How To Make Soap

Diunggah oleh

thoughtseek0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

235 tayangan5 halamanGuide on how to make body, cleaning and laundry soap using basic ingredients.

Judul Asli

How to make soap

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniGuide on how to make body, cleaning and laundry soap using basic ingredients.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

235 tayangan5 halamanHow To Make Soap

Diunggah oleh

thoughtseekGuide on how to make body, cleaning and laundry soap using basic ingredients.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

SOAP-MAKING GUIDE

~ Body, House and Laundry soaps ~

Soap is easy to make with a bit of help.

Familiar oils can be used such as palm,

coconut, shea, allanblackia and cocoa.

The water used in soap manufacture can

be infused with medicinal plants like

moringa, even citrus peel or flowers to

add fragrance. Additions such as honey,

aloe and citrus juice all have beneficial

properties.

This guide presents succinctly the tool,

steps and procedure for making soap. Also included are basic recipes for

body, general use and laundry soaps.

Introduction

1. Equipment

2. Safety and Precautions

3. Oils

4. Caustic Soda Preparation

5. Soap Making

6. Recipes

7. Moulds

8. Labels

~ Contents ~

1. Equipment

Pot for heating oil

Filter for oil

2 tomato paste tins, clean and dry (approx 1/4 cup each)

1 plastic bottle that holds 1L

1 soup spoon

1 knife

1 small bowl or cup

2 plastic buckets

1 long wooden stick

Latex gloves (or plastic bags to cover hands)

Moulds (wooden, silicone or tetrapaks)

1 wooden or plastic spatula

Basic ingredients found in all soaps :

Clean and filtered water

Caustic soda (sometimes called << white spirit >> )

Filtered and pourable oil (warmed to the point it is fluid)

Secrtariat du Rseau Africain de Forts Modles

BP 33678 / Yaound, Cameroun

Tl : +237-77696804

www.africanmodelforests.net

Cuso International

200-44 Eccles Street / Ottawa, Ontario, Canada

K1R 6S4

www.cusointernational.org

VSO Cameroon

BP 25127 Messa / Yaound, Cameroun

Tl : +237-22217607

www.vsointernational.org

26-09-2013 par T Stanton-Kennedy

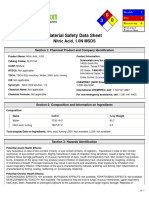

2. Safety and Precautions

While making soap is simple, is can be

dangerous if we do not take basic security

precautions.

1. Always work in a well-ventilated and

sheltered area to avoid toxic vapours from

burning eyes and lungs.

2. Wear protective equipment :

Glasses or goggles

Face mask (like a scarf or surgical

mask)

Latex gloves

Clothing that covers the length of

your arms, legs and close-toed shoes

3. Never use any equipment made of

aluminium if it will come in contact with

the caustic soda.

4. Do not use soap-making equipment for any other purpose - especially

the preparation of food.

5. The caustic soda is always added to water - never the reverse so as to

avoid dangerous explosions.

6. Finished body soap must dry very well is a sheltered and protected

area during minimum 4 weeks before use to ensure chemical burns do

not occur.

Skin burns from caustic

soda are very dangerous.

Treatment : Rinse the area

well with vinegar then

follow with cold water.

Repeat during 20 minutes.

Palm and coconut oils are

naturally sudsing. Including them

eliminates the need to buy and

add an artificial sudsing agent.

For all body soaps it is better to

never use more the 75% refined

palm oil as an ingredient as it can

be very drying for the skin. As

such, for a recipe requiring 1.5 L

of oils one would not use more

than 1 L of refined palm oil.

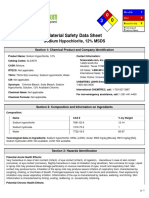

3. Oils 4. Caustic soda preparation

The caustic soda and water mixture should be prepared well in advance

of the mixing with oil stage. If one wishes to make soap in the morning,

the caustic soda solution should be prepared the night before. At least

12 hours should elapse to permit the solution to cool completely, which

in turn will diminish the potential for burns.

3 full tomato tins of caustic soda (about 14 tbs or 200 mL)

1 L filtered water

The caustic soda is ALWAYS added to the water, NEVER the reverse in

order to avoid explosions. Stir gently while adding the soda until all of it

has dissolved.

Be careful as this mixture

releases TOXIC VAPOURS!

Caution - this mixture can

BURN you badly.

ss -.o-sc-ro

.+-s s.oss o.

-.+s-rc .+ss

..s+--rs

-.o-sc-s: .

+s o. sc+.-

.os s.ssss +:

cos.s: .sss

-ss- -.o-sc-s: . c.oss:-os s-oss

Add lemon juice

and / or honey to

the cooled and

filtered oils.

4

Prepare the caustic

soda solution

5. Soap Making

Soap is the result of a chemical reaction

between oil and caustic soda called

saponification.

At each step ensure hands and body are protected by

adequate clothing. Use gloves even when cutting the soap

after its initial set.

1

Allow the solution to

cool between 12 and

24 hours.

2

If desired, whiten the palm

oil. Warm oil to the point it

pours easily and can be

readily filtered. Filter the oil

and then allow it to cool to

room temperature. Combine

all oils to be used

together in one bucket.

3

Slowly add the caustic

soda solution to the oils,

gently stirring in a single

direction the entire time..

5

Hold the stirrer at almost 90

degrees to the bucket while

continuing to stir the mixture

vigorously in the same

direction during 20 to 30

minutes while monitoring for

evidence of the trace. The

trace is the stage where the

mixture is well combined and

ready to pour into moulds. It

occurs when the mix

resembles fufu or peanut butter. A line

drawn on the top remains.

6

Place moulds on a large piece of plastic or

banana leaves. Pour the soap into the

forms and allow to harden during 24 hours.

7

** If one is adding perfume, add it at the stage of the trace and before pouring into moulds.

Remove the soap from

the moulds and cut or

clean it as required.

Allow the soap to dry on

its side over 4 weeks in a

well-ventilated area,

protected from dust and

inaccessible to children.

Be sure to rotate the

soap from side to side

each week to ensure even drying. This step - called the cure - ensures

the soap is well-dried and hard as well as ensuring that the chemical

reactions of saponification have finished thus diminishing the chance

of burning the skin. If making house cleaning soap, the bars are useable

after one week of curing.

8

Clean your tools well in readiness for the next batch! 9

fin

-.+s-rc s-ss- o.

.+++ .s+ss

- sss .o: so+-

: ss -o.ss c.s+rs so+-

6. Recipes

The recipes below were developed by the

womens shea butter cooperative COFTRAKOL ,

from Bangangt, Cameroon.

You can experiment with oil type, infusions in

water as well as natural additions like citrus,

honey and aloe. To make soap you only need oil,

water and caustic soda - but additions bring their

own benefits for skin. The important thing to

remember is to not exceed the 5 small tomato tins

of liquid in the recipe (about equivalent of 23 tbs

or 340 mL).

.o: so+-

1 L clean and filtered water

3 tomato tins of caustic soda

1.5 L oil

3 tomato tins of honey

2 tomato tins of lemon juice or other

acid fruit (oranges, limes, grapefruit,

pineapple, etc.)

2 soup spoons of fragrance (if desired,

not required)

-o.ss so+-

1/2 L clean and filtered water

1 tomato tin plus one soup spoon of caustic

soda (210 g)

1.5 L whitened palm oil

.+.:. -o:s.

5 L clean and filtered water

1 kg caustic soda

5 L palm oil, warmed to liquid

kg sodium bicarbonate

1 cup kitchen or sea salt

5 soup spoons (10 mL) liquid bleach

1 soup spoon of fragrance

1 coffee spoon of laundry blue powder

1 spoon to 500 mL of artificial sudsing

agent (as desired based on level of

bubbles sought)

Large plastic sheet over which to pour

mixture

1 metal screen to shred hardened soap

into powder

:r.sc-ros

Add the laundry blue to the oil, then add the salt,

bleach and sudsing agent.

Stir vigorously.

Slowly add the caustic soda solution while continuing

to stir.

Stir the mixture until the trace stage is reached.

Add fragrance if desired.

Pour the mixture over the plastic cloth and allow to

dry during 24 hours.

Grate the soap using a metal sieve or screen.

In a thin layer, leave the powder to dry several days

more on the plastic sheet.

coftrakoln@yahoo.fr

8. Labels

If you are hoping to sell soap, a label adds visual impact

and permits the buyer to contact the maker. A stamp can

also be used to mark the bar with a design or logo but

needs to be very sharp to be effective. Cloth bags, home-

made paper or ribbons can all be used to create simple but

attractive packaging.

A simple label is a piece of paper covered with clear

tape or cling film.

List ingredients used in the soap by order of

greatest proportion to least.

Dont forget to include contact information!

7. Moulds

Anything can be used as a soap mould

unless it contains aluminium. The best

moulds make removing soap easy and are

simple to clean. You may need to clean

the bar of soap using a knife if there are

stained or uneven areas. Silicone moulds

are the best for soap production but are

unfortunately expensive.

A mould can be made of wood with many

openings to create bars of identical

measure thus eliminating the need to but

a large block into even sizes. However,

removing the soap takes time. A single

block of soap must be measured and cut,

but the form can be lined with plastic to

ease removal. Tetrapaks can also be used

as moulds, but are easy to destroy after a

single use.

Cuso International recognises funding support for this project from the Government of Canada s Ministry of Natural Resources

Anda mungkin juga menyukai

- 10 Glycerin Soap Recipes That Are Simple : To Make Make Your Own Melt and Pour Glycerin Soaps From Natural Ingredients With This Simple RecipeDari Everand10 Glycerin Soap Recipes That Are Simple : To Make Make Your Own Melt and Pour Glycerin Soaps From Natural Ingredients With This Simple RecipeBelum ada peringkat

- Making Soap From WoodDokumen6 halamanMaking Soap From WoodmastabloidBelum ada peringkat

- Soap Making How To Make SoapDokumen9 halamanSoap Making How To Make Soapjmweaver1951100% (1)

- How To Make Castile SoapDokumen75 halamanHow To Make Castile SoapWignya Cahyana100% (2)

- Good Goat SoapDokumen5 halamanGood Goat SoapJason GrohBelum ada peringkat

- Soap Making: 71 Homemade Soap RecipesDokumen64 halamanSoap Making: 71 Homemade Soap RecipesLyubomyr Yatsyk89% (27)

- Cold Process Soap Making MethodDokumen6 halamanCold Process Soap Making MethoddreamerBelum ada peringkat

- How To Make Soap and Safety When Soap MakingDokumen7 halamanHow To Make Soap and Safety When Soap Makinglancasterpd100% (1)

- Homemade Soap RecipesDokumen68 halamanHomemade Soap Recipessunita100% (5)

- Traditional Soap MakingDokumen16 halamanTraditional Soap Makingbcline44325067Belum ada peringkat

- How To Make Liquid DetergentDokumen2 halamanHow To Make Liquid DetergentiamdaphyBelum ada peringkat

- How To Make Honey-Cream PDFDokumen24 halamanHow To Make Honey-Cream PDFmuveBelum ada peringkat

- Making SoapDokumen6 halamanMaking Soapresister100% (2)

- 20DIYBeautyRecipeseBook PDFDokumen28 halaman20DIYBeautyRecipeseBook PDFDaphne BritoBelum ada peringkat

- BeeswaxDokumen4 halamanBeeswaxJessa Quiambao100% (1)

- Soap From KlerekDokumen19 halamanSoap From Klerekfade memoryBelum ada peringkat

- How To Make Your Own SoapDokumen267 halamanHow To Make Your Own Soapsantorini192797% (34)

- Coconut Oil Shampoo Bar Recipe (Video Tutorial) PDFDokumen249 halamanCoconut Oil Shampoo Bar Recipe (Video Tutorial) PDFYadi Roma100% (1)

- Natural Facial Soaps EbookDokumen39 halamanNatural Facial Soaps EbookRiddhima Singh100% (6)

- How To Make Soap: (One Thing About Soap Making You Will Learn.... There Are Always So Many Choices To Make!)Dokumen50 halamanHow To Make Soap: (One Thing About Soap Making You Will Learn.... There Are Always So Many Choices To Make!)Jai DevBelum ada peringkat

- Making Cold Process Soap PDFDokumen3 halamanMaking Cold Process Soap PDFCosmina Georgiana0% (1)

- Soap Making A Quick Soap Making BookDokumen109 halamanSoap Making A Quick Soap Making Bookloay2008100% (19)

- Cosmetics 11112 PDFDokumen37 halamanCosmetics 11112 PDFcacolina100% (4)

- Making Castile Soap ReciepesDokumen11 halamanMaking Castile Soap ReciepesckennanBelum ada peringkat

- SoapDokumen7 halamanSoapShivansh Rajput100% (1)

- Hot Process Honey Oatmeal SoapDokumen1 halamanHot Process Honey Oatmeal SoapEly GarciaBelum ada peringkat

- SoapsDokumen413 halamanSoapsKathryn Bax83% (6)

- 12 Steps To Better Hot ProcessDokumen8 halaman12 Steps To Better Hot ProcesstamaraiivanaBelum ada peringkat

- Shampoo Recipes: Phase ADokumen40 halamanShampoo Recipes: Phase Atony_lopez_3100% (2)

- How To Make Laundry DetergentDokumen16 halamanHow To Make Laundry DetergentAbraham Oluwole55% (11)

- Herbal CosmeticsDokumen40 halamanHerbal CosmeticsBiren Shah100% (1)

- Liquid Soap ProcessDokumen3 halamanLiquid Soap ProcessAnnette40% (5)

- Soap Making - Kelly Kohn (CreateSpace, 2012)Dokumen108 halamanSoap Making - Kelly Kohn (CreateSpace, 2012)ShadabAhmad100% (1)

- Cold Process Soap MakingDokumen9 halamanCold Process Soap MakingMaria LavenderBelum ada peringkat

- The Ultimate Guide To Homemade SoapDokumen368 halamanThe Ultimate Guide To Homemade SoapAustin RamirezBelum ada peringkat

- Deodorants 503312724Dokumen12 halamanDeodorants 503312724Pavan KumarBelum ada peringkat

- Naturally Fermented Alchoolic Drinks RecipesDokumen9 halamanNaturally Fermented Alchoolic Drinks RecipesDeNiBelum ada peringkat

- SoapDokumen23 halamanSoapPrakash Giri67% (3)

- How To Make and Earn From Liquid Soap PDFDokumen16 halamanHow To Make and Earn From Liquid Soap PDFMohammed Abdulkhader100% (4)

- How To Make GlassDokumen11 halamanHow To Make GlassFrastioOktavianoAmchoryBelum ada peringkat

- Narrative Essay Grade 4 EnglishDokumen3 halamanNarrative Essay Grade 4 EnglishMarykeBelum ada peringkat

- Liquid Soap MakingDokumen14 halamanLiquid Soap MakingAldjo Sjaaf83% (6)

- Homemade Recipes Book Soaps Ointments Candles Shampoos and BalmsDokumen196 halamanHomemade Recipes Book Soaps Ointments Candles Shampoos and BalmsRachel Ward100% (15)

- The Art of Soap-MakingDokumen324 halamanThe Art of Soap-MakingKristos Bakayiannis86% (7)

- Easy Natural Soapmaking - How To Make Natural Soaps That Rejuvenate, Revitalize, and Nourish Your Skin. (PDFDrive)Dokumen100 halamanEasy Natural Soapmaking - How To Make Natural Soaps That Rejuvenate, Revitalize, and Nourish Your Skin. (PDFDrive)Nova Erxa100% (3)

- Liquid Soap Making TechniqueDokumen4 halamanLiquid Soap Making Techniqueluchoosorio100% (3)

- Cold Process Soap MakingDokumen9 halamanCold Process Soap MakingkiwipumpsBelum ada peringkat

- Soap Making Business Startup: How To Start, Run & Grow A Million Dollar Success From Home! - Suzanne CarpenterDokumen6 halamanSoap Making Business Startup: How To Start, Run & Grow A Million Dollar Success From Home! - Suzanne Carpenterzitutija0% (3)

- Crockpot Shampoo Bar RecipeDokumen6 halamanCrockpot Shampoo Bar RecipeLizaChirau100% (1)

- Fun and Simple Soap Making RecipesDokumen19 halamanFun and Simple Soap Making RecipesZeth KiyoskeBelum ada peringkat

- Bath & Body: Answers To 10 of Your Most Frequently Asked QuestionsDokumen14 halamanBath & Body: Answers To 10 of Your Most Frequently Asked QuestionsRaluca ChioreanBelum ada peringkat

- Vodca Preparation MethodDokumen7 halamanVodca Preparation MethodNahusenay TewodrosBelum ada peringkat

- DIY-GUIDE - SkincareDokumen25 halamanDIY-GUIDE - Skincarepriyankitha100% (2)

- Making Natural Soaps - Melt and Pour TechniqueDokumen5 halamanMaking Natural Soaps - Melt and Pour TechniqueDr Srinivasan Nenmeli -K100% (1)

- Beginner Soapmaking Instructions and Recipes Revised PDFDokumen37 halamanBeginner Soapmaking Instructions and Recipes Revised PDFstefanovicsanjaBelum ada peringkat

- Easy Herbal Homemade Soap Recipes: Homemade Soap Making for BeginnersDari EverandEasy Herbal Homemade Soap Recipes: Homemade Soap Making for BeginnersPenilaian: 2 dari 5 bintang2/5 (1)

- Millennial Homesteading: Skills For Our Post-Apocalyptic LifestyleDari EverandMillennial Homesteading: Skills For Our Post-Apocalyptic LifestyleBelum ada peringkat

- Nitric Acid PDFDokumen6 halamanNitric Acid PDFshella168Belum ada peringkat

- Environmental LawDokumen17 halamanEnvironmental LawSaleemBelum ada peringkat

- HSE ManualDokumen49 halamanHSE ManualMuhammad FahadBelum ada peringkat

- CHMM Exam Essential PracticeDokumen18 halamanCHMM Exam Essential PracticeDaniel FarcasBelum ada peringkat

- Msds Reach Fineamin 15 enDokumen6 halamanMsds Reach Fineamin 15 ensogetsu17Belum ada peringkat

- Msds (Sodium Hydrochlorite) PDFDokumen6 halamanMsds (Sodium Hydrochlorite) PDFAyman Medaney100% (1)

- HCL 37 %Dokumen7 halamanHCL 37 %Yohana MelianthaBelum ada peringkat

- MSDS 01Dokumen8 halamanMSDS 01chokribBelum ada peringkat

- Operating Instructions L-BL2: 2BL2041 2BL2061 2BL2101 2BL2141 2BL2251 2BL2281 2BL2341Dokumen34 halamanOperating Instructions L-BL2: 2BL2041 2BL2061 2BL2101 2BL2141 2BL2251 2BL2281 2BL2341MIGUEL GONZALEZBelum ada peringkat

- Molybdovanadate ReagentDokumen7 halamanMolybdovanadate ReagentAnisa Ul HusnaBelum ada peringkat

- Material Safety Data Sheet: 1 Identification of SubstanceDokumen5 halamanMaterial Safety Data Sheet: 1 Identification of SubstanceSILVIA KARINABelum ada peringkat

- Climax-Catalog LUBRICANTES Y SELLANTES PDFDokumen30 halamanClimax-Catalog LUBRICANTES Y SELLANTES PDFNini Jhoana Ardila CamachoBelum ada peringkat

- Potassium HydroxideDokumen6 halamanPotassium HydroxideSiti Fatimah NasarBelum ada peringkat

- Case Ih Puma 165 225 CVX Service ManualDokumen20 halamanCase Ih Puma 165 225 CVX Service ManualVivian100% (54)

- The Formula ManualDokumen289 halamanThe Formula Manualpeacons93% (30)

- Sds Caustic SodaDokumen8 halamanSds Caustic Sodaabil khausarBelum ada peringkat

- Aquaseal LV A-Epoxy Resin & B-AmineDokumen8 halamanAquaseal LV A-Epoxy Resin & B-AmineJodyBelum ada peringkat

- Sds Sodium Hydroxide 50%Dokumen9 halamanSds Sodium Hydroxide 50%Wici WiciBelum ada peringkat

- Nh4oh MSDSDokumen8 halamanNh4oh MSDSDavid SaguilBelum ada peringkat

- List of GHS Hazard Statement & PictogramsDokumen33 halamanList of GHS Hazard Statement & PictogramsKhairul BarsriBelum ada peringkat

- Msds NaOHDokumen8 halamanMsds NaOHFarhan RivaldiBelum ada peringkat

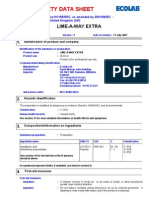

- Lime A Way ExtraDokumen5 halamanLime A Way ExtraProsenjit76Belum ada peringkat

- Aero 3477 PDFDokumen9 halamanAero 3477 PDFLUIS XV100% (1)

- Development Control Rules, MumbaiDokumen228 halamanDevelopment Control Rules, Mumbaid-fbuser-5111737288% (8)

- ToxicologyDokumen76 halamanToxicologyAsma SikanderBelum ada peringkat

- PD 881 - Household Hazardous ActDokumen6 halamanPD 881 - Household Hazardous ActMelchor B. BrillantesBelum ada peringkat

- Unit 6: Chemistry Lab Skills II (A2 Edexcel)Dokumen15 halamanUnit 6: Chemistry Lab Skills II (A2 Edexcel)Kazi Unysah NabiBelum ada peringkat

- SDS Chemrock 958BDokumen2 halamanSDS Chemrock 958BmangengueyBelum ada peringkat

- Automatic Product Identification During Unloading: Relevant For: Chemical-, Petro-And Beverage IndustryDokumen3 halamanAutomatic Product Identification During Unloading: Relevant For: Chemical-, Petro-And Beverage Industryping dengBelum ada peringkat

- Revision For Acids, Bases and SaltsDokumen5 halamanRevision For Acids, Bases and SaltsAshvik AnumakondaBelum ada peringkat