Standard Bolts Shear Area Calcs

Diunggah oleh

ramnadh803181Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Standard Bolts Shear Area Calcs

Diunggah oleh

ramnadh803181Hak Cipta:

Format Tersedia

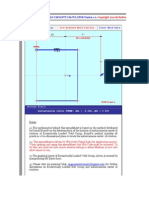

Standard Metric Bolt Shank Dimensions

Page 1 of 2

undefined

2001-06-12, Rev. 2002-09-10.

2002 Garrett D. Euler

All countries in the world except USA, Liberia, and Myanmar use millimeters (mm). USA citizens: Conversion factor is

25.400000 mm/inch. Areas herein are accurate to five significant digits using exact converted USA diameters and pitches (not rounded USA

diameters and pitches listed herein). M and MJ are metric thread profiles. Size designations not beginning with "M" in Table 1 are UN and

UNJ thread profiles (non-metric). Blank values in Table 1 mean nonexistent fastener size. Dark shaded values mean typically never used and

typically unavailable fastener size.

Table 1 Standard Metric and USA Bolt Shank Dimensions (All dimensions in units of mm or mm2 unless otherwise specified.)

Coarse Pitch Threads

Fine Pitch Threads

Size Nominal Nominal Threads Pitch Pitch Minor M,

MJ, Threads Pitch Pitch Minor M,

MJ,

Desig- (Major) Shank per

(mm Dia- Dia- UNC, UNJC per

(mm Dia- Dia- UNF, UNJF

nation Diam- Area, inch,

per meter, meter UNRC Tensile inch,

per meter, meter UNRF Tensile

n

thread), dp Area, Tensile Stress

n

thread), dp Area, Tensile Stress

eter,

An

Dn

p

As Stress Area,

As Stress Area,

Area, A ts

p

Area, A ts

A ts

A ts

0

M1.6

1

M2

2

M2.5

3

4

M3

M3.5

6

M4

8

10

M5

12

M6

0.2500

0.3125

M8

0.3750

M10

0.4375

M12

0.5000

M14

0.5625

0.6250

M16

0.7500

M20

M22*

0.8750

M24

1.0000

M27*

1.1250

M30

1.2500

1.5240

1.6000

1.8542

2.0000

2.1844

2.5000

2.5146

2.8448

3.0000

3.5000

3.5052

4.0000

4.1656

4.8260

5.0000

5.4864

6.0000

6.3500

7.9375

8.0000

9.5250

10.000

11.112

12.000

12.700

14.000

14.288

15.875

16.000

19.050

20.000

22.000

22.225

24.000

25.400

27.000

28.575

30.000

31.750

1.8241

2.0106

2.7002

3.1416

3.7476

4.9087

4.9662

6.3561

7.0686

9.6211

9.6497

12.566

13.628

18.292

19.635

23.641

28.274

31.669

49.483

50.265

71.256

78.540

96.987

113.10

126.68

153.94

160.33

197.93

201.06

285.02

314.16

380.13

387.95

452.39

506.71

572.56

641.30

706.86

791.73

64

56

48

40

32

32

24

24

20

18

16

14

13

12

11

10

9

8

7

7

0.35000 1.3727 1.0762

0.39688 1.5964 1.4074

0.40000 1.7402 1.7890

0.45357 1.8898 1.9986

0.45000 2.2077 2.9801

0.52917 2.1709 2.6222

0.63500 2.4324 3.2045

0.50000 2.6752 4.4734

0.60000 3.1103 5.9997

0.79375 2.9896 4.8075

0.70000 3.5453 7.7496

0.79375 3.6500 7.7166

1.0583 4.1386 9.3546

0.8000 4.4804 12.683

1.0583 4.7990 13.277

1.0000 5.3505 17.894

1.2700 5.5251 17.351

1.4111 7.0210 29.267

1.2500 7.1881 32.841

1.5875 8.4939 43.741

1.5000 9.0257 52.292

1.8143 9.9341 60.210

1.7500 10.863 76.247

1.9538 11.431 81.103

2.0000 12.701 104.71

2.1167 12.913 104.55

2.3091 14.375 130.20

2.0000 14.701 144.12

2.5400 17.400 194.84

2.5000 18.376 225.19

2.5000 20.376 281.53

2.8222 20.392 270.51

3.0000 22.051 324.27

3.1750 23.338 355.51

3.0000 25.051 427.09

3.6286 26.218 447.18

3.5000 27.727 518.99

3.6286 29.393 574.10

http://euler9.tripod.com/bolt-database/23.html

1.2700

1.6915

2.0732

2.3847

3.3908

3.1386

3.8922

5.0308

6.7752

5.8615

8.7787

9.0379

11.311

14.183

15.590

20.123

20.530

33.826

36.609

49.994

57.990

68.586

84.267

91.548

115.44

117.38

145.81

156.67

215.78

244.79

303.40

297.89

352.50

390.80

459.41

492.44

560.59

625.23

1.4799

2.0016

2.3784

2.8049

3.8280

3.7014

4.6467

5.6210

7.5979

7.0199

9.8720

10.464

13.452

15.766

18.088

22.484

23.976

38.715

40.581

56.663

63.981

77.508

92.687

102.63

126.70

130.96

162.30

169.74

237.79

265.22

326.09

326.59

381.91

427.77

492.90

539.88

603.79

678.55

80

0.31750 1.3178 0.9704 1.1588 1.3639

72

0.35278 1.6251 1.5304 1.7920 2.0741

64

0.39688 1.9266 2.1874 2.5383 2.9153

56

48

0.45357 2.2200 2.9116 3.3741 3.8707

0.52917 2.5011 3.6555 4.2611 4.9130

40

0.63500 3.0928 5.6424 6.5440 7.5124

36

32

0.70556 3.7073 8.2910 9.5016 10.795

0.79375 4.3104 11.311 12.899 14.593

28

0.90714 4.8972 14.576 16.638 18.836

28

24

0.90714 5.7608 21.006

1.0583 7.2501 33.826

1.0000 7.3505 36.030

1.0583 8.8376 52.170

1.2500 9.1881 56.297

1.2700 10.288 70.327

1.2500 11.188 86.037

1.2700 11.875 95.903

1.5000 13.026 116.13

1.4111 13.371 121.82

1.4111 14.958 154.86

1.5000 15.026 157.47

1.5875 18.019 226.65

1.5000 19.026 259.00

1.5000 21.026 319.20

1.8143 21.047 310.03

2.0000 22.701 364.61

2.1167 24.025 402.94

2.0000 25.701 473.22

2.1167 27.200 523.82

2.0000 28.701 595.96

2.1167 30.375 660.54

24

20

20

18

18

16

14

12

12

12

23.467

37.462

39.167

56.663

61.199

76.591

92.072

103.20

124.55

130.96

165.13

167.25

240.62

271.50

333.06

328.69

384.42

427.77

495.74

552.08

621.20

692.22

26.065

41.284

42.435

61.342

66.304

83.123

98.311

110.76

133.26

140.42

175.74

177.32

255.00

284.30

347.21

347.90

404.74

453.34

518.79

581.08

646.97

724.65

12/6/2013

Standard Metric Bolt Shank Dimensions

M33

1.3750

M36

1.5000

33.000

34.925

36.000

38.100

855.30

957.99

1017.9

1140.1

6

6

Page 2 of 2

3.5000 30.727 647.19

4.2333 32.175 680.06

4.0000 33.402 759.28

4.2333 35.350 834.73

693.55

745.09 813.09

816.72 876.26

906.62 981.47

12

12

2.0000 31.701 732.83

2.1167 33.550 813.09

2.0000 34.701 883.85

2.1167 36.725 981.47

760.80

848.20

914.53

1020.0

789.29

884.06

945.74

1059.3

* M22 x 2.5 and M27 x 3 for high strength structural steel fasteners only.

M and MJ are metric thread profiles. Size designations not beginning with "M" in Table 1 are UN and UNJ thread profiles (non-metric), no

longer used anywhere in the world except in a few behind-the-times organizations in USA.

You can look up each value in Table 1, above, or you can use the Table 2 formulas to calculate the values yourself. In the

following table, Dn is nominal shank diameter (fastener size) from Table 1. Pitch p is fastener longitudinal length per thread.

Note that p = 1 / n, where n = threads per unit length. Le is thread engagement length.

Table 2 Bolt Shank Geometric Formulas

Fastener Stress Analysis

Quantity Description

Value (for various Thread Profiles)

UN, UNR

MJ

Symbol

60

60

60

Minor diameter

Dm

Dn 1.226869 p

Dn 1.299038 p

Same as

M profile.

Tensile stress diameter

Dts

Dn 0.938194 p

Dn 0.974279 p

Pitch diameter

dp

Dn 0.75 p sin

Shear stress diameter, shank in

shear plane

Shear stress diameter, threads in

shear plane

Ds

Dn

Ds

Dts. Or you can conservatively use Dm.

Thread shear (stripping) area,

sloppy thread tolerances

Ath

0.333 dp Le

Thread shear area, both threads

class 2 or 3 (ISO class 6H/6g)

thread tolerance

Ath

0.5 dp Le

Thread profile angle

UNJ

60

Source

ISO 68-1, 1998, Fig. 1, p. 2.

ISO 898-1, 1999, Sect. 8.2,

Same as

p. 13; ASME B1.1, 1989, Sect.

UNR profile.

8.3.1.f, p. 53.

dp

ISO 898-1, 1999, Sect. 8.2,

p. 13; MIL-HDBK-60, 1990,

Sect. 110.1, p. 27.

ISO 724, 1993, p. 2.

NASA TM-106943, 1995,

p. 16.

Barrett, Fastener Design

Manual, NASA RP-1228, 1990,

p. 21.

FED-STD-H28/2B, 1991, Table

II.B.1, p. 57, Eq. 7.

Thread engagement length. In general, according to Machine Design magazine, the minimum recommended length of engagement is

0.75 to 1 times the bolt major diameter for threading into steel and other materials of comparable hardness; and 1 to 1.5 times the bolt major

diameter for threading into brass, cast iron, and aluminum. These lengths of engagement specified are for full threads engaged, not overall bolt

length. Regarding partial threads in the chamfers on the ends of internal or external threads, FED-STD-H28/2B, 1991, Sect. 7.7.2, p. 61,

specifies that approximately half the countersink or chamfer depth may be included in the length of engagement calculation.

Return to Structural Analysis Reference Library.

http://euler9.tripod.com/bolt-database/23.html

2002 Garrett D. Euler

12/6/2013

Anda mungkin juga menyukai

- Thread ChartDokumen1 halamanThread Chartkgkganesh8116Belum ada peringkat

- Central Machinery Multi Purpose Machine Model 44142Dokumen34 halamanCentral Machinery Multi Purpose Machine Model 44142G3090% (1)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Portal Frame Rafter DesignDokumen132 halamanPortal Frame Rafter DesignBobor Emmanuel OfovweBelum ada peringkat

- Microsoft Word - Design Station Purlins & Girts-Rev3Dokumen31 halamanMicrosoft Word - Design Station Purlins & Girts-Rev3khairul4008Belum ada peringkat

- BW120AD-4 OpMenuDokumen100 halamanBW120AD-4 OpMenuDedek SukmaBelum ada peringkat

- Indice Norma: Menú Principal Indice Manual Indice VolumenDokumen1 halamanIndice Norma: Menú Principal Indice Manual Indice Volumencmrn5Belum ada peringkat

- Bolt Design For Steel Connections As Per AISCDokumen24 halamanBolt Design For Steel Connections As Per AISCDjordjeDj100% (1)

- Welding 01Dokumen307 halamanWelding 01belkadelBelum ada peringkat

- ShoringDokumen7 halamanShoringARUN RAWATBelum ada peringkat

- Beam FLexureDokumen4 halamanBeam FLexureNikitaBhattaraiAcharyaBelum ada peringkat

- 2016 HSC Engineering StudiesDokumen40 halaman2016 HSC Engineering StudiesR MathewBelum ada peringkat

- Ultimate Design Capacity of High Strength Friction GripDokumen5 halamanUltimate Design Capacity of High Strength Friction GripSanthi KrishnaBelum ada peringkat

- Install. Instruc BZ-10-15-20 080218Dokumen29 halamanInstall. Instruc BZ-10-15-20 080218Pavel100% (1)

- Metric FastenersDokumen26 halamanMetric FastenersvijayjaghanBelum ada peringkat

- Sherman - Extended Shear TabsDokumen148 halamanSherman - Extended Shear TabsRohan KarandeBelum ada peringkat

- Design Example ASD GirderDokumen12 halamanDesign Example ASD GirderEdward van MartinoBelum ada peringkat

- Anchor Bolt Design Sprea..Dokumen153 halamanAnchor Bolt Design Sprea..hatot100% (1)

- Fischer THB INT 110640 082013Dokumen445 halamanFischer THB INT 110640 082013arunks4uBelum ada peringkat

- Shaft Design - Overheads PDFDokumen20 halamanShaft Design - Overheads PDFRyan BaleBelum ada peringkat

- Design of JointsDokumen41 halamanDesign of JointsVivek LevinBelum ada peringkat

- Simply SupportedDokumen9 halamanSimply Supportedpackya7191Belum ada peringkat

- 7 Die Maintenance Handbook Chapter 12 PDFDokumen17 halaman7 Die Maintenance Handbook Chapter 12 PDFAtthapol YuyaBelum ada peringkat

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Dokumen11 halamanMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiBelum ada peringkat

- Hollow Sections PropertiesDokumen20 halamanHollow Sections PropertiesHorace Prophetic DavisBelum ada peringkat

- SWD-CSA-A23.3-04 Shear Wall Design ManualDokumen82 halamanSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimBelum ada peringkat

- Anchor Force CalculationsDokumen40 halamanAnchor Force CalculationsImmanuel SBelum ada peringkat

- Prefab ManualDokumen282 halamanPrefab ManualjiyadBelum ada peringkat

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDari EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsBelum ada peringkat

- Aa Spec 371002Dokumen5 halamanAa Spec 371002JDBelum ada peringkat

- Deck Design Project ReportDokumen23 halamanDeck Design Project ReportOzzoman DukeBelum ada peringkat

- Lapped Joints in Compression: TechnicalDokumen2 halamanLapped Joints in Compression: TechnicalNBV2381Belum ada peringkat

- New - Reinforcement of NozzleDokumen31 halamanNew - Reinforcement of NozzleChagar HarshpalBelum ada peringkat

- Triumph Sprint ST 1050 Manual 2005pdfDokumen441 halamanTriumph Sprint ST 1050 Manual 2005pdfweverton lenkerBelum ada peringkat

- Bibby CouplingsDokumen36 halamanBibby Couplingsmarklamb1hotmailcouk100% (1)

- Anchor Design HILTIDokumen14 halamanAnchor Design HILTIRohit GadekarBelum ada peringkat

- Bolted JointsDokumen20 halamanBolted JointsNurcahyo Djati WBelum ada peringkat

- Discrete Element Method to Model 3D Continuous MaterialsDari EverandDiscrete Element Method to Model 3D Continuous MaterialsBelum ada peringkat

- Cummins EQB140-20 SO10863 Parts CatalogueDokumen10 halamanCummins EQB140-20 SO10863 Parts CatalogueChen Caroline0% (1)

- Shear Strength of High-Strength BoltsDokumen61 halamanShear Strength of High-Strength Boltsloox600Belum ada peringkat

- S03 Rotory Drill RHR50 BoltingDokumen18 halamanS03 Rotory Drill RHR50 BoltingCRACBelum ada peringkat

- Basics of Steel Connections PDFDokumen74 halamanBasics of Steel Connections PDFSantosh RaiBelum ada peringkat

- Heidenhain Encoders For Servo Drives PDFDokumen72 halamanHeidenhain Encoders For Servo Drives PDFluizlou5308Belum ada peringkat

- BS 750Dokumen30 halamanBS 750Jabnon Nonjab100% (1)

- Iso Inch Thread With A Standard Unc-2A Tolerance: Relationship Between The TolerancesDokumen1 halamanIso Inch Thread With A Standard Unc-2A Tolerance: Relationship Between The TolerancesMiguelito MaxBelum ada peringkat

- DesignDokumen4 halamanDesignJigneshkumar PatelBelum ada peringkat

- Reactions As Per The ModelDokumen2 halamanReactions As Per The Modelwaweng22Belum ada peringkat

- Gang-Nail Systems LTD: Top/C BTM/C WEB Wedge Member Grade DepthDokumen9 halamanGang-Nail Systems LTD: Top/C BTM/C WEB Wedge Member Grade DepthcetinidrisBelum ada peringkat

- Machine Design Lec3Dokumen75 halamanMachine Design Lec3sam0415Belum ada peringkat

- Roof TrussDokumen4 halamanRoof TrussShamie Dela Cruz CaldeaBelum ada peringkat

- Stramit Bridging Detailing GuideDokumen8 halamanStramit Bridging Detailing Guidenifty25Belum ada peringkat

- SteelDesign PlateGirder Fu NewDokumen32 halamanSteelDesign PlateGirder Fu NewFhatony Silvershadows BondanBelum ada peringkat

- Weld Analysis - IC MethodDokumen4 halamanWeld Analysis - IC MethodNicholas RiveraBelum ada peringkat

- Steelwise PDFDokumen3 halamanSteelwise PDFYan Naung KoBelum ada peringkat

- Conveyor Truss Connections Calcs - 11Dokumen4 halamanConveyor Truss Connections Calcs - 11René Mella CidBelum ada peringkat

- Concrete Design PDFDokumen37 halamanConcrete Design PDFCris BandaBelum ada peringkat

- Fatigue Analysis v3 PDFDokumen73 halamanFatigue Analysis v3 PDFAndonny Daq DelgadoBelum ada peringkat

- 4 Tension MemberDokumen15 halaman4 Tension Memberhari1008108Belum ada peringkat

- EPA Wind CalculatorDokumen1 halamanEPA Wind CalculatorSandip SenguptaBelum ada peringkat

- Ms Plate WeightDokumen2 halamanMs Plate Weightemran meBelum ada peringkat

- Nascc2015 DurasquirtDokumen2 halamanNascc2015 DurasquirtSquidwardBelum ada peringkat

- Load Carrying Capacity of Z-Purlins With A.C. Sheet CladdingDokumen21 halamanLoad Carrying Capacity of Z-Purlins With A.C. Sheet CladdingSRINIVAS DBelum ada peringkat

- DS Prestress HBDokumen28 halamanDS Prestress HBBrian James MarzanBelum ada peringkat

- Shear Lug Verification Example PDFDokumen12 halamanShear Lug Verification Example PDFKarthikeyan PanchatcharamBelum ada peringkat

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionDokumen3 halamanConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionVenu GopalBelum ada peringkat

- RHS Connection To AISC 360Dokumen11 halamanRHS Connection To AISC 360tamerragaaBelum ada peringkat

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Dokumen7 halamanEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Chong Ting Sheng100% (1)

- Example 4Dokumen4 halamanExample 4dane05Belum ada peringkat

- Circular WeldDokumen12 halamanCircular WeldJohn Paul UmaliBelum ada peringkat

- Pile StirrupDokumen1 halamanPile Stirrupbuffyto5377Belum ada peringkat

- Hollow Sections ConnectionsDokumen4 halamanHollow Sections Connectionsאחמד סלאח כאמלBelum ada peringkat

- Standard Metric Bolt Shank Dimensions PDFDokumen2 halamanStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- Standard Metric Bolt Shank DimensionsDokumen3 halamanStandard Metric Bolt Shank DimensionsRajwinder SinghBelum ada peringkat

- Npk calibration certificateDokumen3 halamanNpk calibration certificateramnadh803181Belum ada peringkat

- Valtech Catalog FlangesDokumen76 halamanValtech Catalog FlangesEsteban Valencia RamírezBelum ada peringkat

- Gasket Documents PDFDokumen66 halamanGasket Documents PDFramnadh803181Belum ada peringkat

- The Steel Pipe Buyer'S GuideDokumen8 halamanThe Steel Pipe Buyer'S Guideramnadh803181Belum ada peringkat

- VSP Expo Amtec NA 131121 PDFDokumen50 halamanVSP Expo Amtec NA 131121 PDFAlenJozićBelum ada peringkat

- Gasket Documents PDFDokumen66 halamanGasket Documents PDFramnadh803181Belum ada peringkat

- Optimal Design of Swept, Leaned and Skewed Blades in A Transonic Axial CompressorDokumen11 halamanOptimal Design of Swept, Leaned and Skewed Blades in A Transonic Axial Compressorramnadh803181Belum ada peringkat

- 198 Modern STPDokumen23 halaman198 Modern STPramnadh803181Belum ada peringkat

- Bosch Software Innovations Iot Whitepaper StrategyDokumen22 halamanBosch Software Innovations Iot Whitepaper Strategyramnadh803181Belum ada peringkat

- Guidelines For Corporates To Set Up IncubatorsDokumen6 halamanGuidelines For Corporates To Set Up Incubatorsramnadh803181Belum ada peringkat

- TP1023ENDokumen5 halamanTP1023ENramnadh803181Belum ada peringkat

- Hoover F5914900Dokumen40 halamanHoover F5914900mattjvaBelum ada peringkat

- Dhp481z ManualDokumen76 halamanDhp481z ManualmmesariciBelum ada peringkat

- Blank Copy of PHE - Estimate For BLOCK 4Dokumen34 halamanBlank Copy of PHE - Estimate For BLOCK 4basantadrreddys100% (2)

- Installation and Operation User Guide: Global Leader in Marine Satellite Antenna SystemsDokumen147 halamanInstallation and Operation User Guide: Global Leader in Marine Satellite Antenna SystemsAnonymous SHWrJOBelum ada peringkat

- Microsoft Word - A927-000-81-41-46052 - 1Dokumen9 halamanMicrosoft Word - A927-000-81-41-46052 - 1bondsivamaniBelum ada peringkat

- ZEN AIR TECH 175H ManualDokumen38 halamanZEN AIR TECH 175H ManualjassimBelum ada peringkat

- Spare Partsl BP PR PlusDokumen15 halamanSpare Partsl BP PR PlusIgor BuhBelum ada peringkat

- Ariston at 84 English ManualDokumen80 halamanAriston at 84 English ManualpikasiakBelum ada peringkat

- Repair Information: Eaton Hydrualics DivisionDokumen8 halamanRepair Information: Eaton Hydrualics DivisionZafiro Feliz GalanBelum ada peringkat

- KTR KatalogDokumen6 halamanKTR KatalogAhmet HamamcıoğluBelum ada peringkat

- HardDog Hideaway Hitch Instr. Moss 909-370 - SuppInstDokumen2 halamanHardDog Hideaway Hitch Instr. Moss 909-370 - SuppInsthutz5000Belum ada peringkat

- Areta Suite CabinetDokumen43 halamanAreta Suite CabinetAhmed IbrahimBelum ada peringkat

- HOBSON - Low Tensile Bolts and NutsDokumen2 halamanHOBSON - Low Tensile Bolts and NutsJJ FloresBelum ada peringkat

- Eaton V Series 3525v Standard Double Pump Parts Data I 3203 S en UsDokumen4 halamanEaton V Series 3525v Standard Double Pump Parts Data I 3203 S en Uskieshuto100% (1)

- Fill Rite KitsDokumen127 halamanFill Rite Kitsroberto carlos ortizBelum ada peringkat

- Polarie ManualDokumen28 halamanPolarie ManualMuneer SalimBelum ada peringkat

- AVK Malaysia Water Supply Brochure RFSDokumen52 halamanAVK Malaysia Water Supply Brochure RFSgaluBelum ada peringkat