Transport Phenomena

Diunggah oleh

Ong ZhangHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Transport Phenomena

Diunggah oleh

Ong ZhangHak Cipta:

Format Tersedia

INTRODUCTION

Transport Phenomena

and Unit Operations III

1

Introduction

What are unit operations?

In chemical engineering and related fields, a unit

operation is a basic step in a process (like a piece of

component in LEGO). A chemical plant is just an

assembly of many unit operations. Examples include

pumps, heat exchangers, distillation towers, and

many others.

What are transport phenomena?

Transport phenomena are just a way that chemical

engineers group the knowledge about momentum,

heat and mass transfer. Transport phenomena

provide the physical principles for understanding

and improving various unit operations.

2

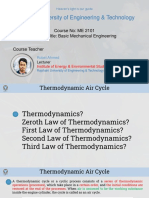

Characteristics of transport phenomena

Thermodynamics

Concerns initial and final states (not the process)

1st law of thermodynamics energy conservation

2nd law transport direction of momentum, energy or mass

Transport phenomena

Momentum transfer (Fluid mechanics) rate of momentum

transport

Momentum in transit due to velocity gradient

Heat transfer rate of thermal energy transport

Energy in transit due to temperature gradient

Mass transfer rate of mass transport

Mass in transit due to concentration gradient

3

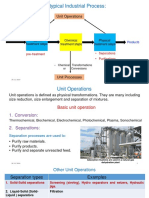

Characteristics of unit operations

Physical processes, usually involves no chemical or

biochemical reactions.

Most chemical industry processing includes a

combination of unit operations.

The individual operations in different chemical

industry processing have common techniques and

are based on the same scientific principles. Therefore,

the equipments are universal.

4

Examples of units of unit operations

Momentum

transfer

Heat transfer

Mass transfer

5

Chemical Industrial

processing, complicated and

different

Chemical or

biochemical

reactions

Physical

processes

divided into a series of

steps, called Unit

Operations. Examples

include pumping,

evaporation and

extraction.

Transport

Phenomena,

including

momentum, heat

and mass

transport

Physical

principles

Operation

Methods

6

Thermodynamics Mass and energy balance

Example: Production of milk powder

7

Example: Production of milk powder

milk clarification (centrifugal

separation) standardization

heating vaporization spray

drying Milk powder

8

Example: Production of milk powder

Milk in

Milk out

Sediment

particles

Clarification---to remove

particles from milk

Heating---to sterilize

9

Example: Production of milk powder

Falling-film evaporator Spray dryer---to get milk powder

10

Another example: Circulation of blood

Pulmonary circulation

and systemic circulation

Can you find organs that

act as pumps, valves and

pipes in this system?

Can you tell where heat

transfer and mass

transfer happen?

11

Process flowsheet: production of fatty

acid and soap

Process flowsheet: Butane isomerization

Units:

- Heaters/heat exchangers

- Pumps

- Distillation units

- Reactors

-

Actions:

- Heat exchange

- Material transport

- Separation

- Mixing

-

Comparison of two processes

What have we learned?

In unit operations I:

Momentum transfer

(Fluid mechanics)

In unit operations II:

Heat transfer

Mass transfer

And the analogy among them

So, what is in Unit operations III?

Fluid flow processes

- fluid transport

- solids fluidization

- mixing

Heat transfer processes

- heating/cooling

- evaporation/condensation

Mass transfer processes

- centrifugation

- absorption

- distillation

- extraction

- adsorption

- drying

Thermodynamic processes

- liquefaction

- refrigeration

Mechanical processes

- crushing

- sieving

- solid transportation

Unit Operations: Classification

Unit operations III is mainly about

separation processes

17

What are separation processes?

Separation processes are defined as those operations

which transform a mixture of substances into two or

more products which differ from each other in

composition.

separated

mixed

Examples of separation processes

18

1. Separation of blood.

2.Purification of drugs.

3.Purification of Au, Ag, Ti.

4.Refining of crude oil.

5.DNA testing.

6.Purification of organic material.

7.Purification of water.

8.Separation of water and waste product of metabolism

from blood Kidney

Why separation processes important?

19

Need for pure material in engineering applications.

Preparation of raw materials into their component.

Need for pure material for materials processing.

Need to remove toxins or inactive components from

solution (drugs, waste)

Need for ultra-pure samples for testing.

Need for analysis of the components of mixture (DNA

testing)

50 to 90 percent of capital investment in chemical

plant is for separation equipment.

Separation mechanisms

Driving force

Size: Membrane (filtration, micro-filtration,

ultra-filtration/nano, reverse osmosis)

Phase change: Distillation, crystallization

Chemical affinity: Absorption (vs. stripping),

extraction, Adsorption (ion exchange,

chromatography)

Others: Electric field(electrophoresis,

electrolysis), Magnetic field,

Gravity/centrifugation (density)

The cost of separation

21

The mixing of chemicals to form a mixture is a

spontaneous, natural process that is accompanied

by an increase in entropy or randomness (S)

The inverse process (the separation of the mixture

into its constituent chemical species) is not

spontaneous process, it requires an expenditure of

energy.

Anda mungkin juga menyukai

- Chemical Engineering Unit OperationsDokumen2 halamanChemical Engineering Unit OperationsChristianBelum ada peringkat

- Basic Principles and Parameters For IndustrialDokumen5 halamanBasic Principles and Parameters For Industrialworlds tour63% (16)

- Adsorption TutorialDokumen44 halamanAdsorption Tutorialjohn ndloviniBelum ada peringkat

- Unit Operations of Agricultural ProcessingDokumen2 halamanUnit Operations of Agricultural ProcessingMonika KshBelum ada peringkat

- Industrial Processes of Heat TransferDokumen4 halamanIndustrial Processes of Heat TransferMontaña, Arabella F.Belum ada peringkat

- Unit Operations Guide for Chemical Engineering SeparationsDokumen38 halamanUnit Operations Guide for Chemical Engineering SeparationsRenu SekaranBelum ada peringkat

- Separation Processes HandoutDokumen10 halamanSeparation Processes Handoutkiran367Belum ada peringkat

- Unit Operation - WikipediaDokumen11 halamanUnit Operation - WikipediaManojkumarBelum ada peringkat

- Lec #2Dokumen37 halamanLec #2hdjdjsysndBelum ada peringkat

- InglésI EVP1 20212 - Piero HerreraDokumen6 halamanInglésI EVP1 20212 - Piero HerreraPIERO MATIAS HERRERA SUAREZBelum ada peringkat

- What is chemical engineeringDokumen8 halamanWhat is chemical engineeringErwin CabangalBelum ada peringkat

- 1 - Introduction To Chemical Process IndustriesDokumen13 halaman1 - Introduction To Chemical Process IndustriesVenus Abigail GutierrezBelum ada peringkat

- Interview QuestionDokumen7 halamanInterview Questionstarshine238100% (5)

- PE 311 (13 Credits) :: Unit Operation For Petroleum IndustryDokumen52 halamanPE 311 (13 Credits) :: Unit Operation For Petroleum IndustryMbarouk Shaame MbaroukBelum ada peringkat

- Separation Processes: Dr. M. Azam SaeedDokumen24 halamanSeparation Processes: Dr. M. Azam SaeedUsama NajamBelum ada peringkat

- Mass Transfer Operation: An OverviewDokumen13 halamanMass Transfer Operation: An OverviewFaturrohman SetyoajiBelum ada peringkat

- Chemical Unit Operations: Lecture - 4Dokumen9 halamanChemical Unit Operations: Lecture - 4Farah MoulydiaBelum ada peringkat

- Mo-Hinh-Hoa - Hoang-Ngoc-Ha - Baigiang - Mohinhhoa - (Cuuduongthancong - Com)Dokumen50 halamanMo-Hinh-Hoa - Hoang-Ngoc-Ha - Baigiang - Mohinhhoa - (Cuuduongthancong - Com)Nguyen Thanh LauBelum ada peringkat

- Mass Transfer Fundamentals Ch.E-304: Muhammad Rashed JavedDokumen18 halamanMass Transfer Fundamentals Ch.E-304: Muhammad Rashed JavedTalha ImtiazBelum ada peringkat

- Chapter 1 - IntroductionDokumen23 halamanChapter 1 - IntroductionHung QuangBelum ada peringkat

- Le01 Up Ma Fa22 IntroDokumen33 halamanLe01 Up Ma Fa22 IntroHamza RahimBelum ada peringkat

- Chapter 1 - Mass Balance New PDFDokumen93 halamanChapter 1 - Mass Balance New PDFMuhammad Azri HaziqBelum ada peringkat

- Unit operations: heart of chemical engineeringDokumen6 halamanUnit operations: heart of chemical engineeringMaten NasradinBelum ada peringkat

- Chemical Plant Is Required Carry Out Transformation Chemical EngineeringDokumen6 halamanChemical Plant Is Required Carry Out Transformation Chemical EngineeringHans August ARBelum ada peringkat

- Process Synthesis (Process Creation)Dokumen32 halamanProcess Synthesis (Process Creation)Göksu KutluBelum ada peringkat

- Lecture 1Dokumen12 halamanLecture 1TaytoBelum ada peringkat

- Important Questions in Mass Transfer Operations 1685190603Dokumen5 halamanImportant Questions in Mass Transfer Operations 1685190603zhyar didarBelum ada peringkat

- Industrial Unit Operations and Processes ExplainedDokumen53 halamanIndustrial Unit Operations and Processes ExplainedQanh ZrarBelum ada peringkat

- Written Report in Heat TransferDokumen4 halamanWritten Report in Heat TransferJoshua PeregrinaBelum ada peringkat

- ChE 220 Mod 1 Introduction 2020-2021Dokumen65 halamanChE 220 Mod 1 Introduction 2020-2021Claire G. MagluyanBelum ada peringkat

- Assignment: Equipments Used in Pharmaceutical Industry For Heat and Mass TransferDokumen17 halamanAssignment: Equipments Used in Pharmaceutical Industry For Heat and Mass TransferM Aftab ShabirBelum ada peringkat

- Unit Operations and Processes in Environmental Engineering Solution Manual FreeDokumen2 halamanUnit Operations and Processes in Environmental Engineering Solution Manual FreeJaime Fisica RedolfoBelum ada peringkat

- Lecture 3 (B) - 308572 ChE 312 PSD1-Part I, Heuristics For Process Synthesis PDFDokumen14 halamanLecture 3 (B) - 308572 ChE 312 PSD1-Part I, Heuristics For Process Synthesis PDFFahad MahmoodBelum ada peringkat

- Ethydo InfinityDokumen18 halamanEthydo Infinitysherifelbayoumy266Belum ada peringkat

- Heat Transfer: An IntroductionDokumen54 halamanHeat Transfer: An Introductionk2027485Belum ada peringkat

- Chemical Engineering: Course Title: Chemical Engineering Process Analysis 1 Course Code CHE 310Dokumen25 halamanChemical Engineering: Course Title: Chemical Engineering Process Analysis 1 Course Code CHE 310Tife BakreBelum ada peringkat

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDokumen37 halamanInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalBelum ada peringkat

- Intro To Chem Eng PDFDokumen7 halamanIntro To Chem Eng PDFAjay SagarBelum ada peringkat

- 1 Introduction UPCT HKBDokumen50 halaman1 Introduction UPCT HKBRohan GohilBelum ada peringkat

- Heuristics For Process SynthesisDokumen26 halamanHeuristics For Process SynthesisThien LeBelum ada peringkat

- Industrial Process Calculations CHE 341Dokumen145 halamanIndustrial Process Calculations CHE 341ZanyboiBelum ada peringkat

- In Plant Training ReportDokumen12 halamanIn Plant Training ReportHrushikesh PatilBelum ada peringkat

- Industrial Chemistry Material BalancesDokumen318 halamanIndustrial Chemistry Material BalancestesfayeBelum ada peringkat

- Unit Operation: 2 Chemical EngineeringDokumen3 halamanUnit Operation: 2 Chemical EngineeringMohammad Hosein KhanesazBelum ada peringkat

- Chemical Processes: Engr. Concordia C. Bacalso M. Eng'g (Education)Dokumen21 halamanChemical Processes: Engr. Concordia C. Bacalso M. Eng'g (Education)Ivan AlcomendrasBelum ada peringkat

- ChE 351 - Lecture 1Dokumen44 halamanChE 351 - Lecture 1mgyekum124Belum ada peringkat

- Chapter 5 - Common Hazards in Chemical Processing PlantsDokumen46 halamanChapter 5 - Common Hazards in Chemical Processing PlantsHaroshi TatsuyaBelum ada peringkat

- Nilesh 2Dokumen54 halamanNilesh 2milBelum ada peringkat

- Thermodynamic Cycle, Gas Turbine, Turbo-Super ChargerDokumen30 halamanThermodynamic Cycle, Gas Turbine, Turbo-Super ChargerTamim Islam JoyBelum ada peringkat

- Mass Transfer Project 1 PDFDokumen25 halamanMass Transfer Project 1 PDFwasie kebire0% (1)

- Petroleum ProcessingDokumen22 halamanPetroleum ProcessingMark Anthony FauneBelum ada peringkat

- Thermal ZiaDokumen4 halamanThermal ZiaImad Uddin khanBelum ada peringkat

- Mulungushi University: School of Science Engineering and Technology CHE 491 - Industrial Chemistry 1Dokumen50 halamanMulungushi University: School of Science Engineering and Technology CHE 491 - Industrial Chemistry 1mukuka lawrenceBelum ada peringkat

- Transport ProcessDokumen32 halamanTransport Processpidexhitam67% (3)

- Heat Transfer Enhancement Using Nanofluid Flow in Microchannels: Simulation of Heat and Mass TransferDari EverandHeat Transfer Enhancement Using Nanofluid Flow in Microchannels: Simulation of Heat and Mass TransferBelum ada peringkat

- WEEE Recycling: Research, Development, and PoliciesDari EverandWEEE Recycling: Research, Development, and PoliciesAlexandre ChagnesBelum ada peringkat

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsDari EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsBelum ada peringkat

- Industrial Chemical Process Analysis and DesignDari EverandIndustrial Chemical Process Analysis and DesignPenilaian: 4 dari 5 bintang4/5 (2)

- Plate Girder DesignDokumen109 halamanPlate Girder Designhasib100% (3)

- Space Programming 1Dokumen10 halamanSpace Programming 1Mache SebialBelum ada peringkat

- Anchor Bolt BiAxialDokumen10 halamanAnchor Bolt BiAxialALPHYL BALASABASBelum ada peringkat

- Digital VLSI System Design Prof. Dr. S. Ramachandran Department of Electrical Engineering Indian Institute of Technology, MadrasDokumen30 halamanDigital VLSI System Design Prof. Dr. S. Ramachandran Department of Electrical Engineering Indian Institute of Technology, MadrasPronadeep BoraBelum ada peringkat

- Ship Stability 5Dokumen31 halamanShip Stability 5jeaneva guiaoBelum ada peringkat

- Objective SAMPLEDokumen4 halamanObjective SAMPLEAnnjen MuliBelum ada peringkat

- Sourav Roy - Loan IQ AnalystDokumen4 halamanSourav Roy - Loan IQ AnalystSourav RoyBelum ada peringkat

- Soalan Assignment Stm10173Dokumen7 halamanSoalan Assignment Stm10173Razanah RozaimayBelum ada peringkat

- Detailed Analysis of Plane Table SurveyingDokumen11 halamanDetailed Analysis of Plane Table SurveyingNirbhay SinghBelum ada peringkat

- LATERAL EARTH PRESSURE CALCULATIONSDokumen55 halamanLATERAL EARTH PRESSURE CALCULATIONSRakesh SheteBelum ada peringkat

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDokumen24 halamanACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaBelum ada peringkat

- COILDATADokumen1 halamanCOILDATABarış TaşkınBelum ada peringkat

- Jockey Pump BrochureDokumen8 halamanJockey Pump BrochuregbogboiweBelum ada peringkat

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDokumen10 halamanA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJEBelum ada peringkat

- Beer and Johnston Detailed Table of ContentsDokumen10 halamanBeer and Johnston Detailed Table of Contentsdhruv001Belum ada peringkat

- Driver Control Master NXT Service Manual 092137-8Dokumen53 halamanDriver Control Master NXT Service Manual 092137-8Piero Capretti0% (1)

- Ducha EmpotradaDokumen1 halamanDucha Empotradagilmar melendresBelum ada peringkat

- Linear System Theory and Desing PDFDokumen688 halamanLinear System Theory and Desing PDFJose David MartinezBelum ada peringkat

- VAS5054ADokumen3 halamanVAS5054AKarim ElmahrokyBelum ada peringkat

- Evo Controller 8200 IP Configuration KODokumen56 halamanEvo Controller 8200 IP Configuration KORogerioBelum ada peringkat

- SHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016Dokumen27 halamanSHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016jscansinoBelum ada peringkat

- Fls Brochure Usa v2 PDFDokumen4 halamanFls Brochure Usa v2 PDFXa ViBelum ada peringkat

- Hydrology Lecture01Dokumen24 halamanHydrology Lecture01Mohd. YunusBelum ada peringkat

- Fabricación de Insertos de Carburo de TungstenoDokumen5 halamanFabricación de Insertos de Carburo de TungstenoRolando Nuñez MonrroyBelum ada peringkat

- UAE Visa Occupation ListDokumen89 halamanUAE Visa Occupation ListSiddharth JaloriBelum ada peringkat

- Faa Gleim Outlines Instrument PilotDokumen130 halamanFaa Gleim Outlines Instrument PilotTalaat SalehBelum ada peringkat

- Centerline Alfa Catalog13Dokumen53 halamanCenterline Alfa Catalog13sisonco100% (1)

- ABB 4 Pole Contactor, 230V, 40ADokumen1 halamanABB 4 Pole Contactor, 230V, 40ASEERALANBelum ada peringkat

- JNTU Previous Paper Questions ThermodynamicsDokumen61 halamanJNTU Previous Paper Questions ThermodynamicsVishnu MudireddyBelum ada peringkat

- IJET 15473 Lavanya PDFDokumen5 halamanIJET 15473 Lavanya PDFDr.S.Sujatha Asst.Prof.Belum ada peringkat