Iso 730 1-1977categorias y Enganches 3 Puntos

Diunggah oleh

Policarpio Mamani HuchaniDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Iso 730 1-1977categorias y Enganches 3 Puntos

Diunggah oleh

Policarpio Mamani HuchaniHak Cipta:

Format Tersedia

S

T

A

N

D

A

R

D

ASABE is a professional and technical organization, of members worldwide, who are dedicated to advancement of

engineering applicable to agricultural, food, and biological systems. ASABE Standards are consensus documents

developed and adopted by the American Society of Agricultural and Biological Engineers to meet standardization

needs within the scope of the Society; principally agricultural eld equipment, farmstead equipment, structures, soil

and water resource management, turf and landscape equipment, forest engineering, food and process engineering,

electric power applications, plant and animal environment, and waste management.

NOTE: ASABE Standards, Engineering Practices, and Data are informational and advisory only. Their use by

anyone engaged in industry or trade is entirely voluntary. The ASABE assumes no responsibility for results attrib-

utable to the application of ASABE Standards, Engineering Practices, and Data. Conformity does not ensure

compliance with applicable ordinances, laws and regulations. Prospective users are responsible for protecting

themselves against liability for infringement of patents.

ASABE Standards, Engineering Practices, and Data initially approved prior to the society name change in July of

2005 are designated as ASAE, regardless of the revision approval date. Newly developed Standards, Engineering

Practices and Data approved after July of 2005 are designated as ASABE.

Standards designated as ANSI are American National Standards as are all ISO adoptions published by ASABE.

Adoption as an American National Standard requires verication by ANSI that the requirements for due process,

consensus, and other criteria for approval have been met by ASABE.

Consensus is established when, in the judgment of the ANSI Board of Standards Review, substantial agreement has

been reached by directly and materially affected interests. Substantial agreement means much more than a simple

majority, but not necessarily unanimity. Consensus requires that all views and objections be considered, and that a

concerted effort be made toward their resolution.

CAUTION NOTICE: ASABE and ANSI standards may be revised or withdrawn at any time. Additionally, procedures

of ASABE require that action be taken periodically to reafrm, revise, or withdraw each standard.

Copyright American Society of Agricultural and Biological Engineers. All rights reserved.

ASABE, 2950 Niles Road, St. Joseph, MI 49085-9659, USA ph. 269-429-0300, fax 269-429-3852, hq@asabe.org

ASAE S217.12 DEC01 (ISO+730-1:1994)

Three-Point Free-Link Attachment for Hitching Implements

to Agricultural Wheel Tractors

ASAE S217.12 DEC01 (ISO+730-1:1994)

Three-Point Free-Link Attachment for Hitching Implements

to Agricultural Wheel Tractors

Proposed by the Advisory Engineering Committee of the Farm and

Industrial Equipment Institute: adopted by ASAE March 1959; revised

1961, 1962, 1963, June 1964, December 1966, March 1971, February

1972, April 1974, February 1975; revised editorially April 1977;

reconrmed December 1979, December 1984, December 1989; revised

December 1991; reafrmed December 1996, December 1997, December

1998; revised editorially March 1999; reafrmed December 1999;

reafrmed for one year January 2001; revised December 2001 to provide

specic comparison to ISO 730-1:1994 E.

0 Forward

0.1 This document is equivalent to ISO 730-1:1994 E. Differences

between ASAE S217.11 and ISO 730-1 pertain to the following areas; 1)

implement mast height, 2) PTO to lower hitch point distance, 3) power

stroke, 4) mast kick-up, and 5) two Category 4 sizes. Designers of new

tractors and implements shall design to ISO 730-1, but should be aware

of the quantity of equipment in use designed to ASAE S217.11 and

consider these differences when completing new designs. Table 0

summarizes the differences between ISO 730-1 and ASAE S217.11. It is

presented only as a brief overview of the differences. Designers should

review both Standards so that they are fully aware of any subtle

differences not contained in this overview.

0.2 Implement mast: The standard implement mast height is shown in

Table 4, dimension h. There is no change from ASAE S217.11

implement mast heights for Category 1 and 4. Category 2 and 3 ASAE

implement mast heights are approximately 125 mm shorter. Footnote 1 of

Table 4 notes the ASAE S217.11 implement mast heights to inform both

the tractor and implement designer for consideration during the transition

period of their equipment to ISO 730-1.

0.3 PTO to lower hitch point: ISO 730-1 provides a dimensional overlap

with ASAE S217.11 in the horizontal dimension from the PTO to the

lower hitch points when the lower link is horizontal for Categories 1 and

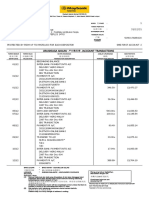

Table 0 Comparison

Dimensions in mm

Description Hitch Category ISO 730-1 ASAE S217.11

Dimensions associated with Implement

Implement mast height (Clause 0) 1 460+/-1.5 457

2 610+/-1.5 483

3 685+/-1.5 559

4L 685+/-1.5 686

4H 1,100+/-1.5 Not Available

Special hitch categories (Clause 0.7) 1N 400 Not Available

2N 683 Not Available

3N 825 822.5825.5

4N 920 919922

Dimensions associated with tractor

PTO to Lower hitch point (Clause 0.3) 1 500575 508559

2 550625 508559

3 575675 508559

4L 575675 508559

4H 610670 Not Available

Minimum transport height (Clause 0.4) 1 820 813

2 950 914

3 1,065 1,016

4L 1,200 1,120

4H 1,200 Not Available

Power range (Clause 0.5) 1 610 559

2 650 610

3 735 660

4L 760 762

4H 900 Not Available

Upper link attaching points (Clause 0.6) 1, 2, 3, 4 3 to 3 deg

+10 to 15 deg

Not Specied

ASAE S217.12 DEC01 ISO730-1:1994 ASABE STANDARDS 2006 95

2. This overlap allows the designer to meet both ASAE S217.11 and ISO

730-1 with the same components. This condition is not the same for

Categories 3 and 4 as the ISO 730-1 minimum dimension is 16mm

longer than the ASAE S217.11 maximum. As a result, tractors and

equipment designed for use in the North American market should be

designed to the minimum ISO dimensions. This will assure backward

compatibility between new tractors and old implements.

0.4 Minimum height for highest position: ISO 730-1 recognizes the

growth of tire sizes in the industry, which accounts for differences

between ISO 730-1 and ASAE S217.11 in the minimum height for the

highest position (transport height).

0.5 Power range: ISO 730-1 recognizes the growth in both tractor power

and implements size. These larger fully mounted implements require

additional power range.

0.6 Upper link attaching points: ISO 730-1 recognizes that implements

worldwide can generally be divided into two classes; 1) those requiring

near parallel lift and 2) those requiring maximum tail clearance when fully

raised. Clause 4.1.2 for these reasons specically requires two different

upper link points on the tractor.

0.7 Special hitch categories (narrow): ISO 730-1 recognizes special

narrow hitch categories commonly used in the North American row

crop market. This information is found in Footnote 1 of Table 2.

0.8 Category 4 light and heavy: ISO 730-1 recognizes the need for both

a light duty and heavy duty hitch category within the current Category

4 power range.

1 Scope

This part of S217.12 (ISO 730) species the dimensions and

requirements of the three-point linkage for the attachment of implements

or equipment to the rear of agricultural wheeled tractors.

It species four categories to be used on different ranges of agricultural

tractors as shown in Table 1.

Category 4 has been divided into two parts, 4L and 4H, depending on the

location of the power take-off (PTO). Category 4L and 4H dimensions

apply to tractors with the PTO, respectively, below and above the rear

axle centerline.

Dimensions and requirements for the three-point linkage for the

attachment of implements or equipment to the front of agricultural

tractors are given in ISO 8759-2[3].

2 Normative references

The following standards contain provisions which, through reference in

this text, constitute provisions of this part of S217.12 (ISO 730). At the

time of publication, the editions indicated were valid. All standards are

subject to revision, and parties to agreements based on this part of

S217.12 (ISO 730) are encouraged to investigate the possibility of

applying the most recent editions of the standards indicated below.

Members of IEC and ISO maintain registers of currently valid

International Standards.

ASAE S349.2 DEC98, Test Procedure for Measuring Hydraulic Lift

Capacity on Agricultural Tractors Equipped With Three-Point Hitch

SAE J711 MAR91, Tire Selection Tables for Agricultural Tractors of

Future Design

SAE J2708 APR93, Agricultural Tractor Test Code

ISO 789-1:1990, Agricultural tractorsTest proceduresPart 1: Power

tests for power take-off.

ISO 2332:1993, Agricultural tractors and machinery

Connection of implements via three-point linkage

Clearance zone around implement.

3 Denitions

For the purposes of this part of S217.12 (ISO 730) the following

denitions for components and dimensions in 3.2. The last element of the

denition number in 3.2 is also the key number for the element of

dimension in Figures 1, 2 and A1.

3.1 General

3.1.1 linkage: Combination of one upper link and two lower links, each

articulated to the tractor and the implement at opposite ends, in order to

connect the implement to the tractor.

3.1.2 hitch point: Articulated connections between link and implement.

NOTE 1 For geometrical purposes the hitch point is the centre of the

articulated connection between link and implement.

3.1.3 link point: Articulated connection between link and tractor.

NOTE 2 For geometrical purposes the link point is the centre of the

articulated connection between link and tractor.

3.1.4 three-point hitch coupler: Device which facilitates the connection

of the tractor three-point linkage to the implement.

1)

3.2 Linkage components and dimensions

3.2.1 upper link: Upper linkage element, tted with an articulated

connection at both ends.

3.2.2 lower link: Lower linkage element, tted with an articulated

connection at both ends.

3.2.3 upper hitch point: Articulated connection between the upper link

and the implement.

3.2.4 lower hitch point: Articulated connection between a lower link

and the implement.

3.2.5 upper link point: Articulated connection between the upper link and

the tractor.

3.2.6 lower link point: Articulated connection between a lower link and

the tractor.

3.2.7 upper hitch attachment: Pin, usually detachable and forming part

of the upper link assembly, by which an upper link is secured.

3.2.8 lower hitch attachment: Pin, or clevis and pin, usually attached to

the implement, by which a lower link is secured.

3.2.9 upper link attachment: Pin by which the upper link is connected

to the tractor.

3.2.10 linch pin: Pin, usually tted with a spring-retaining device, by

which an articulated connection is retained in position.

2)

3.2.11 lift rods: Connections that transmit force to the lower links for

raising and lowering.

3.2.12 mast: Component that provides location of the upper hitch point

on the implement.

3.2.13 mast height: Vertical distance between the upper hitch point and

the common axis of the lower hitch points.

3.2.14 lower hitch point height: Height of the center of the lower hitch

points above ground level when they are fully lowered using the full

1)

For examples, see annex B [4] to [7].

2)

See annex B [2].

Table 1 Categories

Category PTO power at rated rotational frequency of engine

1)

kW

1 up to 48

2 up to 92

3 80 to 185

4 150 to 350

1)

Determined in accordance with ISO 789-1.

ASAE S217.12 DEC01 ISO730-1:1994 96 ASABE STANDARDS 2006

extent of manual adjustment provided in the lift rods in conjunction with

the movement range with the lower hitch point axis maintained horizontal

to the ground in a transverse plane.

3.2.15 levelling adjustment: Movement, measured vertically, of either

lower hitch point higher or lower than the other, to allow inclination of the

implement, measured with one lower link horizontal.

3.2.16 lower hitch point span: Distance between the shoulders of the

lower hitch pins against which the sides of the lower link ball joints abut.

3.2.17 linch pin hole distance: Distance from the centerline of the linch

pin hole to the shoulder of the hitch pin.

3.2.18 movement range: Vertical movement of the lower hitch points

corresponding to the power travel of the lift, excluding any adjustment in

the lift rod linkage.

3.2.19 transport height: Total height of the lower hitch points above the

ground using the full extent of manual adjustment provided in the lift rods

in conjunction with the movement range, with the lower hitch point axis

maintained horizontal to the ground in a transverse plane.

3.2.20 lower hitch point clearance: Clearance expressed as a radial

dimension from the lower hitch point axis to the outside diameter of the

tyre, mudguard or other part of the tractor, measured in a longitudinal

vertical plane with the implement raised to transport height and all side-

sway prevented.

3.2.21 pitch: Angle of the mast to the vertical, considered positive when

anticlockwise viewed from the left-hand side of the tractor.

3.2.22 mast adjustment: Usable range of pitch of the mast from a

vertical plane. It is measured at the maximum and minimum height of the

lower hitch points above the ground between which the mast (3.2.12),

when using the specied mast height, can be adjusted to any inclination

between +5 and 5 from the vertical.

NOTES

3 Mast adjustment is not shown in gure.

4 Adjustment of the mast controls the pitch of the implement.

Specifying the mast adjustment to be provided enables the tractor

designer to determine the minimum acceptable adjustment of the

Figure 1 Components of three-point hitch

ASAE S217.12 DEC01 ISO730-1:1994 ASABE STANDARDS 2006 97

Figure 3 Distance from PTO to lower link points

Figure 2 Dimensions of three-point hitch

ASAE S217.12 DEC01 ISO730-1:1994 98 ASABE STANDARDS 2006

Figure 4 Dimensions concerning tractor hitch points

ASAE S217.12 DEC01 ISO730-1:1994 ASABE STANDARDS 2006 99

length of the top link in relation to the points of attachment of the

linkage. It also permits the implement designer to determine the range

of operating depths of the implement over which pitch adjustment can

be obtained.

3.2.23 torsional free oat distance: Vertical distance that either of the

lower hitch points can move free relative to the other to allow the

implement to roll, with lower links initially horizontal.

3.2.24 transport pitch: Pitch reached by the mast when lifted to

standard transport height from a position with horizontal lower links and

vertical mast.

3.2.25 horizontal convergence distance: Horizontal distance from the

lower hitch points to the point of convergence of the lower links when the

lower links are horizontal and laterally symmetrical, seen in a plan view

(see Figure A1).

3.2.26 vertical convergence distance: Horizontal distance from the

lower hitch points to the point of convergence formed in the vertical

longitudinal plane by the top link and the lower links (see Figure A1).

4 Tractor

4.1 Dimensions

Dimensions apply to the tractor equipped with the normal range of tire

sizes as recommended by the tractor manufacturer.

4.1.1 Hitch points

The dimensions concerning the hitch points shall be as given in Figures

3 and 4, and Table 2.

4.1.2 Upper link point

Upper link point arrangements shall be provided so that transport pitches

of 3 to +3 and +10 to +15 can be achieved with the standard mast

height.

Table 2 Dimensions concerning tractor hitch points

Dimensions in millimeters

Category

Dimension Description See gure 1 2 3 4L 4H

Upper hitch points

D

1

Diameter of hitch pin 4

19

0.08

0

25,5

0.13

0

31.75

0.2

0

45

0.8

0

45

0.8

0

b

1

Width of ball 4 44 max. 51 max. 51 max. 64 max. 64 max.

b

2

Linch pin hole distance 4 76 min. 93 min. 102 min. 140 min. 140 min.

Lower hitch points

d

2

Diameter of hitch pin hole 4

22.4

0

0.25

28.7

0

0.3

37.4

0

0.35

51

0

0.5

51

0

0.5

b

3

Width of ball 4

35

02

0

45

0.2

0

45

0.2

o

57.5

0.5

0

57.5

0.5

0

l

1

Lateral distance from lower hitch point

to centerline of tractor

1)

4 359 435 505 610 or 612 610 or 612

l

2

Lateral movement of lower hitch point 4 100 min. 125 min. 125 min. 130 min. 130 min.

L Distance from end of power take-off to

center of lower hitch point, with the

lower link horizontal

2)3)

3 500 to 575 550 to 625 575 to 675 575 to 675 610 to 670

1)

It may be necessary to vary these dimensions in the case of specialized implements. Where a shorter distance between the lower hitch points appears necessary,

the following values are preferred:

218 mm for category 1;

364 mm for category 2;

435 mm for category 3;

489 mm for category 4.

2)

If a three-point hitch coupler is used, dimension L may be shortened accordingly, so that the distance between PTO and power input connection (PIC) remains the

same.

3)

Dimensions apply only to nominal diameter [1] 35 mm PTO-shafts and shall be increased by 100 mm if a nominal diameter [1] 45 mm PTO-shaft is used.

Table 3 Lift, movement range, and levelling adjustments

Dimensions in millimeters

Category

Denition Subclause 1 2 3 4L 4H

Lower hitch point height 3.2.14 200 max. 200 max. 230 max. 230 max. 230 max.

Levelling adjustment 3.2.15 100 min. 100 min. 125 min. 150 min. 150 min.

Movement range 3.2.18 610 min. 650 max.

1)

735 min. 760 min. 900 min.

Transport height point (lower point axis to be horizontal throughout) 3.2.19 820 min. 950 min. 1,065 min. 1,200 min. 1,200 min.

Lower hitch point clearance 3.2.20 100 min. 100 min. 100 min. 100 min. 100 min.

Mast adjustment height 3.2.22

highest position 508 min. 610 min. 660 min. 710 min. 710 min.

lowest position 200 max. 200 max. 230 max. 255 max. 255 max.

Torsional free oat 3.2.23 60 min. 60 min. 75 min. 75 min. 75 min.

1)

For tractors with PTO power above 65 kW, this dimension shall be 700 mm minimum.

ASAE S217.12 DEC01 ISO730-1:1994 100 ASABE STANDARDS 2006

4.1.3 Torsional free oat

Torsional free oat shall be provided at a distance as given in Table 3.

It shall be possible to block the torsional free oat.

4.1.4 Lift, movement range and levelling adjustments

The ranges of lift, movement range and levelling adjustment shall be as

specied in Table 3.

4.1.5 Convergence distances

See Annex A.

4.2 Restriction of transport height

Tractors shall have means by which the operatorcan easily restrict the

transport height by, for example an adjustable stop, particularly to avoid

damage to the PTO-shafts of the machine.

4.3 Interchangeability

Provisions shall be made in the design of the lower links, or by the use

of double-ended hitch attachments, to enable implements based on the

dimensions of Category 1 to be tted to linkages made in accordance

with Category 2 or vice versa. The same applies in the case of

Categories 2 and 3.

5 Implement

5.1 Dimensions

The hitch attachments dimensions shall be as given in Figure 5 and

Table 4.

Figure 5 Dimensions concerning implement hitch attachments

ASAE S217.12 DEC01 ISO730-1:1994 ASABE STANDARDS 2006 101

5.2 Clearance zone

The clearance for the implement shall be as given in ISO 2332, which

also shows the clearance needed around hitch points.

APPENDIX A

(informative)

Convergence distances

This annex gives recommendations for choosing the vertical and the

horizontal convergence distances for the three-point linkage to achieve

good working conditions for implements, in particular soil-working

implements such as ploughs.

The aim with these recommendations is to make it possible to achieve an

effective tractor-implement combination under all conditions.

A.1 Horizontal convergence distance

The horizontal convergence distance (see Figure A1) is of great

importance for the horizontal stability of implements. (See Annex B [9] to

[16].)

If the horizontal convergence distance is too large, the lateral stability of

directional implements is decreased. For ploughs this means an uneven

and crooked rst furrow.

If the horizontal convergence distance is too short, non-directional

implements, such as harrows, easily nd equilibrium positions somewhat

asymmetric to the tractor. For many implements, especially long multirow

ones, this leads to decreased quality of work.

Experience shows that most implements will function well with the

following horizontal convergence distance:

Category 1: 1,700 mm to 2,400 mm

Category 2: 1,800 mm to 2,400 mm

Category 3: 1,900 mm to 2,700 mm

Category 4: 1,900 mm to 2,800 mm

A.2 Vertical convergence distance

The vertical convergence distance (see Figure A1) is important for stable

working conditions and makes it possible

to reduce the inuence of tractor movements (pitching, rolling,

turning) on connected implements;

for designers of implements to apply the optimal technical

decisions and design criteria for working bodies of an implement

and to use the mass of the implement properly:

to provide for wide interchangeability of tractors and implements

designed by different producers.

To achieve these properties for a linkage, it is recommended that the

vertical convergence distance is not less than 0.9 times the tractor

wheelbase.

Table 4 Dimensions concerning implement hitch attachments

Dimensions in millimeters

Dimension Category

(see Figure 5) Description 1 2 3 4L 4H

Upper hitch attachment

d

1

Diameter of hitch pin hole

19.3

0

0.2

25.7

0

0.2

32

0

0.25

45.2

0

0.3

45.2

0

0.3

b

1

Width between inner faces of yoke 44.5 min. 52 min. 52 min. 65 min. 65 min.

b

2

* Width between outer faces of yoke 69 max. 86 max. 95 max. 132 max. 132 max.

Lower hitch attachment

D

2

Diameter of hitch pin

22

0.2

0

28

0.2

0

36.6

0.2

0

50.8

1.1

0

50.8

1.1

0

b

3

* Linch pin hole distance 39 min. 49 min. 52 min. 68 min. 68 min.

l Lower hitch point span

1)

6831.5 8251.5 9651.5 1,166.51.5 1,166.51.5

Other dimensions

d Diameter for linch pin hole

for upper hitch pin 12 min. 12 min. 12 min. 17.5 min. 17.5 min.

for lower hitch pins 12 min. 12 min. 17 min. 17.5 min. 17.5 min.

h Mast height

2)

4601.5 610 1.5 6851.5 6851.5 1,1001.5

1)

It may be necessary to vary these dimensions in case of specialized implements. Where a shorter distance between the lower hitch points appears necessary, the

following values are preferred:

400 mm for category 1;

683 mm for category 2;

825 mm for category 3;

920 mm for category 4.

2)

Additional mast heights may be provided for specialized implements and frame-type three-point hitch couplers as given by other standards (e.g. 483 mm for category

2 and 559 mm for category 3 as given by SAE J 715 [8]). These additional mast heights shall be within a range of +200 mm from the standard mast height given

in the table.

ASAE S217.12 DEC01 ISO730-1:1994 102 ASABE STANDARDS 2006

Figure A1 Convergence distances

ASAE S217.12 DEC01 ISO730-1:1994 ASABE STANDARDS 2006 103

Annex B

(informative)

Bibliography

B.1 Literature concerning main body of standard

1. ISO 500:1991, Agricultural tractorsRear-mounted power take-offTypes 1,

2 and 3.

2. ISO 7072:1993, Tractors and machinery for agriculture and forestryLinch

pins and spring pinsDimensions and requirements.

3. ISO 8759-2:1985, Agricultural wheeled tractorsFront-mounted linkage and

power take-offPart 2: Front linkage.

4. ISO 11001-1:1993, Agricultural wheeled tractors and implementsThree-

point hitch couplersPart 1: U-frame coupler.

5. ISO 11001-2:1993, Agricultural wheeled tractors and implementsThree-

point hitch couplersPart 2: A-frame coupler.

6. ISO 11001-3:1993, Agricultural wheeled tractors and implementsThree-

point hitch couplersPart 3: Link coupler.

7. ISO 11001-4:1994, Agricultural wheeled tractors and implementsThree-

point hitch couplersPart 4: Bar coupler.

8. SAE J 715-OCT 88 Three-Point Free-Link Hitch Attachment of Implement to

Agricultural Wheeled Tractors.

B.2 Literature concerning Annex A

9. Skalweit, H. Die Fu hrungskra fte von Schlepper-Arbeitsgera ten bei

den genormten Anbausystemem. Grundlagen der Landtechnik,

1953, No. 4, pp. 5456.

10. Ferlage, B. Normung der Dreipunktaufha ngung am Schlepper.

Grundlagen der Landtechnik, 1956, No. 7, pp. 89106.

11. Thaer, R. Untersuchungen u ber die Dreipunkataufha ngung der

Gera te am Schlepper. Grundlagen der Landtechnik, 1956, No. 7, pp.

7288.

12. Cowell, P. A. and Makanjuola, G. A. The lateral stability of tractor

implements, with particular reference to the three-point linkage.

Journal of Agricultural Engineering Research, 1996, vol. 11, No. 3,

pp. 153169.

13. Makanjuola, G. A. and Cowell, P. A. Optimization of the lateral

dynamic behavior of tractor-mounted implements, Journal of

Agricultural Engineering Research, 1970, vol.15, No. 3, pp. 201220.

14. Makanjuola, G. A. The lateral dynamic behavior of tractor-mounted

implements. Ph.D. Thesis, University of Newcastle upon Tyne, 1967.

15. Kepner, R. A., Bainer, R. and Barger, E. L., Principles of Farm

Machinery, 3rd ed., AVI Publishing Company, 1978.

16. Jo hsson, H., A theory for the Inuence of the Hitch on Lateral

Displacement of Implements. Journal of Agricultural Engineering

Research, 1989, vol. 44, No. 1, pp. 3352.

ASAE S217.12 DEC01 ISO730-1:1994 104 ASABE STANDARDS 2006

Anda mungkin juga menyukai

- Ansi Asabe S207.12 - 2004-02Dokumen11 halamanAnsi Asabe S207.12 - 2004-02Stephan100% (1)

- Drawbars-Agricultural Wheel TractorsDokumen4 halamanDrawbars-Agricultural Wheel Tractorselkin880604Belum ada peringkat

- Sae J49-2018 PDFDokumen10 halamanSae J49-2018 PDFNastyBelum ada peringkat

- ASME B18.9 TabDokumen2 halamanASME B18.9 TabmarceloBelum ada peringkat

- Three-Point Free-LinkDokumen10 halamanThree-Point Free-LinkCarlosBelum ada peringkat

- 08 28734a PDFDokumen1 halaman08 28734a PDFSachin JawaleBelum ada peringkat

- HydraulicCylinderTubeST52 ST52 3Dokumen1 halamanHydraulicCylinderTubeST52 ST52 3rjramanathanBelum ada peringkat

- Asae s278.6 Enganche Rapido Modificado 7Dokumen4 halamanAsae s278.6 Enganche Rapido Modificado 7Policarpio Mamani HuchaniBelum ada peringkat

- Din 5480Dokumen44 halamanDin 5480Hussain AliBelum ada peringkat

- 0614 GearSolutionsDokumen60 halaman0614 GearSolutionsMarco Vinicius100% (1)

- AGMA Fatores de ServiçoDokumen4 halamanAGMA Fatores de Serviçochu42Belum ada peringkat

- Tractor Hitch ControlDokumen9 halamanTractor Hitch ControlventsymBelum ada peringkat

- Cast Sae J514 PDFDokumen4 halamanCast Sae J514 PDFmanishkumar FETBelum ada peringkat

- Cotton Picker 9986 PDFDokumen614 halamanCotton Picker 9986 PDFBORISLUFIXBelum ada peringkat

- Parts Catalog: 9976 Cotton PickerDokumen707 halamanParts Catalog: 9976 Cotton PickerGuimaraes Edinaldo SilvaBelum ada peringkat

- Sae J500 EstriadosDokumen2 halamanSae J500 EstriadosMarcel Dandaro100% (1)

- Din 5480-2 - 2006-05Dokumen40 halamanDin 5480-2 - 2006-05Luiz Munari100% (2)

- GB - T 10095.2-2008Dokumen5 halamanGB - T 10095.2-2008taghdirimBelum ada peringkat

- Semi-Topping Shaper CuttersDokumen4 halamanSemi-Topping Shaper CuttersalemarlonstosBelum ada peringkat

- BS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled BushesDokumen14 halamanBS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled Bushesxuanphuong2710Belum ada peringkat

- PBL Series K CatalougeDokumen117 halamanPBL Series K CatalougeankitkanujiyaBelum ada peringkat

- HVATACDokumen2 halamanHVATACHrvatski strelicarski savezBelum ada peringkat

- DIN 5462 - RanhuraDokumen2 halamanDIN 5462 - RanhuraPedro Trindade0% (1)

- Din 7623Dokumen2 halamanDin 7623Racha Amel100% (1)

- Ycl-1340 - 1440 Operation and Parts ManualDokumen42 halamanYcl-1340 - 1440 Operation and Parts ManualJacques Van NiekerkBelum ada peringkat

- ISO 730 - 3 Point LinkageDokumen20 halamanISO 730 - 3 Point LinkageJxyz QwBelum ada peringkat

- Asme B18.8.2 2000Dokumen39 halamanAsme B18.8.2 2000Jesse ChenBelum ada peringkat

- Din 71412 MazaliceDokumen1 halamanDin 71412 MazaliceMiran VidovićBelum ada peringkat

- DIN ISO 12128-1998 Plain Bearings - Lubrication Holes, Grooves and PocketsDokumen10 halamanDIN ISO 12128-1998 Plain Bearings - Lubrication Holes, Grooves and Pocketsxuanphuong2710Belum ada peringkat

- Iso 14 1982 PDFDokumen14 halamanIso 14 1982 PDFBorn ToSin67% (3)

- Din 13-51Dokumen1 halamanDin 13-51anks_raBelum ada peringkat

- Iso 6336-1-2006 C1-2008Dokumen2 halamanIso 6336-1-2006 C1-2008Anonymous opp9k40% (1)

- DIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralDokumen24 halamanDIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralFranciscoBelum ada peringkat

- ISO 2338 B / SN 212771 B: Dowel Pins, SteelDokumen8 halamanISO 2338 B / SN 212771 B: Dowel Pins, SteelSirbu Vasile Liviu100% (1)

- Pec Ifica Tion .PW: Surface Vehicle InformationDokumen11 halamanPec Ifica Tion .PW: Surface Vehicle InformationCelso100% (1)

- BS 3790Dokumen38 halamanBS 3790Simon LawBelum ada peringkat

- A Kinematic Analysis of Meshing Polymer Gear TeethDokumen16 halamanA Kinematic Analysis of Meshing Polymer Gear TeethsandeepBelum ada peringkat

- wn10 eDokumen2 halamanwn10 eRani SaradeBelum ada peringkat

- Iso 6149-1Dokumen1 halamanIso 6149-1Manjunath Shankaran100% (3)

- Norma Din 3961 PDFDokumen12 halamanNorma Din 3961 PDFJosé Francisco Ramos TeixeiraBelum ada peringkat

- Steering Universal JointsDokumen11 halamanSteering Universal JointsAman JainBelum ada peringkat

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDokumen4 halamanMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaBelum ada peringkat

- Unc Thread Ansi - Asme b1.1Dokumen2 halamanUnc Thread Ansi - Asme b1.1Btvnravi TejaBelum ada peringkat

- SAE J518-1993 液压分体法兰 PDFDokumen13 halamanSAE J518-1993 液压分体法兰 PDFliu zhao liu zhaoBelum ada peringkat

- Section Q: Splined Hubs, Drive KitsDokumen8 halamanSection Q: Splined Hubs, Drive KitshaggBelum ada peringkat

- DopplerGear TechBit JIS D 2001-1959-SplinesDokumen1 halamanDopplerGear TechBit JIS D 2001-1959-SplinesJames TsaiBelum ada peringkat

- SplinesDokumen5 halamanSplinesmahesh_belgavi100% (1)

- AISI 4340 NitridingDokumen8 halamanAISI 4340 NitridingVlad Craciun100% (1)

- Design of Bearings & Miscellaneous ElementsDokumen14 halamanDesign of Bearings & Miscellaneous ElementsjvanandhBelum ada peringkat

- As 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionDokumen6 halamanAs 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionSAI Global - APACBelum ada peringkat

- Oring Sizes BS1806 PDFDokumen6 halamanOring Sizes BS1806 PDFalfred2000Belum ada peringkat

- Equivalent Grades of Gray IronDokumen2 halamanEquivalent Grades of Gray Ironsujay13780100% (1)

- DIN 935 - Hexagon Slotted Castle NutsDokumen8 halamanDIN 935 - Hexagon Slotted Castle NutsJmmy Son LiBelum ada peringkat

- Fed STD H28aDokumen11 halamanFed STD H28amurphygtBelum ada peringkat

- Ansi B92.1Dokumen10 halamanAnsi B92.1idrisbooks0% (2)

- Ansi Asabe Ad8759-2-1998 (Dec2010)Dokumen3 halamanAnsi Asabe Ad8759-2-1998 (Dec2010)StephanBelum ada peringkat

- Ansi Asabe S277.2 Feb1972 (R2008)Dokumen5 halamanAnsi Asabe S277.2 Feb1972 (R2008)StephanBelum ada peringkat

- Ansi Asabe Ad8759-1-1998 (Dec2010)Dokumen4 halamanAnsi Asabe Ad8759-1-1998 (Dec2010)StephanBelum ada peringkat

- Ansi Asabe Ad8759-1-1998 (R2013-01)Dokumen7 halamanAnsi Asabe Ad8759-1-1998 (R2013-01)StephanBelum ada peringkat

- Ansi Asabe Ad6489-3-2004 Jun2009Dokumen7 halamanAnsi Asabe Ad6489-3-2004 Jun2009StephanBelum ada peringkat

- N° Placa Marca Detalle Fecha de EntregaDokumen4 halamanN° Placa Marca Detalle Fecha de EntregaPolicarpio Mamani HuchaniBelum ada peringkat

- Gross: 165 KW 221 HP / 2100 Min Net: 163 KW 218 HP / 2100 Min 15955 KG (With Ripper 17885 KG) 4.32 MDokumen20 halamanGross: 165 KW 221 HP / 2100 Min Net: 163 KW 218 HP / 2100 Min 15955 KG (With Ripper 17885 KG) 4.32 MPolicarpio Mamani HuchaniBelum ada peringkat

- Gross: 165 KW 221 HP / 2100 Min Net: 163 KW 218 HP / 2100 Min 15955 KG (With Ripper 17885 KG) 4.32 MDokumen20 halamanGross: 165 KW 221 HP / 2100 Min Net: 163 KW 218 HP / 2100 Min 15955 KG (With Ripper 17885 KG) 4.32 MPolicarpio Mamani HuchaniBelum ada peringkat

- Gross: 165 KW 221 HP / 2100 Min Net: 163 KW 218 HP / 2100 Min 15955 KG (With Ripper 17885 KG) 4.32 MDokumen20 halamanGross: 165 KW 221 HP / 2100 Min Net: 163 KW 218 HP / 2100 Min 15955 KG (With Ripper 17885 KG) 4.32 MPolicarpio Mamani HuchaniBelum ada peringkat

- Whats New 2 7Dokumen14 halamanWhats New 2 7marcos.lopes36291861Belum ada peringkat

- Mack Vmac III E7 Etech Wiring PDFDokumen9 halamanMack Vmac III E7 Etech Wiring PDFGustavo PaezBelum ada peringkat

- Asae s278.6 Enganche Rapido Modificado 7Dokumen4 halamanAsae s278.6 Enganche Rapido Modificado 7Policarpio Mamani HuchaniBelum ada peringkat

- Weapons Equipment of The Napoleonic Wars PDFDokumen198 halamanWeapons Equipment of The Napoleonic Wars PDFsrollins92% (24)

- Gaffney S Business ContactsDokumen6 halamanGaffney S Business ContactsSara Mitchell Mitchell100% (1)

- Los Angeles County Sheriff's Department InvestigationDokumen60 halamanLos Angeles County Sheriff's Department InvestigationBen Harper0% (1)

- Faqs Harvest Moon BTNDokumen245 halamanFaqs Harvest Moon BTNMurloc NightcrawlerBelum ada peringkat

- Farm Gate TasmaniaDokumen20 halamanFarm Gate TasmaniaplouffrBelum ada peringkat

- Study of Indian Wrist Watch Industry and Repositioning Strategy of Titan WatchesDokumen60 halamanStudy of Indian Wrist Watch Industry and Repositioning Strategy of Titan WatchesVinay SurendraBelum ada peringkat

- Marimba ReferenceDokumen320 halamanMarimba Referenceapi-3752991Belum ada peringkat

- Multiple Effect EvaporatorDokumen4 halamanMultiple Effect EvaporatorKusmakarBelum ada peringkat

- Precontraint 502S2 & 702S2Dokumen1 halamanPrecontraint 502S2 & 702S2Muhammad Najam AbbasBelum ada peringkat

- Chapter 4 TeethDokumen17 halamanChapter 4 TeethAbegail RuizBelum ada peringkat

- Engg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Dokumen24 halamanEngg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Manuel MirandaBelum ada peringkat

- Presentation2 Norman FosterDokumen10 halamanPresentation2 Norman FosterAl JhanBelum ada peringkat

- AWS PowerPoint PresentationDokumen129 halamanAWS PowerPoint PresentationZack Abrahms56% (9)

- Anp 203 Group4Dokumen8 halamanAnp 203 Group4ultimate legendBelum ada peringkat

- Competitive Benchmarking Created On 20230208T0816ZDokumen1 halamanCompetitive Benchmarking Created On 20230208T0816ZRrKartika RatnasariBelum ada peringkat

- Palma vs. Fortich PDFDokumen3 halamanPalma vs. Fortich PDFKristine VillanuevaBelum ada peringkat

- Argumentative EssayDokumen5 halamanArgumentative EssayParimalar D/O RathinasamyBelum ada peringkat

- Eris User ManualDokumen8 halamanEris User ManualcasaleiroBelum ada peringkat

- Food Security: Its Components and ChallengesDokumen9 halamanFood Security: Its Components and ChallengesSimlindile NgobelaBelum ada peringkat

- Fallacy of Subjectivity:: ExamplesDokumen2 halamanFallacy of Subjectivity:: ExamplesKaustav MannaBelum ada peringkat

- Social WorkDokumen12 halamanSocial WorkAshutosh SharmaBelum ada peringkat

- Kangar 1 31/12/21Dokumen4 halamanKangar 1 31/12/21TENGKU IRSALINA SYAHIRAH BINTI TENGKU MUHAIRI KTNBelum ada peringkat

- Chapter 4Dokumen20 halamanChapter 4Alyssa Grace CamposBelum ada peringkat

- How 50 Actors Got Their Agents and ManagersDokumen5 halamanHow 50 Actors Got Their Agents and ManagersОля МовчунBelum ada peringkat

- Thesis RadioactivityDokumen13 halamanThesis RadioactivitysaanvicodingBelum ada peringkat

- With Us You Will Get Safe Food: We Follow These 10 Golden RulesDokumen2 halamanWith Us You Will Get Safe Food: We Follow These 10 Golden RulesAkshay DeshmukhBelum ada peringkat

- People Vs SantayaDokumen3 halamanPeople Vs SantayaAbigail DeeBelum ada peringkat

- Week 5 Class 2Dokumen33 halamanWeek 5 Class 2ppBelum ada peringkat

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokumen12 halamanOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodBelum ada peringkat

- Project Presentation (142311004) FinalDokumen60 halamanProject Presentation (142311004) FinalSaad AhammadBelum ada peringkat

- NASA: 45607main NNBE Interim Report1 12-20-02Dokumen91 halamanNASA: 45607main NNBE Interim Report1 12-20-02NASAdocumentsBelum ada peringkat