Burj Dubai Concept Design and Construction Presentation

Diunggah oleh

patricklim1982Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Burj Dubai Concept Design and Construction Presentation

Diunggah oleh

patricklim1982Hak Cipta:

Format Tersedia

Introduction

Introduction

Burj Khalifa (formally Dubai) is the new tallest

tower in the world.

Construction began on 21 September 2004 &

completed on 1 October 2009.

The building was officially opened on 4 J anuary

2010

Height of the Tower is 828m .

Its Owner is EMAAR Properties with total

investments of US$ 1.5 billion.

The tower is designed by Skidmore, Owings

and Merrill (SOM)

Adrian smith was chief architect.

World

World

s Tallest Building

s Tallest Building

From the head start , it has been intended

that the Burj Dubai be the Worlds Tallest

Building.

The official arbiter of height is the Council on

Tall Buildings and Urban the illinois Institute

of Technology in Chicago, Illinois.

The CTBUH measures the height of

buildings (measured from sidewalk at the

main entrance).

Burj Dubai is the tallest skyscraper to

top of spire: 828 m

Building with highest occupied floor in the

world163rd floor

World

World

s Tallest Building

s Tallest Building

Highest outdoor observation deck in the world

(124th floor) at 452 m

World's highest elevator installation, situated

inside a rod at the very top of the building

World's fastest elevators at speed of 64 km/h

(40 mph) or 18 m/s

Highest vertical concrete pumping (for a building):

606 m

World's highest installation of an aluminum and

glass facade, at a height of 512 m

World's highest New Year fireworks display

Architectural Concept

Architectural Concept

The context of the Burj

Dubai being located in the

city of Dubai, UAE, drove

the inspiration for the

building form to

incorporate cultural and

historical particular to the

region.

The influences of the

Middle Eastern domes and

pointed arches in

traditional buildings, spiral

imagery in Middle Eastern

architecture, resulted in

the tri-axial shape of the

building

Architecture

Architecture

Burj Dubai includes163 habitable

floors plus 46 maintenance levels in

the spire and 9 parking levels in the

basement.

Floor Area 309,473 m

2

The Residences

900 residence from floor

Armani Residences

Armani Residences Dubai has

been designed personally by Giorgio

Armani. 144 suites.

Hotel (L39)

Residence

(L108)

Spire

Observator

y (L123)

Communication

(L160)

Office (L153)

Pinnacle

Architecture

Architecture

The observatory

On level 123, At the Top, Burj Dubai, is

a must-see attraction and offers

breathtaking views of the city and the

surrounding emirate.

Connected to the tower are The

Offices, a 12-storey annex of prime

office space

The Corporate Suites:

Are located on the highest levels of the

tower. They occupy 37 floors, with the

top three floors merged into a single

office. Express lifts take office visitors

directly to a lounge lobby at Level 123

Hotel (L39)

Residence

(L108)

Spire

Observatory

(L123)

Communication

(L160)

Office (L153)

Pinnacle

Architecture

Architecture

Mechanical Floors

Seven double-storey mechanical floors

house the equipment that bring Burj

Dubai to life. Located every 30 storeys,

the mechanical floors house the electrical

sub-stations, water tanks and pumps, air-

handling units etc, that are essential for

the operation of the tower and the comfort

of its occupants.

Broadcast and Communications Floors

The top four floors have been reserved for

communications and broadcasting. These

floors occupy the levels just below the

spire.

Main Structure & Design

Main Structure & Design

The tower superstructure of Burj Dubai is

designed as an all reinforced concrete building

with high performance concrete from the

foundation level to level 156, and is topped with

a structural steel braced frame from level 156 to

the pinnacle.

Designers purposely shaped the structural

concrete Burj Dubai Yshaped in plan to

reduce the wind forces on the tower, as well as

to keep the structure simple and foster

constructability.

The structural system can be described as a

buttressedcore. Each wing, with its own high

performance concrete corridor walls and

perimeter columns, buttresses the others via a

six-sided central core, or hexagonal hub

Main Structure & Design

Main Structure & Design

Structural Analysis & Design

Structural Analysis & Design

The top section of the Tower consists of a

structural steel spire utilizing a diagonally

braced lateral system.

The structural steel spire was designed for

gravity, wind, seismic and fatigue in

accordance with the requirements of AISC

Load and Resistance Factor Design

Specification for Structural Steel Buildings

(1999). The exterior exposed steel is

protected with a flame applied aluminum

finish

Main Structure & Design

Main Structure & Design

The result is a tower that is

extremely stiff laterally and

torsionally similar to a closed tube.

Each tier of the building sets back

in a spiral stepping pattern up the

building. The setbacks are

organized with the towers grid,

such that the building stepping is

accomplished by aligning columns

above with walls below to provide a

smooth load path.

The advantage of the stepping and

shaping is to confuse the wind.

The wind vortices never get

organized because at each new tier

the wind encounters a different

building shape.

Main Structure

Main Structure

Structural Analysis & Design

Structural Analysis & Design

The center hexagonal walls are buttressed

by the wing walls and hammer head walls

which behave as the webs and flanges of a

beam to resist the wind shears and

moments.

Structural Analysis & Design

Structural Analysis & Design

Outriggers at the mechanical floors allow

the columns to participate in the lateral load

resistance of the structure; hence, all of the

vertical concrete is utilized to support both

gravity and lateral loads.

Structural Analysis & Design

Structural Analysis & Design

Concrete Dimensions

Concrete Dimensions

The core walls vary in thickness from

1300mm to 500mm. The core walls are

typically linked through a series of 800mm

to 1100mm deep reinforced concrete or

composite link beams at every level.

The residential and hotel floor framing

system of the Tower consists of 200mm to

300mm two-way reinforced concrete flat

plate slabs spanning approximately 9

meters between the exterior columns and

the interior core wall.

Structural Analysis & Design

Structural Analysis & Design

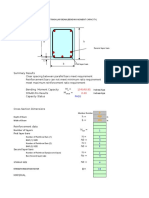

Link Beams

Link Beams

The demands on the link beams vary

greatly.

The typical link beams used in the Burj

Dubai are quite stocky with a shear-span

ratio (l/2h) of 0.85, a width of 650 mm and a

height of 825 mm.

Structural Analysis & Design

Structural Analysis & Design

Link Beams

Link Beams

For the design of reinforced concrete link

beams:

1. The conventional deep beam design method in

the ACI 318-992

2. Strut-and-tie method in ACI 318-023 were

used, with Appendix A enabling the design of

link beams somewhat beyond the

conventionally designed maximum deep beam

stress limit.

3. In the case of members subjected to very large

shear forces, embedded built-up structural

steel sections were provided within the core of

the concrete link beams to carry the entire

shear and flexure demand.

Strut and Tie model for the

Strut and Tie model for the

Link Beam

Link Beam

Design Details of Link

Design Details of Link

Beams

Beams

The geometry, factored loads, and design

methods of four Burj Dubai link beams, LB1

to LB4, are shown in Table 1.

Design Details of Link

Design Details of Link

Beams

Beams

Structural Analysis & Design

Structural Analysis & Design

Clear Heights

Clear Heights

The tower is being constructed utilizing a

horizontal compensation program. Each

story is being constructed incorporating a

modest increase in the typical floor-to-floor

height.

This vertical compensation was selected to

ensure the actual height of the structure,

after the time-dependant shortening effects

of creep and shrinkage, will be greater than

the as-designed final height.

Structural Analysis & Design

Structural Analysis & Design

The structure was analyzed for

gravity (including P-Delta analysis),

wind, and seismic loadings by

ETABS version 8.4 .

The three-dimensional analysis

model consisted of the reinforced

concrete walls, link beams, slabs,

raft, piles, and the spire structural

steel system.

The full 3D analysis model

consisted of over73,500 shells and

75,000 nodes

Structural Analysis & Design

Structural Analysis & Design

Design Code

Design Code

The reinforced concrete structure was designed in accordance with

the requirements of ACI 318-02 Building Code Requirements for

Structural

Concrete.

Structural Analysis & Design

Structural Analysis & Design

Seismic Loads

Seismic Loads

Dubai is situated towards the eastern edge of the

geologically stable Arabian Plate and separated

from the unstable Iranian Fold Belt to the north by

the Arabian Gulf. The site is therefore considered to

be located within a seismically active area.

The Dubai Municipality (DM) specifies Dubai as a

UBC97 Zone 2a seismic region with a seismic zone

factor Z = 0.15 and soil profile Sc.

Structural Analysis & Design

Structural Analysis & Design

Seismic Analysis

Seismic Analysis

The seismic analysis consisted of a site-specific

response spectra analysis.

Seismic loading typically did not govern the design

of the reinforced concrete tower structure. But did

govern the design of the steel spire.

Dr Max Irvine developed site-specific seismic

reports for the project, including a seismic hazard

analysis.

Structural Analysis & Design

Structural Analysis & Design

Dynamic Analysis

Dynamic Analysis

The dynamic analysis indicated the first mode is lateral sidesway

with a period of 11.3 seconds .

The second mode is a perpendicular lateral sidesway with a period

of 10.2 seconds.

Torsion is the fifth mode with a period of 4.3 seconds

Types of wind

Types of wind

Winds that are of interest in the design

of buildings can be classified into

three major types

Prevailing Winds (Trade winds)

seasonal winds

local winds

Types of wind

Types of wind

The characteristics of the prevailing

and seasonal winds are analytically

studied together, whereas those of

local winds are studied separately.

The variations in the speed of

prevailing and seasonal winds are

referred to as fluctuations in mean

velocity. The variations in the local

winds are referred to as gusts.

CHARACTERISTICS OF

CHARACTERISTICS OF

WIND

WIND

Variation of wind velocity with height.

Wind turbulence.

Statistical probability.

Vortex shedding phenomenon.

Dynamic nature of windstructure

interaction.

Variation of Wind Velocity with

Variation of Wind Velocity with

Height

Height

The viscosity of

air reduces its

velocity

adjacent to the

earths surface to

almost zero.

Wind Turbulence

Wind Turbulence

For structural engineering purposes, velocity of

wind can be considered as having two

components:

Mean velocity component that increases with height,

Turbulent velocity that remains the same over height.

Probabilistic Approach

Probabilistic Approach

In wind engineering the speed of wind

is considered to vary with return

periods.

For example, the fastest-mile wind 33

ft (10 m) above ground in Dallas, TX,

corresponding to a 50-year return

period,(30 m/s), compared to the

value of (31.7 m/s) for a 100-year

recurrence interval.

Vortex Shedding

Vortex Shedding

The flow of wind is simplified and

considered two-dimensional

Along wind

transverse wind

Vortex Shedding

Vortex Shedding

At low wind speeds, shedding

occurs at the same instant on

either side of the building, It is

therefore subject to along-

wind oscillations parallel to

the wind direction

At higher speeds, the vortices

are shed alternately, first from

one and then from the other

side. there is an impulse in

the along-wind direction as

before, but in addition, there

is an impulse in the

transverse direction.

Wind behavior

Wind behavior

Dynamic Nature of Wind

Dynamic Nature of Wind

Windloadsassociatedwithgustinessor

turbulencecreatingeffectsmuchlarger

thanifthesameloadswereapplied

gradually.

Windloads,therefore,needtobestudied

asiftheyweredynamicinnature.

Theintensityofawindloaddependson

howfastitvariesandalsoonthe

responseofthestructure.

WIND CLIMATE STUDIES

WIND CLIMATE STUDIES

In the course of the Burj Dubai studies local

ground based data from several weather stations

in the region were used, including most

importantly the data from Dubai International

Airport.

Gust data from all stations were merged into the

equivalent a super-station to obtain an enlarged

database

The 50 year 3 second gust from this analysis

was estimated to be 37.7 m/s in standard open

terrain at the 10 m level.

WIND CLIMATE STUDIES

WIND CLIMATE STUDIES

In addition the mean hourly data from Dubai

were used to obtain a model of the parent

distribution of hourly winds

This yielded a 50 year mean hourly speed of

23.5 m/s, again in standard open terrain

conditions at 10 m.

Depending on exactly which method one

used to estimate the relationship between

mean and gust speeds the corresponding

gust was estimated to be in the range 35.7

m/s to 37.6 m/s.

WIND CLIMATE STUDIES

WIND CLIMATE STUDIES

An important question when designing a tower of

over 600 m height is the nature of the wind

velocity profile and wind turbulence in the upper

levels.

It is a large extrapolation to go from ground-

based data at the 10 m height to heights of over

600 m using standard assumptions

Therefore for Burj Dubai more direct

measurements of upper level winds were sought.

The closest station with balloon records was Abu

Dhabi, where about 16 years of data were

available taken on average about twice per day.

WIND CLIMATE STUDIES

WIND CLIMATE STUDIES

The Wind Engineering of the

The Wind Engineering of the

Burj Dubai Tower

Burj Dubai Tower

For a building of this height and

slenderness, wind forces and the

resulting motions in the upper levels

become dominant factors in the

structural design.

The local wind pressures on the

building envelope and the wind

speeds around the base of the

building and on terraces at various

levels were of concern.

WIND-TUNNEL ENGINEERING

Therefore, an extensive program of wind tunnel

tests and other studies were undertaken

Rigid pressure model

High-frequency force-balance technique

Full multi-degree of freedom aeroelastic model

study

Measurements of local pressures

Pedestrian wind environment studies

These studies used models mostly at 1:500

scale but for the pedestrian wind studies a

larger scale of 1:250 was utilized

Rigid Pressure Model (PM)

Rigid Pressure Model (PM)

The primary purpose of the rigid-

model test is for obtaining cladding

design pressures, get the floor-by-

floor shear forces for the design of

the overall main wind-force-

resisting frame.

The wind-tunnel test is run for a

duration of about 60 sec which

corresponds to approximately 1 hr

in real time.

Cladding Pressure Testing

Cladding Pressure Testing

Cladding Pressure Testing

Cladding Pressure Testing

High

High

-

-

Frequency Base Force

Frequency Base Force

Balance Model

Balance Model

The effect of wind load on a flexible

building can be considered as an

integrated action resulting from three

distinct sources

The mean wind load, that bends and

twists a building,

The fluctuating load from the unsteady

nature of the wind that results in

oscillation of the building

Inertia forces similar to the lateral forces

induced in a building during earthquakes

High

High

-

-

Frequency Base Force

Frequency Base Force

Balance Model

Balance Model

A rigid model is convenient for

measuring local wind pressures

consisting of positive and negative

pressures distributed uniquely around

a building.

These local pressures are integrated

to derive net lateral forces in two

perpendicular directions and a

torsional moment about a vertical axis,

at each level

High

High

-

-

Frequency Base Force

Frequency Base Force

Balance Model

Balance Model

These values have been sufficient for

the design of buildings bracing

system.

HFBFB ignore the influence of gust

factor.

It is necessary to assume a

conservative gust factor to increase

the mean values.

WIND LOADING ON THE MAIN

WIND LOADING ON THE MAIN

STRUCTURE

STRUCTURE

To determine the wind loading on the

main structure wind tunnel tests were

undertaken early in the design using the

high-frequency-force-balance technique.

The model itself is rigid and is mounted

on a fast response force balance

The technique is that it is relatively quick

to undertake and provides the complete

spectra of the wind generated modal

forces acting on the tower.

WIND LOADING ON THE MAIN

WIND LOADING ON THE MAIN

STRUCTURE

STRUCTURE

The results of the force balance tests were

used as early input for the structural design

and allowed parametric studies to be

undertaken on the effects of varying the

towers stiffness and mass distribution.

The wind tunnel data were then combined

with the dynamic properties of the tower in

order to compute the towers dynamic

response and the overall effective wind force

distributions at full scale using aeroelastic

model analysis

The building has essentially six

The building has essentially six

important wind directions

important wind directions

Orientation of the tower

Orientation of the tower

It was noticed that the force spectra

for different wind directions showed

less excitation in the important

frequency range for winds impacting

the pointed or nose end of a wing,

than from the opposite direction (tail).

most frequent strong wind directions

for Dubai: northwest, south and east.

High

High

-

-

Frequency Base Force

Frequency Base Force

Balance Model

Balance Model

Several rounds of force balance tests were

undertaken as the geometry of the tower

evolved and was refined architecturally

After each round of wind tunnel testing, the

data was analyzed and the building was

reshaped to minimize wind effects and

accommodate unrelated changes in the

Clients program.

Original Configuration

Original Configuration

Aeroelastic model study

Aeroelastic model study

Aeroelastic model study attempts to

take the guesswork out of the gust

factor computation by measuring

directly the magnitude of dynamic

loads.

The aeroelastic studies require

similarity of the inertia, stiffness, and

damping characteristics of the

building.

Aeroelastic model study

Aeroelastic model study

Aeroelastic study basically examines the

wind-induced sway response, in addition to

providing information on the overall wind-

induced mean and dynamic loads.

Factors may be used as a guide in making a

decision aeroelastic model study

The building height-to-width ratio is greater than

about 5; i.e., the building is slender.

Approximate calculations show that there is a

likelihood of vortex shedding phenomenon.

Aeroelastic model study

Aeroelastic model study

The structure is light in density on the

order of 8 to 10 lb/ft3 (1.25 to 1.57

kN/m3).

The structural stiffness is concentrated in

the interior of the building, making it

torsionally flexible. A building with a

braced central core is one such example.

The calculated period of oscillation of the

building is long, in excess of 4 or 5 sec.

Aeroelastic model study

Aeroelastic model study

It is more accurate than a force

balance study since the aeroelastic

interaction between the structure and

wind is fully simulated.

Accurate determination of the

relationship between peak response

and RMS response.

Aeroelastic model study

Aeroelastic model study

For the Burj Dubai the modal

deflection shapes were similar to

those of a tapered cantilevered

column.

Therefore it was possible to obtain

excellent agreement between

frequencies and mode shapes on the

model with those predicted at full

scale by using a single machined

metal spine in the model with outer

shell segments attached to it.

Aeroelastic model study

Aeroelastic model study

The aeroelastic model was able to

model the first six sway modes.

Bending moments were measured at

the base as well as at several higher

levels. Accelerations were also

measured in the upper levels.

Comparing aeroelastic model

Comparing aeroelastic model

test results force balance results

test results force balance results

It was found that the base moment

and the accelerations in the upper

levels were significantly lower in the

aeroelastic model results.

Part of this was identified as a

Reynolds number effect because the

force balance tests had been run at

lower Reynolds number.

Comparing aeroelastic model

Comparing aeroelastic model

test results force balance results

test results force balance results

Differences between the force balance

method and the aeroelastic method on Burj

Dubai

Due to approximations in the force balance

procedure as applied to a highly tapered

towered.

Force balance method keep model

resonance frequencies high enough to avoid

them interfering with the frequency range of

interest and one solution is to run at lower

tunnel wind speeds, which entails reducing

the Reynolds number.

BUILDING MOTIONS

BUILDING MOTIONS

Based on the High-Frequency-Force-Balance

test results combined with local wind

statistics the building motions in terms of

peak accelerations were predicted for various

return periods in the 1 to 10 year range.

Initial predictions obtained in May 2003, at

over 37 milli-g for the 5 year return period

By the end of 2004 November 2003 they had

come down to about 19 milli-g for the same

return period

BUILDING MOTIONS

BUILDING MOTIONS

Half of this improvement came about as

a result of improved knowledge of the

wind statistics and the rest through re-

orientation, structural improvements and

shape adjustments.

Several variations of tower height were

tested using aeroelastic models.

The accelerations were reduced to the

range of 12 milli-g.

Human Response to Building

Human Response to Building

Motions

Motions

Building motion under the action of

wind is a serviceability issue.

A commonly used criterion is to limit

the acceleration of a buildings upper

floors to no more than 2.0% of gravity

(20 mg) for a 10-year return period.

PEDESTRIAN WIND STUDIES

PEDESTRIAN WIND STUDIES

A sheet of air moving over the earths

surface is reluctant to rise when it meets

an obstacle such as a tall building. it

prefers to flow around the building rather

than over it

Wind is driven in two directions. Some of

it will be deflected upward, but most of it

will spiral to the ground, creating a so-

called standing vortex or mini tornado at

sidewalk level.

PEDESTRIAN WIND STUDIES

PEDESTRIAN WIND STUDIES

Smooth-skinned skyscrapers may be

subjected to what is called the Mary

Poppins syndrome, referring to the

tendency of the wind to lift the

pedestrian literally off his or her feet.

Another effect, known as the Marilyn

Monroe effect, refers to the billowing

action of womens skirts in the

turbulence of wind around and in the

vicinity of a building.

PEDESTRIAN WIND STUDIES

PEDESTRIAN WIND STUDIES

The comfort of pedestrians at ground

level and on the numerous terrace levels

was evaluated by combining wind speed

measurements on wind tunnel models

with the local wind statistics and other

climatic information.

Two aspects of pedestrian comfort were

considered:

the effect of the mechanical force of the wind

thermal comfort

PEDESTRIAN WIND STUDIES

PEDESTRIAN WIND STUDIES

Initial wind tunnel tests used 1:500

scale models.

Subsequently three 1:250 scale partial

models were employed to examine

ground level areas,

Foundations

Foundations

Soil Investigation

Soil Investigation

Hyder Consulting (UK) Ltd (HCL) were appointed geotechnical

consultant for the works by Emaar and carried out the design

of the foundation system

Soil Investigation in 4 stages included:

23 boreholes

in situ SPTs

40 pressuremeter tests in 3 boreholes,

installation of 4 standpipe piezometers,

laboratory testing, specialist laboratory testing and

contamination testing

3 geophysical boreholes with cross-hole

tomography geophysical surveys

Soil Investigation

Soil Investigation

The quality of core recovered in some of the

earlier boreholes was somewhat poorer than that

recovered in later boreholes.

therefore the defects noted in the earlier rock

cores may not have been representative of the

actual defects present in the rock mass.

Phase 4 of the investigation was targeted to

assess the difference in core quality and this

indicated that the differences were probably

related to the drilling fluid used and the overall

quality of drilling

Soil Investigation & Ground

Soil Investigation & Ground

Water

Water

The groundwater in which the Burj Dubai

substructure is constructed is particularly severe.

The chloride and sulfate concentrations found in

the groundwater are even higher than the

concentrations in sea water.

Measures implemented include specialized

waterproofing systems:

1. Increased concrete cover

2. Addition of corrosion inhibitors to the

concrete mix

3. Stringent crack control design criteria and

4. Impressed current cathodic protection system

utilizing titanium mesh .

5. A controlled permeability formwork liner

Ground Water & Concrete Mix

Ground Water & Concrete Mix

A specially designed concrete mix was

formulated to resist attack from the ground

water.

The concrete mix for the piles was a 60 MPa

mix based on a triple blend with 25% fly ash,

7% silica fume, and a water to cement ratio of

0.32.

The concrete was also designed as a fully self

consolidating concrete, A robust cathodic

protection system for both the bored piles and

the raft foundation

Piles

Piles

The Tower raft is supported by 194 boredcast-

in-place piles

1.5m diameter and 47.45m long with the tower

raft founded at -7.55m

The C60 (cube strength) SCC concrete was

placed by the tremie method utilizing polymer

slurry. When the rebar cage was placed in the

piles, special attention was paid to orient the

rebar cage such that the raft bottom rebar

could be threaded through the numerous pile

rebar cages without interruption, which greatly

simplified the raft construction.

Pile Testing

Pile Testing

1. Static load tests on seven trial piles prior to

foundation construction.

2. Static load tests on eight works piles, carried

out during the foundation construction phase

(i.e. on about 1% of the total number of piles

constructed).

3. In addition, dynamic pile testing was carried

out on 10 of the works piles for the tower and

31 piles for the podium, i.e. on about 5% of

the total works piles.

4. Sonic integrity testing was also carried out on

a number of the works piles.

Static Testing on trial piles

Static Testing on trial piles

The main purpose of the tests was to assess

the general load-settlement behaviour of piles

of the anticipated length below the tower, and

to verify the design assumptions. Each of the

test piles was different, allowing various factors

to be investigated, as follows:

1. The effects of increasing the pile shaft length

2. The effects of shaft grouting

3. The effects of reducing the shaft diameter

4. The effects of uplift (tension) loading

5. The effects of lateral loading

6. The effect of cyclic loading

Static Working Pile Test

Static Working Pile Test

The Tower raft is supported by 194 bored

cast-in-place piles. The piles are 1.5 meter

in diameter and approximately 43 meters

long with a design capacity of 3,000 ton

each.

The Tower pile load test supported over

6,000 ton.

Settlement

Settlement

It was determined the maximum long-term

settlement over time would be about a

maximum of 80mm .

This settlement would be a gradual

curvature of the top of grade over the

entire large site. When the construction

was at Level 135, the average foundation

settlement was 30mm

Construction

Construction

Achieve a three (3) day-cycle for

structural works.

Develop optimum transportation

systems with large capacity high

speed equipment.

Utilize optimum formwork system to

accommodate various building

shapes along the building height.

Develop organized logistic plans

throughout the construction period.

Apply all high-rise construction

technologies available at the time of

construction.

Planning for the concrete

Planning for the concrete

work

work

Prior to the construction of the tower,

extensive concrete testing and quality

control programs were put in place to

ensure that all concrete works are done in

agreement with all parties involved.

Tests are needed to confirm the

construction sequence of these large

elements and to develop curing plans that

are appropriate for the project, considering

major daily and seasonal temperature

fluctuations

Testing Regimes for

Testing Regimes for

Concrete

Concrete

Trial mix designs for all concrete types needed for

the project.

Mechanical properties, including compressive

strength, modulus of elasticity, and split tensile

strength.

Durability tests which included initial surface

absorption test and 30 minute absorption test.

Creep and shrinkage test program for all concrete

mix design.

Water penetration tests and rapid chloride

permeability test.

Shrinkage test program for all concrete mix

designs.

Pump simulation test for all concrete mix design

grades up to at least 600 meters.

Heat of hydration analysis and tests.

Testing Regimes for

Testing Regimes for

Concrete

Concrete

Creep Test

Testing Regimes for

Testing Regimes for

Concrete

Concrete

Pump Simulation Test :using over 600m of pipe

length to confirm the pump capacity and evaluate

the overall pressure losses in the pipes due to

friction /connections /concrete type

Testing Regimes for

Testing Regimes for

Concrete

Concrete

Pump Simulation

Testing Regimes for

Testing Regimes for

Concrete

Concrete

Heat of Hydration Make-op Test

Technologies used to achieve 3

Technologies used to achieve 3

-

-

day

day

cycles

cycles

Auto Climbing formwork system (ACS)

Rebar pre-fabrication

High performance concrete suitable for

providing high strength, high durability

requirement, high modulus, and pumping

Advanced concrete pumping technology

Simple drop head formwork system that

can be dismantled and assembled quickly

with minimum labor requirements

Column/Wall proceeding method, part of

ACS formwork system

Technologies used to achieve 3

Technologies used to achieve 3

-

-

day

day

cycles

cycles

Sequence of Construction and ACS

Sequence of Construction and ACS

The ACS form work is divided into four sections

consisting of the center core wall that is followed by

the wing wall construction along each of the three

tower wings.

Sequence of Construction and ACS

Sequence of Construction and ACS

Rebar Pre

Rebar Pre

-

-

fabrication

fabrication

Most of the reinforcing

bars for the core walls,

wing walls, and the nose

columns were

prefabricated at the

ground level.

This rebar fabrication and

pre-assembly method

resulted in man quality

control advantages and

reduced the number of

workers going up and

down the tower.

The rebar was assembled

in double story modules

to speed up the vertical

element construction

time.

Slab Formwork System

Slab Formwork System

Drop head system (also known as slab

support system is specially designed to

sustain a large combination of grid sizes,

resulting in maximum reusability of formwork

& economy) used for the slab construction

Slab Formwork System

Slab Formwork System

The slab shoring system consists of four levels of shores and one

level of re-shore to control the maximum loads in the slabs at the

lowest level. However, the shoring props at the upper-most slab were

left undisturbed

Day 0

: Conc Pouring

Day 1

: Slab formwork

Day 2

: Slab formwork

: Rebar Installation

: MEP

Day 3

: Conc Pouring

1/3 of

Prop

2/3 of

Prop

Form

2/3 of

Prop

1/2 of

Raking

Shore

Form

Form

1/2 of Raking

Shore

2/3 of

Prop

1/2 of Raking

Shore

N-1

N-2

N-3

N-4

N-5

N+0

Additional

Raking Shore

N+1

Form

Concrete Pumping

Concrete Pumping

CPB#1

CPB#3

CPB#4

CPB#2

Level Height Pouring Method Remarks

Ground ~ L145 531 m Direct Pumping

Target Height

(RC Structure)

L146 ~ L160M 624 m Re-pumping

Secondary Pump on

L124 (East wing 442m)

L160M ~ Spire1 681.7 m Hopper by T/C From Ground Level

Level Pressure Output

Engin

e

Remarks

Pump#1~

#3

185 / 320

bar

71 / 36

m3/hr

470

kw

2 nos. of

Main

1 no. of

Stand by

Pump#4

220 / 260

bar

110 m3/hr

200

kw

Secondary

Pumping

Pumping Area

(Ground Level)

Pipe Lines

Concrete Pump

. Pipe Lines

- D150mm, THK 11mm

- 5 Lines (1 for back up)

Concrete Placing Boom

- 32m boom for Center Core

- 3nos. of 28m boom for Wing Core

Concrete Pumping

Concrete Pumping

Line#2. (L139)

for South Wing

Line#3. (L124)

for East Wing

Line#4. (L112)

for West Wing

Pump#4.

(Secondary Pump on L124)

Line#1. (L160)

for Center Core

Line#5. (L160)

for Back up

L154 : RC Structure

L160Mezzanine : Steel Structure

Top of Finial : Spire

Pinnacle

Pumping Area

Pump#1~#3

. Pipe Lines

- D150mm, THK 11mm

- 5 Lines (1 for back up)

Concrete Pumping

Concrete Pumping

Concrete Pumping

Concrete Pumping

Spire Erection and Pinnacle Assembly

Spire Erection and Pinnacle Assembly

At Level 156, the reinforced concrete core wall will

reach its highest point and serves as the

foundation for the spires structural steel works.

The central pinnacle structure, which consists of

1200mm-2100mm diameter structural steel pipe,

varies in thickness from 60mm at the lowest level

to 30mm at the top.

The erection of the spire and the pinnacle starts

from level 156, and the erection of the spire was

done in traditional steel construction method.

However, the pinnacle pipe sections are stacked

from level 156 and lifted to the final position from

within the spire

Spire Erection and Pinnacle Assembly

Spire Erection and Pinnacle Assembly

The sequence of the pinnacle installation is shown in

Figure below and as follows:

Erection of the spire structure

Installation of the support beam

Installation of the lifting block and assemblies

Installation of the lifting equipment and assemblies

Lifting the pinnacle in a three step process

Installing cladding after each lift

Completing lift of the pinnacle and all connection

connections (gravity and lateral)

Completion of the cladding installation

Spire Erection and Pinnacle Assembly

Spire Erection and Pinnacle Assembly

Survey & Monitoring

Survey & Monitoring

Low Level Tower Control (Classical

Control Method )

XYZ

XYZ

XYZ

XYZ

Survey & Monitoring

Survey & Monitoring

Hight Level Tower Control (GPS Real

Time Kinematic)

Evacuation

Evacuation

Burj Dubai has built in fire protection as its concrete

back bone is naturally fire resistant

But how will people go out in an emergency?

The answer they dont

The burj dubai contains 9 special rooms build throw

layers of reinforced concrete and fire proof sheeting

The walls of these rooms will stand the heat of a fire

for 2 hours

Each room has special supply of air pumped throw

fire resistant pipes, sealed fire proofed doors stop

smoke from leaking in

Evacuation

Evacuation

There is 1 of these rooms in about every 30 floors

How they prevent the smoke from blocking the

access route to the rooms?

Early warning system:

Fire activate a smoke detector

Heat sensor

Water sprinklers

Net work of high power fans kick in

Fans force new clean cool air throw fire

resistant ducts into the building

The fresh air pushes the smoke out of the

stair way keeping the evacuation route

clear.

Evacuation

Evacuation

Cladding

Cladding

30000 glass panels of high quality European glass

enough to cover 17 football fields

The glass is thicker at the top to resist the high

wind

Its designed to let the maximum light in and to

keep heat out

Sunscreen(insideface)is

uselessagainstinfrared

fromthehotdesertsunso

theinnerplaniscoated

withathinlayerofsilver

thatkeepstheheatrays

out.

Outsidecoatreflectsthedaily

solarheatcomesdirectfromthe

sun.

ThemetalcoatingdeflectsU.V.

Radiationthatwillotherwiseheat

upthebuilding

Cladding

Cladding

Test 1 : Air infiltration test

To measure how much air gets in through the joints

Test 2 : static water

test

Water is spread evenly

for 15 minutes from

nozles attached to the

glass

Transducers

measures how much

water gets in

The data is transferred

to computer for

analysis

Cladding

Cladding

Test 3 : Dynamic water Test

Its a simulation for a desert Storm

The wind is Generated by a giant Fan and its

Spread water against the glass for 15 minutes

Cladding

Cladding

Test 4 : Earthquake Test

Earthquake Simulation which move the mock-up

floor of curtain walls 10 mm in two directions

With this test the know that curtain wall wont break

Fa

Fa

ade Maintenance

ade Maintenance

The tower's primary window washing and facade

maintenance system consists of three permanently-installed,

track-mounted, telescopic building maintenance machines

located in internal "garage" positions on uppermost levels.

it will take 36 workers three to four months to clean the entire

exterior facade

Elevators

Elevators

With an intelligent

elevator installation

mechanism, builders

of Burj Dubai ensure

a speedy journey

from the ground to

the 160

th

floor.

57 elevators and

eight escalators to

streamline the needs

of the residents and

visitors to commute

within the tower.

These elevators mark

the highest

installation in any

building and have

been developed by

Otis.

Elevators

Elevators

The main service

elevator that is

positioned in the

central core of Burj

Dubai has the worlds

highest elevator rise

at 504 metres

It moves at a speed

of 9 metres per

second and also has

the worlds longest

travelling distance for

an elevator. The lift to

the spire has the

worlds highest

landing at 636.9

meters.

Elevators

Elevators

Elevators are placed

into different zones.

Each elevator zone

serves different

audiences, maximizing

the efficiency and

saving time.

The sky lobby is an

intermediate floor

where residents,

guests, office staff will

change from an

express elevator to a

local elevator which

stops at each floor

within a certain

segment of the building.

The sky lobbies are

located on level 43, 76

and 123 and will

include a lounge area.

Mosatafa atteya

Ahmed Essam

Ramez Nazir

Mohamed Salah

Anda mungkin juga menyukai

- Burj KhalifaDokumen15 halamanBurj Khalifakavyareddy_17100% (1)

- Burj Dubai ReportDokumen33 halamanBurj Dubai ReportAhmed Essam67% (3)

- Tall Buildings and Its Structural SystemDokumen54 halamanTall Buildings and Its Structural SystemPragya Roy83% (6)

- The Structural Design of Almas Tower DubaiDokumen10 halamanThe Structural Design of Almas Tower Dubaishamimzubery1969100% (2)

- Burj KhalifaDokumen38 halamanBurj Khalifadeepesh3191100% (1)

- Case Studies - Concrete Mixed Use Buildings - Infinity Tower, Dubai, UAE - Portland Cement Association (PCA) PDFDokumen2 halamanCase Studies - Concrete Mixed Use Buildings - Infinity Tower, Dubai, UAE - Portland Cement Association (PCA) PDFMara Tom100% (1)

- Burj Dubai Concept, Design and Construction PresentationDokumen120 halamanBurj Dubai Concept, Design and Construction PresentationAhmed Essam88% (17)

- Engineering Report On The Shanghai TowerDokumen33 halamanEngineering Report On The Shanghai TowerLorenc Bogoviku100% (3)

- Tall Building and Aerodynamic Case StudyDokumen24 halamanTall Building and Aerodynamic Case StudyAnonymous DbxXniOECBelum ada peringkat

- Taipei 101projectDokumen24 halamanTaipei 101projectIoana TomescuBelum ada peringkat

- Highrise - StudyDokumen22 halamanHighrise - StudyMohammad Sajedul Karim Shikder 0920768010Belum ada peringkat

- Burj DubaiDokumen27 halamanBurj DubaiInche Helmi Dori DoriBelum ada peringkat

- Princes TowerDokumen6 halamanPrinces TowerUsman MuheebBelum ada peringkat

- High Rise BuildingsDokumen33 halamanHigh Rise BuildingsrenukaBelum ada peringkat

- Al Hamra Tower: Kuwait City, KuwaitDokumen20 halamanAl Hamra Tower: Kuwait City, Kuwaitayush dattaBelum ada peringkat

- Ocean Heights 2Dokumen3 halamanOcean Heights 2John Ray CuevasBelum ada peringkat

- 111 West 57th Street - 2019 08 18 22 19 23Dokumen2 halaman111 West 57th Street - 2019 08 18 22 19 23Harley soulBelum ada peringkat

- Empire State BuildingDokumen1 halamanEmpire State BuildingNIKZ02Belum ada peringkat

- Chapter 6 Stadium RoofDokumen27 halamanChapter 6 Stadium Roofjayanthi100% (2)

- Presentation Case Studies TaipeiDokumen16 halamanPresentation Case Studies TaipeiBanoth Shankar ce19b005Belum ada peringkat

- Cayan Tower: (Formerly Known As Infinity Tower)Dokumen11 halamanCayan Tower: (Formerly Known As Infinity Tower)Vi0% (1)

- Twisting Tower DesignDokumen17 halamanTwisting Tower Designmajkil1988100% (1)

- The Structural Design of Almas Tower DubaiDokumen10 halamanThe Structural Design of Almas Tower Dubaithanzawtun1981Belum ada peringkat

- Trump Tower Chicago High RiseDokumen13 halamanTrump Tower Chicago High RiseRohit DigraBelum ada peringkat

- IENG2020 Taipei 101 Reseaarch Paper NAGAKANEDokumen19 halamanIENG2020 Taipei 101 Reseaarch Paper NAGAKANEMasato NagakaneBelum ada peringkat

- Session 4 - Structural Systems in Tall BuildingsDokumen36 halamanSession 4 - Structural Systems in Tall BuildingsAlec PBelum ada peringkat

- Structural Systems For High Rise BuildingsDokumen7 halamanStructural Systems For High Rise BuildingsSuncica Zurkovic100% (1)

- Burj Khalifa Construction TimeDokumen8 halamanBurj Khalifa Construction TimeDiwaker Sharan Srivastava100% (1)

- Building Services 2Dokumen2 halamanBuilding Services 2i. tejaswiBelum ada peringkat

- DUBAI - Burj KhalifaDokumen15 halamanDUBAI - Burj Khalifaghoshmonika100% (1)

- High Rise Building ....................Dokumen45 halamanHigh Rise Building ....................Joshua100% (5)

- Buttressed CoreDokumen26 halamanButtressed CoreAnju100% (1)

- 100 Storey John Hancock Center, Chicago: A Case Study of The Design ProcessDokumen5 halaman100 Storey John Hancock Center, Chicago: A Case Study of The Design ProcessCrimsonPoshBelum ada peringkat

- 1 Fundamental of Tall Buildings DDDDDDDDDDDDDDDDDDDDDDDDokumen65 halaman1 Fundamental of Tall Buildings DDDDDDDDDDDDDDDDDDDDDDDعبدو عبدوBelum ada peringkat

- Structural Analysis of Al-Burj DubaiDokumen15 halamanStructural Analysis of Al-Burj DubaiDeepa Sharma100% (1)

- John Hancock Center: Case Study of Structural DesignDokumen37 halamanJohn Hancock Center: Case Study of Structural DesignbaluBelum ada peringkat

- The Retractable Roof and Movable Field at University of Phoenix Stadium ArizonaDokumen4 halamanThe Retractable Roof and Movable Field at University of Phoenix Stadium ArizonaHeitham Bou ChahineBelum ada peringkat

- Abu Dhabi Mosque Development Regulations - Volume 1 PlanningDokumen58 halamanAbu Dhabi Mosque Development Regulations - Volume 1 PlanningHang AyyaBelum ada peringkat

- Structural Design of Taipei 101 TowerDokumen44 halamanStructural Design of Taipei 101 TowerCerasella19100% (2)

- Burj KhalifaDokumen15 halamanBurj KhalifaSanand KarwaBelum ada peringkat

- Conceptual Design and Analysis of Long Span StructureDokumen13 halamanConceptual Design and Analysis of Long Span StructureMuhd YazidBelum ada peringkat

- Damp Proofing-1 PDFDokumen6 halamanDamp Proofing-1 PDFmaneeshaBelum ada peringkat

- Literature Review - Space Efficiency o Service Core in High Rise - Tanmayee PDokumen5 halamanLiterature Review - Space Efficiency o Service Core in High Rise - Tanmayee PTanmayeePanseBelum ada peringkat

- Rigid Frame Systems: High Rise BuildingDokumen42 halamanRigid Frame Systems: High Rise BuildingNidhi MehtaBelum ada peringkat

- Case Study - Taipei 101 & TMDsDokumen78 halamanCase Study - Taipei 101 & TMDsBhushan RaisinghaniBelum ada peringkat

- Architectural Design Studio RequirementsDokumen3 halamanArchitectural Design Studio RequirementsSankrita SivamBelum ada peringkat

- Presentation-Case Study of Shanghai Tower 12-04-14Dokumen48 halamanPresentation-Case Study of Shanghai Tower 12-04-14shreyashBelum ada peringkat

- Cayan Tower InfoDokumen2 halamanCayan Tower InfoAatifBelum ada peringkat

- Turning TorsoDokumen19 halamanTurning TorsoBagoes Rama Al AriefqiBelum ada peringkat

- Burj Dubai Concept Design and Construction PresentationDokumen17 halamanBurj Dubai Concept Design and Construction Presentationmariyam khanBelum ada peringkat

- Burj Khalifa برج خليفةDokumen28 halamanBurj Khalifa برج خليفةQuah Qiu Yu100% (2)

- Design and Construction of Burj-Dubai 104Dokumen11 halamanDesign and Construction of Burj-Dubai 104Selvam KaliamoorthyBelum ada peringkat

- High Rise Construction - ACDDokumen41 halamanHigh Rise Construction - ACDClary DsilvaBelum ada peringkat

- Burj KhalifaDokumen5 halamanBurj KhalifaBianca LegoBelum ada peringkat

- William Frazier BakerDokumen3 halamanWilliam Frazier BakerJoanna Marie NunagBelum ada peringkat

- Report (Print Whole)Dokumen22 halamanReport (Print Whole)rounit prashantBelum ada peringkat

- Burj KhalifaDokumen10 halamanBurj KhalifaSyeda Sana Naqi100% (2)

- Burj KhalifaDokumen5 halamanBurj Khalifa37-SIJO MONACHANBelum ada peringkat

- Almas Tower Nestor Jay Dagalea BSCE 2ADokumen20 halamanAlmas Tower Nestor Jay Dagalea BSCE 2AGerald CatiponBelum ada peringkat

- Burj Al Dubai - Now Known As Burj KhalifaDokumen1 halamanBurj Al Dubai - Now Known As Burj Khalifaherys0310Belum ada peringkat

- Engaging A Structural Engineer - Clients GuideDokumen23 halamanEngaging A Structural Engineer - Clients GuideashikshahBelum ada peringkat

- Design of Concrete Shear Wall BuildingsDokumen10 halamanDesign of Concrete Shear Wall BuildingsGKDATTABelum ada peringkat

- SCI P407 Download PDFDokumen4 halamanSCI P407 Download PDFpatricklim1982Belum ada peringkat

- SCI P409 DownloadDokumen4 halamanSCI P409 Downloadpatricklim1982Belum ada peringkat

- SCI P408 Download PDFDokumen4 halamanSCI P408 Download PDFpatricklim1982Belum ada peringkat

- Concrete Pavement Construction Basics: Tech NoteDokumen12 halamanConcrete Pavement Construction Basics: Tech NoteAbhijeet LimayeBelum ada peringkat

- Glossary of TermsDokumen4 halamanGlossary of Termspatricklim1982Belum ada peringkat

- 2 LoadingDokumen5 halaman2 LoadingRaizil AisyaizniBelum ada peringkat

- Top Down ContnDokumen11 halamanTop Down ContnAnonymous dlSmlsymHBelum ada peringkat

- A Rational Approach To Obtaining Effective Lengths of Compression Members in Framed Structures PDFDokumen6 halamanA Rational Approach To Obtaining Effective Lengths of Compression Members in Framed Structures PDFpatricklim1982Belum ada peringkat

- CUFSM tUTORIALDokumen10 halamanCUFSM tUTORIAL^password0% (1)

- Micro Piles For Structural DesignDokumen25 halamanMicro Piles For Structural DesignPedro Cedeño100% (1)

- Spread Footing Analysis and DesignDokumen21 halamanSpread Footing Analysis and DesignEdwin VizueteBelum ada peringkat

- RCMax Min SizeDokumen5 halamanRCMax Min Sizepatricklim1982Belum ada peringkat

- PDA Testing ResultsDokumen33 halamanPDA Testing Resultspatricklim1982100% (1)

- Wind Loading On Tall BuildingsDokumen14 halamanWind Loading On Tall BuildingsHarish T S GowdaBelum ada peringkat

- Flat Slab BhavikattiDokumen23 halamanFlat Slab BhavikattiSharath GuptaBelum ada peringkat

- Portal Frame Vs Other FrameDokumen20 halamanPortal Frame Vs Other Framepatricklim1982Belum ada peringkat

- Thumb Rules For Steel DesignDokumen3 halamanThumb Rules For Steel Designpranit_rai100% (1)

- RCMax Min SizeDokumen5 halamanRCMax Min Sizepatricklim1982Belum ada peringkat

- Project Management Practice and Risk Perception in Construction CompaniesDokumen6 halamanProject Management Practice and Risk Perception in Construction CompaniesAkhileshkumar PandeyBelum ada peringkat

- Portal Frame Vs Other FrameDokumen20 halamanPortal Frame Vs Other Framepatricklim1982Belum ada peringkat

- Pile Cap Reinforcement - BCA Singapore PDFDokumen11 halamanPile Cap Reinforcement - BCA Singapore PDFkarthicksipBelum ada peringkat

- Thumb Rules For Steel DesignDokumen3 halamanThumb Rules For Steel Designpranit_rai100% (1)

- Failure of Soil Nail WallsDokumen13 halamanFailure of Soil Nail WallsAndy AcousticBelum ada peringkat

- Shear Connection in Composite Bridge Beams - SteelconstructionDokumen12 halamanShear Connection in Composite Bridge Beams - Steelconstructionpatricklim1982Belum ada peringkat

- ThePileDrivingAnalyzer FieldTestingAndDataInterpretationDokumen18 halamanThePileDrivingAnalyzer FieldTestingAndDataInterpretationpatricklim1982Belum ada peringkat

- Structural Capacities of H-Shaped RC Core Wall Subjected To Lateral Load and Torsion PDFDokumen8 halamanStructural Capacities of H-Shaped RC Core Wall Subjected To Lateral Load and Torsion PDFpatricklim1982Belum ada peringkat

- The Analysis and DesignDokumen36 halamanThe Analysis and Designpatricklim1982Belum ada peringkat

- Standard Fire EngineDokumen2 halamanStandard Fire Enginepatricklim1982Belum ada peringkat

- Long ColumnDokumen10 halamanLong ColumnSheenaMarieM.SalvadorBelum ada peringkat

- ABANTI COLOUR TEX LTD. (NEW BUILDINGS) Structural Full 16092019Dokumen107 halamanABANTI COLOUR TEX LTD. (NEW BUILDINGS) Structural Full 16092019ABDUL JABBERBelum ada peringkat

- Bridges - EN - AcelorMittalDokumen52 halamanBridges - EN - AcelorMittalstavros_stergBelum ada peringkat

- Literature Review of Cable Stayed BridgeDokumen8 halamanLiterature Review of Cable Stayed Bridgeea53sm5wBelum ada peringkat

- Calculation Sheet of Residential Building (Pile Caps Type)Dokumen143 halamanCalculation Sheet of Residential Building (Pile Caps Type)Anonymous ciKyr0t100% (1)

- Building Drawing Midterm ExamDokumen6 halamanBuilding Drawing Midterm ExamRahul SinhaBelum ada peringkat

- Fire DamagedDokumen18 halamanFire DamagedSanjoy SanyalBelum ada peringkat

- Prestressed BeamDokumen15 halamanPrestressed BeamMohamed Abbassy100% (1)

- Taper Threaded Rebar Splicing SystemsDokumen20 halamanTaper Threaded Rebar Splicing SystemsHao LuoBelum ada peringkat

- Determination of Ductility (DCM and DCH) Used in EC8Dokumen19 halamanDetermination of Ductility (DCM and DCH) Used in EC8Anonymous O404LiV4CBelum ada peringkat

- PFP 136F Backpropping Flat SlabsDokumen16 halamanPFP 136F Backpropping Flat SlabsAdonis CabrasBelum ada peringkat

- Critical Moment - Lateral Torsional BucklingDokumen31 halamanCritical Moment - Lateral Torsional Bucklingshazrin yusofBelum ada peringkat

- Runway Calculation: Description Unit DataDokumen2 halamanRunway Calculation: Description Unit DataBang OchimBelum ada peringkat

- Asset Management Guide Specs - 2004 Csi Format (Div 01-33) Guide Spec - 2004 Csi Format Division 32 Exterior Improvements 32 1343 Pervious Concrete Pavement 120726Dokumen12 halamanAsset Management Guide Specs - 2004 Csi Format (Div 01-33) Guide Spec - 2004 Csi Format Division 32 Exterior Improvements 32 1343 Pervious Concrete Pavement 120726Muhamad Hafid ABelum ada peringkat

- Petronas Towers PDFDokumen22 halamanPetronas Towers PDFRuSsdy MubaraQhBelum ada peringkat

- Deterioration of Concrete - 034623Dokumen11 halamanDeterioration of Concrete - 034623Hacking SoftwareBelum ada peringkat

- FARM Mechanics Lab.Dokumen124 halamanFARM Mechanics Lab.AYSON N. DELA CRUZBelum ada peringkat

- Lecture 4 - House DesignDokumen18 halamanLecture 4 - House Designkkhan_451062Belum ada peringkat

- Rectangle BeamDokumen5 halamanRectangle BeamAlok SarkarBelum ada peringkat

- Design of Vertical StirrupDokumen3 halamanDesign of Vertical StirrupAnton_Young_1962Belum ada peringkat

- Registers & RecordsDokumen11 halamanRegisters & RecordsShesha ShayanBelum ada peringkat

- Fiber Reinforced Concrete Lif Takviyeli BetonDokumen70 halamanFiber Reinforced Concrete Lif Takviyeli BetonaygunbayramBelum ada peringkat

- Concrete TechnologyDokumen100 halamanConcrete TechnologyAnonymous 2UbC4s94M0100% (2)

- State-Of-The-Art Report On Fiber Reinforced Concrete ACI 544-2002Dokumen66 halamanState-Of-The-Art Report On Fiber Reinforced Concrete ACI 544-2002Attie761367% (3)

- OutputDokumen78 halamanOutputSAI ASSOCIATE100% (1)

- Estimate Construction of London PalaceDokumen6 halamanEstimate Construction of London PalaceRajwinder Singh BansalBelum ada peringkat

- Assignment 4 Model Answer PDFDokumen8 halamanAssignment 4 Model Answer PDFRyan HuangBelum ada peringkat

- Design Sheet Pile Walls Using Truline Update 1 8-8-13Dokumen35 halamanDesign Sheet Pile Walls Using Truline Update 1 8-8-13VenkataLakshmiKorrapati100% (1)

- Concrete Basements, Design and Construction Guide - The Concrete CentreDokumen53 halamanConcrete Basements, Design and Construction Guide - The Concrete CentreMickaelGameiro67% (3)

- Reinforced Concrete Curved Beams in Literature: IOP Conference Series: Materials Science and EngineeringDokumen11 halamanReinforced Concrete Curved Beams in Literature: IOP Conference Series: Materials Science and EngineeringDam HoangBelum ada peringkat