As 4303 en Mini Valves and Rupture Disc Holders

Diunggah oleh

dbmingo0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

15 tayangan6 halamanMini Valves and Rupture Disc Holders are available for hot, cold, wet, freezing, dirty sour gas (H 2 S), carbon dioxide (CO 2 ), amines, corrosion inhibitors, methanol and glycol compounds found in your pipeline and transmission system.

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMini Valves and Rupture Disc Holders are available for hot, cold, wet, freezing, dirty sour gas (H 2 S), carbon dioxide (CO 2 ), amines, corrosion inhibitors, methanol and glycol compounds found in your pipeline and transmission system.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

15 tayangan6 halamanAs 4303 en Mini Valves and Rupture Disc Holders

Diunggah oleh

dbmingoMini Valves and Rupture Disc Holders are available for hot, cold, wet, freezing, dirty sour gas (H 2 S), carbon dioxide (CO 2 ), amines, corrosion inhibitors, methanol and glycol compounds found in your pipeline and transmission system.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

Instrumentation Products

Mini Valves and Rupture Disc Holders

General Features I Mini Valves and Rupture Disc Holders

Introduction

Rugged Design for long term performance in the most demanding environmental conditions and services. Seat and Seal materials are available for

hot, cold, wet, freezing, dirty sour gas (H

2

S), carbon dioxide (CO

2

), amines, corrosion inhibitors, methanol and glycol compounds found in your

pipeline and transmission system. Available with Double O-Ring Stem Seal or PTFE packed. Features like Stem Seal below threads and Back Seat

Design are standard. The Soft Seats are feld replaceable. The valve is also available with an Integral Rupture Disc (1,800 psi [124 bar] rated).

Rupture Disc Holders are available with or without Rupture Disc.

Material Group

AS Material

Designation

Material Grade

acc. to ASTM

Equivalent

UNS-No.

Material

No.

Short Name Mini Valves

Rupture Disc

Holders

Copper Alloys Brass

CW614N CuZn39Pb3

Standard Not available

CW617N CuZn40Pb2

Carbon Steel LF2 LF2 Standard Standard

Austenitic

Stainless Steel

316 quadruple

certifed*

316 S 31600 1.4401 X5CrNiMo17-12-2

Standard Standard

316L S 31603 1.4404 X2CrNiMo17-12-2

Nickel Based

Alloys

Alloy 400 N 04400 2.4360 NiCu30Fe Optional Optional

Alloy C-276 N 10276 2.4819 NiMo 16 Cr 15 W Optional Optional

*

Quadruple Certifed means acc. to ASTM and EN: 316/316L/1.4401/1.4404

Body Material Options

Bore Size 0.138" (3.5 mm)

Soft Seated

Stem Seal

- Double O-Ring Design as standard

- PTFE Packing is also available for all valve types

Standard Rupture Disc 1,800 psi (124 bar) rated

Sour Gas Service:

Standard Features

Wetted Parts according to a. m. material list are supplied as standard

according to NACE MR0175/MR0103 and ISO 15156 (latest issue).

Pressure Test:

A shell test and a seat leakage test are performed at 1.5 times the

maximum working pressure acc. to EN 12266-1 - P10, P11 and P12

respectively MSS-SP61 (and complies also with ASME B31.1 and B31.3).

As standard AS-Schneider Mini Valves are 100% Pressure Tested!

Oxygen Service:

AS-Schneider offers an option cleaned and lubricated for Oxygen Service:

Optional Features

PTFE Packing - Max. 6,092 psi (420 bar)

Pressure-Temperature Rating: max. 6,092 psi @ 140F

420 bar @ 60C

max. 392F @ 1,305 psi

200C @ 90 bar

Not every Valve type is available for Oxygen Service!

Certifcation:

Certifed Mill Test Report (CMTR) as Inspection certifcate 3.1 acc. to

EN 10 204 for valve body material and pressure test available on

request.

If you don't fnd your options in this catalogue, please contact

the factory.

Pressure-Temperature Rating (Soft Seat)

Stem Seal Material

Material Temperature

FKM -13F (-25C) 392F (200C)

FKM (RGD resistant) -35F (-37C) 450F (232C)

FEPM -4F (-20C) 392F (200C)

PTFE -67F (-55C) 450F (232C)

Temperature Limit for Body Material:

- Carbon Steel LF2: -51F (-46C)

- Brass: 14F (-10C)

All other materials are limited by soft goods.

Max. Operating Pressure for Brass Type 3,000 psi (206.80 bar)

Min. Max.

General Features Mini Valves and Rupture Disc Holders AS-Schneider 2

Mini Valves

Packing adjustment may be required during the service life

of the valve.

Valves that have not been cycled for a period of time may

have a higher initial actuation torque.

Components

Brass

Carbon

Steel

Stainless

Steel

Exotic Alloys

Material / Material No.

Body

Brass

LF2 316 / 316L

Alloy

400

Alloy

C-276

Bonnet 316 / 316L

Alloy

400

Alloy

C-276

Seat POM or PCTFE

Valve Stem Brass 316 / 316L

Alloy

400

Alloy

C-276

O-Ring FKM or FEPM

Packing PTFE

Rupture Disc Alloy 625

Hex Plug 316

Gland 316

Stem Nut 316

Lock Nut 316

Set Screw 316

Round Handle Aluminium

Lock Pin A4 (316)

Wetted components listed in bold.

1

.

7

7

"

(

4

5

)

o

p

e

n

2

.

6

0

"

(

6

6

)

o

p

e

n

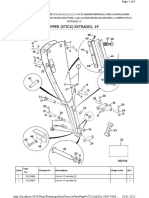

Mini Valves

Features

Bore Size 0.138" (3.5 mm)

Replaceable Valve Seat - POM, optional PCTFE

Stem Seal - O-Rings in FKM (optional RGD resistant)

or FEPM

External Stem Thread - Packing below stem threads. Stem

Threads are protected from process media (non-wetted).

Stem with Cold Rolled Threads, except Brass Type

Blow-out Proof Stem

Back Seat - Metal to metal secondary stem seal

Lock Pin - Eliminates unauthorized removal of the bonnet

Color Coded Dust Cap for operating thread protection

Type with Integral Rupture Disc optional

Round Handle Aluminium, silver anodized -

Optional Round Handle & T Handle in 316SS

Max. Operating Pressure 6,092 psi (420 bar)

Mini Valves are manufacturered to the following

Codes and Specifcations

ASME B31.1 Power Piping

ASME B31.3 Process Piping

ASME B16.34 Valves - Flanged, Threaded and Welding End

API 598 Valve Inspection and Testing

MSS SP-25 Standard Marking Systems for Valves, Fittings and

Flange Unions

MSS SP-99 Instrument Valves

MSS SP-105 Instrument Valves for Code Applications

NACE MR0175 Petroleum and Natural Gas Industries ...

(not available for brass valves)

Double O-Ring Stem Seal PTFE Packing Integral Rupture Disc

Mini Valves 3

Mini Valves

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A 5 S - A N 2 S K D -

A Mini Valves

Basic Design

S Straight Pattern L Angle Pattern

R Straight Pattern + Integral Rupture Disc

Dash

Inlet x Outlet Confguration

A Male x Female C Male x Male

B Female x Female

Inlet and Outlet Thread Sizes

N1 1/8 NPT

N2 1/4 NPT

Material

L Carbon Steel LF2 M Alloy 400 UNS N04400 E Brass (not for Integral Rupture Disc Design)

S 1.4404 / 1.4401 / 316 / 316L H Alloy C-276 UNS N10276

Stem Seal / Packing

K O-Ring FKM A PTFE Packing

J O-Ring FKM (RGD-resistant)

P O-Ring FEPM

Seal Material

D POM

K PCTFE

Dash

Options - Specify in alphabetical order (digits frst, then letters)

18 Valve with Integral Rupture Disc: Assembled with Standard Rupture Disc 1,800 psi (124 bar) rated G Soft Tip POM - For Metal to Metal Seat only

- Valve with Integral Rupture Disc: Assembled with Rupture Disc __00 psi rated I __00 psi __ to be specifed S Stellite Valve Tip - For Metal to Metal Seat only

B Cleaned and Lubricated for Oxygen Service M Wetted Parts with Certifed Mill Test Report (CMTR) as 3.1 certifcate acc. to EN 10204

F Soft Tip PCTFE - For Metal to Metal Seat only

Operation Options

K T Handle - Instead of Round Handle Aluminium

W Round Handle SS - Instead of Aluminium

Wetted Parts according to above mentioned material list are supplied according to NACE MR0175/MR0103 and ISO 15156 (latest issue).

Ordering Information

Straight Pattern Angle Pattern Straight Pattern and Integral Rupture Disc

1

.

7

7

"

(

4

5

)

o

p

e

n

0

.

8

7

"

(

2

2

)

2.13" (54)

1

.

8

1

"

(

4

6

)

o

p

e

n

1

.

0

5

"

(

2

6

.

5

5

)

1.05" (26.6)

2.13" (54)

1

.

9

7

"

(

5

0

)

o

p

e

n

1

.

1

1

"

(

2

8

.

2

5

)

www.as-schneider.com Mini Valves 4

Rupture Disc Holders

Rupture Disc Holders

Features

Standard Rupture Disc 1,800 psi (124 bar) rated

Components

Carbon Steel Stainless Steel Exotic Alloys

Material / Material No.

Body LF2 316 / 316L Alloy 400 Alloy C-276

Rupture Disc Alloy 625

Hex Plug 316

Wetted components listed in bold.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

R D H - A N 2 S -

RDH Rupture Disc Holders

Dash

Inlet x Outlet Confguration

A Male x Female C Male x Male

B Female x Female

Inlet and Outlet Thread Sizes

N2 1/4 NPT

Material

L Carbon Steel LF2 M Alloy 400 UNS N04400

S 1.4404 / 1.4401 / 316 / 316L H Alloy C-276 UNS N10276

Dash

Options - Specify in alphabetical order (digits frst, then letters)

A Rupture Disc Holder without Rupture Disc

18 Assembled with Standard Rupture Disc 1,800 psi (124 bar) rated

__ Assembled with Rupture Disc __00 psi rated I __00 psi __ to be specifed

B Cleaned for Oxygen Service

M Wetted Parts with Certifed Mill Test Report (CMTR) as 3.1 certifcate acc. to EN 10204

Wetted Parts according to above mentioned material list are supplied according to NACE MR0175/MR0103 and ISO 15156 (latest issue).

Continuous product development may from time to time necessitate changes in the details contained in this catalogue. AS-Schneider reserves the right to make such changes at their discretion and

without prior notice. All dimensions shown in this catalogue are approximate and subject to change.

Ordering Information

Male x Female Female x Female Male x Male

1

.

1

1

"

(

2

8

)

2.00" (50.8)

AS-Schneider Rupture Disc Holders 5

AS-4303-EN | April 2014

Tel: +49 7133 101- 0 Fax: +49 7133 101- 148

www.as-schneider.com

Armaturenfabrik Franz Schneider

GmbH + Co. KG

Bahnhofplatz 12 I 74226 Nordheim

Deutschland / Germany

Tel: +65 62 51 39 00

Fax: +65 62 51 39 90

www.as-schneider.sg

AS-Schneider Asia-Pacifc Pte. Ltd.

970 Toa Payoh North, #02-12/14/15

Singapore 318992

Tel: +40 368 41 40 25

Fax: +40 368 41 40 26

www.as-schneider.ro

Armaturenfabrik Franz Schneider SRL

Sales Offce:

Str. Basarabilor, Nr. 7 I 100036 Ploiesti

Romania

Tel: +971 4 880 85 75 Fax: +971 4 880 85 76

www.as-schneider.ae

AS-Schneider Middle East FZE

P.O. Box 18749 I Dubai

United Arab Emirates

AS-Schneider America, Inc.

17421 Village Green Dr I Houston, TX 77040

United States of America

Production Plant:

Str. Mihai Viteazu, Nr. 327i I 507085 Harman

Jud. Braov I Romania

Tel: +40 244 384 963

Fax: +40 244 384 963

Tel: +1 281 2 58 42 63 Fax: +1 281 5 06 79 35

www.as-schneider.com

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Pump Selection GuidelineDokumen101 halamanPump Selection GuidelinefacebookshopBelum ada peringkat

- Norma IsaDokumen22 halamanNorma IsadbmingoBelum ada peringkat

- Daily Diary ReportsDokumen14 halamanDaily Diary ReportsOBERT MASALILABelum ada peringkat

- 08-Section 2-Section 02210 HDPE Pipeline-Version 2.0Dokumen20 halaman08-Section 2-Section 02210 HDPE Pipeline-Version 2.0Avaan IvaanBelum ada peringkat

- Instrument Connection BasicDokumen63 halamanInstrument Connection BasicdbmingoBelum ada peringkat

- Dismantling of BoilerDokumen2 halamanDismantling of BoilerElie ShBelum ada peringkat

- APV STD Insp & Test Plan API6D ValvesDokumen4 halamanAPV STD Insp & Test Plan API6D ValvesdbmingoBelum ada peringkat

- DSI-200 Valve Lubricant: Product DescriptionDokumen11 halamanDSI-200 Valve Lubricant: Product DescriptiondbmingoBelum ada peringkat

- High Pressure Components and Systems For Critical Ser Vice ApplicationsDokumen24 halamanHigh Pressure Components and Systems For Critical Ser Vice ApplicationsdbmingoBelum ada peringkat

- High Pressure Specialty ValvesDokumen19 halamanHigh Pressure Specialty ValvesdbmingoBelum ada peringkat

- Resato 140.HP - EN.05.QUICK CONNECTORS - Brochure (v2.0 - X)Dokumen4 halamanResato 140.HP - EN.05.QUICK CONNECTORS - Brochure (v2.0 - X)dbmingoBelum ada peringkat

- ONG Valve Buyer's Guide: High Pressure Valves and AccessoriesDokumen48 halamanONG Valve Buyer's Guide: High Pressure Valves and AccessoriesdbmingoBelum ada peringkat

- Hose Repairs: Assembly Center Celebrates 20 YearsDokumen2 halamanHose Repairs: Assembly Center Celebrates 20 YearsdbmingoBelum ada peringkat

- As 2601 en E Series Valves and ManifoldsDokumen52 halamanAs 2601 en E Series Valves and ManifoldsdbmingoBelum ada peringkat

- Model 305R Two Valve Coplanar Style Manifold Model 305Rc2 Two Valve Model 305Rc7 Two Valve (Asme B31.1)Dokumen5 halamanModel 305R Two Valve Coplanar Style Manifold Model 305Rc2 Two Valve Model 305Rc7 Two Valve (Asme B31.1)dbmingoBelum ada peringkat

- 2 AdaptersDokumen36 halaman2 Adaptersdbmingo0% (1)

- 4505 DiaphragmValves RWDokumen49 halaman4505 DiaphragmValves RWdbmingoBelum ada peringkat

- 1.5" Fittings and Tubing - Up To 15,000 Psi: Do More With Less!Dokumen1 halaman1.5" Fittings and Tubing - Up To 15,000 Psi: Do More With Less!dbmingoBelum ada peringkat

- PC Op CCDokumen3 halamanPC Op CCWork OfficeBelum ada peringkat

- Asphalt Laying MethodologyDokumen4 halamanAsphalt Laying MethodologyRey ZartigaBelum ada peringkat

- GL XX Mobil Polyrex EM SeriesDokumen3 halamanGL XX Mobil Polyrex EM SeriesRakka HardiyantaBelum ada peringkat

- 9LT HT NEW LP - Price ListDokumen5 halaman9LT HT NEW LP - Price ListnitinpeBelum ada peringkat

- Tugasan Individu No 1 Tall Bulding Construction 2 1920Dokumen5 halamanTugasan Individu No 1 Tall Bulding Construction 2 1920EJ KooBelum ada peringkat

- Energy Efficient Rondavels in The Kruger NationalDokumen8 halamanEnergy Efficient Rondavels in The Kruger NationalMichael DibakwaneBelum ada peringkat

- Effects of Shear Box Size On The Strength For Different Type of Silty Sands in Direct Shear TestsDokumen7 halamanEffects of Shear Box Size On The Strength For Different Type of Silty Sands in Direct Shear TestsJavier MtBelum ada peringkat

- The Behavior of Tied-Back Retaining WallsDokumen25 halamanThe Behavior of Tied-Back Retaining WallsAnand ShawBelum ada peringkat

- Cert Perno Hex A325 5.8 (11) X 1-1.2Dokumen4 halamanCert Perno Hex A325 5.8 (11) X 1-1.2Abril SalinasBelum ada peringkat

- Final Report 00 - 1187-Rev00Dokumen31 halamanFinal Report 00 - 1187-Rev00wafikmh4Belum ada peringkat

- Perfecting Piping and Duct Systems For Revit: Learning ObjectivesDokumen45 halamanPerfecting Piping and Duct Systems For Revit: Learning ObjectivessupportLSMBelum ada peringkat

- RAM Terminals Permit ApplicationDokumen7 halamanRAM Terminals Permit ApplicationbenbyyyyyBelum ada peringkat

- 9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Dokumen4 halaman9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Виталий РогожинскийBelum ada peringkat

- Euro Truss Catalogue 2009Dokumen180 halamanEuro Truss Catalogue 2009Mihnea CostacheBelum ada peringkat

- Plasti-Fab, Inc. Composite Stop Log BrochureDokumen2 halamanPlasti-Fab, Inc. Composite Stop Log BrochurePlasti-Fab100% (1)

- A Brief Presentation On Shoe-Sole MakingDokumen15 halamanA Brief Presentation On Shoe-Sole MakingTahmidBelum ada peringkat

- GM 8.8L Engine Serv PartsDokumen84 halamanGM 8.8L Engine Serv PartsKevin DampmanBelum ada peringkat

- ITS Webinar - Tantangan Pada Pelaksanaan (01.10.2022)Dokumen23 halamanITS Webinar - Tantangan Pada Pelaksanaan (01.10.2022)Destra Dwi Falah SetyamaBelum ada peringkat

- 12mm-Thick Cement Plastering in Cement MortarDokumen4 halaman12mm-Thick Cement Plastering in Cement MortarSathishBelum ada peringkat

- Design, Manufacture and Analysis of Al/Sic Mmcs For Connecting RodDokumen8 halamanDesign, Manufacture and Analysis of Al/Sic Mmcs For Connecting RodBima SorayaBelum ada peringkat

- Mansory 1Dokumen5 halamanMansory 1John Isaac BanaagBelum ada peringkat

- Final Year Project Proposal On Residential Building ProjectDokumen13 halamanFinal Year Project Proposal On Residential Building ProjectPrashant JoshiBelum ada peringkat

- Truss-and-Purlins-Design Alternative DesignDokumen8 halamanTruss-and-Purlins-Design Alternative DesignAiron Kaye SameloBelum ada peringkat

- Seismic Isolation in Existing Complex Structures: P. ClementeDokumen10 halamanSeismic Isolation in Existing Complex Structures: P. Clementejavier salazarBelum ada peringkat

- Forta Ferro Usa Report 20-05Dokumen1 halamanForta Ferro Usa Report 20-05stevecabreraBelum ada peringkat

- Datasheet Polystone P CubX ENDokumen1 halamanDatasheet Polystone P CubX ENjavierBelum ada peringkat