TM 11-6115-470-23P - DC-Generator - G-76 - 1986 PDF

Diunggah oleh

Wurzel1946Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TM 11-6115-470-23P - DC-Generator - G-76 - 1986 PDF

Diunggah oleh

Wurzel1946Hak Cipta:

Format Tersedia

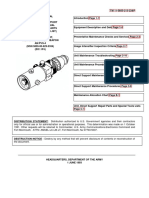

TM 11-6115-470-23&P

TECHNICAL MANUAL

ORGANIZATIONAL AND DIRECT SUPPORT

MAINTENANCE MANUAL INCLUDING REPAIR

PARTS AND SPECIAL TOOLS LIST

EQUIPMENT

DESCRIPTION

PAGE 1-3

ORGANIZATIONAL

MAINTENANCE

PAGE 2-1

PMCS

TABLE

PAGE 2-4

DIRECT SUPPORT

MAINTENANCE

PAGE 3-1

TROUBLESHOOTING

PAGE 3-3

RPSTL

APPENDIX C

PAGE C-1

GENERATORS, DIRECT CURRENT

G-76/G (NSN 6115-01-082-8107) and G-76A/G (NSN 6115-01-192-2080)

ACCESSORY KIT, FIELD RADIO EQUIPMENT, MK-2120/G

(NSN 6115-01-119-9574)

AND

ACCESSORY KIT, PERMISSIVE ACTION LINK, MK-2121/G

(NSN 6115-01-128-2437)

HEADQUARTERS DEPARTMENT OF THE ARMY

1 SEPTEMBER 1986

This publication Is required for official use or for

administrative or operational purposes only.

Distribution Is limited to US Government Agencies.

Other requests for this document must be referred to

Commander, US Army Communications-Electronics

Command and Fort Monmouth, ATTN. AMSEL-ME-P,

Fort Monmouth, NJ 07703-5007.

TM 11-6115-470-23&P

WARNING

Adequate ventilation should be provided while using

TRICHLOROTRIFLUOROETHANE. Prolonged breathing of vapor should be

avoided. The solvent should not be used near heat or open flame; the products of

decomposition are toxic and irritating. Since TRICHLOROTRIFLUOROETHANE

dissolves natural oils, prolonged contact with skin should be avoided. When

necessary, use gloves which the solvent cannot penetrate. If the solvent is taken

Internally, consult a physician immediately.

Electrical shock may result if personnel fail to observe safety precautions.

Do not touch contacts of the generator when it is being cranked.

Do not touch contacts of a cable when it is plugged into a generator being

operated.

Do not touch contacts of any charged battery or one being charged by this

equipment.

Do not try to power any equipment with the G-76/G that is not covered in this

manual. In emergency situations, check with maintenance personnel.

A

TM 11-6115-470-23&P

SAFETY STEPS TO FOLLOW IF SOMEONE IS THE VICTIM OF ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE, TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL POWER, PULL, PUSH, OR LIFT THE

PERSON TO SAFETY USING A DRY WOODEN POLE OR A DRY ROPE OR SOME OTHER

INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF CONTACT WITH THE SOURCE OF

ELECTRICAL SHOCK, MOVE THE PERSON A SHORT DISTANCE AWAY AND

IMMEDIATELY START ARTIFICIAL RESUSCITATION

A

5

1

2

3

4

5

TM 11-6115-470-23&P

Technical Manual HEADQUARTERS

No. 11-6115-470-23&P DEPARTMENT OF THE ARMY

Washington, DC, 1 September 1986

ORGANIZATIONAL AND DIRECT SUPPORT

MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST

GENERATOR, DIRECT CURRENT G-76/G (NSN 6115-01-082-8107)

GENERATOR, DIRECT CURRENT G-76A/G (NSN 6115-01-192-2080)

ACCESSORY KIT, FIELD RADIO EQUIPMENT, MK-2120/G (NSN 6115-01-119-9574)

ACCESSORY KIT, PERMISSIVE ACTION LINK, MK-2121/G (NSN 6115-01-128-2437)

CURRENT AS OF 16 JULY 1986

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes of if you know of a way to

improve the procedures, please let us know. Mail your letter, DA Form 2028

(Recommended Changes to Publications and Blank Forms), or DA Form 2028-2 located

in the back of this manual direct to: Commander US Army Communications Electronics

Command and Fort Monmouth, ATTN: AMSEL-ME-MP, Fort Monmouth, New Jersey

07703-5007. A reply will be furnished to you.

Page

HOW TO USE THIS MANUAL.............................................................................................. iv

CHAPTER 1 INTRODUCTION

Section I General Information................................................................................................................ 1-1

1-1. Scope ..................................................................................................................... 1-1

1-2. Maintenance Forms, Records and Reports............................................................ 1-1

1-3. Destruction of Army Electronics Materiel................................................................ 1-1

1-4. Administrative Storage ........................................................................................... 1-2

1-5. Official Nomenclature, Names and Designations................................................... 1-2

1-6. Reporting Equipment Improvement Recommendations (EIR) ............................... 1-2

1-7. Consolidated Index of Army Publications and Blank Forms................................... 1-2

II Equipment Description and Data............................................................................................ 1-3

1-8. General ................................................................................................................... 1-3

1-9. Equipment Characteristics, Capabilities and Features........................................... 1-3

1-10. Location and Description of Major Components .................................................... 1-4

1-11. Differences Between G-76/G Models..................................................................... 1-5

1-12. Equipment Data...................................................................................................... 1-5

1-13. Equipment Configuration........................................................................................ 1-6

III Principles of Operation ........................................................................................................... 1-8

1-14. General ................................................................................................................... 1-8

1-15. Generator ............................................................................................................... 1-8

1-16. Harmonic Drive....................................................................................................... 1-8

1-17. Power Conditioning Unit (PCU) .............................................................................. 1-8

i

TM 11-6115-470-23&P

Page

CHAPTER 2 ORGANIZATIONAL MAINTENANCE

Section I Repair Parts, Special Tools, Test Measurement and

Diagnostic Equipment (TMDE) and Support Equipment.................................................. 2-1

2-1. Common Tools and Equipment .............................................................................. 2-1

2-2. Organizational Maintenance................................................................................... 2-1

2-3. Repair Parts............................................................................................................ 2-1

II Service Upon Receipt ............................................................................................................. 2-1

2-4. Unpacking............................................................................................................... 2-1

2-5. Removing Contents................................................................................................ 2-3

2-6. Checking Unpacked Equipment ............................................................................. 2-3

III Preventive Maintenance Checks and Services (PMCS)......................................................... 2-3

2-7. General ................................................................................................................... 2-3

IV Maintenance Procedures........................................................................................................ 2-5

2-8. General ................................................................................................................... 2-5

2-9 Organizational Maintenance................................................................................... 2-5

2-10. Cleaning ................................................................................................................. 2-5

2-11. Touch Up Painting.................................................................................................. 2-5

2-12. Accessory Kit, Field Radio Equipment, MK-2120/G............................................... 2-6

2-13. Accessory Kit, Permissive Action Link, MK-2121/G............................................... 2-7

V Preparation for Storage or Shipment ...................................................................................... 2-7

2-14. Packaging Data...................................................................................................... 2-7

CHAPTER 3 DIRECT SUPPORT MAINTENANCE PROCEDURES

Section I Repair Parts, Special Tools, Test Measurement and

Diagnostic Equipment (TMDE) and Support Equipment.................................................. 3-1

3-1. General ................................................................................................................... 3-1

3-2. Special Tools, TMDE and Support Equipment ....................................................... 3-1

3-3. Repair Parts............................................................................................................ 3-1

II Testing .............................................................................................................................. 3-1

3-4. G-76/G Testing....................................................................................................... 3-1

3-5. Generator Head and Handle Assembly Testing..................................................... 3-2

3-6. PCU Testing ........................................................................................................... 3-3

III Troubleshooting...................................................................................................................... 3-3

3-7. General ................................................................................................................... 3-3

3-8. Direct Support Troubleshooting.............................................................................. 3-3

IV Maintenance Procedures........................................................................................................ 3-6

3-9. General ................................................................................................................... 3-6

3-10. PCU Removal ......................................................................................................... 3-6

ii

TM 11-6115-470-23&P

3-11. PCU Replacement............................................................................................... 3-7

3-12. Right Handle Assembly Removal ........................................................................ 3-8

3-13. Right Handle Assembly Replacement ................................................................. 3-8

3-14. Left Handle Assembly Removal .......................................................................... 3-8

3-15. Left Handle Assembly Replacement ................................................................... 3-9

3-16. Generator Head and Handle Assembly Removal............................................... 3-10

3-17. Generator Head and Handle Assembly Replacement ....................................... 3-10

3-18. Tripod Replacement ........................................................................................... 3-10

APPENDIX A. REFERENCES ................................................................................................................... A-1

B. MAINTENANCE ALLOCATION......................................................................................... B-1

Section I. Introduction .................................................................................................. B-1

II. Maintenance Allocation Chart ...................................................................... B-4

III. Tool and Test Equipment Requirements ..................................................... B-6

IV. Remarks....................................................................................................... B-6

Page Illus

Figure

C. ORGANIZATIONAL AND DIRECT

SUPPORT MAINTENANCE REPAIR PARTS AND

SPECIAL TOOLS LIST ............................................................................... C-1

Section I. Introduction ..................................................................................... C-1

Section II. Repair Parts List

Group 00. Generator, Direct Current G-76G and G-76A/G............................. C-1-1 C-1

01. Power Conditioning Unit (No parts authorized)

02. Generator Head and Handle Assembly .......................................... C-2-1 C-2

03. Stand Assembly (No parts authorized)

00. Accessory Kit MK-2120/G............................................................... C-3-1 C-3

00 Accessory Kit MK-2121/G............................................................... C-4-1 C-4

Section lIl. Special Tools List (Not applicable)

IV. National Stock Number and Part Number Index............................. C-I-1

D. EXPENDABLE SUPPLIES AND MATERIALS LIST............................................ D-1

Section I. Introduction ..................................................................................... D-1

II. Expendable Supplies and Materials List ......................................... D-2

iii

TM 11-6115-470-23&P

HOW TO USE THIS MANUAL

Usage

You must familiarize yourself with the entire maintenance procedure before beginning the maintenance task.

Manual Overview

This manual has been prepared in an ascending numbered order of chapters, sections and paragraphs.

The chapters are numbered chapter 1, chapter 2, chapter 3. Each chapter contains sections given in Roman numerical

order such as sections I, II, and Ill in chapters 1 and 2 and such as sections I, II, III, IV and V in chapter 3.

The paragraphs are in numerical order in each chapter. Each paragraph has the chapter number given before the

sequential number of the paragraph. For example paragraph 1-1 is the first paragraph in chapter 1. Paragraph 2-1 is the

first paragraph in chapter 2 and so on throughout the manual.

A bullet () indicates additional information for the paragraph above it.

Special feature:

A locator is provided on the right-hand border of the front cover. This gives the location in the manual of the information

most frequently needed. to use the locator, look at the front cover. If you want to find the topic TROUBLESHOOTING,

open the manual to the correct page by using the block tab on the side of the manual that lines up with the topic

TROUBLESHOOTING.

iv

TM 11-6115-470-23&P

CHAPTER 1

INTRODUCTION

Section I. GENERAL INFORMATION

1-1. SCOPE

This manual covers Organizational and Direct Support Maintenance for Generators, Direct Current G-76/G and G-76A/G.

The generators provide power for communications radios, rechargeable batteries, Permissive Action Links (PAL) and the

M38 fuze setter.

Accessory Kit, Field Radio Equipment, Special Operation and Engineering Mission, MK-2120/G and Accessory Kit,

Permissive Action Link, Artillery Mission, MK-2121/G are used in hookups to provide power from the generators to the

equipment.

Throughout this manual, information on the G-76/G applies to the G-76A/G unless otherwise indicated.

Application of Modification Work Order, MWO-11-6115-470-50-1 converts the G-76/G to a G-76A/G.

1-2. MAINTENANCE FORMS, RECORDS AND REPORTS

Reports of Maintenance and Unsatisfactory Equipment. Department of the Army forms and procedures used for

equipment maintenance will be those prescribed by DA Pam 738-750 as contained in Maintenance Management Update.

Report of Packaging and Handling Deficiencies. Fill out and forward SF 364 (Report of Discrepancy (ROD)) as prescribed

in AR 735-11-2/DLAR 4140.55,NAVMATINST 4355.73B/AFR 400-54/MCO 4430.3H.

Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward Discrepancy in Shipment Report (DISREP) (SF

361) as prescribed in AR 55-38,NAVSUPINST 4610.33C/AFR 75-18/MCO P4610.19D/DLAR 4500.15.

POWER CONDITIONING

UNIT

TRIPOD

GENERATOR HEAD

AND HANDLE ASSEMBLY

1-1

TM 11-6115-470-23&P

1-3. DESTRUCTION OF ARMY ELECTRONICS MATERIEL

Destruction of Army electronics materiel to prevent enemy use shall be in accordance with TM 750-244-2.

1-4. ADMINISTRATIVE STORAGE

Administrative storage of equipment issued to and used by Army activities will have preventive maintenance performed in

accordance with the PMCS chart before storing. When removing the equipment for administrative storage, the PMCS

(table 2-1) should be performed to assure operational readiness. Unpacking and repacking of equipment for shipment or

limited storage are covered in paragraphs 2-5 and 2-14 and figure 2-1.

1-5. OFFICIAL NOMENCLATURE, NAMES AND DESIGNATIONS

The table below gives the nomenclature and common names that are used in this manual.

NOMENCLATURE CROSS-REFERENCE LIST

This listing includes nomenclature cross-references used in this manual.

Common Name Official Nomenclature

G-76/G Generator, Direct Current G-76/G

G-76A/G Generator, Direct Current G-76A/G

PCU Power Conditioning Unit

Generator Head Generator

Tripod Stand Assembly

Foot Pads Cover Assembly, Plate, Nonskid

Generator Cable Cable, Special Purpose, Electrical CX-13175/G, (P/0 MK-2120/G)

Radio Cable Cable, Special Purpose, Electrical CX-13176/G, (P/0 MK-2120/G)

Setter Cable Cable Assembly, Special Purpose, Electrical CX-13205/G, (P/C MK-2221/G)

PAL/M38 Adapter Adapter, Connector, (Part of MK-2121/G)

Generator Bag Bag, Carrying

1-6. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR)

If your equipment needs improvement, let us know. Send us an EIR. You, the user, are the only one who can tell us what

you dont like about the design. Put it on an SF 368 (Quality Deficiency Report). Mail it to: Commander, US Army

Communications-Electronics Command and Fort Monmouth, ATTN: AMSEL-PA-MA-D, Fort Monmouth, New Jersey

07703-5000. Well send you a reply.

1-7. CONSOLIDATED INDEX OF ARMY PUBLICATIONS AND BLANK FORMS

Refer to the latest issue of DA Pam 310-1 to determine whether there are new editions, changes or additional publications

pertaining to the equipment.

1-2

TM 11-6115-470-23&P

Section II. EQUIPMENT DESCRIPTION AND DATA

1-8. GENERAL

The G-76/G is a lightweight, parachute deliverable, hand-cranked generator used in the field to directly power the

AN/PRC-70 and the AN/PSC-3 communication radios. The generator is electromagnetic interference (EMI qualified and

capable of charging 24 volt nickel-cadmium batteries such as the BB-542/U. The G-76/G can indirectly power an

AN/PRC-70 and the AN/PSC-3 through the BB-542/U input plug. The nuclear hardened generator is also capable of

powering the PAL T1533/T1544 and M38 fuze setter used with the M753 nuclear projectile. By varying the cranking

speed, the operator can maintain or adjust the power production rate over a range of temperatures. The G-76/G in its

folded configuration can be transported in a carrying bag by one person. The G-76/G can be operated in all kinds of

weather and terrain and can be installed at fixed sites such as field headquarters and command posts.

The G-76AG is a very quiet generator and can be used to power the same equipment listed above.

Accessory Kit, Field Radio Equipment MK-2120/G and Accessory Kit Permissive Action Link, MK-2121/G are used with

either generator to provide the desired hookups to power equipment.

1-9. EQUIPMENT CHARACTERISTICS, CAPABILITIES AND FEATURES

CHARACTERISTICS

PORTABLE... Easily carried by one soldier, the G-76/G can be air-dropped to the most remote locations.

LIGHTWEIGHT...Weighing only 13.5 pounds, the G-76/G is half the weight yet four times more powerful than

other military systems of its kind. The G-76/G is a few ounces lighter than the G-76A/G.

RUGGED...The G-76/G operates in temperatures of -50to +125F in all types of weather and in all kinds of

terrain.

COMPACT...Ready for transport, the G-76/G measures only 21.5 x 8.5 x 7.5 inches.

QUIET...The G-76A/G is a very quiet version of the G-76/G.

CAPABILITIES AND FEATURES

POWERFUL...The G-76/G provides 200 watts of output power in a package that goes anywhere.

VERSATILE...By varying the cranking speed, the G-76/G provides a range of output power for battery heating

and charging and for direct radio transmission and reception.

EFFICIENT...The G-76/G can be easily operated by one person. An 81:1 output-input RPM ratio means more

power with less effort.

RELIABLE...The G-76/G is built to withstand abuse and adverse weather, yet still deliver when and where you

need it with a demonstrated mean time between failure in excess of 1100 hours.

SIMPLE TO OPERATE...The G-76/G requires no special operator knowledge or skill for set-up and operation.

1-3

TM 11-6115-470-23&P

1-10. LOCATION AND DESCRIPTION OF MAJOR COMPONENTS

GENERATOR HEAD (1). Contains the alternator and harmonic drive unit.

POWER CONDITIONING UNIT (PCU) (2). The PCU contains two indicator lights and the power regulating circuitry.

TRIPOD (3). The stand assembly consists of three legs, an operators seat and provides a mounting platform for the

generator and PCU.

GENERATOR CABLE (4). Cable CX-13175, P/O MK-2120/G. Provides a connection from the PCU to the radio cable or

the B-5 U battery.

RADIO CABLE (5). Cable CX-13176, P/O MK-2120/G. Provides a connection from the generator cable to the PRC-70 or

PSC-3 radio.

PAL/M38 ADAPTER (6). P/O MK-2121/G. Provides a connection from the PCU to the CT1478 cable that is used with the

Permissive Action Links (PAL) T1533/1554, or to the setter cable that is used with the M38 fuze setter.

FOOT PADS (7). P/OMK-2121/G. Nonskid covers for the metal feet on the tripod to retard sliding over hard floors. Use is

optional.

GENERATOR BAG (8). A canvas bag with shoulder and leg straps to carry the G-76/G and the accessory equipment.

SETTER CABLE (9). Cable CX-13205/G, P/O MK-2121/G. Provides a connection between the M38 Fuze Setter and the

PALQ38 Adapter.

* All modified Generators (G-76A/G) will have an MWO label affixed to the PCU.

1-4

TM 11-6115-470-23&P

1-11. DIFFERENCES BETWEEN G-76/G MODELS

The G-76A/G is a quieter version of the G-76/G.

The G-76A/G weighs a few ounces more than the G-76/G.

Both generators can be used with the two accessory kits.

1-12. EQUIPMENT DATA

Weights and Dimensions

Ready to Travel

G-76A/G G-76/G

Weight 6.1 Kg (13.5 Ibs.) 6.0 Kg (13.3 lbs.)

Length 54.6cm (21.5 in.) 54.6cm (21.5 in.)

Width 21.6cm ( 8.5 in.) 21.6 cm ( 8.5 in.)

Height 19.1 cm ( 7.5 in.) 19.1 cm ( 7.5 in.)

GENERATOR APPROXIMATE OUTPUT OUTPUT OUTPUT

OPERATIONAL CRANKING VOLTAGE CURRENT POWER

MODE SPEED (RPM) VDC AMPERES WATTS

Radio:

Tune High 24 4.0 96

Low Power Medium 24 1.5 36

High Power High 24 5.5 132

Radio/Receive Low 30 0.3 9

BB-542/U-Charge Medium-High 28-30 3.0 90

BB-542/U-Heat High 40 3.5 140

PAL T1533/T1554 High 24 5.0 120

M38 Fuze Setter Medium 24 2.5 60

Temperature Range

Operating -50F to +120F

(-45.5C to +51.7C)

Nonoperating (Storage) -50F to +160F

(-45.5C to +71C)

1-5

TM 11-6115-470-23&P

1-13. EQUIPMENT CONFIGURATION

G-76/G TO AN/PRC-70 OR AN/PSC-3 RADIO CONNECTION USING MK-2120/G.

G-76/G TO BB-542/U BATTERY CONNECTION USING MK-2120/G.

1-6

TM 11-6115-470-23&P

EQUIPMENT CONFIGURATION - CONTINUED

G-76/G TO PAL T1533/T1554 CONNECTION USING MK-2121/G.

G-76/G TO M38 FUZE SETTER CONNECTION USING MK-2121/G.

1-7

TM 11-6115-470-23&P

Section III. PRINCIPLES OF OPERATION

1-14. GENERAL

The G-76/G handcrank generator is a device used to convert mechanical power provided by an operator to regulated

electrical power. This output is transmitted to electrical devices by connecting cables included in G-76/G accessory kits.

The G-76/G is a modular design, consisting of two crank arms, a generator head, a power conditioning unit, and a

mounting stand which stabilizes the assembly while cranking.

To achieve high output levels the G-76/G uses an eight pole samarium-cobalt magnet rotor, within a 12 pole, three phase,

Y-connected stator. The device is hand-cranked between 70 and 100 rpm. A harmonic drive increases the input rotation

speed 81 times so that the alternator rotor, enclosed within the drive, turns at about 6,000 to 8,000 rpm. When the rotor

spins at about 8,000 rpm, 100 volts at 2 amps is generated. This output is fed into a three phase step-down transformer in

the PCU. A PCU contains circuits that rectify the three phase alternating current output voltage, provide voltage regulation,

and short-circuit current limiting. It also contains power control circuits that direct power to the radio from either the

generator or the battery or to heat and charge the battery. The transformer contains two windings in the secondary. One

winding steps the voltage down to a minimum of 40 volts (needed to heat the BB-542/U Battery before charging it when at

low temperature), the other to a nominal of 30 volts to operate the radio, the PAL T1 533/Ti554, the M38 fuze setter or to

charge the battery the BB-542/U battery. The transformer is used to isolate the operator load from that of the radios so

that maximum use of cranking speed is achieved.

1-15. GENERATOR

The generator, located in the generator head, is a brushless, permanent samarium-cobalt magnet type having a balanced

three-phase output. This output is sent to the PCU rectifier and regulator circuits which are designed to withstand

repeated shorted circuits without suffering permanent deterioration of performance or mechanical damage. Depending on

the load, the generator produces a 200 watt output at a rotor speed of about 8,000 rpm.

1-16. HARMONIC DRIVE

The harmonic drive in the generator head is used to increase the input speed to several thousand rpm. The harmonic

drive consists of three basic components, a circular spline, a wave generator, and a flexspline. When a torque is applied

to the cranks, this torque is transmitted to the circular spline of the harmonic drive by means of a shaft attached to the

cranks. The cranks are constructed as an integral part of the equipment and can be folded to store or transport the unit.

1-17. POWER CONDITIONING UNIT (PCU)

The PCU contains a step-down transformer and the power control circuits. The electronic circuit is designed to assure that

all power produced by the alternator is available to the radios and batteries as needed by each. The electrical circuit,

which fits two circuit boards, is mounted within the regulator box connected to the rear of the generator. The PCU also

contains two indicator lights on a circuit board. The left light comes on when an output voltage of 24 volts DC is reached.

That voltage is required to operate the AN/PRC-70. The right light indicates that at least 2 amps is flowing into the

equipment being powered.

1-18. DESIGN DIFFERENCES

The G-76/A is a quieter version of the G-76/G. Application of Modification Work Order MWO-1 1-6115-470-50-1 converts

the G-76/G to the quieter G-76A/G.

1-8

TM 11-6115-470-23&P

CHAPTER 2

ORGANIZATIONAL MAINTENANCE

Section I. REPAIR PARTS, SPECIAL TOOLS, TEST MEASUREMENT AND

DIAGNOSTIC EQUIPMENT (TMDE) AND SUPPORT EQUIPMENT

2-1. COMMON TOOLS AND EQUIPMENT

For authorized common tools and equipment, refer to the Modified Table of Organization and Equipment (MTOE)

applicable to your unit. There are no tools required for organizational maintenance personnel for servicing the G-76/G.

2-2. ORGANIZATIONAL MAINTENANCE

At the organizational level, maintenance is limited to equipment inspection and evaluation operations primarily because no

tools or test equipment are authorized. Personnel will require only those expendable supplies required to perform basic

cleaning and touch-up painting as necessary to prevent corrosion. Cleaning rags, sand paper, primer and paints are listed

in appendix D.

2-3. REPAIR PARTS

Repair parts are listed and illustrated in the RPSTL, appendix C of this manual. Maintenance procedures are given in

sections III and IV.

Section II. SERVICE UPON RECEIPT

2-4. UNPACKING

When the G-76/G or G-76A/G is received initially, it will be typically packed as shown in figure 2-1.

2-1

TM 11-6115-470-23&P

Figure 2-1. Packaging Sequence

2-2

TM 11-6115-470-23&P

2-5. REMOVING CONTENTS

Unpack the G-76/G from the container as follows (fig. 2-1):

CAUTION

Carefully pry open wooden shipping crate and carefully open cardboard shipping box.

Do not puncture crates or boxes as damage to Carrying Bag or Generator may result.

a. Cut and remove any metal bands.

b. Carefully open crates and boxes and remove Carrying Bag.

c. Open Carrying Bag flap and remove contents. Attach carrying strap to bag.

d. Save cardboard boxes and cushioning material for temporary storage or return shipments.

2-6. CHECKING UNPACKED EQUIPMENT

When checking unpacked equipment, the following tasks should be performed:

a. Inspect the equipment for damage incurred during shipment. If the equipment has been damaged, report the

damage on SF 364, Report of Discrepancies (ROD).

b. Check the equipment against the packing slip to see if the shipment is complete. Report all discrepancies in

accordance with the instructions of DA Pam 738-750.

c. Check to see whether the equipment has been modified.

2-3

TM 11-6115-470-23&P

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

2-7. GENERAL

Preventive maintenance is the systematic care, inspection, and servicing of equipment to maintain it in serviceable

condition, prevent breakdowns, and assure maximum operational capability. Organizational preventive maintenance

checks and services (PMCS) are performed quarterly (table 2-1). If your equipment fails to operate, troubleshoot with the

proper equipment. Report any deficiencies using the proper forms, see DA Pam 738-750. Always keep in mind the

CAUTIONS and WARNINGS, before you operate, while you operate, and after you operate.

a. Quarterly PMCS will be scheduled in accordance with procedures specified in DA Pam 738-750.

b. The Item No. in table 2-1 shall be used as a source of item numbers for the TM number column on DA Form

2404 (Equipment Inspection and Maintenance Worksheet) in recording the results of the PMCS.

c. If the equipment fails to meet the criteria in the Procedure column of table 2-1, report the failure in accordance with

the procedures specified in DA Pam 738-750.

d. If the equipment must be kept in constant operation, check and service only those items that can be done without

disturbing operation. Perform all checks and services when the equipment can be shut down.

e. Some of the routine checks that may not be listed in the PMCS table are: cleaning, dusting, washing, checking for

frayed cables, stowing items not in use, covering unused receptables, and checking for loose nuts and bolts. These

checks should be done whenever needed.

TABLE 2-1. Organizational Preventive Maintenance Checks and Services Quarterly Schedule

Item Item to be Procedure

No. Inspected (check for and have repaired or adjusted as necessary)

1 Completeness All components required to make the G-76/G operational are on hand.

2 Publications TM 11-6115-470-10 and TM 11-6115-470-23&P are on hand with latest

changes; see DA Pam 310-1 for current publication listings.

3 Modifications Check DA Pam 310-1 to see if any modification work orders (MWOs) are listed

for the G-76/G or its components. All URGENT MWOs must be applied

immediately; all NORMAL MWOs must be scheduled.

4 Metal Surfaces Remove rust, corrosion, and fungus; spot-paint bare metal spots.

5 Connectors Free of corrosion, foreign materials, or damage. Connector covers are

securely attached.

2-4

TM 11-6115-470-23&P

Section IV. MAINTENANCE PROCEDURES

2-8. GENERAL

Refer to Operators Manual, TM 11-6115-470-10, setup procedure in chapter 2, section III and cleaning procedure in

chapter 3, section III. The order of maintenance will be performed according to the group number sequence of the

maintenance allocation chart found in appendix B of this manual.

2-9. ORGANIZATIONAL MAINTENANCE

WARNING

Adequate ventilation should be provided while using TRICHLOROTRIFLUOROETHANE.

Prolonged breathing of vapor should be avoided. The solvent should not be used near

heat or open flame; the products of decomposition are toxic and irritating. Since

TRICHLOROTRIFLUOROETHANE dissolves natural oils, prolonged contact with skin

should be avoided. When necessary, use gloves which the solvent cannot penetrate. If

the solvent is taken internally, consult a physician immediately. Primers, paints and

thinners may contain flammable substances. Check container labels before using.

WARNING

Primers, paints and thinners may contain flammable substances. Check container

labels before using. I

2-10. CLEANING

Wipe away all traces of dirt or grime from the G-76/G using cleaning solvent, item 3, appendix D, and a clean rag.

2-11. TOUCH-UP PAINTING

Examine the protective coating of paint on the G-76/G. If paint was removed by scratching or chipping, perform touch-up

painting as follows:

a. Use fine sandpaper (item 5, appendix D) to remove all corrosion and loose paint. Wipe with clean dry rag (item 2,

appendix D) to remove dust and oil. Refer to TB 43-0118 as necessary.

b. Apply a top coat using a paint which will adhere to and match, the paint already on the equipment. (Item 7,

appendix D.)

c. Allow the coating to air dry at least 48 hours before storing the G-76/G in the Generator Bag. (Specification MIL-E-

52798 allows 72 hours for the paint to reach full hardness.)

2-5

TM 11-6115-470-23&P

Figure 2-2. Tripod Assembly

2-12. ACCESSORY KIT, FIELD RADIO EQUIPMENT MK-2120/G

Perform inspection as follows: (see illustration on page 1-4)

a. Generator Bag. Inspect the entire bag and straps for rips, holes, loose threads, ripped stitching and missing

hardware on straps or bag. If inspection reveals damage that requires repair, replace bag or straps as follows:

(1) Remove strap by detaching both hook snaps and unthreading the doubled portion of the strap out of the

buckle.

(2) Replace straps by attaching both hook snaps and threading strap doubled through the buckle.

(3) Repair of the bag is accomplished by replacement only.

b. Generator Cable CX-13175 and Radio Cable CX-13176. Inspect cables for connector damage, that is crushed

threads and bent or broken pins. Inspect insulation for rips or cracks. If inspection reveals damage, replace entire cable.

2-6

TM 11-6115-470-23&P

2-13. ACCESSORY KIT, PERMISSIVE ACTION LINK MK-2121/G

Perform inspection as follows: (see illustration on page 1-4)

a. Generator Bag. Inspect the entire bag and straps for rips, holes, loose threads, ripped stitching and missing

hardware on straps or bag. If inspections reveals damage that requires repair, replace bag or straps as follows:

(1) Remove strap by detaching both hook snaps and unthreading double portion of the strap out of the buckle.

(2) Replace strap by attaching both hook snaps and threading strap doubled through the buckle.

(3) Repair of the bag is accomplished by replacement only.

b. Setter Cable CX-13205/G. Inspect cable for connector damage, that is, crushed threads or bent or broken pins.

Inspect insulation for rips or cracks. If inspection reveals damage, replace entire cable.

c. Nonskid Foot Pads. Inspect the rubber pads for worn areas or rips. Replace as necessary.

d. PAL/M38 Adapter. Inspect for connector damage, that is crushed threads or bent or broken pins. If inspection

reveals damage, replace connector.

Section V. PREPARATION FOR STORAGE OR SHIPMENT

2-14. PACKAGING DATA

Refer to figure 2-1 for packaging sequence. When packed for shipment, the G-76/G is wrapped with cushioning material.

The generator cable, radio cable and setter cable are coiled. Then each cable, the PAL/M38 Adapter and foot pads are

separately wrapped in cushioning material. All items, except the G-76/G are placed in coated paper bags and sealed.

The carry strap is rolled and tied with twine. Each item is then placed in the Generator Bag which, in turn, is placed in a

close fitting cardboard box. Finally, the cardboard box is packed in a triple wall shipping box and metal banded. For

overseas shipment the close fitting cardboard box is placed in a wooden shipping crate and metal banded to a skid.

2-7/(2-8 blank)

TM 11-6115-470-23&P

CHAPTER 3

DIRECT SUPPORT (DS)

MAINTENANCE PROCEDURES

Section I. REPAIR PARTS, SPECIAL TOOLS, TEST MEASUREMENT AND

DIAGNOSTIC EQUIPMENT (TMDE) AND SUPPORT EQUIPMENT

3-1. GENERAL

Direct Support maintenance personnel will require tools contained in Tool Kit, Electronic Equipment, TK-105/G and

Multimeter AN/USM-223 to service the G-76/G. For additional authorized common tools and equipment, refer to the

Modified Table of Organization and Equipment (MTOE) applicable to your unit.

3-2. SPECIAL TOOLS, TMDE AND SUPPORT EQUIPMENT Refer to TM 11-6625-654-14, Multimeter AN/USM-223

Operators Organizational, Direct and General Support Maintenance Instruction for set up and operating procedures of the

multimeter which is required for testing the G-76/G. There are no special tools or equipment required at this level.

However, the use of a torque wrench is required to replace certain assemblies of the G-76/G. Use the following, or

equivalent, torque wrench: NSN 5120-00-720-1975 (part of Tool Kit, Electronic Equipment TK-101/G).

3-3. REPAIR PARTS

Repairs parts are listed and illustrated in the RPSTL, appendix C of this manual.

Section II. TESTING

3-4. G-76/G TESTING

Prepare the G-76/G for testing as follows:

a. Refer to TM 11-6625-654-14, Multimeter AN/USM-223 Operators Organizational, Direct and General Support

Maintenance Instructions and prepare the multimeter to obtain dc voltage readings for the G-76/G.

b. Set up the G-76/G for operation as shown in Operators Manual, TM 11-6115-470-10 and crank to a speed of 95-

100 RPM.

c. Check the reading from the PCU output connector (J2) figure 3-1, at Pin D (positive) and Pin B (negative). The

dc voltage reading should be 29 to 32 volts dc.

d. Check the reading from the PCU output connector (J2) at Pin A (positive) and Pin C (negative). The dc voltage

should be 40 volts dc minimum.

e. If the G-76/G does not meet the minimum voltage requirements, further testing is required to determine which

component is faulty, the PCU or the generator head assembly.

3-1

TM 11-6115-470-23&P

Figure 3-1. PCU Output Connector J2 Pin Locations.

3-5. GENERATOR HEAD AND HANDLE ASSEMBLY TESTING

Prepare the head and handle assembly for testing as follows:

a. Remove the PCU from the tripod. Refer to paragraph 3-10.

b. Refer to TM 11-6625-654-14, Multimeter AN/USM-223, Operators, Organizational, Direct and Genera Support

Maintenance Manual and set up multimeter to obtain ac voltage readings for the G-76/G head assembly.

c. Crank the handle to a speed of 95-100 RPM.

d. See figure 3-2 and check ac voltage from the generator head output connector between pins A & B, ; & E and A &

E. Reading for each must be 60 volts ac minimum.

e. Refer to TM 11-6625-654-14, Multimeter AN/USM-223 Operators Organizational, Direct and General Support

Maintenance Manual and set up multimeter to obtain continuity readings for the GS-76/G head assembly.

f. See Figure 3-2 and check continuity resistance from the generator head output connector between pins A & B, B

& E and A & E. Continuity resistance must be less than 10 ohms.

g. The generator head and handle assembly must meet the ac voltage test and continuity test or it will be considered

faulty and require replacement. Return faulty assembly to depot.

3-2

TM 11-6115-470-23&P

Figure 3-2. Generator Head Output Connector Pin Locations

3-6. PCU TESTING

By the process of elimination, a faulty PCU can be determined. If the generator head assembly tests all right as in

paragraph 3-5 and the complete G-76/G does not meet the voltage readings required in paragraph 3-4, then the PCU is

defective. Return the faulty PCU to depot.

Section III. TROUBLESHOOTING

3-7. GENERAL

Table 3-1, Direct Support Troubleshooting, is a symptom index of the electrical conditions which might exist i faulty G-

76/G. Personnel at DS maintenance level are qualified to observe symptoms specified, follow t procedure indicated and

perform the corrective action required of this troubleshooting table.

3-8. DIRECT SUPPORT TROUBLESHOOTING Refer to table 3-1 and find the symptom which describes the condition of

the G-76/G. Follow the procedure given for that symptom and perform the corrective action required. If a symptom is not

listed or is no corrected by the listed corrective action, refer to the next higher level of maintenance.

3-3

TM 11-6115-470-23&P

TABLE 3-1. Direct Support Troubleshooting

(PARA 3-4)

(PARA 3-4)

(PARA 3-11)

(PARA 3-17

(PARA 3-5)

(PARA 3-4)

3-4

(PARA 3-10)

(PARA 3-11)

TM 11-6115-470-23&P

REFER TO PARA 3-4 THRU

3-6 FOR TESTING OF PCU

AND GENERATOR

ASSEMBLY

(PARA 3-4)

(PARA 3-11)

3-5

TM 11-6115-470-23&P

Section IV. MAINTENANCE PROCEDURES

3-9. GENERAL

Direct Support maintenance procedures deal mostly with repair and replacement of major assemblies of the G-76/G, i.e.,

Power Conditioning Unit (PCU), generator head assembly, right and left handle assembly and tripod, see figure 3-3.

Figure 3-3. G-76/G Repairable/Replaceable Assemblies

3-10. PCU REMOVAL

Proceed as follows to remove PCU:

a. Using No.2 Phillips screwdriver and socket found in Electronic Took Kit TK-105/G, remove the four hex nuts,

lockwashers, flat washers and screws holding the PCU to the tripod. See figure 3-4. Retain hardware for 3-6 reuse during

assembly.

b. Press the flat portion of the snap lock spring on the PCU input connector (J1) and separate the PCU from the

generator head assembly, see figure 3-4.

3-6

TM 11-6115-470-23&P

Figure 3-4. PCU Attaching Hardware

3-11. PCU REPLACEMENT

Proceed as follows to replace the PCU:

NOTE

Just loosening the four generator head cap screws may be required for proper

alinement of PCU input connector (J1) and generator head output connector. See

figure 3-5.

a. Aline the PCU input connector (J1) with the generator head assembly output connector.

b. Press the flat portion of the snap lock spring and slowly slide the PCU toward the generator head assembly until

the connector snaps and the two units are in place. Release the snap lock spring. See figure 3-5.

c. If the four generator head cap screws were loosened to ease alinement of the two units, they should-be tightened

before securing the PCU to the tripod. Torque the PCU attaching screws to 15 2 in. lbs. tightening in cross-rotation

numerical sequence like that shown in figure 3-5. (See appendix B, maintenance allocation chart (MAC) for required

torque wrench.)

3-7

TM 11-6115-470-23&P

Figure 3-5. Tripod

3-12. RIGHT HANDLE ASSEMBLY REMOVAL

Remove right handle assembly as follows:

a. Using a No. 10 hex key and 3/8" socket found in Electronic Tool Kit TK-105/G, loosen two hex nuts, lockwashers

and capscrews. They need not be completely removed to slide the assembly off the shaft. See figure 3-6.

b. Carefully slide the assembly off the low speed shaft.

3-13. RIGHT HANDLE ASSEMBLY REPLACEMENT

Replace right handle assembly as follows:

a. Position handle assembly on low speed shaft as shown in figure 3-6. Slowly push handle on shaft as far as it will

go without forcing which may cause rounding of shaft or drive inserts.

b. To insure handle assembly is positioned correctly on shaft verify that locking pin will fit into the slot of the stand

assembly when the hand grip is in the closed position. See TM 11-6115-470-10, Operators Manual, right hand crank

handle set up in section III. Also verify that the handle does not hit the tripod leg when cranked.

c. Apply one drop of Adhesive Sealant, MIL-S-46163, to the threads of each of the two cap screws and assemble

lockwashers and hex nuts. Torque the cap screws to 50 5 in. lbs. then tighten hex nuts.

3-14. LEFT HANDLE ASSEMBLY REMOVAL

Remove left handle assembly as follows:

a. Using a No. 2 Phillips head screwdriver found in Electronic Tool Kit TK-105/G, remove the flat head machine

screw, spacer washer and engagement nut. See figure 3-6. Retain hardware for reuse during assembly.

3-8

TM 11-6115-470-23&P

NOTE

The flat head screw is only procurable with the entire left handle assembly, be especially careful to

retain that screw for reuse during assembly.

b. Carefully slide the assembly off the low speed shaft.

c. Using the No. 8 hex key, loosen two cap screws holding the arm crank shaft adapter. They need not be

completely removed to slide the adapters off the shaft. Remove the adapters from the shaft.

3-15. LEFT HANDLE ASSEMBLY REPLACEMENT

Replace the left handle assembly as follows:

a. Apply one drop of Adhesive Sealant, MIL-S-46163 to the threads of two arm crank adapter capscrews. Assemble

the capscrews to the adapters and slide them on the low speed shaft in position as shown in figure 3-6.

b. Push the low speed shaft, as if through the generator head, as far right as possible. Locate the adapters to leave

a slight gap between them and the generator head collar.

c. Tighten the adapter capscrews and torque to 50 +5 in. lbs.

d. Position left handle assembly on low speed shaft as shown in figure 3-6 so that it fits tight against the arm crank

shaft adapters. Thread engagement nut on shaft securely in position and install spacer washer, with countersink out and

flat head machine screws. Torque screw to 15 + 1 in. lbs.

Figure 3-6. Right and Left Handle Assembly Attaching Hardware

3-9

TM 11-6115-470-23&P

3-16. GENERATOR HEAD ASSEMBLY REMOVAL

Proceed as follows to remove assembly:

a. Remove PCU by following procedure in paragraph 3-10.

b. Using a No. 10 Allen wrench found in Electronic Tool Kit TK-105/G, remove four cap screws and washers as

shown in figure 3-7.

c. Slowly lift assembly upward from its mounted position on the tripod.

3-17. GENERATOR HEAD ASSEMBLY REPLACEMENT

Place the generator head and handle assembly in position on tripod. Apply one drop of Adhesive Sealant, MIL-S-46163, to

the threads of each of the four capscrews and attach them to the generator head and tripod with washers as shown in

figure 3-7. Once generator head, handle assembly and PCU are properly assembled torque capscrews to 15 2 in. lbs.,

tightening in cross-rotation numerical sequence like that shown in figure 3-7.

Figure 3-7. Generator Head and Handle Assembly

Attaching Capscrews

3-18. TRIPOD REPLACEMENT

If inspection done in organizational maintenance showed the tripod to be unserviceable, it must be sent to depot. The

repair procedure at DS level is replacement. However, simple tightening or adjusting of screws, nuts and bolts to make

the tripod serviceable is all right.

3-10

TM 11-6115-470-23&P

APPENDIX A

REFERENCES

A-1 SCOPE

This appendix lists all forms, field manuals, technical manuals and miscellaneous publications referenced in this manual.

A-2 FORMS

Recommended Changes to Publications and Blank Forms........................................................................ DA Form 2028

Recommended Changes to Equipment Technical Manuals .................................................................... DA Form 2028-2

Equipment Inspection and Maintenance Worksheet................................................................................... DA Form 2404

Quality Deficiency Report ........................................................................................................................................ SF 368

A-3 FIELD MANUALS

First Aid for Soldiers ......................................................................................................................................... FM-21-111

A-4 TECHNICAL MANUALS

Operators Manual for XM753 Atomic Projectile and M754 Training Atomic Projectile ........................TM 9-1110-220-10

Operators Manual for Radio Set, AN/PRC-70 (NSN 5820-01-062-8246) ..........................................TM 11-5820-553-10

Operators Manual, AN/PSC-3 Radio (To Be Published) ....................................................................TM 11-5820-841-10

Operators Manual, Generator, Direct Current,

G-76(V)1/G (NSN 6115-01-119-8170), G-76(V)2/G (NSN 6115-01-124-0833).....................TM 11-6115-470-10

Operators, Organizational, Direct Support, General Support, and Depot

Maintenance Manual including Repair Parts and Special Tools List for

Non-Aircraft Nickel-Cadmium Batteries ............................................................................. TM 11-6140-203-15-5

Operators Organizational, Direct Support, and General Support Maintenance

Repair Parts and Special Tools List (Including Depot Maintenance Repair

Parts and Special Tools List) for Multimeter, AN/USM-223 ...................................................TM 11-6625-654-14

Administrative Storage of Equipment ............................................................................................................. TM 740-90-1

Procedures for Destruction of Electronics Materiel to Prevent Enemy Use

(Electronics Command).................................................................................................................. TM 750-244-2

A-5 MISCELLANEOUS PUBLICATIONS

Consolidation Index of Army Publications and Blank Forms....................................................................... DA Pam 310-1

The Army Maintenance Management System (TAMMS)........................................................................ DA Pam 738-750

Preservation, Packaging, Packing and Marking Materials, Supplies and Equipment

Used by the Army ..............................................................................................................................................SB 38-100

Field Instructions for Painting and Preserving Electronics Command Equipment

Including Camouflage Pattern Painting of Electrical Equipment Shelters........................................................TB 43-0118

A-1/(A-2 blank)

TM 11-6115-470-23&P

APPENDIX B

MAINTENANCE ALLOCATION

SECTION I. Introduction

B-1. GENERAL

a. This section provides a general explanation of all maintenance and repair functions authorized at various

maintenance levels.

b. The Maintenance Allocation Chart (MAC) in Section II designates overall responsibility for the performance of

maintenance functions on the identified end item or component. The implementation of the maintenance functions upon

the end item or component will be consistent with the assigned maintenance functions.

c. Section III lists the special tools and test equipment required for each maintenance function as referenced In

section II.

d. Section IV contains supplemental instructions on explanatory notes for a particular maintenance function.

B-2. MAINTENANCE FUNCTIONS

a. Inspect. To determine the serviceability of an item by comparing its physical, mechanical, and/or electrical

characteristics with established standards through examination.

b. Test To verify serviceability and detect incipient failure by measuring the mechanical or electrical characteristics of

an item and comparing those characteristics with prescribed standards.

c. Service. Operations required periodically to keep an item in proper operating condition, i.e., to clean

(decontaminate), to preserve, to drain, to paint, or to replenish fuel, lubricants, hydraulic fluids, or compressed air supplies.

d. Adjust. To maintain within prescribed limits by bringing into proper or exact position, or by setting the operating

characteristics to specified parameters.

e. Align. To adjust specified variable elements of an item to bring about optimum or desired performance.

f. Calibrate. To determine and cause corrections to be made or to be adjusted on instruments or test measuring

and diagnostic equipment used in precision measurement. Consists of comparisons of two instruments, one of which is a

certified standard of known accuracy to detect and adjust any discrepancy in the accuracy of the instrument being

compared.

g. Install. The act of implacing, seating, or fixing into position an item, part, or module (component or assembly) in a

manner to allow the proper functioning of the equipment/system.

h. Replace. The act of substituting a serviceable like-type part, subassembly, or module (component or assembly)

for an unserviceable counterpart.

B-1

TM 11-6115-470-23&P

i. Repair. The application of maintenance services or other maintenance actions to restore serviceability to an item

by correcting specific damage, fault, malfunction, or failure in a part, subassembly, module (compartment or assembly),

end item, or system.

j. Overhaul. That maintenance effort (services/actions) necessary to restore an item to a completely

serviceable/operational condition as prescribed by maintenance standards (i.e. DMWR) in appropriate technical

publications. Overhaul is normally the highest degree of material maintenance performed by the Army. Overhaul does not

normally return an item to like new condition.

k. Rebuild. Consists of those services/actions necessary for the restoration of unserviceable equipment to like-new

condition in accordance with original manufacturing standards. Rebuild is the highest degree of material maintenance

applied to Army equipment. The rebuild operation includes the act of returning to zero those age measurements

(hours/miles, etc.) considered in classifying Army equipment/components.

B-3. COLUMN ENTRIES USED IN THE MAC.

a. Column 1, Group Number. Column 1 lists group numbers, the purpose of which is to identify components,

assemblies, subassemblies, and modules with the next higher assembly.

b. Column 2, Component/Assembly. Column 2 contains the names of components, assemblies, subassemblies, and

modules for which maintenance is authorized.

c. Column 3, Maintenance Functions. Column 3 lists the functions to be performed on the item listed in column 2.

(For detailed explanation of these functions, see para B-2.)

d. Column 4, Maintenance Level. Column 4 specifies, by the listing of a "work time" figure in the appropriate

subcolumn(s), the lowest level of maintenance authorized to perform the function listed in column 3. This figure

represents the active time required to perform the maintenance function at the indicated level of maintenance. If

thenumberorcomplexityofthetaskswithinthelistedmaintenancefunctionvaryatdifferent maintenance levels, appropriate "work

time" figures will be shown for each level. The number of manhours specified by the "work time" figure represents the

average time required to restore an item (assembly, subassembly, component, module, end item, or system) to a

serviceable condition under typical field operating conditions. This time includes preparation time, troubleshooting time,

and quality assurance/quality control time in addition to the time required to perform the specific tasks identified for the

maintenance functions authorized in the maintenance allocation chart. The symbol designations for the various

maintenance levels are as follows:

C....................................Operator or crew.

O....................................Organizational maintenance.

F ....................................Direct support maintenance.

H....................................General support maintenance.

D....................................Depot maintenance.

e. Column 5, Tools and Equipments. Column 5 specifies by code, those common tool sets (not individual tools) and

special tools, test, and support equipment required to perform the designated function.

f. Column 6, Remarks. Column 6 contains letter codes in alphabetic order which are keyed to the remarks

contained in section IV.

B-2

TM 11-6115-470-23&P

B-4. COLUMN ENTRIES USED IN TOOL AND TEST EQUIPMENT REQUIREMENTS

(SECTION III)

a. Column 1, Tool or Test Equipment Reference Code. The tool and test equipment code correlates with a

maintenance function on the identified end item or component.

b. Column 2, Maintenance Level. The lowest level of maintenance authorized to use the tool or test equipment.

c. Column 3, Nomenclature. Name or identification of the tool or test equipment.

d. Column 4, National/NATO Stock Number. The National or NATO stock number of the tool or test equipment.

e. Column 5, Tool Number. The manufacturers part number.

B-5. EXPLANATION OF COLUMNS IN SECTION IV

a. Reference Code. The code scheme recorded in column 1, section III.

b. Remarks. This column lists information pertinent to the maintenance function being performed as indicated in the

MAC, section II.

B-3

TM 11-6115-470-23&P

SECTION II. MAINTENANCE ALLOCATION CHART

FOR

GENERATOR, DC, G-76A/G & ACCESSORY KITS MK-2120/G & MK-2121/G

(1) (2) (3) (4) (5) (6)

MAINTENANCE LEVEL

GROUP MAINTENANCE TOOLS AND

NUMBER COMPONENT ASSEMBLY FUNCTION C O F H D EQUIPMENT REMARKS

00 GENERATOR DIRECT CURRENT INSPECT 0.1 G

G 76A/G TEST 0.2 A

REPLACE 0.2

REPAIR 0.4 1-3 B

TEST 0.5 1 A

01 POWER CONDITIONING UNIT INSPECT 0.2 G

TEST 0.2 1

REPLACE 0.2 2

REPAIR 2.0 1-7 C, E

0101 HOUSING ASSEMBLY INSPECT 0.3 H

TEST 0.5 1

REPLACE 0.2 2

REPAIR 0.5 2 C

0102 PLATE ASSEMBLY INSPECT 0.3 H

TEST 0.5 1

REPLACE 0.2 2

REPAIR 0.5 2 C

02 GENERATOR HEAD AND HANDLE INSPECT 0.1 G

ASSEMBLY TEST 0.2 1

REPLACE 0.2 2,3 D

REPAIR 1-7

0201 GENERATOR HEAD ASSEMBLY INSPECT 0.1

TEST 0 2 1

REPLACE 0 3 2,3

REPAIR 3.0 1-7 E

020101 ELECTRO MECH ASSEMBLY INSPECT 0.5

REPLACE 0.5 I

REPAIR 2.0 F

0202 HANDLE ASSEMBLY RIGHT INSPECT 0.1

REPLACE 0.2 2, 3

REPAIR 2.0 2, 3 D

0203 HANDLE ASSEMBLY LEFT INSPECT 0.1

REPLACE 0.2 2.3

REPAIR 2.0 2,3 D

03 STAND ASSEMBLY INSPECT 0.1

REPLACE 0.5 2, 3

REPAIR 2.0 2.3 D

00/03 ACCESSORY KIT MK-2120/G INSPECT 0.2 G

(FOR G-76A/G REPAIR 0.2 D

SPECIAL OPERATION AND

ENGINEERING MISSION)

00/04 ACCESSORY KIT MK-2121/G INSPECT 0.2 G

(FOR G-76A/G REPAIR 0.2 D

ARTILLERY MISSION)

B-4

TM 11-6115-470-23&P

SECTION III. TOOL AND TEST EQUIPMENT REQUIREMENTS

FOR

GENERATOR, DC G-76/G, G-76A/G & ACCESSORY KITS MK-2120/G & M-2121/G

TOOL OR TEST MAINTENANCE NATIONAL/NATO TOOL

EQUIPMENT CATEGORY NOMENCLATURE STOCK NUMBER NUMBER

REF CODE

1 F, D MULTIMETER AN/PSM-45 6625-01-139-2512

2 F, D TOOL KIT, ELECTRONIC EQUIPMENT TK-105/G 5180-00-610-8177

3 F, 0 TORQUE WRENCH (PART OF TK-101/G) 5120-D0-72D-1975

4 D RESISTOR, 10 OHMS, 100 WATTS

5 D PP-7545 6130-01-070-5856

6 D MEG OHMMETER TESTER INSULATION 6625-00-366-1447

7 D RESISTOR DECADE BOX ZM-57 5985-01-068-5195

B-5

TM 11-6115-470-23&P

SECTION IV. REMARKS

GENERATOR, DC. G 76A/G & ACCESSORY KITS MK 2120/G & MK-2121/G

REFERENCE REMARKS

CODE

A NORMAL OPERATIONAL TEST.

B REPAIR BY REPLACEMENT OF PARTS WHICH BECAME DEFECTIVE:

POWER CONDITIONING UNIT, HEAD ASSEMBLY, HANDLE ASSEMBLIES AND STAND

ASSEMBLY.

C REPAIR BY REPLACEMENT OF ONE OR MORE SUBASSEMBLIES AND/OR

COMPONENTS

(CIRCUIT CARDS, LIGHT EMITTING DIODE).

D REPAIR BY REPLACEMENT OF ONE OR MORE SUBASSEMBLIES.

E ITEMS MUST MEET SPECIFICATION MIL-G-49369 (ER), 15 APR 80.

F TO BE REPAIRED BY DEPOT WHEN CONTRACTOR NO LONGER WILL DO REPAIRS.

G VISUAL INSPECTION OF ALL EXTERNAL AREAS.

H VISUAL INSPECTION OF ALL INTERNAL AND EXTERNAL AREAS.

I TO BE REPAIRED BY CONTRACTOR.

B-6

TM 11-6115-470-23&P

APPENDIX C

ORGANIZATIONAL AND DIRECT SUPPORT MAINTENANCE

REPAIR PARTS AND SPECIAL TOOLS LIST

Section I. INTRODUCTION

C- 1. Scope

This appendix lists and authorizes spares and repair parts; special tools; special test, measurement, and diagnostic

equipment (TMDE), and other special support equipment required for performance of organizational and direct support

maintenance of the G-76/G and G-76A/G. It authorizes the requisitioning, issue, and disposition of spares, repair parts

and special tools as indicated by the source, maintenance and recoverability (SMR) codes.

C-2. General

This Repair Parts and Special Tools List is divided into the following sections:

a. Section II. Repair Parts List. A list of spares and repair parts authorized by this RPSTL for use in the performance

of maintenance. The list also includes parts which must be removed for replacement of the authorized parts. Parts lists

are composed of functional groups in ascending numeric sequence, with the parts in each group listed in ascending item

number sequence. Figure numbers are listed directly beneath the group header.

b. Section III. Special Tools List. Not applicable.

c. Section IV. National Stock Number and Part Number Index. A list, in National item identification number (NIIN)

sequence, of all National stock numbered items appearing in the listings, followed by a list in alphameric sequence of all

part numbers appearing in the listings. National stock numbers and part numbers are cross-referenced to each illustration

figure and item number appearance.

C-3. Explanation of Columns (Section II and ill)

a. Item No. (Column (1)). Indicates the number used to identify items called out in the illustration.

b. SMR Code (Column (2)). The source, maintenance, and recoverability (SMR) code is a five-position code containing

supply/requisitioning information, maintenance category authorization criteria, and disposition instruction, as shown in the

following breakout:

Source Maintenance Recoverability

Code Code Code

XX XX XX

How you get an item. 3d position 4th position

Who determined

disposition action on

Who can install, Who can do an unserviceable

replace, use complete item

the item repair on

item

C-1

1st two

positions

TM 11-6115-470-23&P

NOTE

Complete repair: Maintenance capacity, capability, and authority to perform all corrective

maintenance tasks of the "Repair" function in a use/user environment in order to restore

serviceability to a failed item.

Code Explanation

PA

PB

PC

PD

PE

PF

PG

KB

KD

KF

MO - Made at Org/AVUM

category

MF - Made at DS/AVIM

category

MH - Made at GS category

ML - Made at Specialized

Repair Activity (SRA)

MD - Made at Depot

AO - Assembled by Org/AVUM

category

AF - Assembled by DS/AVIM

category

AH - Assembled by GS category

AL - Assembled by SRA

AD - Assembled by Depot

Stocked items: use applicable NSN to request and/or requisition items with

these source codes. They are authorized to the category indication by the

code entered in the third position of the SMR code

NOTE

Items coded PC are subject to deterioration.

Items with these codes are not to be requested and/or requisitioned

individually. They are part of a kit which is authorized to the maintenance

category indicated in the third position of the SMR code. The complete kit

must be requisitioned and applied.

Items with these codes are not to be requested and/or requisitioned

individually. They must be made from bulk material which is identified by

the part number in the description and usable on code (UOC) column and

listed in the Bulk Material group of the repair parts list. If the item is

authorized to you by the third position code of the SMR code, but the

source code indicates it is made at a higher category, order the item from

the higher category of maintenance.

Items with these codes are not to be requested and/or requisitioned

individually. The parts that make up the assembled item must be

requisitioned or fabricated and assembled at the category of maintenance

indicated by the source code. If the third position code of the SMR code

authorizes you to replace the item, but the source code indicates the item

is assembled at a higher category, order the item from the higher category

of maintenance.

C-2

TM 11-6115-470-23&P

NOTE

Cannibalization or controlled exchange, when authorized, may be used as a source of supply for

items with the above source codes, except for those source coded "XA" or those aircraft support

items restricted by requirements of AR 750-1.

(2) Maintenance Code. Maintenance codes tell you the category of maintenance authorized to USE and REPAIR

support items. The maintenance codes are entered in the third and fourth positions of the SMR code as follows:

(a) The maintenance code entered in the third position tells you the lowest maintenance category authorized to

remove, replace, and use an item. The maintenance code entered in the third position will indicate authorization to one of

the following categories of maintenance.

Code Application/Explanation

C -- Crew or operator maintenance done within organizational or aviation maintenance.

O -- Organizational or aviation unit category can remove, replace, and use the item.

F -- Direct support or aviation intermediate category can remove, replace, and use the item.

H --General support category can remove, replace, and use the item.

L -- Specialized repair activity can remove, replace, and use the item.

D -- Depot category can remove, replace, and use the item.

(b) The maintenance code entered in the fourth position tells whether or not the item is to be repaired and identifies

the lowest maintenance category with the capability to do complete repair (i.e., perform all authorized repair functions).

This position will contain one of the following maintenance codes:

NOTE

Some limited repair may be done on the item at a lower category of maintenance, if authorized by

the Maintenance Allocation Chart (MAC) and SMR codes.

Code Application/Explanation

O --Organizational or aviation unit is the lowest category that can do complete repair of the item.

F --Direct support or aviation intermediate is the lowest category that can do complete repair of the item.

H --General support is the lowest category that can do complete repair of the item.

L --Specialized repair activity (designate the specialized repair activity) is the lowest category that can do complete

repair of the item.

D --Depot is the lowest category that con do complete repair of the item.

Z --Nonreparable. No repair is authorized.

B --No repair is authorized. (No ports or special tools are authorized for the maintenance of a "B" coded item.)

However, the item may be reconditioned by adjusting, lubricating, etc., at the user category.

(3) Recoverability Code. Recoverability codes are assigned to items to indicate the disposition action on

unserviceable items. The recoverability code is entered in the fifth position of the SMR Code as follows:

C-3

TM 11-6115-470-23&P

Recoverability

codes Application/Explanation

Z --Nonreparable item. When unserviceable, condemn and dispose of the item at the category of maintenance shown in

the third position of SMR Code.

0 --Reparable item. When uneconomically reparable, condemn and dispose of the item at organizational or aviation

unit category. %I F -Reparable item. When uneconomically reparable, condemn and dispose of the item at the

direct support or aviation intermediate category.

H --Reparable item. When uneconomically reparable, condemn and dispose of the item at general support category.

D --Reparable item. When beyond lower level repair capability, return to depot. Condemnation and disposal of item not

authorized below depot category.

L --Reparable item. Condemnation and disposal not authorized below specialized repair activity (SRA).

A --Item requires special handling or condemnation procedures because of specific reasons (e.g., precious metal

content, high dollar value, critical material, or hazardous material). Refer to appropriate manuals/directives for

specific instructions.

c. FSCM (Column (3)). The Federal Supply Code for Manufacturer (FSCM) is a 5-digit numeric code which is used

to identify the manufacturer, distributor, or Government agency, etc., that supplies the item.

d. Part Number (Column (4)). Indicates the primary number used by the manufacturer (individual, company, firm,

corporation, or Government activity), which controls the design and characteristics of the item by means of its engineering

drawings, specifications, standards, and inspection requirements to identify an item or range of items.

NOTE

When you use a NSN to requisition an item, the item you receive may have a different part number

from the part ordered.

e. Description and Usable on Code (UOC)(Column (5)). This column includes the following information.

(1) The Federal item name and, when required, a minimum description to identify the item.

(2) Usable on code, when applicable (para 5).

(3) The statement "END OF FIGURE" appears just below the last item description in Column (5) for a given

figure in both section II and section lIl.

f. Qty (Column (6)). Indicates the quantity of the item used in the breakout shown on the illustration figure, which is

prepared for a functional group, subfunctional group, or an assembly. A "V" appearing in this column in lieu of a quantity

indicates that the quantity is variable and the quantity may vary from application to application.

C-4. Explanation of Columns (Section IV)

a. National Stock Number (NSN) Index.

(1) Stock number column. This column lists the NSN by National item identification number (NIIN) sequence.

The NIIN consists of the last nine digits of the NSN. When using this column to locate an item, ignore the first four digits of

the NSN. When requisitioning items use the complete NSN (13 digits).

C-4

TM 11-6115-470-23&P

(2) Fig. column. This column lists the number of the figure where the item is identified/located. The

illustrations are in numerical sequence in sections II and III.

(3) Item column. The item number identifies the item associated with the figure listed in the adjacent Fig.

column. This item is also identified by the NSN listed on the same line.

b. Part Number Index. Part numbers in this index are listed by part number in ascending alphameric sequence.

(1) FSCM column. This column lists the Federal supply code for manufacturer (FSCM).

(2) Part number column. This column indicates the part number assigned to the item.

(3) Stock number column. This column lists the National stock number for the associated part number and

manufacturer identified in the part number and FSCM columns to the left.

(4) Fig. column. This column lists the number of the figure where the item is identified/located in sections II

and III.

(5) Item column. The item number is that number assigned to the item as it appears in the figure referenced in

the adjacent figure number column.

C-5. Special Information

a. Usable on Code. The usable on code appears in the lower left corner of the description column heading. Usable

on codes are shown as "UOC: ..." in the description column (justified left) on the first line applicable item description

nomenclature. Uncoded items are applicable to all models. Identification of the usable on codes used in this RPSTL are:

Code Used on

EUY G-76/G

EUZ G- 76A/G

b. National Stock Numbers. National stock numbers (NSNs) that are missing from P source coded items have been

applied for and will be added to this TM by future change/revision when they are entered in the Army Master Data File

(AMDF). Until the NSNs are established and published, submit exception requisitions to: Commander, US Army

Communications-Electronics Command and Fort Monmouth, ATTN: AMSEL-MM, Fort Monmouth, NJ 07703-5006 for the

part required to support your equipment.

C-6. How to Locate Repair Parts

a. When National stock number or part number is not known.

(1) First. Using the table of contents, determine the assembly group or subassembly group to which the item

belongs. This is necessary since figures are prepared for assembly groups and subassembly groups, and listings are

divided into the same groups.

(2) Second. Find the figure covering the assembly group or subassembly group to which the item belongs.

(3) Third. Identify the item on the figure and note the item number.

C-5

TM 11-6115-470-23&P

(4) Fourth. Refer to the Repair Parts List for the figure to find the part number for the item number noted on the

figure.

(5) Fifth. Refer to the Part Number Index to find the NSN, if assigned.

b. When National stock number or part number is known.

(1) First. Using the Index of National stock numbers and part numbers, find the pertinent National stock

number or port number. The NSN index is in National item identification number (NIIN) sequence (para 4a(1)). The part

numbers in the part number index are listed in ascending alphameric sequence (para 4b). Both indexes cross-reference

you to the illustration figure and item number of the item you are looking for.

(2) Second. After finding the figure and item number, verify that the item is the one youre looking for, then

locate the item number in the repair parts list for the figure.

C-7. Abbreviations

Not applicable.

C-6

TM 11-6115-470-23&P

Figure C-1. Generator, Direct Current G-76/G and G-76A/G (sheet 1 of 2)

TM 11-6115-470-23&P

Figure C-1. Generator, Direct Current G-76/G and G-76A/G (sheet 2 of 2)

SECTION II. TM 11-6115-470-23&P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 00 GENERATOR, DIRECT CURRENT

G-76/G AND G-76A/G

FIGURE C-1

1 PAFDD 19202 11743318 GEN, HD & HDLE ASSY .......................................................... 1

2 PAFDD 19202 11733425 POWER COND UNIT ............................................................... 1

3 PAFDD 19202 11738233 STAND ASSEMBLY.................................................................. 1