Motoare Diesel - Propulsie

Diunggah oleh

Dan Aurelian PopaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Motoare Diesel - Propulsie

Diunggah oleh

Dan Aurelian PopaHak Cipta:

Format Tersedia

MARINE PROPULSION

DIESEL ENGINE

MARINE PROPULSION

DIESEL ENGINE

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Careful consideration of both people and the environment is indispensable

for the next generation of marine propulsion systems.

Research & Development at Daihatsu Diesel continues along dual tracks

that aim to boost power, save on fuel and deliver maintenance-free products,

while also forging the engineering technology for drastically cutting emissions

of harmful substances like NOx found in exhaust gas.

DKM

/

DCM

/

DEM

series

Gentleness toward People and the Environment

Our Technological Cornerstone

Solid Reliability

Based on Performance

Daihatsu Diesel engines have powered a wide

variety of ships over the years, and won high

acclaim everywhere.

Energy Savings

and Low Maintenance

By thoroughly revising everything, from fuels to

the number of parts, we have achieved excellent

economy.

Full Compliance with

NOx Secondary Regulations

We also responded quickly to secondary regulations on NOx

emissions. Featuring both low vibration and low noise, our

engines are truly gentle on people and the environment.

2 3

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Careful consideration of both people and the environment is indispensable

for the next generation of marine propulsion systems.

Research & Development at Daihatsu Diesel continues along dual tracks

that aim to boost power, save on fuel and deliver maintenance-free products,

while also forging the engineering technology for drastically cutting emissions

of harmful substances like NOx found in exhaust gas.

DKM

/

DCM

/

DEM

series

Gentleness toward People and the Environment

Our Technological Cornerstone

Solid Reliability

Based on Performance

Daihatsu Diesel engines have powered a wide

variety of ships over the years, and won high

acclaim everywhere.

Energy Savings

and Low Maintenance

By thoroughly revising everything, from fuels to

the number of parts, we have achieved excellent

economy.

Full Compliance with

NOx Secondary Regulations

We also responded quickly to secondary regulations on NOx

emissions. Featuring both low vibration and low noise, our

engines are truly gentle on people and the environment.

2 3

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Cost-performing

Navi gable

Reliable

Aftercare

Service

Thorough

Quality

Control

Proven

Over and Over

Again

Tough,

Dependable &

Environment-

Friendly

No More

Critical

Revolutions

Optimal

Geared

System

Improved

Propulsion

Efficiency

Heavy-Fuel

Drive

Front Power

Take-Off & Shaft

Generator

Effective

Utilization of

Waste Heat

Simple

Maintenance &

Inspections

Designed for

Low Vibration

& Low Noise

Cost-performing

Navi gable

Reliable

Daihatsu's geared diesel engines are

employed in ferry boats, tankers, freighters,

working craft and many other types vessels.

Our marine engines are highly acclaimed all

over as reliable propulsion systems.

Years of enduring R & D has made us tough

and proud of our successful record and won

us the trust of many faithful customers. Our

search for progress and betterment continues

with strong emphasis on reducing emissions

of harmful substances.

Both the engine and shaft drive system are no

longer operated in fear of critical revolutions when

shifting from idle to rated rpm. The merits are well

demonstrated in fuel-saving cruising at reduced

speed. Moreover, thanks to our in-house

developed doughnut RD coupling, we have

eliminated the problem of torsional vibration. Now,

customers are free to select shafting and propeller

to suit their vessel's needs.

Our manufacturing plants are certified by JG,

NK, LR, AB and CCS, moreover the famed

ISO9001 for excellence in quality assurance

systems. Thanks to this, the hi-tech and high

quality we stand by are known worldwide.

Daihatsu Diesel has offices and dealers all

over the world. We offer complete aftercare

service and make every effort to communicate

with customers.

The generator and cargo oil pump are driven

by a crank shaft through the reduction gear

and front engine block. This saves on space,

reduces maintenance and offers other

advantages.

Daihatsu's geared diesel engines were the

first in the world to run on heavy fuel

(H.O.7000 cSt/50C). Moreover, they can run

in the low-load region.

Adopting an exhaust gas economizer and hot

effluent circulation system, waste heat energy

is recovered and efficiently utilized as an

onboard heat source to heat tanks, lines, living

quarters, etc.

We have spared no efforts in shortening

maintenance time and reducing the number of

parts. As a result, maintenance and inspections are

both simple and speedy for mid-speed engines.

Propeller revolutions can also be freely set. A

larger diameter propeller and multiple-input

gear system greatly boosts economy, sailing

speed and tow-tug force.

Customers can freely select reduction gears

and gear ratio to suit vessel usage.

Furthermore, with additions like Daihatsu's

CRASH ASTERN system, slipping control and

2-speed slip-clutch reduction gears, vessels

can go smoothly and directly from full-speed

to dead-slow ahead.

Our mid-speed engines have a low

vibromotive force, resonate with vessel natural

vibrations and are quiet. Furthermore,

dynamic load is small and torque fluctuation

minimized, making them advantageous.

Aftercare

Service

Thorough

Quality

Control

Proven

Over and Over

Again

Tough,

Dependable &

Environment-

Friendly

No More

Critical

Revolutions

Optimal

Geared

System

Improved

Propulsion

Efficiency

Heavy-Fuel

Drive

Front Power

Take-Off & Shaft

Generator

Effective

Utilization of

Waste Heat

Simple

Maintenance &

Inspections

Designed for

Low Vibration

& Low Noise

4 5

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Power, Cost and Navigability ... Daihatsu's Geared Diesel Engines

Meet Expectation with Overall Performance.

At Daihatsu Diesel, in order to produce geared diesel engines customers can be satisfied with,

we pump a lot of effort into improving basic performance while also constructively

and logically challenging new technological development.

Customers turn us for most everything ... power, cost-performance, navigability, etc.

Our geared diesel engines are highly respected and evaluated for

being forward-looking and always one step ahead.

Cost-performing

Navi gable

Reliable

Aftercare

Service

Thorough

Quality

Control

Proven

Over and Over

Again

Tough,

Dependable &

Environment-

Friendly

No More

Critical

Revolutions

Optimal

Geared

System

Improved

Propulsion

Efficiency

Heavy-Fuel

Drive

Front Power

Take-Off & Shaft

Generator

Effective

Utilization of

Waste Heat

Simple

Maintenance &

Inspections

Designed for

Low Vibration

& Low Noise

Cost-performing

Navi gable

Reliable

Daihatsu's geared diesel engines are

employed in ferry boats, tankers, freighters,

working craft and many other types vessels.

Our marine engines are highly acclaimed all

over as reliable propulsion systems.

Years of enduring R & D has made us tough

and proud of our successful record and won

us the trust of many faithful customers. Our

search for progress and betterment continues

with strong emphasis on reducing emissions

of harmful substances.

Both the engine and shaft drive system are no

longer operated in fear of critical revolutions when

shifting from idle to rated rpm. The merits are well

demonstrated in fuel-saving cruising at reduced

speed. Moreover, thanks to our in-house

developed doughnut RD coupling, we have

eliminated the problem of torsional vibration. Now,

customers are free to select shafting and propeller

to suit their vessel's needs.

Our manufacturing plants are certified by JG,

NK, LR, AB and CCS, moreover the famed

ISO9001 for excellence in quality assurance

systems. Thanks to this, the hi-tech and high

quality we stand by are known worldwide.

Daihatsu Diesel has offices and dealers all

over the world. We offer complete aftercare

service and make every effort to communicate

with customers.

The generator and cargo oil pump are driven

by a crank shaft through the reduction gear

and front engine block. This saves on space,

reduces maintenance and offers other

advantages.

Daihatsu's geared diesel engines were the

first in the world to run on heavy fuel

(H.O.7000 cSt/50C). Moreover, they can run

in the low-load region.

Adopting an exhaust gas economizer and hot

effluent circulation system, waste heat energy

is recovered and efficiently utilized as an

onboard heat source to heat tanks, lines, living

quarters, etc.

We have spared no efforts in shortening

maintenance time and reducing the number of

parts. As a result, maintenance and inspections are

both simple and speedy for mid-speed engines.

Propeller revolutions can also be freely set. A

larger diameter propeller and multiple-input

gear system greatly boosts economy, sailing

speed and tow-tug force.

Customers can freely select reduction gears

and gear ratio to suit vessel usage.

Furthermore, with additions like Daihatsu's

CRASH ASTERN system, slipping control and

2-speed slip-clutch reduction gears, vessels

can go smoothly and directly from full-speed

to dead-slow ahead.

Our mid-speed engines have a low

vibromotive force, resonate with vessel natural

vibrations and are quiet. Furthermore,

dynamic load is small and torque fluctuation

minimized, making them advantageous.

Aftercare

Service

Thorough

Quality

Control

Proven

Over and Over

Again

Tough,

Dependable &

Environment-

Friendly

No More

Critical

Revolutions

Optimal

Geared

System

Improved

Propulsion

Efficiency

Heavy-Fuel

Drive

Front Power

Take-Off & Shaft

Generator

Effective

Utilization of

Waste Heat

Simple

Maintenance &

Inspections

Designed for

Low Vibration

& Low Noise

4 5

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Power, Cost and Navigability ... Daihatsu's Geared Diesel Engines

Meet Expectation with Overall Performance.

At Daihatsu Diesel, in order to produce geared diesel engines customers can be satisfied with,

we pump a lot of effort into improving basic performance while also constructively

and logically challenging new technological development.

Customers turn us for most everything ... power, cost-performance, navigability, etc.

Our geared diesel engines are highly respected and evaluated for

being forward-looking and always one step ahead.

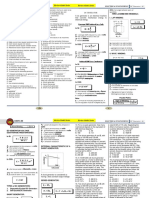

MARINE PROPULSION

DIESEL ENGINE

1

5

0

2

0

0

2

5

0

3

0

0

2

0

0

0

3

0

0

0

4

0

0

0

P

ro

p

e

lle

r re

v

o

lu

tio

n

s

(m

in

-1

)

0

.4

6

0

.4

8

0

.5

0

0

.5

2

0

.5

4

0

.5

6

0

.5

8

0

.6

0

0

.6

2

0

.6

4

P

ro

p

e

lle

r d

ia

m

e

te

r

P

ro

p

e

lle

r e

ffic

ie

n

c

y

6 7

Ship equipped with

CRASH ASTERN

system

Ship not equipped with

CRASH ASTERN

system

"Go Astern" command Full stop

"Go Astern"

command

Neutral

Full ahead

Full ahead

Full stop

Generator

Reduction

gear

Fire pump,

cargo oil pump, etc.

Clutch

Engine

A Wide Variation to Meet a Wide Range of Needs

Daihatsu's geared diesel engines come in a wide line-up from single-engine single-shaft

systems to large multiple-input systems. Customers can choose the best system based on

ship size, fuel, usage, etc.

Multiple-

Geared

Diesel

Engines

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

6DKM-20e

6DEM-23750min-1

6DEM-23900min-1

6DKM-26e

6DKM-28e

8DKM-28e

6DCM-32e

6DKM-36e

8DCM-32e

8DKM-36e

12DKM-36e

kWm 6000

Power output on D.O. Power output on H.F.O.

Daihatsu's multiple-geared diesel engines are ideal for ships with twin-shaft propellers or

low ceiling engine rooms. We offer a wide selection to choose including a twin-engine

single-shaft system, single-engine twin-shaft system, four-engine twin-shaft system,

four-engine single-shaft system and eight-engine twin-shaft system. Engine cut-off is also

possible according to ship speed.

Single-Engine Twin-Shaft System for Double-Bow Ships

Daihatsu Diesel engines are at work onboard double-bow ships navigating narrow channels

or short routes, or which operate as sightseeing boats on river cruises, etc. A single engine

drives the propellers on the bow and stern. Any combination of single-engine twin-shaft

system and Daihatsu's remote control system can be selected according to steering

demands and guarantees improved navigation.

Single-engine twin-shaft system

Two-engine twin-shaft system

6DKM-20(e)

With the right size propeller, fuel consumption is reduced by as much as 3% in comparison

with conventional propellers running at the same nautical speed, when propeller rpm is

lowered by 10%. Daihatsu Diesel can set the propeller that best matches the vessel thus

offering greatly improved propulsion efficiency.

CRASH

ASTERN

System

With a low-rpm large-diameter propeller, engine stalling is always a problem when moving

astern because of increased torque and engine overload. For this reason, Daihatsu geared

diesel engines employ our own CRASH ASTERN system. It can also be effectively operated

from the bridge.

With Daihatsu's geared diesel engines, generators, cargo oil pumps and other machinery

can be driven using power drawn through the front engine block and reduction gear. This

system greatly reduces fuel consumption. What's more, one of the generators used in

conventional systems can be omitted, which enables more effective use of dead space. In

addition, this kind of system reduces labor and costs in running and maintenance. Also,

engine and onboard control systems can be freely designed.

* Performance will vary according to ship speed, type of vessel and sea conditions.

6DKM-20(e)

Large

Diameter

Propeller

model

Power

Take-Off

& Engine

Layout

Single-Engine Single-Shaft System

Two-engine

single-shaft

system

Four-engine

twin-shaft

system

Four-engine

single-shaft

system

P

ro

p

e

lle

r

d

ia

m

e

te

r

(m

m

)

Propeller Efficiency

for 499G/T Tanker

(2000PS Engine)

MARINE PROPULSION

DIESEL ENGINE

1

5

0

2

0

0

2

5

0

3

0

0

2

0

0

0

3

0

0

0

4

0

0

0

P

ro

p

e

lle

r re

v

o

lu

tio

n

s

(m

in

-1

)

0

.4

6

0

.4

8

0

.5

0

0

.5

2

0

.5

4

0

.5

6

0

.5

8

0

.6

0

0

.6

2

0

.6

4

P

ro

p

e

lle

r d

ia

m

e

te

r

P

ro

p

e

lle

r e

ffic

ie

n

c

y

6 7

Ship equipped with

CRASH ASTERN

system

Ship not equipped with

CRASH ASTERN

system

"Go Astern" command Full stop

"Go Astern"

command

Neutral

Full ahead

Full ahead

Full stop

Generator

Reduction

gear

Fire pump,

cargo oil pump, etc.

Clutch

Engine

A Wide Variation to Meet a Wide Range of Needs

Daihatsu's geared diesel engines come in a wide line-up from single-engine single-shaft

systems to large multiple-input systems. Customers can choose the best system based on

ship size, fuel, usage, etc.

Multiple-

Geared

Diesel

Engines

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

6DKM-20e

6DEM-23750min-1

6DEM-23900min-1

6DKM-26e

6DKM-28e

8DKM-28e

6DCM-32e

6DKM-36e

8DCM-32e

8DKM-36e

12DKM-36e

kWm 6000

Power output on D.O. Power output on H.F.O.

Daihatsu's multiple-geared diesel engines are ideal for ships with twin-shaft propellers or

low ceiling engine rooms. We offer a wide selection to choose including a twin-engine

single-shaft system, single-engine twin-shaft system, four-engine twin-shaft system,

four-engine single-shaft system and eight-engine twin-shaft system. Engine cut-off is also

possible according to ship speed.

Single-Engine Twin-Shaft System for Double-Bow Ships

Daihatsu Diesel engines are at work onboard double-bow ships navigating narrow channels

or short routes, or which operate as sightseeing boats on river cruises, etc. A single engine

drives the propellers on the bow and stern. Any combination of single-engine twin-shaft

system and Daihatsu's remote control system can be selected according to steering

demands and guarantees improved navigation.

Single-engine twin-shaft system

Two-engine twin-shaft system

6DKM-20(e)

With the right size propeller, fuel consumption is reduced by as much as 3% in comparison

with conventional propellers running at the same nautical speed, when propeller rpm is

lowered by 10%. Daihatsu Diesel can set the propeller that best matches the vessel thus

offering greatly improved propulsion efficiency.

CRASH

ASTERN

System

With a low-rpm large-diameter propeller, engine stalling is always a problem when moving

astern because of increased torque and engine overload. For this reason, Daihatsu geared

diesel engines employ our own CRASH ASTERN system. It can also be effectively operated

from the bridge.

With Daihatsu's geared diesel engines, generators, cargo oil pumps and other machinery

can be driven using power drawn through the front engine block and reduction gear. This

system greatly reduces fuel consumption. What's more, one of the generators used in

conventional systems can be omitted, which enables more effective use of dead space. In

addition, this kind of system reduces labor and costs in running and maintenance. Also,

engine and onboard control systems can be freely designed.

* Performance will vary according to ship speed, type of vessel and sea conditions.

6DKM-20(e)

Large

Diameter

Propeller

model

Power

Take-Off

& Engine

Layout

Single-Engine Single-Shaft System

Two-engine

single-shaft

system

Four-engine

twin-shaft

system

Four-engine

single-shaft

system

P

ro

p

e

lle

r

d

ia

m

e

te

r

(m

m

)

Propeller Efficiency

for 499G/T Tanker

(2000PS Engine)

8 9

Reversible reduction gear

Coaxial

Model

Offset

Daihatsu's Reduction Gears - One Supporting Element of Engine High Reliability

Our reduction gears have a built-in main thrust bearing and wet hydraulic clutch, and can

be incorporated in the CRASH ASTERN system. We also have a wide selection of

speed-increasing and reduction gears for driving any type of machinery, which can be used

on the engine front end block.

DICS

(Daihatsu Slipping

Clutch System)

Constant-

Speed

Shaft

Generator

DRA-50F

Reversible

Reduction

Gear

Though low-speed and high thrust are necessary for port navigation, high-speed cruising

performance is needed on the open seas. Our 2-speed reduction gear is ideal for the situation.

We developed the 2-speed system (2-step ahead, 2-step astern) to maximize efficiency in

normal and low-speed sailing. Because the reduction gear is suited to all kinds of vessels,

from freighters to fishing trawlers, captains all over have favorably evaluated it.

Clutch fluid is electronically controlled to slip the clutch. As such, propeller revolutions

below idling rpm are freely controlled.

(Vertically offset,

Horizontally offset)

Single-engine

single-shaft

Multiple engine

single-shaft

Special

speed-increasing/

reduction gear

1. Enables dead-slow sailing ahead/astern with a fixed pitch propeller (FPP).

2. Enables shockless, smooth clutch meshing.

3. Propeller revolutions remain stable even under fluctuating engine revolution

and propeller load.

Features

1. An electronic governor keeps

constant generator revolutions,

thus ensuring a stable power

supply.

2. Because of the 2-speed

slipping clutch, the generator

can operate a wide engine

revolution range from idling to

rated rpm.

3. Generator revolutions and droop

can be adjusted easily during

generator operation. Load

switching to other generators and

parallel operation can performed

easily.

A compact constant-speed shaft generator is built into the reduction gear. Clutch fluid is

automatically controlled by an electronic governor. By slipping the clutch, generator

revolutions can be kept constant even under fluctuating engine revolution.

DRA-80F

MARINE PROPULSION

DIESEL ENGINE

2-Speed

Reduction

Gears

Features

Non-reversible reduction gear

Reversible reduction gear

Reversible reduction gear

Non-reversible reduction gear

Clutchless reduction gear

Front-end speed-increasing/

reduction gear

Front-end off set type

2-speed reversible reduction gear

(2-speed ahead, 1-speed astern)

2-speed reversible reduction gear

(2-speed ahead, 1-speed astern)

Non-reversible reduction gear

Astern hydraulic clutch

Secondary pinion gear

Astern clutch shaft

Ahead clutch shaft

Thrust collar

Output shaft

Reversible gear (2)

Primary gear (2)

Reversible gear (1)

W

h

e

n

a

h

e

a

d

W

h

e

n

a

s

te

rn

Input shaft

Ahead hydraulic clutch

Primary gear (1)

Secondary pinion gear

Secondary wheel gear

Propeller Thrust

Bearing

White metal

Mitchell's system

Shaft

Forged steel with precision finish

Highly rigid

Gear Case

Cast-iron

Highly rigid. Lower vibration.

Hydraulic Clutch

High heat-resistant lining

Shockless mesh because of hydraulic control

Gears

Induction quenched carbon steel and alloyed steel

Precision ground finish

25 pressure angle

Crowning gear

Bearing

White metal

Precision fit

Long-lasting

Reduced maintenance costs

RCB, RCBH

DRD (Two-engine single-shaft)

DRF

(Four-engine single-shaft)

RCD (Two-engine single-shaft)

RCF (Four-engine single-shaft)

RG

FG

AGP

DRA

DR2A

RCA

DRB, DRBH

DR2B

High pressure

control valve

Astern slip

region Ahead slip region

Astern direct

coupling

region

Control lever

Neutral

Ahead direct

coupling

region

Control

panel

Slip control valve

Clutch direct-coupling

control valve

Ahead clutch

Clutch operating

valve

Propeller

Astern

clutch

Engine

Reduction gear

System oil

(Reduction gear

lubricating oil)

Control Lever (Example)

Astern Ahead

Full

Dead

slow

N

e

u

t

r

a

l

Dead

slow

Full

10 knots

R

e

v

s

.

Shift Shift

Engine Revs.

Constant (Idling revs)

Clutch direct

coupling

Clutch direct

coupling

Propeller Revs.

Slip Slip

Approx.

0.9 DS

Approx.

30 min

-1

Generator

panel

Generator

Generator drive

Constant speed

Pulse

sensor

Primary clutch

Secondary

clutch

Control panel

S

a

f

e

t

y

d

e

v

ic

e

s

ig

n

a

l

M

a

in

p

o

w

e

r

s

u

p

p

ly

Clutch control oil pressure (2-speed)

Clutch control oil pressure (1-speed)

Oil pressure

control bloc

Pulse sensor

Engine

Varying speed

Engine clutch

Engine driver

8 9

Reversible reduction gear

Coaxial

Model

Offset

Daihatsu's Reduction Gears - One Supporting Element of Engine High Reliability

Our reduction gears have a built-in main thrust bearing and wet hydraulic clutch, and can

be incorporated in the CRASH ASTERN system. We also have a wide selection of

speed-increasing and reduction gears for driving any type of machinery, which can be used

on the engine front end block.

DICS

(Daihatsu Slipping

Clutch System)

Constant-

Speed

Shaft

Generator

DRA-50F

Reversible

Reduction

Gear

Though low-speed and high thrust are necessary for port navigation, high-speed cruising

performance is needed on the open seas. Our 2-speed reduction gear is ideal for the situation.

We developed the 2-speed system (2-step ahead, 2-step astern) to maximize efficiency in

normal and low-speed sailing. Because the reduction gear is suited to all kinds of vessels,

from freighters to fishing trawlers, captains all over have favorably evaluated it.

Clutch fluid is electronically controlled to slip the clutch. As such, propeller revolutions

below idling rpm are freely controlled.

(Vertically offset,

Horizontally offset)

Single-engine

single-shaft

Multiple engine

single-shaft

Special

speed-increasing/

reduction gear

1. Enables dead-slow sailing ahead/astern with a fixed pitch propeller (FPP).

2. Enables shockless, smooth clutch meshing.

3. Propeller revolutions remain stable even under fluctuating engine revolution

and propeller load.

Features

1. An electronic governor keeps

constant generator revolutions,

thus ensuring a stable power

supply.

2. Because of the 2-speed

slipping clutch, the generator

can operate a wide engine

revolution range from idling to

rated rpm.

3. Generator revolutions and droop

can be adjusted easily during

generator operation. Load

switching to other generators and

parallel operation can performed

easily.

A compact constant-speed shaft generator is built into the reduction gear. Clutch fluid is

automatically controlled by an electronic governor. By slipping the clutch, generator

revolutions can be kept constant even under fluctuating engine revolution.

DRA-80F

MARINE PROPULSION

DIESEL ENGINE

2-Speed

Reduction

Gears

Features

Non-reversible reduction gear

Reversible reduction gear

Reversible reduction gear

Non-reversible reduction gear

Clutchless reduction gear

Front-end speed-increasing/

reduction gear

Front-end off set type

2-speed reversible reduction gear

(2-speed ahead, 1-speed astern)

2-speed reversible reduction gear

(2-speed ahead, 1-speed astern)

Non-reversible reduction gear

Astern hydraulic clutch

Secondary pinion gear

Astern clutch shaft

Ahead clutch shaft

Thrust collar

Output shaft

Reversible gear (2)

Primary gear (2)

Reversible gear (1)

W

h

e

n

a

h

e

a

d

W

h

e

n

a

s

te

rn

Input shaft

Ahead hydraulic clutch

Primary gear (1)

Secondary pinion gear

Secondary wheel gear

Propeller Thrust

Bearing

White metal

Mitchell's system

Shaft

Forged steel with precision finish

Highly rigid

Gear Case

Cast-iron

Highly rigid. Lower vibration.

Hydraulic Clutch

High heat-resistant lining

Shockless mesh because of hydraulic control

Gears

Induction quenched carbon steel and alloyed steel

Precision ground finish

25 pressure angle

Crowning gear

Bearing

White metal

Precision fit

Long-lasting

Reduced maintenance costs

RCB, RCBH

DRD (Two-engine single-shaft)

DRF

(Four-engine single-shaft)

RCD (Two-engine single-shaft)

RCF (Four-engine single-shaft)

RG

FG

AGP

DRA

DR2A

RCA

DRB, DRBH

DR2B

High pressure

control valve

Astern slip

region Ahead slip region

Astern direct

coupling

region

Control lever

Neutral

Ahead direct

coupling

region

Control

panel

Slip control valve

Clutch direct-coupling

control valve

Ahead clutch

Clutch operating

valve

Propeller

Astern

clutch

Engine

Reduction gear

System oil

(Reduction gear

lubricating oil)

Control Lever (Example)

Astern Ahead

Full

Dead

slow

N

e

u

t

r

a

l

Dead

slow

Full

10 knots

R

e

v

s

.

Shift Shift

Engine Revs.

Constant (Idling revs)

Clutch direct

coupling

Clutch direct

coupling

Propeller Revs.

Slip Slip

Approx.

0.9 DS

Approx.

30 min

-1

Generator

panel

Generator

Generator drive

Constant speed

Pulse

sensor

Primary clutch

Secondary

clutch

Control panel

S

a

f

e

t

y

d

e

v

ic

e

s

ig

n

a

l

M

a

in

p

o

w

e

r

s

u

p

p

ly

Clutch control oil pressure (2-speed)

Clutch control oil pressure (1-speed)

Oil pressure

control bloc

Pulse sensor

Engine

Varying speed

Engine clutch

Engine driver

10 11

1060

1200

1500

1960

2250

2560

3010

4000

3450

4500

6600

MDO

kWm

980

1200

1500

1660

1957

2560

3010

4000

3450

4500

6600

900

750

900

750

750

750

750

750

600

600

600

HFO

kWm

Output

Engine revs.

min

1

Bore

mm

Stroke

mm

No. of

cylinders

R/G model Gear ratio

Propeller

revs.

min

1

Propeller

diam.

Z=4mm

Propeller

diam.

Z=5mm

Intermediate

shaft diam.

mm

Propeller

shaft diam.

mm

3.429

2.358

3.029

3.198

3.400

2.371

2.576

2.734

2.595

2.800

3.030

2.700

3.101

3.353

2.700

3.101

3.353

3.014

2.972

2.430

2.740

3.149

2.862

3.263

3.722

2.862

3.263

3.722

262

318

248

281

265

316

291

274

289

268

248

278

242

224

309

274

238

249

252

247

219

191

210

184

161

210

184

161

2250

2110

2390

2380

2450

2380

2480

2600

2640

2830

2950

2850

3060

3280

2750

2950

3250

3340

3320

3190

3430

3720

3730

4030

4370

3990

4200

4550

2160

2080

2350

2340

2410

2280

2380

2500

2540

2720

2840

2740

2940

3150

2700

2900

3150

3280

3260

3070

3300

3580

3580

3880

4200

3910

4180

4470

145

150

160

165

165

165

170

175

180

185

190

200

205

220

210

220

230

235

235

225

235

245

260

270

280

290

305

315

180

190

200

210

210

210

210

220

220

240

240

250

260

280

260

270

290

295

295

280

290

310

330

340

360

370

385

405

DRA-16F

DRA-19F

DRB-19F

DRA-25F

DRB-25H

DRA-25F

DRB-25H

DRA-35H

DRB-35H

DRA-50F

DRB-50F

DRA-80F

DRB-80F

DRA-100F

DRB-100F

DRA-80F

DRB-80F

DRA-120F

DRB-120F

DRA-150F

DRB-150F

200

230

230

260

280

280

320

320

360

360

360

300

320

320

380

390

390

400

400

480

480

480

6

6

6

6

6

8

6

8

6

8

12V

6DKM-20e

6DEM-23

750min

1

6DEM-23

900min

1

6DKM-26e

6DKM-28e

8DKM-28e

6DCM-32e

8DCM-32e

6DKM-36e

8DKM-36e

12DKM-36e

Output for all engine given for crank shaft end.

Engine model

Specifications

MARINE PROPULSION

DIESEL ENGINE

Specifications

1 1 1 1

1: D.O.

Intake and exhaust

valves

Fuel nozzle

Fuel injection system

Fuel system

Piston

Camshaft

Crankshaft

Connecting rod

Cylinder head

Automatic backwash

sediment trap

Engine frame

Main metal, crankpin metal

Exhaust pipe

Cylinder liner

6DEM-23 6DCM-32 6DKM-26

6DE-23Engine Cross Sectional View

10 11

1060

1200

1500

1960

2250

2560

3010

4000

3450

4500

6600

MDO

kWm

980

1200

1500

1660

1957

2560

3010

4000

3450

4500

6600

900

750

900

750

750

750

750

750

600

600

600

HFO

kWm

Output

Engine revs.

min

1

Bore

mm

Stroke

mm

No. of

cylinders

R/G model Gear ratio

Propeller

revs.

min

1

Propeller

diam.

Z=4mm

Propeller

diam.

Z=5mm

Intermediate

shaft diam.

mm

Propeller

shaft diam.

mm

3.429

2.358

3.029

3.198

3.400

2.371

2.576

2.734

2.595

2.800

3.030

2.700

3.101

3.353

2.700

3.101

3.353

3.014

2.972

2.430

2.740

3.149

2.862

3.263

3.722

2.862

3.263

3.722

262

318

248

281

265

316

291

274

289

268

248

278

242

224

309

274

238

249

252

247

219

191

210

184

161

210

184

161

2250

2110

2390

2380

2450

2380

2480

2600

2640

2830

2950

2850

3060

3280

2750

2950

3250

3340

3320

3190

3430

3720

3730

4030

4370

3990

4200

4550

2160

2080

2350

2340

2410

2280

2380

2500

2540

2720

2840

2740

2940

3150

2700

2900

3150

3280

3260

3070

3300

3580

3580

3880

4200

3910

4180

4470

145

150

160

165

165

165

170

175

180

185

190

200

205

220

210

220

230

235

235

225

235

245

260

270

280

290

305

315

180

190

200

210

210

210

210

220

220

240

240

250

260

280

260

270

290

295

295

280

290

310

330

340

360

370

385

405

DRA-16F

DRA-19F

DRB-19F

DRA-25F

DRB-25H

DRA-25F

DRB-25H

DRA-35H

DRB-35H

DRA-50F

DRB-50F

DRA-80F

DRB-80F

DRA-100F

DRB-100F

DRA-80F

DRB-80F

DRA-120F

DRB-120F

DRA-150F

DRB-150F

200

230

230

260

280

280

320

320

360

360

360

300

320

320

380

390

390

400

400

480

480

480

6

6

6

6

6

8

6

8

6

8

12V

6DKM-20e

6DEM-23

750min

1

6DEM-23

900min

1

6DKM-26e

6DKM-28e

8DKM-28e

6DCM-32e

8DCM-32e

6DKM-36e

8DKM-36e

12DKM-36e

Output for all engine given for crank shaft end.

Engine model

Specifications

MARINE PROPULSION

DIESEL ENGINE

Specifications

1 1 1 1

1: D.O.

Intake and exhaust

valves

Fuel nozzle

Fuel injection system

Fuel system

Piston

Camshaft

Crankshaft

Connecting rod

Cylinder head

Automatic backwash

sediment trap

Engine frame

Main metal, crankpin metal

Exhaust pipe

Cylinder liner

6DEM-23 6DCM-32 6DKM-26

6DE-23Engine Cross Sectional View

12 13

Dimensions

DRA Type

H

8

H

e

i

g

h

t

f

o

r

R

/

G

w

i

t

h

d

r

a

w

a

l

H

8

H

e

i

g

h

t

f

o

r

R

/

G

w

i

t

h

d

r

a

w

a

l

H

3

H

e

i

g

h

t

f

o

r

p

i

s

t

o

n

w

i

t

h

d

r

a

w

a

l

DRB Type

OUTPUT

INTPUT

MARINE PROPULSION

DIESEL ENGINE

mm

L L1 L2 B B1 H1 H2 H3 H4 D H5 H6 H7 H8 H9 B2 B3 R/G model Engine model

DRA-16F

DRB-16F

DRA-19F

DRB-19F

DRA-25F

DRB-25H

DRA-25F

DRB-25H

DRA-35H

DRB-35H

DRA-50F

DRB-50F

DRA-80F

DRB-80F

DRA-100F

DRB-100F

DRA-80F

DRB-80F

DRA-120F

DRB-120F

DRA-150F

DRB-150F

4555

4525

4910

4655

5025

4810

5295

5010

5615

5595

7075

6745

6967

5966

8655

8515

7285

7075

8865

8665

11178

10978

3135

3135

3150

3150

3150

3150

3350

3350

3675

3675

4535

4535

3907

3907

5185

5185

4465

4465

5595

5595

7378

7378

1420

1390

1760

1505

1875

1660

1945

1660

1940

1920

2540

2210

3060

2060

3480

3330

2820

2610

3270

3070

3800

3600

1480

1480

1725

1725

1725

1725

1835

1835

2160

2535

2160

2160

2090

2090

2090

2090

3224

3224

960

960

1050

1050

1050

1050

1180

1180

1220

1220

1220

1220

1450

1450

1450

1450

1680

1680

1680

1680

1920

1920

1885

1885

1870

1870

1870

1870

2110

2110

2563

2563

2719

2719

3022

2871

3450

3450

3270

3270

3270

3270

3372

3372

365

365

350

350

350

350

400

400

430

430

430

430

500

500

500

500

605

605

605

605

605

605

1680

1680

1710

1710

1710

1710

1970

1970

2065

2065

2065

2065

2295

2295

2295

2295

2930

2930

2930

2930

2710

2710

695

695

820

820

820

820

830

830

850

850

850

850

1030

1030

1030

1030

1200

1200

1200

1200

1305

1305

1000

1000

1000

1000

1150

1150

1200

1200

1310

1310

1310

1310

1400

1400

1400

1400

1400

1400

1400

1400

70

120

80

80

80

70

80

200

90

200

100

260

70

50

250

250

250

250

250

300

300

350

445

490

500

600

565

630

600

630

640

640

750

800

800

800

850

900

800

830

900

1000

1200

1300

870

1050

1005

1155

1040

1133

1040

1130

1435

1186

1160

1335

1564

1354

1415

1650

1362

1583

1590

1760

1700

1850

1200

1200

1300

1200

1380

1200

1380

1200

1820

1700

1650

1650

1800

1500

2000

2500

1800

2300

2100

2300

2400

2600

475

563

600

600

609

770

772

871

927

1002

1150

1610

1610

1530

1530

1530

1530

1950

1950

1880

1880

1880

1880

2160

2160

2160

2160

2060

2060

2060

2060

3074

3074

970

1040

1020

1190

1090

1300

1500

1300

1240

1400

1500

1640

1600

1650

1870

1870

1600

2000

2050

2300

2500

2700

10.5

14.0

14.0

18.0

22.0

28.0

35.0

42.0

51.0

67.0

80.0

2.5

2.8

3.0

3.8

3.5

3.8

3.5

6.0

5.5

8.5

8.0

12.0

18.0

12.0

20.0

25.0

Weight (ton)

Engine R/G

MARINE PROPULSION

DIESEL ENGINE

Dimensions

6DKM-20e

6DEM-23

750min

1

6DEM-23

900min

1

6DKM-26e

6DKM-28e

8DKM-28e

6DCM-32e

8DCM-32e

6DKM-36e

8DKM-36e

12DKM-36e

12 13

Dimensions

DRA Type

H

8

H

e

i

g

h

t

f

o

r

R

/

G

w

i

t

h

d

r

a

w

a

l

H

8

H

e

i

g

h

t

f

o

r

R

/

G

w

i

t

h

d

r

a

w

a

l

H

3

H

e

i

g

h

t

f

o

r

p

i

s

t

o

n

w

i

t

h

d

r

a

w

a

l

DRB Type

OUTPUT

INTPUT

MARINE PROPULSION

DIESEL ENGINE

mm

L L1 L2 B B1 H1 H2 H3 H4 D H5 H6 H7 H8 H9 B2 B3 R/G model Engine model

DRA-16F

DRB-16F

DRA-19F

DRB-19F

DRA-25F

DRB-25H

DRA-25F

DRB-25H

DRA-35H

DRB-35H

DRA-50F

DRB-50F

DRA-80F

DRB-80F

DRA-100F

DRB-100F

DRA-80F

DRB-80F

DRA-120F

DRB-120F

DRA-150F

DRB-150F

4555

4525

4910

4655

5025

4810

5295

5010

5615

5595

7075

6745

6967

5966

8655

8515

7285

7075

8865

8665

11178

10978

3135

3135

3150

3150

3150

3150

3350

3350

3675

3675

4535

4535

3907

3907

5185

5185

4465

4465

5595

5595

7378

7378

1420

1390

1760

1505

1875

1660

1945

1660

1940

1920

2540

2210

3060

2060

3480

3330

2820

2610

3270

3070

3800

3600

1480

1480

1725

1725

1725

1725

1835

1835

2160

2535

2160

2160

2090

2090

2090

2090

3224

3224

960

960

1050

1050

1050

1050

1180

1180

1220

1220

1220

1220

1450

1450

1450

1450

1680

1680

1680

1680

1920

1920

1885

1885

1870

1870

1870

1870

2110

2110

2563

2563

2719

2719

3022

2871

3450

3450

3270

3270

3270

3270

3372

3372

365

365

350

350

350

350

400

400

430

430

430

430

500

500

500

500

605

605

605

605

605

605

1680

1680

1710

1710

1710

1710

1970

1970

2065

2065

2065

2065

2295

2295

2295

2295

2930

2930

2930

2930

2710

2710

695

695

820

820

820

820

830

830

850

850

850

850

1030

1030

1030

1030

1200

1200

1200

1200

1305

1305

1000

1000

1000

1000

1150

1150

1200

1200

1310

1310

1310

1310

1400

1400

1400

1400

1400

1400

1400

1400

70

120

80

80

80

70

80

200

90

200

100

260

70

50

250

250

250

250

250

300

300

350

445

490

500

600

565

630

600

630

640

640

750

800

800

800

850

900

800

830

900

1000

1200

1300

870

1050

1005

1155

1040

1133

1040

1130

1435

1186

1160

1335

1564

1354

1415

1650

1362

1583

1590

1760

1700

1850

1200

1200

1300

1200

1380

1200

1380

1200

1820

1700

1650

1650

1800

1500

2000

2500

1800

2300

2100

2300

2400

2600

475

563

600

600

609

770

772

871

927

1002

1150

1610

1610

1530

1530

1530

1530

1950

1950

1880

1880

1880

1880

2160

2160

2160

2160

2060

2060

2060

2060

3074

3074

970

1040

1020

1190

1090

1300

1500

1300

1240

1400

1500

1640

1600

1650

1870

1870

1600

2000

2050

2300

2500

2700

10.5

14.0

14.0

18.0

22.0

28.0

35.0

42.0

51.0

67.0

80.0

2.5

2.8

3.0

3.8

3.5

3.8

3.5

6.0

5.5

8.5

8.0

12.0

18.0

12.0

20.0

25.0

Weight (ton)

Engine R/G

MARINE PROPULSION

DIESEL ENGINE

Dimensions

6DKM-20e

6DEM-23

750min

1

6DEM-23

900min

1

6DKM-26e

6DKM-28e

8DKM-28e

6DCM-32e

8DCM-32e

6DKM-36e

8DKM-36e

12DKM-36e

14 15

Advantages

of Electric

Propulsion

Ships

Electrical propulsion systems are different from the systems on conventional ships, where

the propellers are turned directly by the main diesel engine; instead, the propellers are

turned by an electric motor. This energy-saving, next-generation system covers economical,

propulsion and safety demands.

This equipment consists of plural sensor units, inserted into crankcase side wall of each

cylinder on diesel engine, and an integrated controller which controls sensor units by the

communication link.

Sensor units is compactly designed to detect oil mist by the natural diffusion system without air

suction mechanism by moving parts like a fan, driving air, and piping, as well as, realizes

improved reliability, and easy maintenance.

Controller constantly monitors the oil mist density in the crankcase, and indicates the oil mist

level. Additionally it will indicate status with alarm in case the oil mist density will be increased

over normal level by overheated bearing etc, so can realize early detecting and reasonable

precaution for the serious accident in a low-, medium-, and high-speed diesel engines.

Daihatsu Diesel Equipment for

Marine Applications

Loading capacity is increased by reducing the size of the engine room. The engine room and

propellers can also be optimally located to create the ideal hull form.

The use of a medium-speed engine allows vibrations and noises to be reduced. Compact,

lightweight components also enhance work safety.

Gentle to Ships

Gentle to People

Gentle to the Earth's

Environment

A medium-speed engine reduces NOx

emissions. By optimally controlling the

number of generators in operation, fuel

consumption and CO2 emissions are

also reduced.

Counter-rotating

propellers

Generator unit

Inverter

Propulsion

motor

Flexible installation

in open spaces

A compact motor

Propulsion Motor

Electric Power

Daihatsu Generating Engines Distribution

Panel

"TAHO" Cement Carrier

A hull with a narrow stern for

less resistance.

*Dotted lines: Hull form of the existing ship.

The Oil Mist Detector Monitors your engine

to detect major engine failure.

Since 1976, Daihatsu Diesel Mfg. Co., Ltd. has put OIL MIST DETECTOR continuously on the

market. In 2004, model MD-SX which is of sensor type mounted on crankcasewas developed.

It can directly measure the oil mist density inside crankcase in a waythe sensor is so mounted

that the sensing part is sticking into the crankcase.

Conventional system has to take out oil mist for measurement from crankcase insidethrough piping.

The new system provides following merits by the oil mist level is sent out for thecontroller as

digital signal.

(1) Speedy response in less than 1 sec. with max. No. of sensor 16

(2) Self diagnosis functions to display the time for sensor replacement

In recent years, as fire prevention measures for tankers, earlier detection on abnormaloil mist level

in engine room is required as it is thought to be effective in pin-point the cause and its measures.

Daihatsu Diesel Mfg. Co., Ltd. has further advanced MD-SX typedetector into OIL MIST

MONITORING DEVICE, OMM type, whose development is based on thetechnologies of MD-SX

type many classes give TYPE APPROVAL.

The new OMM type can provide visual display on oil mist level where it is likely togenerate.

The OMM type is expected to go into the market October, '07.

The system does not guarantee prevention of disaster, such as a fire.

Early detection of the oil mist abnormalities in the

engine room and prevention of firing

Oil Mist

Monitor

DOMM

Oil Mist

Detector

MD-SX

Equipments Propulsion

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Electrical Propulsion Systems

That Are Kinder to the Earth

ENGINE SIDE WALL

CRANKCASE

OTHER

SENSORS

COMMUNICATION

LINK CABLE

CONTROLLER SENSOR UNIT

CONTROLLER SENSOR HEAD

Sensor Type

14 15

Advantages

of Electric

Propulsion

Ships

Electrical propulsion systems are different from the systems on conventional ships, where

the propellers are turned directly by the main diesel engine; instead, the propellers are

turned by an electric motor. This energy-saving, next-generation system covers economical,

propulsion and safety demands.

This equipment consists of plural sensor units, inserted into crankcase side wall of each

cylinder on diesel engine, and an integrated controller which controls sensor units by the

communication link.

Sensor units is compactly designed to detect oil mist by the natural diffusion system without air

suction mechanism by moving parts like a fan, driving air, and piping, as well as, realizes

improved reliability, and easy maintenance.

Controller constantly monitors the oil mist density in the crankcase, and indicates the oil mist

level. Additionally it will indicate status with alarm in case the oil mist density will be increased

over normal level by overheated bearing etc, so can realize early detecting and reasonable

precaution for the serious accident in a low-, medium-, and high-speed diesel engines.

Daihatsu Diesel Equipment for

Marine Applications

Loading capacity is increased by reducing the size of the engine room. The engine room and

propellers can also be optimally located to create the ideal hull form.

The use of a medium-speed engine allows vibrations and noises to be reduced. Compact,

lightweight components also enhance work safety.

Gentle to Ships

Gentle to People

Gentle to the Earth's

Environment

A medium-speed engine reduces NOx

emissions. By optimally controlling the

number of generators in operation, fuel

consumption and CO2 emissions are

also reduced.

Counter-rotating

propellers

Generator unit

Inverter

Propulsion

motor

Flexible installation

in open spaces

A compact motor

Propulsion Motor

Electric Power

Daihatsu Generating Engines Distribution

Panel

"TAHO" Cement Carrier

A hull with a narrow stern for

less resistance.

*Dotted lines: Hull form of the existing ship.

The Oil Mist Detector Monitors your engine

to detect major engine failure.

Since 1976, Daihatsu Diesel Mfg. Co., Ltd. has put OIL MIST DETECTOR continuously on the

market. In 2004, model MD-SX which is of sensor type mounted on crankcasewas developed.

It can directly measure the oil mist density inside crankcase in a waythe sensor is so mounted

that the sensing part is sticking into the crankcase.

Conventional system has to take out oil mist for measurement from crankcase insidethrough piping.

The new system provides following merits by the oil mist level is sent out for thecontroller as

digital signal.

(1) Speedy response in less than 1 sec. with max. No. of sensor 16

(2) Self diagnosis functions to display the time for sensor replacement

In recent years, as fire prevention measures for tankers, earlier detection on abnormaloil mist level

in engine room is required as it is thought to be effective in pin-point the cause and its measures.

Daihatsu Diesel Mfg. Co., Ltd. has further advanced MD-SX typedetector into OIL MIST

MONITORING DEVICE, OMM type, whose development is based on thetechnologies of MD-SX

type many classes give TYPE APPROVAL.

The new OMM type can provide visual display on oil mist level where it is likely togenerate.

The OMM type is expected to go into the market October, '07.

The system does not guarantee prevention of disaster, such as a fire.

Early detection of the oil mist abnormalities in the

engine room and prevention of firing

Oil Mist

Monitor

DOMM

Oil Mist

Detector

MD-SX

Equipments Propulsion

Environmentally Friendly Engines Compliant with

IMO Secondary Regulations

Electrical Propulsion Systems

That Are Kinder to the Earth

ENGINE SIDE WALL

CRANKCASE

OTHER

SENSORS

COMMUNICATION

LINK CABLE

CONTROLLER SENSOR UNIT

CONTROLLER SENSOR HEAD

Sensor Type

16 17

Engine Room

(

Example

)

Daihatsus geared diesel engines are used in ships of all classes and types, including

vessels for public offices, ferries, coastal vessels, working crafts, and fishing boats.

Their outstanding performance has been highly acclaimed by all customers.

MARINE PROPULSION

DIESEL ENGINE

Using a generator driven by the speed reducer shaft.

750 G/T Tanker

5,000 m

3

Tanker

3,500 m

3

Tanker

500 G/T Cargo Ship

6DKM-26

6DKM-26

6DCM-32F

6DCM-32

16 17

Engine Room

(

Example

)

Daihatsus geared diesel engines are used in ships of all classes and types, including

vessels for public offices, ferries, coastal vessels, working crafts, and fishing boats.

Their outstanding performance has been highly acclaimed by all customers.

MARINE PROPULSION

DIESEL ENGINE

Using a generator driven by the speed reducer shaft.

750 G/T Tanker

5,000 m

3

Tanker

3,500 m

3

Tanker

500 G/T Cargo Ship

6DKM-26

6DKM-26

6DCM-32F

6DCM-32

18 19

Proof of Success

Vessels for public offices

Ferries

MARINE PROPULSION

DIESEL ENGINE

Kobe University of Mercantile Marine Fukae Maru

Training ship 6DLM-26S1

Tokyo University of Mercantile Marine Shioji Maru

Training ship 6DLM-26SL1

Ministry of Land, Infrastructure and Transport Nippon Maru

Training ship 6DSMB-28NS2

Fisheries Agency Taka Maru

Reserch vessel 6DKM-20FL1

Japan Marine Science & Technology Center Mirai

Reserch vessel 6DKM-28F(L)4

Japan Coast Guard Kaiyo

Reserch vessel 6DLM-24S(L)2

Japan Metrorological Agency Ryoufu Maru

Reserch vessel 6DLM-40AL1

Hokkaido Government Hokuo Maru

Fishery Control Boat 6DKM-28(L)2

Reiyo Highschool Kumamoto Maru

Training ship 6DKM-26F1

Tokyo University Hakuho Maru

Reserch vessel 6DSM-28N(L)4

Yuge National College of Maritime Technology Yuge Maru

Training ship 6DLM-24SL1

Ministry of Defense Suou Asakuma

Support vessel 6DLM-282

Kampu Ferry Co., Ltd. Hamayu

Ferry boat 8DLM-40A(L)2

Kyusyu Yusen K.K. Emerald Karatsu

Ferry boat 8DKM-282

Nomo Shosen K. K. Taiko

Ferry boat 8DLM-32(L)2

Ie village office, Okinawa Gusuku

Ferry boat 6DLM-28S(L)2

Kyusyu Shosen Co., Ltd. Ferry Kumamoto

Ferry boat 6DLM-26S(L)2

Iheya village office, Okinawa Ferry Iheya

Ferry boat 6DKM-28(L)2

Koshiki Shosen K. K. New Koshiki

Ferry boat 8DKM-26(L)2

Uwajima Unyu Co., Ltd. Oita

Ferry boat 6DKM-36(L)2

Kitanihon Kaiun K.K. Asakaze #2

Ferry boat 6DKM-362

Heart Land Ferry Saiplia Soya

Ferry boat 8DKM-28(L)2

Kamiyaku town, Kagoshima Ferry Taiyo

Ferry boat 6DKM-26(L)2

Oki Kisen Ferry Oki

Ferry boat 6DKM-36(L)2

18 19

Proof of Success

Vessels for public offices

Ferries

MARINE PROPULSION

DIESEL ENGINE

Kobe University of Mercantile Marine Fukae Maru

Training ship 6DLM-26S1

Tokyo University of Mercantile Marine Shioji Maru

Training ship 6DLM-26SL1

Ministry of Land, Infrastructure and Transport Nippon Maru

Training ship 6DSMB-28NS2

Fisheries Agency Taka Maru

Reserch vessel 6DKM-20FL1

Japan Marine Science & Technology Center Mirai

Reserch vessel 6DKM-28F(L)4

Japan Coast Guard Kaiyo

Reserch vessel 6DLM-24S(L)2

Japan Metrorological Agency Ryoufu Maru

Reserch vessel 6DLM-40AL1

Hokkaido Government Hokuo Maru

Fishery Control Boat 6DKM-28(L)2

Reiyo Highschool Kumamoto Maru

Training ship 6DKM-26F1

Tokyo University Hakuho Maru

Reserch vessel 6DSM-28N(L)4

Yuge National College of Maritime Technology Yuge Maru

Training ship 6DLM-24SL1

Ministry of Defense Suou Asakuma

Support vessel 6DLM-282

Kampu Ferry Co., Ltd. Hamayu

Ferry boat 8DLM-40A(L)2

Kyusyu Yusen K.K. Emerald Karatsu

Ferry boat 8DKM-282

Nomo Shosen K. K. Taiko

Ferry boat 8DLM-32(L)2

Ie village office, Okinawa Gusuku

Ferry boat 6DLM-28S(L)2

Kyusyu Shosen Co., Ltd. Ferry Kumamoto

Ferry boat 6DLM-26S(L)2

Iheya village office, Okinawa Ferry Iheya

Ferry boat 6DKM-28(L)2

Koshiki Shosen K. K. New Koshiki

Ferry boat 8DKM-26(L)2

Uwajima Unyu Co., Ltd. Oita

Ferry boat 6DKM-36(L)2

Kitanihon Kaiun K.K. Asakaze #2

Ferry boat 6DKM-362

Heart Land Ferry Saiplia Soya

Ferry boat 8DKM-28(L)2

Kamiyaku town, Kagoshima Ferry Taiyo

Ferry boat 6DKM-26(L)2

Oki Kisen Ferry Oki

Ferry boat 6DKM-36(L)2

20 21

Proof of Success

MARINE PROPULSION

DIESEL ENGINE

Coastal vessels

Imoto Line, Ltd. Takasago

Container Carrier 6DKM-28(L)1

Omaezaki Kaiun Kotoku

Tanker 6DKM-26L1

Non ballast ship

Tabuchi Kaiun K.K. Kosei Maru

Chemical Tanker 6DKM-28L1

Wakamiya Kisen K.K. Risshin Maru

Cement Tanker 6DKM-36F1

Daiichi Kaiun K.K. Asuzan Maru

Asphalt Tanker 6DKM-26F1

Arita Unyu K.K. Arita Maru

Cargo 6DKM-26L1

Fujiitsuna Kaiun K. K. Kosyu Maru #8

Tanker 6DCM-321

Toda Kisen K.K. Morning Breeze

LNG Tanker 6DKM-361

Kinriki Kisen K.K. Kinyo Maru #2

Tanker 6DCM-321

Kokoku Kaiun K.K. Daiko Maru 21

Pure Car Carrier 6DKM-361

Seimei Kaiun Seimei

Tanker 6DKM-26L1

Tanba Kisen K.K. Tensho Maru #2

Tanker 6DKM-26L1

Working craft

Nakamura Shoji Hokuyo Maru # 5

Pusher boat 6DKM-28F(L)2

Nitto Tugboat Co., Ltd. Hoki Maru

Tug boat 6DKM-26(L)2

Fukada Salvage & Marine Works Co., Ltd. Naruto Maru

Tug boat 6DLM-28FS2

Daikai Marine Co.Nippon Telegraph & Telephone Co. Daiki MaruSubaru

Pusher boatCable Laying ship 6DKM-26(L)2

20 21

Proof of Success

MARINE PROPULSION

DIESEL ENGINE

Coastal vessels

Imoto Line, Ltd. Takasago

Container Carrier 6DKM-28(L)1

Omaezaki Kaiun Kotoku

Tanker 6DKM-26L1

Non ballast ship

Tabuchi Kaiun K.K. Kosei Maru

Chemical Tanker 6DKM-28L1

Wakamiya Kisen K.K. Risshin Maru

Cement Tanker 6DKM-36F1

Daiichi Kaiun K.K. Asuzan Maru

Asphalt Tanker 6DKM-26F1

Arita Unyu K.K. Arita Maru

Cargo 6DKM-26L1

Fujiitsuna Kaiun K. K. Kosyu Maru #8

Tanker 6DCM-321

Toda Kisen K.K. Morning Breeze

LNG Tanker 6DKM-361

Kinriki Kisen K.K. Kinyo Maru #2

Tanker 6DCM-321

Kokoku Kaiun K.K. Daiko Maru 21

Pure Car Carrier 6DKM-361

Seimei Kaiun Seimei

Tanker 6DKM-26L1

Tanba Kisen K.K. Tensho Maru #2

Tanker 6DKM-26L1

Working craft

Nakamura Shoji Hokuyo Maru # 5

Pusher boat 6DKM-28F(L)2

Nitto Tugboat Co., Ltd. Hoki Maru

Tug boat 6DKM-26(L)2

Fukada Salvage & Marine Works Co., Ltd. Naruto Maru

Tug boat 6DLM-28FS2

Daikai Marine Co.Nippon Telegraph & Telephone Co. Daiki MaruSubaru

Pusher boatCable Laying ship 6DKM-26(L)2

23 22 22

Proof of Success

MARINE PROPULSION

DIESEL ENGINE

Working craft

Fishing boats

Zamil Operations & Maintenance Co., Ltd. Zamil # 5

Supply vessel 6DKM-26(L)2

Shanghai Maritime Rescue and Salvage Bureau Ministry of Communication Hua Cai

Ocean Salvage Tug boat 8DKM-28(L)2

Japan Ocean Tug Co., Ltd. & The Nippon Salvage Co., Ltd. Koyo Maru

Ocean Salvage Tug boat 8DLM-40A(L)2

Yorigami Maritime Construction Co., Ltd. Shinsei Maru # 8

Pusher boat 6DLM-22S(L)2

Nippon Telegraph & Telephone Co. Subaru

Cable Laying ship 8DK-324

Chang Jiang Waterway Bureau Chang Jin 2

Dredger 8000m

3

12DKM-362

Shoyo Kisen K.K. Seiyo Maru

Tug boat 6DKM-32(L)2

Norihiro Takemura Sensho Maru # 1

Skipjack Pole & Line Fishing boat 6DKM-26L1

Myojin Fishery Sagamyojin Maru # 83

Skipjack Pole & Line Fishing boat 6DKM-28L1

Fukushima Fishery Sofo Maru #83

Purse Seiner 6DKM-36L1

Kanei Bussan Co. Wakaba Maru # 6

Purse Seiners 8DLM-321

Daiyu Fishery Tenno Maru #81

Purse Seiner 6DKM-28F1

Kanei Bussan Co. Genpuku Maru # 81

Purse Seiners 6DKM-321

K.K. Taishu Ikitsuki

Fishery Control Boat 8DKM-28L1

Yoshikazu Ishikura Sanko Maru

Skipjack Pole & Line Fishing boat 6DKM-28L1

Dredger 8DKM-362

23 22 22

Proof of Success

MARINE PROPULSION

DIESEL ENGINE

Working craft

Fishing boats

Zamil Operations & Maintenance Co., Ltd. Zamil # 5

Supply vessel 6DKM-26(L)2

Shanghai Maritime Rescue and Salvage Bureau Ministry of Communication Hua Cai

Ocean Salvage Tug boat 8DKM-28(L)2

Japan Ocean Tug Co., Ltd. & The Nippon Salvage Co., Ltd. Koyo Maru

Ocean Salvage Tug boat 8DLM-40A(L)2

Yorigami Maritime Construction Co., Ltd. Shinsei Maru # 8

Pusher boat 6DLM-22S(L)2

Nippon Telegraph & Telephone Co. Subaru

Cable Laying ship 8DK-324

Chang Jiang Waterway Bureau Chang Jin 2

Dredger 8000m

3

12DKM-362

Shoyo Kisen K.K. Seiyo Maru

Tug boat 6DKM-32(L)2

Norihiro Takemura Sensho Maru # 1

Skipjack Pole & Line Fishing boat 6DKM-26L1

Myojin Fishery Sagamyojin Maru # 83

Skipjack Pole & Line Fishing boat 6DKM-28L1

Fukushima Fishery Sofo Maru #83

Purse Seiner 6DKM-36L1

Kanei Bussan Co. Wakaba Maru # 6

Purse Seiners 8DLM-321

Daiyu Fishery Tenno Maru #81

Purse Seiner 6DKM-28F1

Kanei Bussan Co. Genpuku Maru # 81

Purse Seiners 6DKM-321

K.K. Taishu Ikitsuki

Fishery Control Boat 8DKM-28L1

Yoshikazu Ishikura Sanko Maru

Skipjack Pole & Line Fishing boat 6DKM-28L1

Dredger 8DKM-362

Please refer to the separate brochure for "DAIHATSU AFTER-SERVICE NETWORK".

All information contained in this Pamphlet is corrected at the time of printing, but will be subject to change without notice.

www.dhtd.co.jp

PRINTED IN JAPAN

Head Office

Tokyo Office

Moriyama Division

Taiwan Office

Daihatsu Diesel (Europe) Ltd.

Daihatsu Diesel (AMERICA), Inc.

Daihatsu Diesel (ASIA PACIFIC) Pte.Ltd.

Daihatsu Diesel (SHANGHAI) Co.,Ltd.

1-30, Oyodo Naka1-chome, Kita-ku, Osaka, 531-0076 Japan

TEL:81-6-6454-2393 FAX:81-6-6454-2686

16-11, Nihonbashi 1-Chome Chuo-ku, Tokyo, 103-0027 Japan

TEL:81-3-3279-0827 FAX:81-3-3245-0359

45 Amura-cho, Moriyama-city, Shiga, 524-0035 Japan

TEL:81-77-583-2551 FAX:81-77-582-5714

c/o Marine Technical Industries Co., Ltd.

No.14 Tai-Tang RD. Lin-Hai Industrial Zone, Kaohsiung, 812 Taiwan

TEL:886-7-803-1082 FAX:886-7-801-9179

5th Floor, Devon House, 58-60 St. Katharine's Way, London E1W 1LB, U.K.

TEL:44-20-7977-0280 FAX:44-20-7702-4325

180 Adams Avenue,Hauppauge,NY 11788,U.S.A.

TEL:1-631-434-8787/8/9 FAX:1-631-434-8759

128 Pioneer Road Singapore 639586

TEL:65-6270-7235 FAX:65-6270-6236

Room A Floor 9, Huamin Empire Plaza, No.726 Yanan Rd(w), Shanghai, China

TEL:86-21-6225-7876/7 FAX:86-21-6225-9299

ISO 9001 Accredited

Quality Assurance System Standards of the International

Organization for Standardization

Conforming Sites : Head Office Moriyama Factory

Anda mungkin juga menyukai

- Vietshipping 2008Dokumen22 halamanVietshipping 2008minus89aspire100% (1)

- Daihatsu DE-23Dokumen4 halamanDaihatsu DE-23Shyam Kishore0% (1)

- Daihatsu de SeriesDokumen32 halamanDaihatsu de Seriesfernando_cassol100% (1)

- ABC Brochure VDZC enDokumen2 halamanABC Brochure VDZC enMartin KratkyBelum ada peringkat

- Kamome Propeller Co., LTD.: ProductDokumen3 halamanKamome Propeller Co., LTD.: ProductZaw Win MyatBelum ada peringkat

- 2021 - 09 - 01 FC-23160-2 Maintenance Failure of TDI 45M Air MotorDokumen2 halaman2021 - 09 - 01 FC-23160-2 Maintenance Failure of TDI 45M Air MotorengdpaliBelum ada peringkat

- MC-engines Danish Built EnginesDokumen11 halamanMC-engines Danish Built Engineshpss77100% (2)

- D2842 Heavy DutyDokumen4 halamanD2842 Heavy Dutym_najman100% (2)

- CXZ-MAN Supplies Diesel Engine Spare Parts and Marine Equipment To Ships - Welcome To Consult The PriceDokumen18 halamanCXZ-MAN Supplies Diesel Engine Spare Parts and Marine Equipment To Ships - Welcome To Consult The Pricexin zhangBelum ada peringkat

- BookDokumen8 halamanBookPrince ChaudharyBelum ada peringkat

- E20081024286 - 1-Regular Overhaul NoticeDokumen10 halamanE20081024286 - 1-Regular Overhaul NoticeIvanciu Ionut-FabianBelum ada peringkat

- Catalogo - Electro Adda FullDokumen25 halamanCatalogo - Electro Adda Fulljcpp_18Belum ada peringkat

- MarineDokumen210 halamanMarinecmendezBelum ada peringkat

- Specification Sheet of S6R2-T2MPTK Marine Diesel Engine: Item No. M0209-0012E Date April 2013Dokumen4 halamanSpecification Sheet of S6R2-T2MPTK Marine Diesel Engine: Item No. M0209-0012E Date April 2013Nguyễn Văn CảnhBelum ada peringkat

- Man BWDokumen24 halamanMan BWDhanie KhruxzBelum ada peringkat

- Scania Technical Data - Issue-13Dokumen51 halamanScania Technical Data - Issue-13kman548Belum ada peringkat

- Service Bulletin RTA-43.3 RT-flex-05Dokumen12 halamanService Bulletin RTA-43.3 RT-flex-05Gaby CrisBelum ada peringkat

- Arneson Surface Drives CatalogueDokumen12 halamanArneson Surface Drives CatalogueWoodsy12Belum ada peringkat

- D2876 Medium DutyDokumen4 halamanD2876 Medium Dutyfajar saputra100% (1)

- MF-072-2 V02-DK20 Instrauction Manual (Maintenance)Dokumen173 halamanMF-072-2 V02-DK20 Instrauction Manual (Maintenance)ИгорьBelum ada peringkat

- L35 MC 6Dokumen351 halamanL35 MC 6chuminhBelum ada peringkat

- Marine Engine Program 2014 PDFDokumen164 halamanMarine Engine Program 2014 PDFAlbertoJim90Belum ada peringkat

- Abbtc Bro1100 Our RangeDokumen15 halamanAbbtc Bro1100 Our RangearesobscureBelum ada peringkat

- Gear BoxDokumen5 halamanGear Boxxfile34100% (1)

- Sis 2.0 Sebf8146Dokumen38 halamanSis 2.0 Sebf8146JuanBelum ada peringkat

- Wartsila O E RT82Dokumen24 halamanWartsila O E RT82Gennadiy Kovalyov100% (1)

- Imo Ace PumpsDokumen12 halamanImo Ace Pumpsrentz76Belum ada peringkat

- MaK 8M25C MaintenancePlanDokumen36 halamanMaK 8M25C MaintenancePlanЮрий Семёнов100% (1)

- Yanmar Shop - 6AYM-WSTDokumen64 halamanYanmar Shop - 6AYM-WSTReda SyaifulBelum ada peringkat

- FV Engine Power January 2015Dokumen903 halamanFV Engine Power January 2015Otavio GomesBelum ada peringkat

- PDF 1Dokumen45 halamanPDF 1Deepak ShoriBelum ada peringkat

- Main Engine Doosan 8K90MC-CDokumen1 halamanMain Engine Doosan 8K90MC-CRonald Sol Salen JordasBelum ada peringkat

- Mitsubishi Tech Fuel Consumption For Marine EngineDokumen40 halamanMitsubishi Tech Fuel Consumption For Marine EngineReddy RiyadieBelum ada peringkat

- Main Engine Manual 12038-41 - CulatasDokumen23 halamanMain Engine Manual 12038-41 - CulatasEduardoCastillo100% (1)