation ModelAbhishek0% (1)

- Prototyping Benefits of Paper PrototypesDokumen34 halamanPrototyping Benefits of Paper PrototypesDiman IonutBelum ada peringkat

- Top Deals on OnePlus MobilesDokumen8 halamanTop Deals on OnePlus MobilesParinita PariharBelum ada peringkat

- CSC 510 Syllabus Spring 2012 Software EngineeringDokumen7 halamanCSC 510 Syllabus Spring 2012 Software EngineeringAnubhav JainBelum ada peringkat

- Panasonic KW1M HDokumen11 halamanPanasonic KW1M Hbole90Belum ada peringkat

- Kerio Control Adminguide en 9.2.8 3061Dokumen352 halamanKerio Control Adminguide en 9.2.8 3061Nushabe CeferovaBelum ada peringkat

- TOC-Pearson - Selling and Sales Management, 9 - E - David Jobber & Geoffrey LancasterDokumen2 halamanTOC-Pearson - Selling and Sales Management, 9 - E - David Jobber & Geoffrey LancasterDaleBelum ada peringkat

- Omron Sysmac WayDokumen40 halamanOmron Sysmac WayAurellioBelum ada peringkat

- (Hons,) SyllabusDokumen13 halaman(Hons,) SyllabusDhawal RajBelum ada peringkat

- IC Risk Register Template For Banks 9419Dokumen2 halamanIC Risk Register Template For Banks 9419Rahmat ChenaarBelum ada peringkat

- Ujian SPSS TatiDokumen21 halamanUjian SPSS TatiLina NaiwaBelum ada peringkat

- Difficulties in Learning Basic Concepts in Probability and Statistics: Implications For ResearchDokumen21 halamanDifficulties in Learning Basic Concepts in Probability and Statistics: Implications For ResearchRoy Umaña CarrilloBelum ada peringkat

- Sri Final Job SheetDokumen4 halamanSri Final Job SheetMohan LalBelum ada peringkat

- Survey MSTDokumen29 halamanSurvey MSTAnonymous a3K3WgBelum ada peringkat

- SAP EWM DeconsolidationDokumen2 halamanSAP EWM DeconsolidationS BanerjeeBelum ada peringkat

- Generator Auto Start Mod Rolando Mod 8 ChokeDokumen3 halamanGenerator Auto Start Mod Rolando Mod 8 Chokeali mohammedBelum ada peringkat

- Daa Lab Term Work - Pcs 409Dokumen13 halamanDaa Lab Term Work - Pcs 409Tem PBelum ada peringkat

- Signal To Interference Ratio & Signal To Noise Ratio: Lovely Professional University TopicDokumen7 halamanSignal To Interference Ratio & Signal To Noise Ratio: Lovely Professional University TopicRavi RajBelum ada peringkat

- DM NVX Network Min RequirementsDokumen1 halamanDM NVX Network Min Requirementsblesson123Belum ada peringkat

- Munyisia Et Al 2011bDokumen12 halamanMunyisia Et Al 2011bpita romawatiBelum ada peringkat

- Telit GL865-DUAL-QUAD Hardware User Guide r7Dokumen76 halamanTelit GL865-DUAL-QUAD Hardware User Guide r7salasugo5751Belum ada peringkat