Ceramics - Engineer's Handbook

Diunggah oleh

hatharasingheHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ceramics - Engineer's Handbook

Diunggah oleh

hatharasingheHak Cipta:

Format Tersedia

Engineering Materials - Ceramics

Materials: Ceramics

Introduction Ceramic Types Online Resources

Introducti on to Cerami cs

Ceramics are inorganic non-metallic materials.

Metal oxides (Al2O3, FeO, etc.) are common

examples of ceramics, but other compounds

such as carbides and nitrides are also included.

Porcelain, glass, bricks and refractory

materials are some examples of traditional

ceramics. In the last 30 years, advances in

material science have transformed formerly

brittle ceramics into materials tough enough to

withstand engine environments. Ceramics are

used in a variety of applications including

window glass, implantable teeth, brick,

ceramic bones, nuclear fuel, tennis racquets,

solid-state electronic devices, engine

components, cutting tools, valves, bearings,

and chemical-processing equipment.

The properties for which ceramics are most often selected include:

High-temperature resistance (High melting temperatures.)

High electrical resistivity (Although some ceramics are superconductors.)

Broad range of thermal conductivity (Some ceramics are excellent insulators)

High hardness (Many ceramics are brittle.)

Good chemical and corrosion resistance.

Low cost of raw materials and fabrication for some ceramics.

Good appearance control through surface treatments, colorization, etc.

Ceramics are generally more brittle than metals

and can have similar stiffness (modulus of

elasticity) and similar strength, particularly in

compression. But in a tensile test they are likely

to fail at a much lower applied stress. This is

because the surfaces of ceramics nearly always

contain minute cracks ("Griffith cracks"), which

magnify the applied stress.

Since ceramics often have very high

wear-resistance and hardness, most ceramic

parts are formed as near net shape as possible.

Ceramics are most often produced by

compacting powders into a body which is then

sintered at high temperatures. During sintering

the body shrinks, the grains bond together and a

solid material is produced. Other ceramic

forming processes include: Dry Pressing,

Isostatic Pressing, Roll Compaction, Continuous

Tape Casting, Slip Casting, Extrusion, Injection Molding, Pre-Sinter Machining, Hot-Pressing, Hot Isostatic

Engineer's

Handbook

Reference

Tables

Rapid

Prototyping

Manufacturing

Methods

Engineering

Materials

Engineering

Software

Reference

Books

Mechanical

Components

Site Index Material Properties Ferrous Metals Non Ferrous Metals Plastics Ceramics Composites

Ceramic

Refractory

vitcas.com/Cera

UK Manufacturer of

Ceramic Fibre

Adhesive, High

Quality

Refractories

...

Crusher & Mill for

Mining

shanghai-crusher.com/Stone_Crusher

Supply 25-1000t/h Stone Crushing

Line,Grinding Line,Sand Making

Line

Ceramics - Engineer's Handbook http://www.engineershandbook.com/Materials/ceramics.htm

1 of 5 2014-05-20 9:54 ..

Pressing, Grinding, Lapping and Polishing.

Ceramics are generally separated into the following categories.

Metallic Oxides 1.

Glass Ceramics 2.

Nitrides and Carbides 3.

Glass 4.

Carbon and Graphite 5.

Porcelain 6.

Ceramic Fibers 7.

Ceramic Type Characteristics

Metallic Oxides

Alumina Abundant and easily fabricated.

Good strength and hardness.

Wear and Temperature Resistant.

Good electrical insulators.

Low dielectric loss.

Beryllium Oxides Exceptionally high thermal conductivities (for ceramics)

at low to moderate temperatures.

Zirconia Extreme inertness to most metals.

Good toughness and strength.

Glass Ceramics

Glass-Ceramics Low, mediumor high thermal expansion depending on

composition type.

Good electrical insulators.

Transparent

One can be machined with steel tools.

Nitrides and Carbides

Silicon Nitrides Resistant to high temperatures, to thermal stress and

shock.

High strength and oxidation resistant.

Good electrical insulators.

Boron Carbide High hardness and low density.

Best abrasion resistance of any ceramic.

Low strength at high temperatures.

Ceramics - Engineer's Handbook http://www.engineershandbook.com/Materials/ceramics.htm

2 of 5 2014-05-20 9:54 ..

Silicon Carbides Low electrical resistivity.

High strength and resistance to chemical attack, high

temperature and thermal stress.

Tungsten Carbides Used for tool tips.

Excellent hardness and mechanical strength.

Good thermal conductivity.

Good wear and abrasion resistance.

Glass

Glasses

Oxide (silica)

Silicates

Phosphates

Borosilicates

Good resistance to thermal shock.

Large range of special optical characteristics.

Transperent.

Low thermal expansion and high dielectric strength.

Good chemical resistance.

Carbon and Graphite

Carbons and Graphites Poor strength except when produced as fibre.

Good electrical and thermal conductivity

Creep resistant at high temperatures in non-oxidizing

conditions.

Self-lubricating.

Good refractoriness and thermal shock resistance.

Low density and chemically inert.

Carbon/Carbon

Composites

High strength and low coefficient of thermal expansion

at temperatures above 2000C.

Excellent thermal shock resistance.

Superior toughness, excellent thermal and electrical

conductivity

Resistance to corrosion and abrasion.

High cost.

Porcelain

Porcelain Good chemical and thermal resistance.

High density, strength, resistivity and dielectric strength

Good thermal shock, wear and hot strength.

Chemically inert.

Ceramic Fibers

Ceramic Fibers Oxides spun to fiber and bulked to felt.

Used for high temperature insulation including former

applications of asbestos.

Ceramic Links

Resource Sites

Introduction to Ceramics

Ceramics - Engineer's Handbook http://www.engineershandbook.com/Materials/ceramics.htm

3 of 5 2014-05-20 9:54 ..

A good article on the background of the ceramics industry provided by The American Ceramics Society.

Advanced Ceramic Technology Center

The Advanced Ceramic Technology Center has the resources to help U.S. industry overcome the high

cost of machining and certifying structural ceramics, especially for stringent applications such as heat engines.

Ceramics Industry Magazine - Reference Tables

This site has some great references including: Material Properties, Drying/Firing Tables,

Forming/Finishing Info., Refractories and Testing Methods.

Dynamic-Ceramic - Design Guides

A series of guides are intended to act as an aid to engineers and designers wishing to produce cost

effective designs for advanced ceramic manufacture. The design tips also refer primarily to components which

have to be finish ground to tight tolerances.

Dynamic-Ceramic - Material Properties

This site was designed to aid in the selection of advanced ceramics with a selection of pages, which

provide both comparative data on the available materials in addition to a more in-depth analysis of the

individual materials and their mechanical and physical properties.

Dynamic-Ceramic - Manufacturing Processes

Ceramic forming processes may be classified as traditional - die pressing, cold isostatic pressing, slip

casting and extrusion - or as new and emerging, such as injection moulding and tape casting.

Magazines, Periodicals, Newsletters

Ceramic Industry Magazine

Ceramic Industry magazine is the exclusive voice of ceramic manufacturing, serving the advanced

ceramics, glass, whitewares, structural clay, refractories and decorating technology industries.

Ceramic Bulletin

Ceramic Bulletin provides authoritative coverage of established and emerging processing technology

that will impact ceramic manufacturing around the world.

Societies and Organizations

The American Ceramic Society

ACerS, an international association that provides the latest technical, scientific and educational

information to its Members and others in the ceramics and related materials field, structures its services, staff

and capabilities to meet the needs of the ceramics community, related fields, and the general public.

Swedish Ceramic Institute

Informative site with a 2-minute introduction to ceramics, material data and other useful information.

Meta Sites

Metallurgical and Materials Engineering Global Links

Ceramics and Industrial Minerals

Metallurgical and Materials Engineering Global Links

The WWW Virtual Library: Technical Ceramics

Ceramics - Engineer's Handbook http://www.engineershandbook.com/Materials/ceramics.htm

4 of 5 2014-05-20 9:54 ..

Top of Page

Copyright 2004 - 2006 -- EngineersHandbook.com - All Rights Reserved - Disclaimer

Contact Information

Privacy Policy

Ceramics - Engineer's Handbook http://www.engineershandbook.com/Materials/ceramics.htm

5 of 5 2014-05-20 9:54 ..

Anda mungkin juga menyukai

- Discover the History and Uses of Ceramic MaterialsDokumen7 halamanDiscover the History and Uses of Ceramic Materialsletter_ashish4444Belum ada peringkat

- Ceramics Manufacturing, Properties & ApplicationsDokumen6 halamanCeramics Manufacturing, Properties & ApplicationsRavi VermaBelum ada peringkat

- Ceramic Cutting Tools: Materials, Development and PerformanceDari EverandCeramic Cutting Tools: Materials, Development and PerformancePenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Glass-Ceramics Their ProductionDokumen69 halamanGlass-Ceramics Their ProductionTomas Jefferson100% (1)

- Tieng Anh Chuyen Nganh SilicatDokumen77 halamanTieng Anh Chuyen Nganh SilicatChết SợBelum ada peringkat

- Firing of Porcelain TilesDokumen5 halamanFiring of Porcelain TilesRajarshi Dionysus BhattacharyyaBelum ada peringkat

- Fire More For Less PDFDokumen5 halamanFire More For Less PDFJose Vicente Nuguid ErictaBelum ada peringkat

- Introduction To Ceramic Engineering DesignDokumen457 halamanIntroduction To Ceramic Engineering DesignRaghavendra nathBelum ada peringkat

- Roller Hearth Kiln - IjoeDokumen6 halamanRoller Hearth Kiln - IjoeSunit AroraBelum ada peringkat

- 15-Porcelain-Raw Materials, Processing, Phase Evolution, and Mechanical Behavior PDFDokumen18 halaman15-Porcelain-Raw Materials, Processing, Phase Evolution, and Mechanical Behavior PDFmichael.cretzuBelum ada peringkat

- Roller KilnsDokumen3 halamanRoller Kilnsjohan_nieuwoudtBelum ada peringkat

- An Introduction To Ceramic Engineering DesignDokumen457 halamanAn Introduction To Ceramic Engineering DesignRaul100% (1)

- Daniel RhodesDokumen3 halamanDaniel RhodeskenneBelum ada peringkat

- Silicon Nitride - Synthesis, Properties and Application (2012)Dokumen176 halamanSilicon Nitride - Synthesis, Properties and Application (2012)Daud BabaBelum ada peringkat

- Pendahuluan Ceramic MaterialsDokumen45 halamanPendahuluan Ceramic MaterialsRaniBelum ada peringkat

- Deformations in CeramicsDokumen6 halamanDeformations in CeramicsashutoshgoelBelum ada peringkat

- Sintering of Ceramics-Overview PDFDokumen83 halamanSintering of Ceramics-Overview PDFEstelle Maurice-ArgentBelum ada peringkat

- FeldsparDokumen7 halamanFeldsparRiChy KantuBelum ada peringkat

- Ceramics: Windows To The FutureDokumen75 halamanCeramics: Windows To The FuturevishwanathanskBelum ada peringkat

- Energy Saving in Sintering of Porcelain StonewareDokumen8 halamanEnergy Saving in Sintering of Porcelain StonewareTasha Tashlihatul AmaliahBelum ada peringkat

- White Wares by K-H SchullerDokumen17 halamanWhite Wares by K-H SchullerChuff123Belum ada peringkat

- Slip CastingDokumen13 halamanSlip CastingRishi DasguptaBelum ada peringkat

- (Advanced Ceramics, 1) James F. Shackelford-Bioceramics-Taylor & Francis (1999) PDFDokumen75 halaman(Advanced Ceramics, 1) James F. Shackelford-Bioceramics-Taylor & Francis (1999) PDFjerry cristianoBelum ada peringkat

- FIRE Compendium Series: Refractory Castable EngineeringDokumen2 halamanFIRE Compendium Series: Refractory Castable EngineeringKhaled BOUALIBelum ada peringkat

- New Model Predicts Particle Size from Impact CrushingDokumen4 halamanNew Model Predicts Particle Size from Impact CrushingKallol MahalanabisBelum ada peringkat

- Silicon Nitride CeramicDokumen43 halamanSilicon Nitride CeramicSukmaSuciBelum ada peringkat

- Alumina Manufacturing ProcessesDokumen7 halamanAlumina Manufacturing Processesm_hassanaliBelum ada peringkat

- Processing The DentureDokumen8 halamanProcessing The DentureMody ShaheenBelum ada peringkat

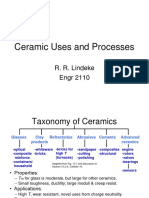

- Ceramic Uses and ProcessesDokumen22 halamanCeramic Uses and ProcessesWang Zheng FengBelum ada peringkat

- Injection Molding - Why & How To Do Gate-Seal Experiments - Plastics TechnologyDokumen4 halamanInjection Molding - Why & How To Do Gate-Seal Experiments - Plastics TechnologySandeep LeeBelum ada peringkat

- Flame Spray Drying Equipment, Mechanism, and Perspectives by Mariia Sobulska, Ireneusz ZbicinskiDokumen159 halamanFlame Spray Drying Equipment, Mechanism, and Perspectives by Mariia Sobulska, Ireneusz ZbicinskiJose Bermeo VBelum ada peringkat

- Effect of Organic Solvents on Electrodeposition and Wear of Ni-Alumina CoatingsDokumen47 halamanEffect of Organic Solvents on Electrodeposition and Wear of Ni-Alumina CoatingsRosa VasquezBelum ada peringkat

- Methods of Shaping Ceramic PowdersDokumen6 halamanMethods of Shaping Ceramic PowdersIr AyenBelum ada peringkat

- History of PlasticsDokumen47 halamanHistory of PlasticsVenkat Reddy YedullaBelum ada peringkat

- Understading About Liquid Polishing CompoundDokumen3 halamanUnderstading About Liquid Polishing CompoundcuibaprauBelum ada peringkat

- Ceramics 1 MCG2361 2016Dokumen42 halamanCeramics 1 MCG2361 2016Jessica BarhomaBelum ada peringkat

- 16 - Silicon NitrideDokumen6 halaman16 - Silicon NitrideMd. Rafiqul IslamBelum ada peringkat

- Advanced heating glassDokumen44 halamanAdvanced heating glassmetalman_m67% (3)

- Ceramics & Glass STUDENTS, 2018Dokumen20 halamanCeramics & Glass STUDENTS, 2018aviBelum ada peringkat

- METAL CASTING GUIDEDokumen18 halamanMETAL CASTING GUIDEvelavansuBelum ada peringkat

- Vitreous Enamel Coatings Degradation FactorsDokumen7 halamanVitreous Enamel Coatings Degradation FactorsFernando BarreraBelum ada peringkat

- CeramicsDokumen54 halamanCeramicsDëv PacificarBelum ada peringkat

- Refractory Material Selection For Steelmaking: Emerging Ceramics & Glass TechnologyDokumen52 halamanRefractory Material Selection For Steelmaking: Emerging Ceramics & Glass Technologyemregnes0% (1)

- Advanced Ceramics ProcessingDokumen17 halamanAdvanced Ceramics ProcessingLuis Kike RiveraBelum ada peringkat

- Revised DraftDokumen45 halamanRevised DraftEva LloydBelum ada peringkat

- Pilkington Float GlassDokumen27 halamanPilkington Float GlassVivek RanganathanBelum ada peringkat

- TN680 MHTC 96 Drop CalorimetryDokumen9 halamanTN680 MHTC 96 Drop CalorimetryMiruna PetriaBelum ada peringkat

- 20 Faust Porcelain Vitreous EnamelsDokumen9 halaman20 Faust Porcelain Vitreous Enamelsyanda prBelum ada peringkat

- Copper (II) OxideDokumen5 halamanCopper (II) OxideWill Aguilar MamaniBelum ada peringkat

- Effect of Soaking On Phase Composition and Topography and Surface MicrostructureDokumen9 halamanEffect of Soaking On Phase Composition and Topography and Surface MicrostructureRafaelBelum ada peringkat

- Applied Thermal EngineeringDokumen45 halamanApplied Thermal EngineeringMp SiyadBelum ada peringkat

- Silicon NitrideDokumen2 halamanSilicon NitrideNishanth ShannmugamBelum ada peringkat

- Damage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanDokumen10 halamanDamage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanPham tony1604Belum ada peringkat

- POlymer CompoundingDokumen3 halamanPOlymer CompoundingSourav SutradharBelum ada peringkat

- Adjusting Engobe Layer to Avoid Water MarksDokumen16 halamanAdjusting Engobe Layer to Avoid Water MarkserrairachidBelum ada peringkat

- Lost Foam Cast ProcemssDokumen22 halamanLost Foam Cast ProcemssSebastian PeterBelum ada peringkat

- Inorganic Chemistry 4 - SCH 304Dokumen10 halamanInorganic Chemistry 4 - SCH 304Arsalan ChoudharyBelum ada peringkat

- Casting MethodDokumen15 halamanCasting MethodGabriela Maira Sanches VolpiBelum ada peringkat

- MT308 Fuels, Furnaces and RefractoriesDokumen3 halamanMT308 Fuels, Furnaces and RefractoriesMerrin John VarkeyBelum ada peringkat

- Ian J. McColm (Auth.) - Dictionary of Ceramic Science and Engineering (1994, Springer US)Dokumen391 halamanIan J. McColm (Auth.) - Dictionary of Ceramic Science and Engineering (1994, Springer US)Rolando Nuñez Monrroy100% (1)

- Polyactic Acid Shrink Films and MethodsDokumen16 halamanPolyactic Acid Shrink Films and MethodshatharasingheBelum ada peringkat

- Guide To Polyolefin FilmDokumen42 halamanGuide To Polyolefin FilmswordprakashBelum ada peringkat

- Shrink FilmDokumen29 halamanShrink Filmhatharasinghe100% (2)

- Chemical Engineering StudentsDokumen41 halamanChemical Engineering StudentshatharasingheBelum ada peringkat

- Canon ManualDokumen220 halamanCanon ManualMúsico de SáBelum ada peringkat

- Problems in Film ProcessingDokumen33 halamanProblems in Film ProcessinghatharasingheBelum ada peringkat

- SAW DUST To Transport FuelDokumen84 halamanSAW DUST To Transport FuelhatharasingheBelum ada peringkat

- PE FilmProcessingGuideDokumen8 halamanPE FilmProcessingGuideHicham HafianiBelum ada peringkat

- DhammiDokumen1.251 halamanDhammihatharasingheBelum ada peringkat

- Marketing ManagementDokumen40 halamanMarketing ManagementhatharasingheBelum ada peringkat

- SRI LANKA STANDARDS INSTITUTION PRODUCTS REQUIRING SLS MARKDokumen3 halamanSRI LANKA STANDARDS INSTITUTION PRODUCTS REQUIRING SLS MARKhatharasingheBelum ada peringkat

- Dendropower AnalysisDokumen28 halamanDendropower AnalysishatharasingheBelum ada peringkat

- Biomass Gasification: PHALTAN-415523, Maharashtra, IndiaDokumen21 halamanBiomass Gasification: PHALTAN-415523, Maharashtra, IndiahatharasingheBelum ada peringkat

- Section MN: FL WL SK CL FL WL SK CL FL WL SK CLDokumen1 halamanSection MN: FL WL SK CL FL WL SK CL FL WL SK CLS Amit RaoBelum ada peringkat

- Proceedings of The Inter-ISC 18 PDFDokumen240 halamanProceedings of The Inter-ISC 18 PDFLiviu GruiaBelum ada peringkat

- MagnetronDokumen45 halamanMagnetronAnonymous c75J3yX33100% (2)

- CV Indah Dita Oktaviani PDFDokumen1 halamanCV Indah Dita Oktaviani PDFLovely KittyBelum ada peringkat

- HVDC Transmission LinesDokumen12 halamanHVDC Transmission LinesDIPAK VINAYAK SHIRBHATE100% (2)

- Ureteral Stents Technology: Biodegradable and Drug-Eluting PerspectiveDokumen20 halamanUreteral Stents Technology: Biodegradable and Drug-Eluting Perspectivevw5ohgjrBelum ada peringkat

- Using the Georgia Tech Network Simulator to Conduct Simulation ExperimentsDokumen148 halamanUsing the Georgia Tech Network Simulator to Conduct Simulation ExperimentsJatin JaniBelum ada peringkat

- Arithmetic and Logic InstructionsDokumen83 halamanArithmetic and Logic InstructionsAkash PandaBelum ada peringkat

- Learnings from penetration testing a university websiteDokumen3 halamanLearnings from penetration testing a university websiteLovepreetSidhu100% (1)

- IT General Controls QuestionnaireDokumen6 halamanIT General Controls Questionnairewktso0% (1)

- Store 150Dokumen12 halamanStore 150shawanqureshi1706160Belum ada peringkat

- SDMX Reference Architecture v1Dokumen20 halamanSDMX Reference Architecture v1Vishal BiseswarBelum ada peringkat

- Liste de Prix BCM Juin 2010Dokumen4 halamanListe de Prix BCM Juin 2010bakzazamBelum ada peringkat

- Gama de Perfiles Europeos 1 European SecDokumen251 halamanGama de Perfiles Europeos 1 European SecHolman Josue Reyes MoralesBelum ada peringkat

- Katalog Pipa HDPE Wavin BlackDokumen2 halamanKatalog Pipa HDPE Wavin BlackChristian MakigaweBelum ada peringkat

- 0653 s16 QP 62Dokumen20 halaman0653 s16 QP 62yuke kristinaBelum ada peringkat

- Lifting Plan DetailsDokumen2 halamanLifting Plan DetailssivaavissriBelum ada peringkat

- Homemade Solar Food DehydratorDokumen6 halamanHomemade Solar Food DehydratorHilion FLAVIO100% (1)

- Moodle User Manual for UJ StudentsDokumen14 halamanMoodle User Manual for UJ StudentsalexBelum ada peringkat

- Parts Catalog: 0CR10-M63901ENDokumen50 halamanParts Catalog: 0CR10-M63901ENPedro AntãoBelum ada peringkat

- Les 02Dokumen3 halamanLes 02Jessica JcaBelum ada peringkat

- Contoh Perhitungan Lifting Set Dan PadeyesDokumen4 halamanContoh Perhitungan Lifting Set Dan Padeyesnur azisBelum ada peringkat

- Nimco Special Loader ValvesDokumen83 halamanNimco Special Loader ValvesMarusya KlimovaBelum ada peringkat

- 09931372A Clarus 590 User's GuideDokumen284 halaman09931372A Clarus 590 User's GuideLuz Idalia Ibarra RodriguezBelum ada peringkat

- Dialog - Undergraduate Program Metalurgy & Material EngineeringDokumen5 halamanDialog - Undergraduate Program Metalurgy & Material EngineeringAlfa DamaBelum ada peringkat

- Five Generations of ComputersDokumen4 halamanFive Generations of ComputersMohammed Abu ShaibuBelum ada peringkat

- Iptc-17413-Ms EspDokumen22 halamanIptc-17413-Ms Espamramazon88Belum ada peringkat

- Steam Tank Pressure & QualityDokumen5 halamanSteam Tank Pressure & QualityAri Reza KBelum ada peringkat

- Factors To Consider in Foundation Design Chapter # 02Dokumen18 halamanFactors To Consider in Foundation Design Chapter # 02Ali ShaheryarBelum ada peringkat