Epoxy Anchoring Adhesive: Simpson Strong-Tie Anchoring and Fastening Systems For Concrete and Masonry

Diunggah oleh

Jonathan Douglas0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

12 tayangan1 halamanEDOT adhesive is formulated to provide an economical and high-strength solution for transportation projects. Resin and hardener are dispensed and mixed simultaneously through the static mixing nozzle. EDOT meets the requirements of ASTM C-881 and AASHTO M235 specifications for Type I, II, IV and V, Grade 3, Class C.

Deskripsi Asli:

Judul Asli

C-SAS-2012-p047

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniEDOT adhesive is formulated to provide an economical and high-strength solution for transportation projects. Resin and hardener are dispensed and mixed simultaneously through the static mixing nozzle. EDOT meets the requirements of ASTM C-881 and AASHTO M235 specifications for Type I, II, IV and V, Grade 3, Class C.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

12 tayangan1 halamanEpoxy Anchoring Adhesive: Simpson Strong-Tie Anchoring and Fastening Systems For Concrete and Masonry

Diunggah oleh

Jonathan DouglasEDOT adhesive is formulated to provide an economical and high-strength solution for transportation projects. Resin and hardener are dispensed and mixed simultaneously through the static mixing nozzle. EDOT meets the requirements of ASTM C-881 and AASHTO M235 specifications for Type I, II, IV and V, Grade 3, Class C.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

47

C

-

S

A

S

-

2

0

1

2

2

0

1

2

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Simpson Strong-Tie

Anchoring and Fastening Systems for Concrete and Masonry

E

p

o

x

y

A

d

h

e

s

i

v

e

s

EDTA22P EMN22i

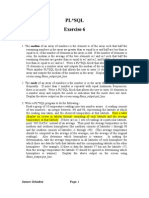

EDOT Epoxy Anchoring Adhesive

EDOT adhesive is formulated to provide an economical and high-strength

solution for transportation projects.* It is a two component, high-solids

epoxy-based system that is a non-shrink anchor grouting material. Resin

and hardener are dispensed and mixed simultaneously through the static

mixing nozzle. EDOT meets the requirements of ASTM C-881 and AASHTO

M235 specications for Type I, II, IV and V, Grade 3, Class C.

*Visit www.strongtie.com/dot for specic state DOT approvals.

USES: Threaded rod anchoring

Rebar doweling

APPLICATION: Surfaces to receive epoxy must be clean. The base material

temperature must be 40F or above at the time of installation. For best

results, material should be 70F80F at the time of application. Cartridges

should not be immersed in water to facilitate warming. To warm cold

material, the cartridges should be stored in warm, uniformly heated area or

storage container for a sufcient time to allow epoxy to warm completely.

Mixed material in nozzle can harden in 5-7 minutes at a temperature of 40F

or above.

INSTALLATION: See pages 7071.

SHELF LIFE: 24 months from date of manufacture in unopened container.

STORAGE CONDITIONS: For best results, store between 45F90F. To store

partially used cartridges, leave hardened nozzle in place. To re-use, attach

new nozzle.

COLOR: Resin white, hardener brown

When properly mixed, EDOT adhesive will be a uniform and consistent tan

color.

CLEAN UP: Uncured material Wipe up with cotton cloths. If desired, scrub

area with abrasive, waterbased cleaner and ush with water. If approved,

solvents such as ketones (MEK, acetone, etc.), lacquer thinner, or adhesive

remover can be used. DO NOT USE SOLVENTS TO CLEAN ADHESIVE FROM

SKIN. Take appropriate precautions when handling ammable solvents.

Solvents may damage surfaces to which they are applied. Cured material

Chip or grind off surface.

TEST CRITERIA: Anchors installed with EDOT adhesive have been tested in

accordance with ASTM E488 and ASTM E1512.

PROPERTY TEST METHOD RESULTS

Consistency (77F) ASTM C-881 Non-sag/ thixotropic paste

Heat deection ASTM D-648 129F (54C)

Bond strength (moist cure) ASTM C-882 3054 psi (2 days)

3425 psi (14 days)

Water absorption ASTM D-570 0.04% (24 hours)

Compressive yield strength ASTM D-695 10,053 psi (7 days)

Compressive modulus ASTM D-695 393,000 psi (7 days)

Gel time ASTM C-881 46 min. @ 73 F (23C)

32 min. @ 90 F (32C)

CHEMICAL RESISTANCE Very good to excellent against distilled water,

dilute inorganic acids and alkalis. Fair to good against organic acids and

alkalis, and many organic solvents. Poor against ketones. For more detailed

information, visit www.strongtie.com or contact SimpsonStrong-Tie.

SUGGESTED SPECIFICATIONS: Anchoring adhesives shall be a two-

component high solids epoxy based system dispensed through a static

mixing nozzle supplied by the manufacturer. Epoxy shall meet the minimum

requirements of ASTM C881 and AASHTO M235 specication for Type

I, II, IV, and V, Grade 3, Class C, and must develop a minimum 10,000

psi compressive yield strength after 7 day cure. Epoxy must have a heat

deection temperature of a minimum 125F (52C). Adhesive shall be

EDOT adhesive from SimpsonStrong-Tie, Pleasanton, CA. Anchors shall

be installed per SimpsonStrong-Tie instructions for EDOT adhesive.

ACCESSORIES: See pages 7277 for information on dispensing tools, mixing

nozzles and other accessories.

Cure Schedule

In-Service Temperature

Sensitivity

Pot Life for 1

gallon mixed

Base Material

Temperature

Cure

Time

F C

40 4 72 hrs

60 16 24 hrs

80 27 24 hrs

100 38 24 hrs

Base Material

Temperature

Percent of

Allowable

load

F C

40 4 100%

70 21 100%

110 43 100%

135 57 85%

Adhesive

Temperature

Pot

Life

time

(min)

F C

60 16 60

70 21 35

80 27 25

90 32 15

100 38 10

EDOT Package Systems

Model No.

Capacity

(cubic

inches)

Package

Type

Carton

Quantity

Dispensing Tool(s)

Mixing

Nozzle

EDOT22

22 ounces

(39.7)

Cartridge,

Side-by-side

10

EDT22S, EDTA22P,

EDT22CKT

EMN22i

EDOT56

56 ounces

(101.1)

Cartridge,

Side-by-side

6 EDTA56P

EMN22i or

EMN50

EDOT1KT

1 gallon kit

(231)

(2)

1

2 gal

pails

1 kit Metering pump EMN37A

EDOT10KT

10 gallon

kit (2,310)

(2) 5 gallon

pails

1 kit Metering pump EMN37A

EDOT100KT

100 gallon

kit (23,100)

(2) 50 gallon

drums

1 kit Metering pump EMN37A

1. Cartridge and bulk Estimation Guides are available on pages 4851.

2. Detailed information on dispensing tools, mixing nozzles and other adhesive

accessories is available on pages 7277.

3. Use only appropriate SimpsonStrong-Tie

mixing nozzle in accordance with

SimpsonStrong-Tie instructions. Modification or improper use of mixing nozzle

may impair epoxy performance.

4. Metering pumps offered by third-party manufacturers.

IMPORTANT See Pages 7071 for Installation Instructions

EDOT22

EDOT 1 gallon kit EDOT 10 gallon kit

EDOT56

Anda mungkin juga menyukai

- 5CT PDVSA em - 18!00!05 EnglishDokumen27 halaman5CT PDVSA em - 18!00!05 EnglishJuan Gutierrez100% (1)

- MAT Foundation DesignDokumen35 halamanMAT Foundation DesignHim Yilay100% (2)

- InvoiceDokumen1 halamanInvoiceKidambi SureshBelum ada peringkat

- Surface Mount Technology Terms and ConceptsDari EverandSurface Mount Technology Terms and ConceptsPenilaian: 5 dari 5 bintang5/5 (1)

- Examples of Consonant BlendsDokumen5 halamanExamples of Consonant BlendsNim Abd MBelum ada peringkat

- Safety Training Brochure MetaboDokumen4 halamanSafety Training Brochure MetaboJonathan DouglasBelum ada peringkat

- Amercoat 370Dokumen3 halamanAmercoat 370Victor Hugo Bustos Beltran100% (1)

- ASTM A193 - Portland Bolt PDFDokumen2 halamanASTM A193 - Portland Bolt PDFJonathan Douglas100% (1)

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignDokumen12 halamanBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliBelum ada peringkat

- Dow Corning RTV InfoDokumen20 halamanDow Corning RTV InfoLevent ÖnderBelum ada peringkat

- 2 Ton Epoxy: Technical Data SheetDokumen2 halaman2 Ton Epoxy: Technical Data SheetLeomar TorrealbaBelum ada peringkat

- 2 Ton Epoxy TDSDokumen2 halaman2 Ton Epoxy TDSFrichsGabinoCondoriMonzonBelum ada peringkat

- 3M2216Dokumen8 halaman3M2216pat_kunal1601Belum ada peringkat

- Grout AlternatesDokumen2 halamanGrout AlternatesAnonymous ua66zYwrpBelum ada peringkat

- 323 Data Sheet and Application GuideDokumen4 halaman323 Data Sheet and Application Guidejast111Belum ada peringkat

- Euco 452 EpoxyDokumen2 halamanEuco 452 Epoxypravi3434Belum ada peringkat

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDokumen8 halaman3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaBelum ada peringkat

- 0091 Amercoat 91 PDS May 08Dokumen2 halaman0091 Amercoat 91 PDS May 08donaldoguerreroBelum ada peringkat

- Floor Patch Fast CureDokumen2 halamanFloor Patch Fast CureStevenFerrelBelum ada peringkat

- CE604 Pavement Sealant TDS 11.17Dokumen2 halamanCE604 Pavement Sealant TDS 11.17Aditya WiratamaBelum ada peringkat

- Basf Masterflow 668 TdsDokumen4 halamanBasf Masterflow 668 Tdsgazwang478Belum ada peringkat

- Devran 224HS PdsDokumen2 halamanDevran 224HS Pdsjopedro96Belum ada peringkat

- File 1495037066Dokumen4 halamanFile 1495037066Paul WheelerBelum ada peringkat

- DevCon 5 Minute Epoxy Technical Data SheetDokumen2 halamanDevCon 5 Minute Epoxy Technical Data Sheetjohn432questBelum ada peringkat

- Epoxylite 578EB - TDS - 2008Dokumen3 halamanEpoxylite 578EB - TDS - 2008beemer5Belum ada peringkat

- Nitobond Ep..Dokumen4 halamanNitobond Ep..budhikurniawanBelum ada peringkat

- Conbextra Ep65Dokumen3 halamanConbextra Ep65Angelo Carlo MalabananBelum ada peringkat

- Interseal 670 HSDokumen4 halamanInterseal 670 HSSyawaluddin Fitri AwangBelum ada peringkat

- Conbextra EP Data SheetDokumen4 halamanConbextra EP Data Sheetprabhu81Belum ada peringkat

- Datasheet SP 2000wDokumen2 halamanDatasheet SP 2000wWilliam Boyle Jr.Belum ada peringkat

- DP8805NS + DP8810NS Tech Data SheetDokumen6 halamanDP8805NS + DP8810NS Tech Data SheetPaul TushausBelum ada peringkat

- Hind ERS 31 (LV)Dokumen2 halamanHind ERS 31 (LV)Rajesh GiriBelum ada peringkat

- Flexane 80 CompoundDokumen3 halamanFlexane 80 Compoundabh_omegaBelum ada peringkat

- Devran 224HS Epoxy 4392 P Eng Usa LTRDokumen4 halamanDevran 224HS Epoxy 4392 P Eng Usa LTRAlex Torres CamizanBelum ada peringkat

- Amercoat 450H PDSDokumen7 halamanAmercoat 450H PDSNnamdi AmadiBelum ada peringkat

- Interzone 101Dokumen0 halamanInterzone 101hennawijayaBelum ada peringkat

- Loctite 324™: Technical Data SheetDokumen3 halamanLoctite 324™: Technical Data SheetUgan Git PadayacheeBelum ada peringkat

- MasterEmaco ADH 326 (Concresive Liq)Dokumen4 halamanMasterEmaco ADH 326 (Concresive Liq)RodCorniBelum ada peringkat

- Carbo Guard 893 SGDokumen2 halamanCarbo Guard 893 SGsuzilamatsallehBelum ada peringkat

- Kodak, Single-Use Chemistry Kit, ProcessDokumen8 halamanKodak, Single-Use Chemistry Kit, ProcessErden Sizgek100% (2)

- Azko Coating Hjf14r r4 Es eDokumen4 halamanAzko Coating Hjf14r r4 Es eKrishna KumarBelum ada peringkat

- Upvc Solvent CementsDokumen1 halamanUpvc Solvent CementsMathi Vinoth PillaiBelum ada peringkat

- ChemflakeDokumen5 halamanChemflakeManohar SeetharamBelum ada peringkat

- Sealbond 218 P Pressure Injection EpoxyDokumen1 halamanSealbond 218 P Pressure Injection EpoxyLeoven Jef Suzara Lorin0% (1)

- TDS Nitobond EP Saudi Arabia2Dokumen3 halamanTDS Nitobond EP Saudi Arabia2subhashisBelum ada peringkat

- Anquamine 731Dokumen4 halamanAnquamine 731Cloudy DayBelum ada peringkat

- 870 AbDokumen4 halaman870 Ablacsmm982Belum ada peringkat

- Interbond 600 PDFDokumen4 halamanInterbond 600 PDFTrịnh Minh KhoaBelum ada peringkat

- Scotch KoteDokumen4 halamanScotch KoteJavier Gomez ReyesBelum ada peringkat

- Sikadur - 42 HES (VP) : 3-Part, High Performance, Low Exothermic, Pourable Epoxy Grouting SystemDokumen4 halamanSikadur - 42 HES (VP) : 3-Part, High Performance, Low Exothermic, Pourable Epoxy Grouting SystemAjay SastryBelum ada peringkat

- Ceilcote 680 Primer AKZO PDFDokumen4 halamanCeilcote 680 Primer AKZO PDFamitzalteBelum ada peringkat

- Physical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRDokumen1 halamanPhysical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRAlberto GutierrezBelum ada peringkat

- Carboguard 891: Selection & Specification DataDokumen4 halamanCarboguard 891: Selection & Specification DataPrakashBelum ada peringkat

- Loctite 5182Dokumen3 halamanLoctite 5182ccorp0089Belum ada peringkat

- Amercoat® 385: Product Data SheetDokumen8 halamanAmercoat® 385: Product Data SheetSampath GaneshBelum ada peringkat

- Euco 620 EpoxyDokumen2 halamanEuco 620 Epoxypravi3434Belum ada peringkat

- Epoxoline Series 141: Product ProfileDokumen2 halamanEpoxoline Series 141: Product ProfileD_D_76Belum ada peringkat

- Loctite 567Dokumen3 halamanLoctite 567Nandani MangaleeBelum ada peringkat

- Formula 152 Topcoat (MILDTL-24441)Dokumen4 halamanFormula 152 Topcoat (MILDTL-24441)Trịnh Minh KhoaBelum ada peringkat

- Five Star Rapid Epoxy GroutDokumen2 halamanFive Star Rapid Epoxy GroutJohnprasannaBelum ada peringkat

- (Painting) Jotamastic 87Dokumen5 halaman(Painting) Jotamastic 87Mohd FadliBelum ada peringkat

- WF Ae390Dokumen6 halamanWF Ae390dadang2121Belum ada peringkat

- C Eagle (Va10 51) TDSDokumen1 halamanC Eagle (Va10 51) TDSzoranbr1Belum ada peringkat

- Euco 352 EpoxyDokumen2 halamanEuco 352 Epoxypravi3434Belum ada peringkat

- HysolDokumen2 halamanHysoljorgequijanoBelum ada peringkat

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Devmat - 142HB - Eng - A4 - 20150205Dokumen4 halamanE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Devmat - 142HB - Eng - A4 - 20150205z6ytg7mcrjBelum ada peringkat

- DF2 SS LS DatasheetDokumen4 halamanDF2 SS LS DatasheetJonathan DouglasBelum ada peringkat

- Technical Data: Drillfast Stainless Df12-Ss Standard FastenersDokumen6 halamanTechnical Data: Drillfast Stainless Df12-Ss Standard FastenersJonathan DouglasBelum ada peringkat

- Ropower 50R PDFDokumen2 halamanRopower 50R PDFJonathan DouglasBelum ada peringkat

- Chapter 4 - FasteningsDokumen12 halamanChapter 4 - FasteningsJonathan DouglasBelum ada peringkat

- C A 2018 ET HP DesigninfoDokumen9 halamanC A 2018 ET HP DesigninfoJonathan DouglasBelum ada peringkat

- DS Grinder Sell Sheet US1074 051717Dokumen2 halamanDS Grinder Sell Sheet US1074 051717Jonathan DouglasBelum ada peringkat

- HSBR14 Tec Dgu GB 1Dokumen2 halamanHSBR14 Tec Dgu GB 1Jonathan DouglasBelum ada peringkat

- Limited Edition Angle Grinder: Safety Clutch: 50 AnniversaryDokumen1 halamanLimited Edition Angle Grinder: Safety Clutch: 50 AnniversaryJonathan DouglasBelum ada peringkat

- Next Gen Grinder Broch US1054 041017 TrifoldDokumen2 halamanNext Gen Grinder Broch US1054 041017 TrifoldJonathan DouglasBelum ada peringkat

- Performance Grinder Brochure US1069 051616ADokumen4 halamanPerformance Grinder Brochure US1069 051616AJonathan DouglasBelum ada peringkat

- ASTM A194 - Portland BoltDokumen3 halamanASTM A194 - Portland BoltJonathan DouglasBelum ada peringkat

- Anchoring Adhesive: AcrylicDokumen1 halamanAnchoring Adhesive: AcrylicJonathan DouglasBelum ada peringkat

- Fixfast DF12 H15 DatasheetDokumen6 halamanFixfast DF12 H15 DatasheetJonathan DouglasBelum ada peringkat

- Fixfast DF12 HT DatasheetDokumen6 halamanFixfast DF12 HT DatasheetJonathan DouglasBelum ada peringkat

- Fixfast DF2 LS Stitcher Datasheet 2Dokumen6 halamanFixfast DF2 LS Stitcher Datasheet 2Jonathan DouglasBelum ada peringkat

- 2 Cellulose Filter Cassettes 631933000 English PDFDokumen1 halaman2 Cellulose Filter Cassettes 631933000 English PDFJonathan DouglasBelum ada peringkat

- Suction Hose 27 MM L 3 5 M A-58 30 35mm Antistatic 631939000 English PDFDokumen1 halamanSuction Hose 27 MM L 3 5 M A-58 30 35mm Antistatic 631939000 English PDFJonathan DouglasBelum ada peringkat

- VGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveDokumen5 halamanVGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveJonathan DouglasBelum ada peringkat

- Estimating Guides: Estimating Guide For 8.5 Oz. Cartridge Using Threaded Rod - Installations Per CartridgeDokumen4 halamanEstimating Guides: Estimating Guide For 8.5 Oz. Cartridge Using Threaded Rod - Installations Per CartridgeJonathan DouglasBelum ada peringkat

- Stonecoal v3 Guidelines 2023-03-22Dokumen71 halamanStonecoal v3 Guidelines 2023-03-22Esha RamaswamiBelum ada peringkat

- RCU II Open Protocol Communication Manual FV 9 10 31 08 PDFDokumen17 halamanRCU II Open Protocol Communication Manual FV 9 10 31 08 PDFAndrés ColmenaresBelum ada peringkat

- Micron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesDokumen92 halamanMicron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesAEBelum ada peringkat

- Legal NoticeDokumen3 halamanLegal NoticeT Jayant JaisooryaBelum ada peringkat

- Thermo Exam QuestionsDokumen4 halamanThermo Exam QuestionssiskieoBelum ada peringkat

- Annual Premium Statement: Bhupesh GuptaDokumen1 halamanAnnual Premium Statement: Bhupesh GuptaBhupesh GuptaBelum ada peringkat

- Police Log September 24, 2016Dokumen14 halamanPolice Log September 24, 2016MansfieldMAPoliceBelum ada peringkat

- Graph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)Dokumen8 halamanGraph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)LeeshaaLenee Paramanantha KumarBelum ada peringkat

- KC CVDokumen2 halamanKC CVVishal KeshriBelum ada peringkat

- Electrochemistry DPP-1Dokumen2 halamanElectrochemistry DPP-1tarunBelum ada peringkat

- Bird Beak Adaptations: PurposeDokumen9 halamanBird Beak Adaptations: PurposelilazrbBelum ada peringkat

- Report On Sonepur MelaDokumen4 halamanReport On Sonepur Melakashtum23Belum ada peringkat

- Syllabus Financial AccountingDokumen3 halamanSyllabus Financial AccountingHusain ADBelum ada peringkat

- Keepa ApiDokumen55 halamanKeepa ApiQazi Sohail AhmadBelum ada peringkat

- Irshad KamilDokumen11 halamanIrshad Kamilprakshid3022100% (1)

- Flexure Hinge Mechanisms Modeled by Nonlinear Euler-Bernoulli-BeamsDokumen2 halamanFlexure Hinge Mechanisms Modeled by Nonlinear Euler-Bernoulli-BeamsMobile SunBelum ada peringkat

- Yusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, VietnamDokumen19 halamanYusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, Vietnamadamant751Belum ada peringkat

- Fractal Approach in RoboticsDokumen20 halamanFractal Approach in RoboticsSmileyBelum ada peringkat

- 2 Issues in Language LearningDokumen30 halaman2 Issues in Language LearningEva JakupcevicBelum ada peringkat

- Osssc JR Clerk Odia Paper 2015 - 20171207 - 0001Dokumen7 halamanOsssc JR Clerk Odia Paper 2015 - 20171207 - 0001songspk100Belum ada peringkat

- Congenital Abnormalities of The Female Reproductive TractDokumen14 halamanCongenital Abnormalities of The Female Reproductive TractMary SheshiraBelum ada peringkat

- ADM-FR-003 Student Directory FormDokumen2 halamanADM-FR-003 Student Directory FormRahayuBelum ada peringkat

- PL SQL Exercise6Dokumen2 halamanPL SQL Exercise6Nishant AndhaleBelum ada peringkat

- HandwritingDokumen4 halamanHandwritingManujBelum ada peringkat

- Isabela State University: Republic of The Philippines Roxas, IsabelaDokumen17 halamanIsabela State University: Republic of The Philippines Roxas, IsabelaMarinette MedranoBelum ada peringkat