Dresiani Mareti

Diunggah oleh

Surya WijayaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dresiani Mareti

Diunggah oleh

Surya WijayaHak Cipta:

Format Tersedia

http://jba.sagepub.

com/

Journal of Biomaterials Applications

http://jba.sagepub.com/content/16/2/149

The online version of this article can be found at:

DOI: 10.1106/BGNY-V5DA-VMWB-TC2W

2001 16: 149 J Biomater Appl

Filiz Keyf and Glay Uzun

Strength, Deflection and Modulus of Elasticity of a Provisional Fixed Partial Denture Resin

The Effects of Glass Fiber Reinforcement at Different Concentrations on the Transverse

Published by:

http://www.sagepublications.com

can be found at: Journal of Biomaterials Applications Additional services and information for

http://jba.sagepub.com/cgi/alerts Email Alerts:

http://jba.sagepub.com/subscriptions Subscriptions:

http://www.sagepub.com/journalsReprints.nav Reprints:

http://www.sagepub.com/journalsPermissions.nav Permissions:

http://jba.sagepub.com/content/16/2/149.refs.html Citations:

What is This?

- Oct 1, 2001 Version of Record >>

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

The Effects of Glass Fiber

Reinforcement at Different

Concentrations on the Transverse

Strength, Deflection and Modulus

of Elasticity of a Provisional

Fixed Partial Denture Resin

FI

LI

Z KEYF*

Associate Professor Doctor, Department of Prosthodontics,

School of Dentistry, Hacettepe University, Shhye 06100, Ankara, Turkey

GU

LAY UZUN

Assistant Professor Doctor, School of Dental Technology,

Hacettepe University, Shhye 06100, Ankara, Turkey

ABSTRACT: This study focused on some mechanical properties such as the

transverse strength, maximal deflection and modulus of elasticity of a resin

reinforced with untreated, chopped form glass fibers at different concentrations.

A Teflon mould was used to prepare four groups of specimens. The specimens

were prepared with different concentrations of the glass fiber to the mass of the

powder/liquid mix (0.5, 1, 1.5%), and a mix without fiber was used as the control

group. All the specimens were subjected to transverse testing with a cross-head

speed of 5 mm/min. The load to fracture for each specimen with the maximum

deflection at the point of loading in a three-point load test was recorded. The

transverse strength of 0.5% fiber concentration was 54.45 MPa. The lowest

value was 49.67 MPa for the 1% fiber concentration. The highest mean strength

was for the specimens reinforced with 0.5% glass fiber. This mean was higher

than for the mean of the control without fiber specimens. The specimens

demonstrated an insignificant decrease in the transverse strength and the

maximum deflection when the fiber concentration was increased. The inclusion

*Author to whom correspondence should be addressed.

JOURNAL OF BIOMATERIALS APPLICATIONS Volume 16 October 2001 149

0885-3282/01/02 014908 $10.00/0 DOI: 10.1106/BGNY-V5DA-VMWB-TC2W

2001 Sage Publications

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

of 1% glass fiber reduced the transverse strength, although the result was not

statistically significant.

KEY WORDS: glass fiber reinforcement, concentration, provisional fixed

partial denture resin.

INTRODUCTION

D

ifferent types of fibers have been added to polymer materials to

improve their mechanical properties. Acrylic resins have been

successfully reinforced with glass, carbon, and aramid fibers. There are

also a number of studies on the use of fibers in dentistry. In

periodontics, glass fibers have been tested as additives to BIS-GMA

resin for temporary splints to immobilize teeth [1]. In orthodontics,

aramid fibers have been found useful in reinforcing orthodontic

appliances [2]. In prosthodontics, fibers have been used to improve the

fracture resistance or modulus of elasticity of polymer materials [38].

Glass fibers have been studied as a means of strengthening

polymethyl methacrylate materials [5,7,8] and carbon fibers have been

used to reinforce prosthodontic restorations [3,9,10]. Aramid fibers have

also been found to enhance the fracture resistance of an acrylic resin

denture base material [11]. In recent years, there has been considerable

interest in polyethylene fibers even though this type of fiber is not

commonly used in dentistry [1214].

If fibers are used to strengthen a polymer material, optimal adhesion

between fibers and polymer matrix is essential. To improve adhesion,

the surface of the fibers can be silane-treated [15] or plasma-treated

[16].

The quantity of fibers and their behavior in a polymer matrix also

have an effect on the mechanical properties of fiberpolymer combina-

tions [10,17].

This study investigated the effects on the transverse strength,

maximal deflection and modulus of elasticity of specimens with different

concentrations of chopped form fibers in a resin material used for

provisional fixed partial denture.

MATERIALS AND METHODS

A commercially available autopolymerizing acrylic resin used for

the construction of provisional fixed partial dentures was used.

This material is composed of polyethyl methacrylate powder and

n-butylmethacrylate liquid (Dentalon Plus, Heraeus Kulzer GmbH,

150 FI

LI

Z KEYF AND GU

LAY UZUN

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

Wehrheim, Germany). The manufacturers suggested powder-to-liquid

ratio of 2.0 g1.0 mL was used. The resin was hand-mixed for 40 s and

poured into a Teflon mould to form bar-shaped specimens of

60 10 4 mm. Glass fiber (Z.19.101) (Construcciones Aeronaticas

Socieded Anonima, Madrid, Spain) was used. Four groups were prepared

with different concentrations of glass fiber to mass of the powder/liquid

mix (0.5, 1, and 1.5%). Group A (0.5%) and Group B (1%) consisted of

seven specimens, and Group C (1.5%) and Group D (without fiber)

consisted of six specimens. Untreated chopped form glass fiber was cut

into 3 mm length. A desired mass of glass fiber was first mixed

thoroughly with a predetermined volume of monomer before the

required mass of powder was added to the mix. The powder/liquid mix

was placed in the mould. The mould was placed in a hydraulic press

(Rucker PHI, Birmingham, U.K) and a slow closing pressure was

applied to allow excess dough to extrude. A pressure of 20 psi (140 kPa)

was applied during the 5-minute polymerization time.

After processing, the specimens were removed from the mould, and

their dimensions were measured with a micrometer. Differences in

dimensions were eliminated by grinding with wet silicon carbide paper

until predetermined dimensions were reached. The control group had no

fiber reinforcement. All the specimens were prepared according to the

same procedure throughout the test programme.

Each group was subjected to transverse strength testing under three-

point loading, using a cross-head speed of 5 mm/min, with a screw-

driven universal testing machine (Lloyd Lr. 30 K materials testing

machines, Lloyd Instruments Ltd, Farnham, U.K.). A transverse-testing

jig, which consisted of two parallel stainless steel rods that supported

the specimen, was used to apply the load centrally. The transverse

strength (S) was calculated with the following formula [18]:

S 3LP=2WT

2

where P is the fracture load, L is the distance between the supports

(50 mm), W is the specimen width (10 mm), and T is the specimen

thickness (4 mm). For the modulus of elasticity determination, the

machine was calibrated so that the maximum deflection observed in

the specimen at the point of fracture could be determined automatically

by the testing machine.

After data collection, the mean values and standard deviations were

calculated with the SPSS statistical software program (SPSS Inc.,

Chicago, III). The KruskalWallis analysis of variance was used to

compare the groups.

The Effects of Fiber Reinforcement 151

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

The surfaces of the cross-sections of test specimens were studied using

a scanning electron microscope (SEM) (Jeol, JEM 1200 EX, Tokyo,

Japan) at 80 kV and micrographs were taken at a magnification of 600

to make a visual analysis (Figure 1). The cross sections of the test

specimens were made with a micromotor (KaVo EWL K10, Germany)

after the fracture resistance measurement.

RESULTS

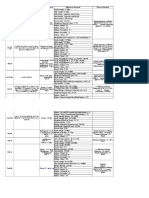

The mean values and the standard deviations of the transverse

strength, the maximal deflection and modulus of elasticity are presented

in Table 1.

The KruskalWallis analysis of variance was used to determine the

effect of fiber concentration on the transverse strength.

The results revealed that 0.5% fiber concentration enhanced the

transverse strength value of the test specimens. When the concentration

of fiber was increased, the transverse strength values decreased. But the

difference was not statistically significant (

2

2.525, p 0.471).

For the maximum deflection, the difference between the four groups

was not statistically significant (

2

4.636, p 0.200) and the

Figure 1. SEM micrograph of cross-section of 1% fiber addition-reinforced test specimen

(original magnification 600).

152 FI

LI

Z KEYF AND GU

LAY UZUN

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

differences between all groups was not statistically significant for the

modulus of elasticity (

2

3.982, p 0.263)

For the transverse strength, the highest value was 54.45 MPa for 0.5%

fiber concentration. The lowest value was 49.67 MPa for 1% fiber

concentration. The control group (without fibers) had 52.82 MPa.

DISCUSSION

Acrylic resin denture materials can be strengthened by incorporation

of different fibers. Glass, carbon, polyethylene and aramid fibers had

a significant strengthening effect when the amount of fibers was high

enough and the technique was properly applied [317].

According to Vallittu et al. [10] longitudinal form fibers spread out

laterally in the mould. This problem does not arise during the use of

chopped form fibers. Because of this, chopped form fibers were preferred

in this study.

The fibers were dipped in monomer before mixing to increase fiber

resin adhesion.

Vallittu et al. [10] found that an increase in the amount of the fibers

in the acrylic resin polymer matrix enhanced the fracture load of the

test specimens.

Gutteridge [14] found that increasing the fiber concentration

decreased the effect on the transverse strength. This finding was in

agreement with the findings of the present study.

Stipho [5] demonstrated that low concentrations of glass fiber in the

polymethyl methacrylate resin enhanced some of the mechanical

properties of the acrylic resin such as the transverse strength. These

findings were in agreement with the present study. No significant

Table 1. The transverse strength, maximal deflection and modulus of elasticity

for glass fiber reinforcement and un-reinforcement specimens for the

different concentrations tested.

Type Number

Transverse

Strength (MPa)

Maximal

Deflection (mm)

Modulus of

Elasticity (MPa)

Std.

Mean

Std.

Error

Std.

Mean

Std.

Error

Std.

Mean

Std.

Error

0.5% fiber addition 7 54.4543 2.9595 3.9200 0.5027 1797.4286 17.5362

1% fiber addition 7 48.1329 1.8190 2.7129 0.1528 1890.5714 60.6131

1.5% fiber addition 6 49.6700 1.7197 3.0233 0.1288 1873.8333 57.8915

Without fiber 6 52.8250 3.6421 3.9917 0.7003 1797.0000 68.5483

The Effects of Fiber Reinforcement 153

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

mechanical advantages were found by the incorporation of higher than

5% glass fiber contents.

This study has demonstrated that the addition of 0.5, 1 and 1.5% of

fibers have an effect on the transverse strength of specimens. At 0.5%

level, specimens were stronger than the control group and specimens

containing 1 and 1.5% fiber. The strength of the resin was reduced at 1%

level of addition.

Williamson et al. [4] found that polyethylene fibers slightly increased

the transverse strength of acrylic resin at a loading of 0.5% by mass.

However, the addition of higher amounts of fibers resulted in decreased

strength that was not statistically different from both 0% or 0.5%

groups and fiber loading did not significantly affect the deflection and

the modulus of elasticity of the resin. These findings are in agreement

with those of the present study.

The transverse strength of the specimens containing 1% fibers was

lower than the control, but there was no statistically significant

difference between the control group and the specimens containing 1%

fiber. The maximum deflection values were related to the transverse

strength.

The 0.5% fiber concentration specimens and those without fibers had

the same modulus of elasticity (1797 GPa). The results revealed only

a small difference between the means, and statistical differences were

not found.

The addition of fibers could readily be used routinely, affording

a preventive approach to the problem of denture fracture. The fibers

incorporated in the acrylic resin material enhanced the transverse

strength, but with a higher concentration of fibers, a decrease in strength

was found. SEM examination revealed well-impregnated glass fiber with

polymer matrix (Figure 1). The use of higher concentration of fibers as a

strengthener may cause formationof voids inside the fiber-matrix system.

Further studies should also consider additional factors such as the

resinfiber interfacial characteristics and the effect of fiber surface

treatment.

CONCLUSIONS

The following conclusions were drawn concerning the three-point

bending test of autopolymerizing acrylic resin reinforced with and

without glass fibers:

1. There were statistically insignificant differences between groups.

The specimens prepared with 0.5% fiber concentration exhibited

154 FI

LI

Z KEYF AND GU

LAY UZUN

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

the highest transverse strength value, whereas specimens prepared

with 1.5% fiber concentration exhibited the lowest.

2. An indication that the specimens with 1% and 1.5% were slightly

more brittle than 0.5% and the control.

3. The resin with 0.5% fiber concentration showed a higher deflection

value than did the resin with 1 and 1.5% fiber concentrations. The

specimens containing 1% fiber concentration were weaker than those

in the control group.

4. The modulus of elasticity of 0.5% fiber concentration was found to be

identical with the specimens without fiber.

5. The fiber incorporated in the acrylic resin material enhanced the

transverse strength, but the decreased strength was found with

higher concentration of fiber.

REFERENCES

1. Friskopp, J. and Blomlof, L. (1984). Intermediate fiberglass splints.

J. Prosthet. Dent., 51: 334337.

2. Mullarky, R.H. (1985). Aramid fiber reinforcement of acrylic appliances.

J. Clin. Orthod., 19: 655658.

3. Larson, W.R., Dixon, D.L., Aquilino, S.A. and Clancy, J.M.S. (1991). The

effect of carbon graphite fiber reinforcement on the strength of provisional

crown and fixed partial denture resins. J. Prosthet. Dent., 66: 816820.

4. Williamson, D.L., Boyer, D.B., Aquilino, S.A. and Leary, J.M. (1994). Effect

of polyethylene fiber reinforcement on the strength of denture base resins

polymerized by microwave energy. J. Prosthet. Dent., 72: 635638.

5. Stipho, H.D. (1998). Repair of acrylic resin denture base reinforced with

glass fiber. J. Prosthet. Dent., 80: 546550.

6. Uzun, G., Hersek, N. and Tinc er, T. (1999). Effect of five woven fiber

reinforcements on the impact and transverse strength of a denture base

resin. J. Prosthet. Dent., 81: 616620.

7. Vallittu, P.K. (1999). Flexural properties of acrylic resin polymers reinforced

with unidirectional and woven glass fibers. J. Prosthet. Dent., 81: 318326.

8. Keyf, F. and Uzun, G. (2000). The effect of glass fibre-reinforcement on the

transverse strength, deflection and modulus of elasticity of repaired acrylic

resins. Int. Dent. J., 50: 9397.

9. Bjork, N., Ekstrand, K. and Ruyter, I.E. (1986). Implant-fixed, dental

bridges from carbon/graphite fibre reinforced poly(methyl methacrylate).

Biomaterials, 7: 7375.

10. Vallittu, P.K., Lassila, V.P. and Lappalainen, R. (1994). Acrylic resin-fiber

composite part I: The effect of fiber concentration on fracture resistance.

J. Prosthet. Dent., 71: 607612.

11. Berrong, J.M., Weed, R.W. and Young, J.M. (1990). Fracture resistance

of Kevlar-reinforced poly(methyl methacrylate) resin preliminary study.

Int. J. Prosthodont., 3: 391395.

The Effects of Fiber Reinforcement 155

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

12. Gutteridge, D.L. (1988). The effect of including ultra-high-modulus

polyethylene fibre on the impact strength of acrylic resin. Br. Dent. J.,

164: 177180.

13. Dixon, D.L. and Breeding, L.C. (1992). The transverse strengths of three

denture base resins reinforced with polyethylene fibers. J. Prosthet. Dent.,

67: 417419.

14. Gutteridge, D.L. (1992). Reinforcement of poly(methyl methacrylate) with

ultra-high-modulus polyethylene fibre. J. Prosthet. Dent., 20: 5054.

15. Solnit, G.S. (1991). The effect of methyl methacrylate reinforcement with

silane-treated and untreated glass fibers. J. Prosthet. Dent., 66: 310314.

16. Ramos, V. Jr., Runyan, D.A. and Christensen, L.C. (1996). Effect of plasma-

treated polyethylene fiber on the fracture strength of polymethyl metha-

crylate. J. Prosthet. Dent., 76: 9496.

17. Uzun, G. and Keyf, F. (2001). The effect of woven, chopped and longitudinal

glass fibers reinforcement on the transverse strength of a repair resin.

J. Biomater. Appl., 15: 351358.

18. Philips, R.W. (1991). Skinners Science of Dental Materials, 9th Edn.

Philadelphia: WB Saunders, p. 39.

156 FI

LI

Z KEYF AND GU

LAY UZUN

at The University of Melbourne Libraries on January 12, 2014 jba.sagepub.com Downloaded from

Anda mungkin juga menyukai

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessDari EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessBelum ada peringkat

- Flexural Strength of Heat Polymerized PoDokumen4 halamanFlexural Strength of Heat Polymerized PoMorteza AtaeiBelum ada peringkat

- Pulp and Paper Industry: Nanotechnology in Forest IndustryDari EverandPulp and Paper Industry: Nanotechnology in Forest IndustryPenilaian: 5 dari 5 bintang5/5 (1)

- Studying The Flexural Properties and Max - Shear Stress of Self Cure Pmma Resin For Denture ApplicationsDokumen14 halamanStudying The Flexural Properties and Max - Shear Stress of Self Cure Pmma Resin For Denture ApplicationsJawad K. OleiwiBelum ada peringkat

- Experimental Characterization of Tensile Properties of Epoxy Resin by Using Micro-Fiber SpecimensDokumen10 halamanExperimental Characterization of Tensile Properties of Epoxy Resin by Using Micro-Fiber SpecimenskumareshBelum ada peringkat

- Short Fiber Reinforced Composite The Effect of Fiber Length and Volume FractionDokumen10 halamanShort Fiber Reinforced Composite The Effect of Fiber Length and Volume FractionMiranti AuliaBelum ada peringkat

- Sasaki2016 Effect of Long-term Water Immersion or Thermal Shock on Mechanical PropertiesDokumen6 halamanSasaki2016 Effect of Long-term Water Immersion or Thermal Shock on Mechanical Propertiesnafsiyah xyzBelum ada peringkat

- Fiber TestingDokumen11 halamanFiber TestingSandy YansikuBelum ada peringkat

- Bond Strength of Six Soft Denture Liners Processed Against Polymerized and Unpolymerized Poly (Methyl Methacryiate)Dokumen5 halamanBond Strength of Six Soft Denture Liners Processed Against Polymerized and Unpolymerized Poly (Methyl Methacryiate)Naresh TeresBelum ada peringkat

- Failure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreDokumen8 halamanFailure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreGerardo XZBelum ada peringkat

- Study of The Behaviour of Hybrid Nano Jute Fiber Composite Under Impact LoadsDokumen4 halamanStudy of The Behaviour of Hybrid Nano Jute Fiber Composite Under Impact LoadsTJPRC PublicationsBelum ada peringkat

- Effect of Glass Fiber Diameter on Flexural Strength of Dental CompositesDokumen8 halamanEffect of Glass Fiber Diameter on Flexural Strength of Dental CompositeskalvinamyBelum ada peringkat

- 931 1627 1 SM PDFDokumen5 halaman931 1627 1 SM PDFDesyBelum ada peringkat

- Tps 381Dokumen34 halamanTps 381Aidil AriefBelum ada peringkat

- ASTM D415 Journal Proof Gunay2008Dokumen5 halamanASTM D415 Journal Proof Gunay2008Abinash PurushothamanBelum ada peringkat

- Characterization of Properties of Epoxy Sisal / Glass Fiber Reinforced Hybrid CompositeDokumen7 halamanCharacterization of Properties of Epoxy Sisal / Glass Fiber Reinforced Hybrid CompositeMr. K.S. Raghul Asst Prof MECHBelum ada peringkat

- of ProjectDokumen24 halamanof ProjectamarparimiBelum ada peringkat

- Camera Ready Paper 2Dokumen9 halamanCamera Ready Paper 2Shri Narayan Agnihotri EPGDMAI Batch 1Belum ada peringkat

- 13 Ijmperdaug201813Dokumen7 halaman13 Ijmperdaug201813TJPRC PublicationsBelum ada peringkat

- DR SamsuddeenDokumen11 halamanDR SamsuddeenVinod ViswanathanBelum ada peringkat

- Nanocomposite Compresssive and FlexuralDokumen5 halamanNanocomposite Compresssive and FlexuralRITIK sharmaBelum ada peringkat

- Leatracher RivewDokumen11 halamanLeatracher Rivewabuki bekriBelum ada peringkat

- thomas2015Dokumen4 halamanthomas2015nafsiyah xyzBelum ada peringkat

- Review Paper 3 PPDokumen42 halamanReview Paper 3 PPKRISHNA VAMSIBelum ada peringkat

- In vitro evaluation of MWCNT-reinforced nanofibers for dental compositesDokumen9 halamanIn vitro evaluation of MWCNT-reinforced nanofibers for dental compositesNurrahmiBelum ada peringkat

- Synopsis: in This Project Used Different Materials. There AreDokumen5 halamanSynopsis: in This Project Used Different Materials. There Areabdulhere4uBelum ada peringkat

- Mechanical Property Evaluation of Jute-GlassDokumen6 halamanMechanical Property Evaluation of Jute-GlassiaetsdiaetsdBelum ada peringkat

- An Application of Nanotechnology in Advanced Dental MaterialsDokumen9 halamanAn Application of Nanotechnology in Advanced Dental MaterialsSevgi SözügeçerBelum ada peringkat

- Water Absorption and Thermal Properties of Pmma Reinforced by Natural Fibers For Denture ApplicationsDokumen12 halamanWater Absorption and Thermal Properties of Pmma Reinforced by Natural Fibers For Denture ApplicationsJawad K. OleiwiBelum ada peringkat

- 2013xu Refuerzo Con Fibras VegetalesDokumen7 halaman2013xu Refuerzo Con Fibras VegetalesIsaac Gabriel LarreaBelum ada peringkat

- Palf PDFDokumen50 halamanPalf PDFHuỳnh PhanBelum ada peringkat

- Stacking SequenceDokumen12 halamanStacking SequenceAndrés MercadoBelum ada peringkat

- Resistencia Mecanica de La Fibra de VidrioDokumen8 halamanResistencia Mecanica de La Fibra de VidriozayraBelum ada peringkat

- J Korean Acad Conserv DentDokumen22 halamanJ Korean Acad Conserv Dentsweet_apple921587Belum ada peringkat

- Effect of Fiber Volume Fraction and Length On TheDokumen10 halamanEffect of Fiber Volume Fraction and Length On TheMiranti AuliaBelum ada peringkat

- Kubo Et Al. - 2010 - Three-Year Clinical Evaluation of A Flowable and A Hybrid Resin Composite in Non-Carious Cervical LesionsDokumen10 halamanKubo Et Al. - 2010 - Three-Year Clinical Evaluation of A Flowable and A Hybrid Resin Composite in Non-Carious Cervical Lesionsjanvier_89Belum ada peringkat

- Experimental Investigation of Hybrid Fibre Reinforced Polymer Composite Material and Its Microstructure PropertiesDokumen7 halamanExperimental Investigation of Hybrid Fibre Reinforced Polymer Composite Material and Its Microstructure PropertiesAranas TrishaBelum ada peringkat

- Finite Element Analysis of IPN Reinforced Woven Fabric CompositeDokumen6 halamanFinite Element Analysis of IPN Reinforced Woven Fabric CompositeCody LeeBelum ada peringkat

- Mechanical Properties of Flax Fiber Reinforced Composites Manufactured Using Hand Layup and Compression Molding-A ComparisonDokumen9 halamanMechanical Properties of Flax Fiber Reinforced Composites Manufactured Using Hand Layup and Compression Molding-A ComparisonsriyajambukarBelum ada peringkat

- Mechanical Properties Investigation of Green CompoDokumen10 halamanMechanical Properties Investigation of Green CompoMUHAMMAD AZIZRYAN RACHMADIBelum ada peringkat

- Single fibre fragmentation test data analysisDokumen11 halamanSingle fibre fragmentation test data analysisgusanito09Belum ada peringkat

- Effect of Fiber Orientation On Mechanical Properties of Sisal Fiber Reinforced Epoxy CompositesDokumen6 halamanEffect of Fiber Orientation On Mechanical Properties of Sisal Fiber Reinforced Epoxy CompositeskumareshBelum ada peringkat

- Physical, Mechanical and Thermal Properties of Jute and Bamboo Fiber Reinforced Unidirectional Epoxy CompositesDokumen7 halamanPhysical, Mechanical and Thermal Properties of Jute and Bamboo Fiber Reinforced Unidirectional Epoxy Compositesdennisitty01Belum ada peringkat

- Electrospun Eri Silk Fibroin Scaffold Coated With Hydroxyapatite For Bone Tissue Engineering ApplicationsDokumen11 halamanElectrospun Eri Silk Fibroin Scaffold Coated With Hydroxyapatite For Bone Tissue Engineering ApplicationsSenthil KumarBelum ada peringkat

- Effect of Denture Cleansers On Tensile Bond Strength of Soft Liners To Denture Base ResinDokumen8 halamanEffect of Denture Cleansers On Tensile Bond Strength of Soft Liners To Denture Base ResinMUHAMMAD INDRABelum ada peringkat

- Fleksural and Diametral Tensil CompositeDokumen6 halamanFleksural and Diametral Tensil CompositeSampahAjaBelum ada peringkat

- Ismail: Effect of Roselle Fibres on Compressive and Tensile Strength of Cement CompositesDokumen10 halamanIsmail: Effect of Roselle Fibres on Compressive and Tensile Strength of Cement CompositesNelson OkoyeBelum ada peringkat

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Dokumen8 halamanIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationBelum ada peringkat

- 1AA1AA1AA IMP, 27!47!28022016 Mechanical Evaluation of Polyvinyl-Acetate - PVA - Polyol and Kaolin SpecimensDokumen4 halaman1AA1AA1AA IMP, 27!47!28022016 Mechanical Evaluation of Polyvinyl-Acetate - PVA - Polyol and Kaolin SpecimensFaroikDahmchiBelum ada peringkat

- Epoxy CompositesDokumen150 halamanEpoxy CompositesTahar BachiriBelum ada peringkat

- Size Effects in Ductile Cellular Solid 2Dokumen13 halamanSize Effects in Ductile Cellular Solid 2ulsanbada9343Belum ada peringkat

- Fracture of Fiber-Reinforced Composites Analyzed Via Acoustic EmissionDokumen8 halamanFracture of Fiber-Reinforced Composites Analyzed Via Acoustic EmissionSubayyal IlyasBelum ada peringkat

- ISSN 2277 - 7164 Original Article: Advances in Polymer Science and Technology: An International JournalDokumen7 halamanISSN 2277 - 7164 Original Article: Advances in Polymer Science and Technology: An International JournalNarasimha Murthy InampudiBelum ada peringkat

- The Properties of Nanofiber Membranes Made of Aloe Vera Gel Combined With Polyvinyl AlcoholDokumen9 halamanThe Properties of Nanofiber Membranes Made of Aloe Vera Gel Combined With Polyvinyl AlcoholziziBelum ada peringkat

- Preparation and Investigation of Some Properties of Acrylic Resin Reinforced With Siwak Fiber Used For Denture Base ApplicationsDokumen6 halamanPreparation and Investigation of Some Properties of Acrylic Resin Reinforced With Siwak Fiber Used For Denture Base ApplicationsJawad K. OleiwiBelum ada peringkat

- Mechanical Characterization of NanocelluloseJute Fiber Based CompositesDokumen4 halamanMechanical Characterization of NanocelluloseJute Fiber Based CompositesInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Ijp 10 1 Kawano 9Dokumen6 halamanIjp 10 1 Kawano 9አነኬ ቹህቺዶሃሠኪቺጆቺBelum ada peringkat

- Hybrid Layer Thickness Resin Tags and Bond STRNGTHDokumen7 halamanHybrid Layer Thickness Resin Tags and Bond STRNGTHmaroun ghalebBelum ada peringkat

- Bonding Effectiveness of Composite-Dentin Interfaces After Mechanical Loading With A New Device (Rub&Roll)Dokumen7 halamanBonding Effectiveness of Composite-Dentin Interfaces After Mechanical Loading With A New Device (Rub&Roll)Verônica Pereira de LimaBelum ada peringkat

- Nanosilica's Effect on Composite Strength & FlexibilityDokumen5 halamanNanosilica's Effect on Composite Strength & FlexibilitySana AshfaqueBelum ada peringkat

- Planning, Motivation, and Evaluation in Orientation To The Future: Latent Structure AnalysisDokumen8 halamanPlanning, Motivation, and Evaluation in Orientation To The Future: Latent Structure AnalysisSurya WijayaBelum ada peringkat

- Extra Oral RadiographyDokumen28 halamanExtra Oral Radiographycaduceus001Belum ada peringkat

- Management of Anterior Dental Crossbite With Removable AppliancesDokumen4 halamanManagement of Anterior Dental Crossbite With Removable AppliancesSurya WijayaBelum ada peringkat

- Tongue Support of Complete Denture in The ElderlyDokumen6 halamanTongue Support of Complete Denture in The ElderlySurya WijayaBelum ada peringkat

- Extra Oral RadiographyDokumen28 halamanExtra Oral Radiographycaduceus001Belum ada peringkat

- Combining Traditional Techniques To Correct AJODO 2013Dokumen9 halamanCombining Traditional Techniques To Correct AJODO 2013Surya WijayaBelum ada peringkat

- Cone Beam PAI Estrela Et Al 2008Dokumen7 halamanCone Beam PAI Estrela Et Al 2008Surya WijayaBelum ada peringkat

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Semiconductor introduction: A guide to intrinsic and extrinsic materialsDokumen9 halamanSemiconductor introduction: A guide to intrinsic and extrinsic materialsYitayew TegodBelum ada peringkat

- Concrete Industrial Ground Floor Slab Design (TR34)Dokumen3 halamanConcrete Industrial Ground Floor Slab Design (TR34)Nihar ShahBelum ada peringkat

- Carnot Vapor Compression SystemsDokumen1 halamanCarnot Vapor Compression SystemsSUMITBelum ada peringkat

- Elastomer I C Bearings PDFDokumen8 halamanElastomer I C Bearings PDFMiguel Belda DiezBelum ada peringkat

- Design Analysis of PVDokumen114 halamanDesign Analysis of PVDivakar Panigrahi100% (8)

- Understanding elastic deformation in pre-stressed concrete structuresDokumen1 halamanUnderstanding elastic deformation in pre-stressed concrete structuresKunalBelum ada peringkat

- Elementary Structural Analysis - by Wilbar NorrisDokumen349 halamanElementary Structural Analysis - by Wilbar Norrisajay72% (18)

- E0018 - 08 - 21 HRCDokumen36 halamanE0018 - 08 - 21 HRCServando LozanoBelum ada peringkat

- Mechanical, Thermal & Physical Properties of Common Engineering MaterialsDokumen2 halamanMechanical, Thermal & Physical Properties of Common Engineering MaterialsCelineKevinBelum ada peringkat

- Marangoni Effect Coffee RingDokumen5 halamanMarangoni Effect Coffee RingOjasvi MongaBelum ada peringkat

- DPC DR Moin by Suhan KhalidDokumen9 halamanDPC DR Moin by Suhan KhalidRasheed doustamBelum ada peringkat

- Lecture Method of Consistent Deformation PDFDokumen76 halamanLecture Method of Consistent Deformation PDFAbbasabbasi77% (13)

- Ref Metallo RotorDokumen8 halamanRef Metallo Rotorabet_singkong8930Belum ada peringkat

- ANSYS Shell 63 HelpDokumen10 halamanANSYS Shell 63 HelpFarid TataBelum ada peringkat

- In Uence of The Concentration of A Gelling Agent and The Type of Surfactant On The Rheological Characteristics of OleogelsDokumen7 halamanIn Uence of The Concentration of A Gelling Agent and The Type of Surfactant On The Rheological Characteristics of OleogelsmajaBelum ada peringkat

- Reinforced Concrete DesignDokumen217 halamanReinforced Concrete Designmortada JasimBelum ada peringkat

- Microalloyed Ferrite-Pearlite Steel Structure and PropertiesDokumen70 halamanMicroalloyed Ferrite-Pearlite Steel Structure and Propertiesfroylan sanchez hernandezBelum ada peringkat

- Experiment 6. Adsorption Official Power PointDokumen40 halamanExperiment 6. Adsorption Official Power PointElaine Tan100% (4)

- Manusriptc Cilamce 2017 SenkoDokumen16 halamanManusriptc Cilamce 2017 SenkoMarcelo CavalcantiBelum ada peringkat

- Frantz & Breen 1980Dokumen262 halamanFrantz & Breen 1980groger23Belum ada peringkat

- Case Studies of Expanding Cement To Prevent Microannular FormationDokumen8 halamanCase Studies of Expanding Cement To Prevent Microannular FormationEmad JamshidiBelum ada peringkat

- Viscosity Temperature DependenceDokumen14 halamanViscosity Temperature Dependencejrlr65Belum ada peringkat

- COSMOSM Fatigue Module GuideDokumen51 halamanCOSMOSM Fatigue Module GuideVladeta JevremovićBelum ada peringkat

- Khanz e ZhangDokumen14 halamanKhanz e ZhangRosemeri BasilioBelum ada peringkat

- Adsorption IsothermsDokumen3 halamanAdsorption IsothermsKrushit PatelBelum ada peringkat

- Quantum Dot Laser Full ReportDokumen38 halamanQuantum Dot Laser Full ReportRajeev Sndhr50% (2)

- Super-Hydrophobic Surfaces From A Simple Coating Method: A Bionic Nanoengineering ApproachDokumen5 halamanSuper-Hydrophobic Surfaces From A Simple Coating Method: A Bionic Nanoengineering ApproachLaura Horta RomarísBelum ada peringkat

- Design of Doubly Reinforced BeamDokumen2 halamanDesign of Doubly Reinforced BeamZnake Von LucasBelum ada peringkat

- MD Elements1Dokumen22 halamanMD Elements1Ben LopezBelum ada peringkat

- IPS E-Max PressDokumen40 halamanIPS E-Max PressFabio WenoBelum ada peringkat