NGP Section 13

Diunggah oleh

poonam_ranee39340 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

84 tayangan26 halamanglass fittings

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniglass fittings

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

84 tayangan26 halamanNGP Section 13

Diunggah oleh

poonam_ranee3934glass fittings

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 26

National Glass can supply glass and ttings

packages for toughened door assemblies,

sliding doors, facades and shopfronts,

spider wall systems, point xings or stainless

steel stand offs, balustrading, pool gates,

fences and shower screen enclosures.

13

frameless

glass

installations

Typical spider xing.

Type B bottom rail top corner patch toughened entry door Australia Glass.

72

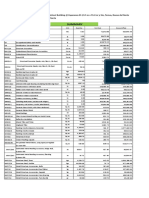

heavyweight glass chart

Glass types Thickness (mm)

Clear 10/12/15/19/25

Grey 10/12

Bronze 10/12

Green 10/12

Blue 10/12

Acid etched 10/12

Low-iron 10/12/15/19

Sunergy low-E 10

Please check on availability upon request.

Typical oor spring.

Typical corner

patch tting.

73

pivot doors

Pivoting glass doors and associated panels such as sidelites

and highlights must be a minimum of 10/12mm toughened

safety glass (Please check with AS1288 to determine actual

thickness required). These doors are the most common

frameless type used in commercial and residential applications.

The doors use either a concealed top or bottom self closer

mechanism with a pivot point connecting to a discrete metal

patch tting at the top and bottom corners of the door or

alternatively, a full width metal door rail can also be used.

pivot door types

Corner patch ttings Type B and C

Full length rails Type A and B

Offset pivot doors Types A, B and C

Centre x pivot doors Types A, B and C

G-tech pivot doors See pages 78-79

See Diagram 13.1.

corner patch fitting doors

Shown as Type B combination and Type C doors on

Diagram 13.1, patch ttings are simply a bolt through glass

metal tting requiring a corner cutout and hole in the glass.

These discrete patches provide a sleek and clean frameless look,

ideal for shop displays.

A lock body patch tting can also be installed. The patch body

covers are available in a variety of nishes including anodised,

powder coated, plated brass and stainless nishes.

Maximum door sizes using 10/12mm thickness glass is 2400mm

x 1000mm. 15mm glass thickness 2400mm x 900mm. Bigger

size doors should use a top and bottom full length rail. Please

note that windloading and other loading considerations may

override the sizes and thicknesses noted above. Please check

with the appropriate standards.

full length rail doors

Shown as Type A and combination Type B doors on

Diagram 13.1, these metal rails are clamped onto the glass

edge. No holes or cutouts required. The main features of the rail

are to act as a kick plate to lesson chance of glass breakage

and for oversize doors, where the patch tting is not suited.

Rail body covers are available in a variety of nishes including

anodised, powder coated, plated brass and stainless nishes.

Type A top and bottom rail toughened entry doors Glasstech Cairns.

Type C top and bottom corner patch toughened entry door Australia Glass.

74

diagram 13.1: frameless pivot door and entry types

B1 COC B2 COC B1 B2 B3 B4 B6 B5

B7 B8 B9 B10

C1 C1 COC C2 C2 COC C3 C4 C5

C6 C7 C8 C9 C10

A1 A1 COC A2 A2 COC

type A full length top and bottom rails

type B top corner patch fittings and full length bottom rails

type C top and bottom corner patch fittings

75

highlite glass fin design

Some frameless door entry types require stabilising toughened

ns to reduce deection created by the loads acting on the entry.

These include external and internal wind loading, human impact

and the motion of the door during operation.

Minimum design requirements are:

0 Fins should always be mechanically xed to the structure

by means of a back to back steel or stainless steel

n bracket ;

0 Structural ns should not be less than 12mm in thickness

and should always be toughened (see also Diagram 13.3);

0 Internal entries When the width of the sidelite (A) plus

the height of the highlite (B) exceeds a total of 1000mm a

structural n is required (see also Diagram 13.2);

0 External entries A windload design should always be

carried out to determine thickness and width of n.

diagram 13.2

A

B

Typical cantilevered n with bolt through back to back

stainless steel head mounted n bracket Qld Glass.

Cantilevered glass with bolt through stainless steel head mounted bracket

and 2 way spider xing for face glass connection Glass Solutions.

Offset pivot detail.

12mm grey toughened door with offset pivot..

76

diagram 13.3:

cantilever fin detail

0 With highlite n designs, (X) must be no less than 2/3 of

the n width required.

centre fix pivot doors

This pivot system is used when a larger door width is required.

(e.g. greater than 1000mm). The pivot point is moved towards

the centre of the door. One point to be aware of is that the door

glass will extend out more so than a nor mal pivoting door when

open. Centre x bottom patch shown is also available in rails.

offset pivot doors

In this pivot system the pivot centre is not directly under the

glass. It is offset to one side allowing the door to swing back

180, nishing parallel with the sidelite. This pivot system

can only work on oor springs or free pivots and additional

lock troughs are required to hold the door open in the open

position. The offset bottom patch is as shown, but it is also

available in rails.

pivot door closers

Self closing concealed overhead closers and oor spring closers

are required to prevent the door from opening or shutting

forcefully during normal use and high wind situations. Different

closer mechanisms or types allow the door to always close

(NHO non hold open) to its correct position and stay closed, or

stay open at a specic angle (90 HO hold open at 90 angle).

These closers are double action, meaning that the door can

swing fully through a 180 angle.

Because of the large variation of door sizes and applications,

the closers are manufactured in varying closing strengths.

A stronger strength spring action is required with larger doors.

The stronger spring prevents the wind from opening the door

and forces the door shut. The disadvantage is that the door may

be more difcult to open for some people or may contravene

disability regulations.

Closers can be installed over the top of the doors in the ceiling

in an aluminium transom box (COC Concealed overhead

closer) or in the oor (oor spring).

X

12mm clear toughened door with centre x pivot QLD Glass.

NG166/7 small door pivot sets.

NG131 patch hinge side hinged.

77

A door stop is recommended where the door leaf is over

900mm wide. The stop should be located in the 100 position

to prevent damage to the COC.

Floor springs require the installer to x the device inside the

oor. Floor springs are generally specied for larger door

applications or where a ceiling mounted closer is not possible.

free pivot doors

NG166/7 small door pivot sets

Pivot doors can be installed without self closers. However,

they are only recommended for doors with infrequent use or

showcases. It is advisable to use door stops to prevent breakage

or damage to walls. An alternative style of free pivoting door

patches is the NG166/7 small door pivot set. These top and

bottom patches are suited for 8/10/12mm thickness glass up

to 60kg in door glass weight. They are xed to the head and sill

and swing one way only.

NG131 patch hinge side hinged

Butt type hinge to suit 8/10/12mm glass thickness for glass

doors up to 60kg. Maximum size doors 2100mm x 900mm.

These doors are only suited for xing into solid jamb framework

and swing one way only.

Free pivot door using NG166/7 small door pivot set Glass Solutions.

G-tech pivot door system

A design alternative to standard corner patch and door rail

systems, G-tech components are made from 304 grade

stainless steel material with either proud or countersunk ush

glass xings.

To suit 10/12mm toughened glass, door leaf sizes up to

2400 x 1000mm.

diagram 13.4:

G-tech pivot door types

type A

78

G-tech pivot door system QLD Glass.

Full height rod G-tech pivot door.

Bottom pivot close up QLD Glass.

79

diagram 13.4: G-tech pivot door types continued

type B type C

type D type E

type F type G

All photos: NG150 series top hung sliding door

C & B Glass.

80

manual sliding doors

There are two manual sliding systems available:

0 NG150 Top hung sliding doors These doors have

suspended rollers tted to a top patch and slide in a track

in the ceiling. A oor guide is mounted on the oor at the

sliding end of the opening to keep the door plumb;

0 Bottom track These doors have rollers tted in the

bottom of a rail which roll on a continuous bottom track.

The top guide is a continuous top chan nel recessed into the

ceiling. Door stops have to be tted to the top and bottom

to stop the doors at full opening and closing.

The bottom track system has a continu ous track running

the full length of the opening. This may affect the oor

nish and may create a stepping problem. The track will

also allow dirt or rubbish to collect and the door panel

must be securely locked to prevent direct lifting out of

its opening.

diagram 13.5:

NG150 series sliding door

81

GSD440 GSD423

GSD151 or GSD153

GSD420

G-tech sliding door system

A design alternative to standard top hung and bottom track

sliding systems, G-tech components are made from 304 grade

stainless steel material. To suit 10/12mm toughened glass.

Sliding panel door sizes up to 2400mm x 1200mm or 90kg.

Glass xings available in either proud or countersunk

ush ttings.

diagram 13.6

G-tech sliding door system QLD Glass.

G-tech sliding door wall mounted.

G-tech door hanger set.

Door rail

Parking bay

when closed

Top track

Door rail

82

bi-fold doors

These systems provide for the open shopfront look. The panels

are hinged together, fold back against each other when opened

and stack against the walls at either end of the opening.

stacking doors

These frameless glass door systems have been designed so that

shopfronts can be left completely open during trading hours

and securely locked after hours. The panels slide in a top track

with a roller system and are stacked away in a storage/stacking

bay either parallel or at right angles to the main track or in a

stacking bay located away from the shopfront line. The stacking

bays can also be located in a cupboard so that the panels will

be completely out of view. Pivot doors can also be included in

the system.

diagram 13.7: bi-fold doors

diagram 13.8: stacking doors

Top and bottom tracks

(More than 2 glass panels)

No tracks

(Maximum 2 glass panels)

Top and bottom tracks

with a pivot door

BMW car showroom single tier shopfront with full height supporting n

Bradnams Commercial.

83

F/P Edge

X

F/P Edge

Optional

channel notch

F/G Edge

glazed walls single tier

Generally, single tier glazed panels are restricted by original

glass sheet sizes, toughening and laminating capabilities and

Australian Standards/BCA rules. In Australia, toughened glass

is available up to 5500mm x 2800mm and laminated glass is

available up to 5100mm x 3210mm. These glazed structures are

generally bottom loaded or the glass is dead load supported by

the oor. Where there is a run or a large open expanse to be

glazed, glass support ns may be required to prevent panels from

being blown in or pulled out during high wind load conditions.

fin support

Fins which are silicone glazed to facing panels as shown,

provide a four-sided support or fully framed support for these

facing panels. Fins are used to prevent glass facing panels from

deecting, breaking or falling out through windload pressures.

AS1288 requires ns where two edge only supported glazings

are insufcient in coping with applicable windloads. Glass ns

in most cases must run the full length of the panel height and

be channel glazed or mechani cally secured depending on the

application. Fin thick ness and width is determined by windload,

facing panel size and silicone joint bite size.

no fin support

Where ns are not desired for appearance or other reasons,

windload is a critical factor in determining glass thickness. Areas

not subject to windload, such as enclosed shopping centres/malls,

may in some situations utilise this type of shopfront design.

diagram 13.9:

full height fin design

With full height n designs, (X) must be no less than 2/3 of the

n width required.

Single tier shopfront with full height supporting n Bradnams Commercial.

84

glazed walls multi tier

Where openings require multi tiers or levels of glass panels,

self supporting structural glass walls are mandatory. There are

three types of structural glass glazing methods, suspended,

stacked and structural stand-off systems. Designed for glazing

large open ings in buildings, these systems provide maximum

visibility and daylighting. Traditional aluminium mul lions or

transoms are replaced by thick toughened glass ns or steel

tension trusses. These ns and trusses are designed to resist

wind load.

suspended glass walls

The glass panels are hung from the building structure like a

curtain. The top tier panels are connected to the structure by

adjustable hangar brackets and subsequent lower panels are

connected by metal ttings such as spiders, at their corners.

The faade is located into channels at the perimeter and all

glass joints and channels are sealed with silicone sealant.

The support structure, top tier glass and hangar brackets must

be able to sustain the vertical weight of the glass below as well

as wind loading.

The adjustable suspension system in conjunction with

perimeter channels permits the system to move independently

of the building structure. This compensates for construction

dimensional variations and overcomes problems associated

with building movement, vibration and seismic loads.

The hanging assembly is normally stabilised against wind load

by glass ns located and xed to the sup port structure with

ttings at the corner joints. It is also possible to x the glass

panels to metal mul lions, trusses, space frames or other support

struc tures for lateral support. Depending on engineering

specications glass walls as high as 20 metres can be installed.

stacked glass

The opposite of suspended systems, stacked systems allow

multiple tiers to be stacked on top of each other. The glass dead

load is imposed on the bottom tier panels and to the oor.

The glass panels are located into channels at the perimeter

and all the glass joints are sealed with silicone sealant. Like

suspended systems, the glass faade is stabilised against wind

load by ns or other structures. The glass panels are connected

by special metal ttings to the glass ns. Depending on

engineering specications a maximum glazed height of

8 metres and no more than 2 tiers are recommended.

Multi-tier suspended glass faade system using 10mm green toughened glass.

Photo left: Multi tier structural stand-off system glass faade using

30.56mm thick Cyclone resistant multi-laminated glass connected to

bolt through stainless steel point xings, xed to stainless steel full

height supports behind glass. Glass used is 30.56mm Cyclone resistant

laminated. Make-up 10mm Azuria toughened / 2.28mm SGP / 10mm

clear toughened / 2.28mm SGP / 6mm Energy Advantage low-E (#4)

toughened Fletcher Construction American Samoa.

Glazed by National Glass. Architect Lively Architects.

85

structural stand-off

systems

Stainless steel stand-offs or spiders are xed to building

support structures such as concrete columns, steel mullions and

posts or metal/cable truss systems. This method allows the glass

to be cantilevered off the support struc ture. The system can

allow for an unlimited height in glazing provided that there are

inter mediary structural supports at given spans.

structural fittings

spiders

Used in glass wall and canopy openings, spider point xings

are primarily designed to connect multiple tiers or panels of

glass. Spider xings are also used in high wind load areas where

conventional silicone and glass n support are not sufcient to

cope with loadings. Made from quality 316 stainless steel.

Four way spider xing.

Multi tier structural stand-off system glass faade using four way spider xing bolted

off stainless steel ns 12mm grey toughened glass Jon Kendall & Associates.

Two way spider xing.

Four way spider xing.

86

structural balustrading

Structural glass balustrading systems are a contemporary

alternative to timber or aluminium framed systems. It is

generally a free standing system with fewer vertical or

horizontal supports.

balustrades 1000mm from

FFL with handrail

All balustrades protecting a difference in levels equal to greater

than 1000mm shall have a structural interlink ing handrail so

that in the event of glass breakage, the handrail will sustain the

required loadings as per AS1288 and AS1170.

general specifications

Like all aspects of glass in buildings, frameless glass

balustrading/pool fences and gates are subject to strict

standards and regulations many of which have to be cross

checked for compliance.

Some of these include:

0 BCA (Building Code of Australia) local authority

requirements;

0 AS1170: Wind load, dead and live load requirements;

0 AS1288: Glass in buildings;

0 AS1926: Fences for swimming pools;

0 AS2820: Gate units for private for swimming pools.

Check with our technical staff on choosing the correct glass.

grouted bottom cantilevered

method

Requires the bottom of the panel to be fully and rigidly xed

for the full length of the panel, usually into a grouted channel.

Glass should be heat soak treated.

diagram 13.10

C

E

B

D

A

G

F

B

C

A Toughened glass panel (Heat soaked treated)

Typically thicknesses of 12/15/19/25mm or as designed.

Rail fixed to structural wall

(when required)

Continuous non-shrinkable grout (SIKA 212HP).

Neoprene setting block 25mm wide x 10mm high.

100mm long strips at 750mm centres.

D

E

Silicone topping as required.

Concrete channel continues the length of the balustrade.

Alternative pressed steel channel may be used.

F

G

Height of balustrade or pool fence to standard.

Depth of recess 90-100mm.

H

I

Width of recess 50mm.

Minimum distance from glazing channel to concrete

perimeter refer structural engineer.

I H

87

Glazed by Thump Architectural Fittings.

12mm clear toughened glass bottom grouted cantilevered Tewantin Glass.

88

stub post fixing

Glass panels are bolted together with stainless steel stub posts

which are xed into concrete through core drilled holes or

surface mounted.

clamp fittings 2 edge support

Glass panels are supported by stainless steel clamp xings to

vertical posts on each side. No holes required in glass.

See Diagram 13.11.

spider fixing 2 edge support

Glass panels are supported by bolt through 2 way stainless steel

spider ttings to vertical posts on each side. Provides 2 panel

link with ush or proud glass connectors.

channel glazed 2 edge support

Glass panels are supported in a channel xed to vertical posts

on each side.

hand rail stand-off brackets

Range of 304/316 grade stainless steel bolt through brackets

for mounting of handrail.

diagram 13.11:

clamp fittings 2 edge support

The glazing panels are supported by clamp ttings to vertical

posts at each side.

Spider xing 2 edge supported NT Handrails.

Close up detail of spider xing.

Photo below: Typical stainless steel hand rail stand off

brackets with stainless steel handrail. Glazed by

QLD Glass. Hand rail by Associated Aluminium Service.

Span

NG1260-F

316 stainless steel clamp

tting 10/12mm glass.

89

Glazed by Thump Architectural Fittings.

Stub posts 329 Stainless steel.

Stub posts Surface mount.

Stub posts Core drilled.

D

G

B

C

C

C

F

A E

Rail fixed to

structural wall

(when required)

Countersunk

Hex head screw

32/38/50mm

diameter

OR

Gasket

Fixing rod

Chemset into concrete

Glass 10/20/30/40/50mm

6/10mm

Flat cap

diagram 13.12: typical stainless

steel point fixing (stand off)

diagram 13.13: point fix balustrade

90

point fixed

This structural balustrade system xes the glass to con crete

hobs, walls, timber and metal framing via bolt through stainless

steel point xings or stand offs. Most intended glazing

applications require specialist engi neering to determine

the following (see Diagram 13.13):

0 Glass thickness, type, width of panel (A);

0 Number of xings, diameter size, length of point xing or

stand off and length of xing rod (B) (see also stand-off detail,

Diagram 13.12);

0 Minimum distance between holes, hole to glass edge and

concrete edge (C);

0 Type of hob/structure construction and width to de termine

adequacy or strength of the hob/structure to take loading

imposed by the balustrade (D).

Further to the above, the balustrade must comply to minimum

height regulations (E) with no ability to use the backing hob or

xing structure as a climbable mount (F). Gap between glass

must be in accordance with minimum regulations (G).

All point xings or stand offs are made from 316 Ma rine Grade

Stainless Steel.

All balustrades protecting a difference in level equal to greater

than 1000mm shall have a structural interlinking handrail so

that in the event of glass breakage, the handrail will sustain the

required loadings as per AS1288 and AS1170.

91

Point xed with stainless steel stand offs structural balustrade NT Handrails.

92

pool gates

When gates are required, there are 2 options available. The

rst option uses corner xed metal patch ttings with non-

hold open oor springs (see diagram 13.14, A,B,C). The oor

spring is concealed in the concrete slab. The second option

uses self closing hinges without the requirement of a oor

spring (see diagram 13.14 D). All options must have latches. All

components are subject to relevant codes and regulations.

diagram 13.14

Frameless 12mm clear toughened pool gate with top/bottom

corner patches and oor spring Complete Design Fabrication.

A

B

D C

squash courts

Glass back wall squash court packages are available offering

the maximum view for spectators whilst providing a structural

back wall for the court allowing play not to be interrupted.

These courts are made from 12mm toughened safety glass and

structural ns all xed together with countersunk screws and

bushes to leave the playing surface ush. A surface mount door

closer is xed to the outside of the door allowing easy access and

adjustment. The external xing angle is made from prefabricated

aluminium cut to size and ready to install. The standard size

available is 2134mm (height) x 6401mm (width), which is the

competition size, but non-standard sizes can be made on request.

G-tech partition system

This unique system using stainless steel bolt through xings

allows for the construction of frameless glass designs with

out the use of framing or conventional U type channel

(see middle and bottom photos). G-tech partition is designed

to suit 10/12mm toughened glass with either proud or

countersunk ush glass xing components.

overhead glazing

Depending on situation and code requirements, an nealed

laminated, H/S laminated, toughened lami nated and monolithic

toughened can be used in overhead glazing.

H/S laminated glass

A characteristic of heat strengthened laminated glass when

broken is that the glass will break into larger pieces. This is

useful for overhead glazing where the glass is then less likely

to sag and fall out of the opening. However, in these situations

the framing system should allow for adequate capture or cover

to ensure that when both lites of the H/S laminated are broken,

the glass does not fall out.

point fixed overhead glazing

A countersunk tting should be avoided in these situations

as broken glass is more likely to fall out and around the

countersunk tting. A proud xing is the preferred method with

adequate sized plates which will help retain the glass in the

opening. Toughened laminated is the preferred glazing type in

this application.

diagram 13.15

Proud fixing

93

G-tech glass Cube Brisbane Boys Grammar School Australia Glass.

Close up detail of G-tech wall to glass xing.

Glass back wall squash courts Emerald QLD.

94

frameless shower screens

Frameless toughened safety glass can provide an alternative to

standard aluminium framed shower screens. National Glass can

supply shower door options as shown.

Minimum recommended thickness should be 10mm toughened

safety glass.

fixing methods

Subject to AS1288 guidelines, there are two main methods of

installing frameless toughened shower screens:

0 The recommended method is to mechanically x the glass

with special bolt through plated brass or stainless steel

angle brackets;

0 A second method is to use an aluminium or plated brass

U channel which is screw xed to the wall and oor and

the glass is xed into the channel using structural grade

silicone.

maximum shower door

width/height

Width (mm)

Wall hung doors 600700

Glass hung doors 550650

Height (mm)

Wall hung doors 18502100

Glass hung doors 18502100

structural bracing

header bars

For any glass to glass hinge shower panels and free standing

xed shower panels, structural bracing will be required to

reduce excessive deection of the glass.

Options include:

0 6-10mm toughened glass panel, 100150mm wide, running

the length from sidelite to sidelite or wall to return panel,

over the door;

0 metal header bar in the same nish as hinges etc;

0 10mm toughened glass quadrant (as shown left) UV adhesive

or silicone xed to glass and wall.

All photos: Bradnams Showerscreens.

95

diagram 13.16: frameless shower screen types

type A

type D

type H

type F

type B type C

type J type I

type G

type E

type DJ

type D

type SJ

type BS

Hob

type A type C type B

Hob Hob Hob

96

waterproofing requirements

AS3740-2004 Waterproong for wet areas within residential

buildings sets out the posi tional requirements of glass panels

for hobs and hobless showers. Shower panels should be ush

with the shower area side of the hob. Hobless showers requires

the glass to be positioned over a prescribed waterproong oor

angle. Please consult AS3740 for further information.

It is further recommended that no oor xings be used where

there is likely penetration of the waterproong membrane.

Alternatively, a structural silicone sealant should be used

combined with wall xings and header bars.

Special note should be made with regards to wall tiling

requirements under AS3740. This is with particular reference to

substitution of glass splashbacks or cladding for tiling.

frameless shower fittings

shower door hinges

0 Self centering hinges for doors up to 36kg;

0 All xings and mechanical parts produced from stainless

steel. Body parts produced from quality brass. Finishes

available in chrome, titanium gold and satin chrome plate;

0 To suit glass thicknesses 10mm.

bracket fittings

0 Solid brass to suit 10mm glass;

0 Finishes available in chrome, titanium gold,

satin chrome plate.

handles and knobs

0 Pull handles and towel bars sets are made from 304 Grade

stainless steel tubing. Finishes include satin and polished

stainless and titanium plated gold nish;

0 Knobs made from solid brass plated in chrome, titanium

gold and satin chrome nishes.

glazing U channel

0 Available in polished silver anodised aluminium

16mm x14mm x 1.8mm wall thickness at 3000mm lengths;

header bars

0 Made from 19mm diameter 304 grade stainless steel tubing;

0 Available in satin stainless, polished and titanium

gold nishes.

diagram 13.17: seals and wipes

diagram 13.18: waterbars

0 Chrome, satin and gold nishes.

97

NG992-2 180 glass to glass chrome shower hinge. NG990-1 wall to glass gold shower hinge.

NG48-1L 90 wall to glass chrome bracket. NG48-1 oor to glass satin bracket.

NG3540 chrome door knob. NG3838 clear glass door knob.

NG01 150mm D handle. NG12-1A wall to glass header bar.

Anda mungkin juga menyukai

- Toughened Glass InstallationDokumen26 halamanToughened Glass Installationsyedaltaf_ibnsaleh33% (3)

- Universal Fittings Technical Brochure 0113Dokumen160 halamanUniversal Fittings Technical Brochure 0113Kristaps PuļķisBelum ada peringkat

- Sliding Window DetailsDokumen18 halamanSliding Window DetailsArif NadafBelum ada peringkat

- Signum 120 Min Fire Rated Sliding Door SpecsDokumen2 halamanSignum 120 Min Fire Rated Sliding Door Specssupersac18Belum ada peringkat

- 9784 Intermat ENGDokumen64 halaman9784 Intermat ENGmitica_grigoreBelum ada peringkat

- BC Assignment Chapter 2Dokumen30 halamanBC Assignment Chapter 2ThabisBelum ada peringkat

- Australian Standards For Glass in BuildingsDokumen2 halamanAustralian Standards For Glass in BuildingsSushanta TakhellambamBelum ada peringkat

- Ascot Roller Shutter General BrochureDokumen16 halamanAscot Roller Shutter General Brochureiask5275Belum ada peringkat

- Ma Griffith Tundish Access Panel BrochDokumen2 halamanMa Griffith Tundish Access Panel BrochMichael LambertBelum ada peringkat

- MetalworkDokumen2 halamanMetalworkmmzamo1Belum ada peringkat

- Toughened Safety GlassDokumen6 halamanToughened Safety GlassNor Hasni TaibBelum ada peringkat

- Doors and WindowsDokumen57 halamanDoors and WindowspravinBelum ada peringkat

- Glass SafetyDokumen1 halamanGlass SafetyDoris TownsendBelum ada peringkat

- Stop LogsDokumen8 halamanStop LogsLakshmiWijayasiriBelum ada peringkat

- Doors - WindowsDokumen57 halamanDoors - WindowsUjas PandyaBelum ada peringkat

- Aluminum GlazingDokumen4 halamanAluminum Glazingdox4printBelum ada peringkat

- Ivc Single Faced Sluice Gate Valve Valvula de CompuertaDokumen14 halamanIvc Single Faced Sluice Gate Valve Valvula de CompuertaSurendra ReddyBelum ada peringkat

- Application of Precast StaircaseDokumen10 halamanApplication of Precast StaircaseAhmad FaizBelum ada peringkat

- Tender Boq For Proposed Ins Branch New DelhiDokumen6 halamanTender Boq For Proposed Ins Branch New DelhiSakthi VeeraBelum ada peringkat

- Radial GatesDokumen12 halamanRadial GatesCHEL TAKBelum ada peringkat

- Sliding Door Gear System For 8 12mm Thick Glass Doors Up To 100kg in WeightDokumen6 halamanSliding Door Gear System For 8 12mm Thick Glass Doors Up To 100kg in WeightGrigoreOzonBelum ada peringkat

- Dorma RailDokumen12 halamanDorma RailCristi NaeBelum ada peringkat

- PSL Corporate Brochure Oct 2020Dokumen15 halamanPSL Corporate Brochure Oct 2020akhil jainBelum ada peringkat

- JAC Aluminium ProfileDokumen3 halamanJAC Aluminium ProfileGinene RomanoBelum ada peringkat

- Neoporte BrochureDokumen32 halamanNeoporte Brochurejanaaab5068Belum ada peringkat

- MG900 G BrochureDokumen7 halamanMG900 G BrochureAnnaBelum ada peringkat

- Sdi 117Dokumen9 halamanSdi 117laurenjiaBelum ada peringkat

- Tilt&Turn Window CADokumen1 halamanTilt&Turn Window CAManuel TrentiniBelum ada peringkat

- Beyond: Anti-Pinch Door SystemDokumen16 halamanBeyond: Anti-Pinch Door SystemfreannBelum ada peringkat

- Timber Doors & WindowsDokumen18 halamanTimber Doors & WindowsJayamal InduruwaBelum ada peringkat

- Slide GateDokumen11 halamanSlide Gate陈淀Belum ada peringkat

- Patent Glazing.. GRP PresentationDokumen33 halamanPatent Glazing.. GRP PresentationPooja ParekhBelum ada peringkat

- SDI - 127 Standard Steel Doors and FramesDokumen14 halamanSDI - 127 Standard Steel Doors and FramesIsang BertingBelum ada peringkat

- Modular System of Fittings For Shutters: Hardware Systems For Windows and DoorsDokumen16 halamanModular System of Fittings For Shutters: Hardware Systems For Windows and DoorsBoban ButrićBelum ada peringkat

- Shower Brochure PDFDokumen40 halamanShower Brochure PDFJesus Kevin LojeBelum ada peringkat

- HMI Aluminum Storm DoorsDokumen11 halamanHMI Aluminum Storm DoorsmcfdwBelum ada peringkat

- Chiltern 90mtsDokumen15 halamanChiltern 90mtssmartscsBelum ada peringkat

- Aluminium Door Samar HafizDokumen25 halamanAluminium Door Samar HafizShafiur RahmanBelum ada peringkat

- Casement WindowsDokumen45 halamanCasement WindowsТијана Радиновић100% (1)

- Amweold 15le17le SpecificationsDokumen10 halamanAmweold 15le17le SpecificationsJorge H. GrajedaBelum ada peringkat

- Stegbar Standard SizesDokumen20 halamanStegbar Standard Sizeslipz18Belum ada peringkat

- Aluminium Doors - Doors - GharExpertDokumen3 halamanAluminium Doors - Doors - GharExpertdishkuBelum ada peringkat

- Glass Case Study and Market StudyDokumen57 halamanGlass Case Study and Market StudymintuBelum ada peringkat

- Kilargo IS8035SiDokumen1 halamanKilargo IS8035SiJirapong AnansuttivaraBelum ada peringkat

- ENG Technish Grill HD StijlDokumen6 halamanENG Technish Grill HD StijlBoyko IzoffBelum ada peringkat

- H2 TimberWindowsDokumen8 halamanH2 TimberWindowsdjDangerBurgersBelum ada peringkat

- Building Materials and Construction 15CV36: Doors, Windows and VentilatorsDokumen22 halamanBuilding Materials and Construction 15CV36: Doors, Windows and VentilatorsAnonymous Qm0zbNkBelum ada peringkat

- En Brosura Usi Sectionale Pentru Garaj MCA WebDokumen6 halamanEn Brosura Usi Sectionale Pentru Garaj MCA WebMCAGrupBelum ada peringkat

- Doors Landing-Facade UKDokumen2 halamanDoors Landing-Facade UKfcristovao2Belum ada peringkat

- As1288-2006 Australian Standards Glass in BuildingDokumen8 halamanAs1288-2006 Australian Standards Glass in Buildingla_civilBelum ada peringkat

- Seccional Richards Wilcox t150Dokumen2 halamanSeccional Richards Wilcox t150Milu Madrid MedinaBelum ada peringkat

- 2 SpecificationDokumen20 halaman2 Specificationshakil nagoriBelum ada peringkat

- Metalwork: Rolled Steel Window and Door FramesDokumen6 halamanMetalwork: Rolled Steel Window and Door FramesAdjei BaldanBelum ada peringkat

- Cs Timberformed Is Fitted With Timber Jamb Liners and Has A Heavy Duty Track, With Ultra-Smooth Running' WheelsDokumen4 halamanCs Timberformed Is Fitted With Timber Jamb Liners and Has A Heavy Duty Track, With Ultra-Smooth Running' WheelsJames BentBelum ada peringkat

- Family Handyman Quick & Easy ProjectsDari EverandFamily Handyman Quick & Easy ProjectsFamily HandymanBelum ada peringkat

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersDari EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersBelum ada peringkat

- Crime Against WomenDokumen38 halamanCrime Against WomenAaditya BhattBelum ada peringkat

- RelaxationDokumen13 halamanRelaxationGigel PuscoiuBelum ada peringkat

- Indo Global SummitDokumen26 halamanIndo Global Summitpoonam_ranee3934Belum ada peringkat

- Hyundia Brio CarDokumen8 halamanHyundia Brio Carpoonam_ranee3934Belum ada peringkat

- JAM 2014 BrochureDokumen30 halamanJAM 2014 BrochureRahul MehtaBelum ada peringkat

- Construction Tolerances PDFDokumen11 halamanConstruction Tolerances PDFmohamed4879Belum ada peringkat

- The Secret of SuccessDokumen72 halamanThe Secret of SuccessStudioCentroVeneto s.a.s.Belum ada peringkat

- Phaser PrinterDokumen4 halamanPhaser Printerpoonam_ranee3934Belum ada peringkat

- ConflictDokumen6 halamanConflictapi-306437258Belum ada peringkat

- TravelDokumen28 halamanTravelAnnamma Shammy100% (2)

- Golds Gym INdiaDokumen12 halamanGolds Gym INdiapoonam_ranee3934Belum ada peringkat

- Calm in The Storm 40Dokumen40 halamanCalm in The Storm 40poonam_ranee3934Belum ada peringkat

- Epson Stylus Pro 7890 9890 Professional Photographic Product BrochureDokumen8 halamanEpson Stylus Pro 7890 9890 Professional Photographic Product BrochureLucho F.Belum ada peringkat

- Problems Relating To NRI Marriages: Dos and DontsDokumen6 halamanProblems Relating To NRI Marriages: Dos and Dontspoonam_ranee3934Belum ada peringkat

- Cyber Crimes PDFDokumen7 halamanCyber Crimes PDFSellappan RathinamBelum ada peringkat

- Calm in The Storm 40Dokumen40 halamanCalm in The Storm 40poonam_ranee3934Belum ada peringkat

- Construction Tolerances PDFDokumen11 halamanConstruction Tolerances PDFmohamed4879Belum ada peringkat

- Quality Control Manual Papua New GuineaDokumen59 halamanQuality Control Manual Papua New Guineapoonam_ranee3934Belum ada peringkat

- Survey - Women-Cosmetics IndiaDokumen17 halamanSurvey - Women-Cosmetics Indiapoonam_ranee3934100% (1)

- India - Cosmetics Imports & Regulatory AspectsDokumen6 halamanIndia - Cosmetics Imports & Regulatory AspectsSuruchi ChopraBelum ada peringkat

- Survey - Women-Cosmetics IndiaDokumen17 halamanSurvey - Women-Cosmetics Indiapoonam_ranee3934100% (1)

- MBA For Working ExecutivesDokumen7 halamanMBA For Working Executivespoonam_ranee3934Belum ada peringkat

- Hacking Indian LawsDokumen16 halamanHacking Indian LawsPRATICK RANJAN GAYENBelum ada peringkat

- Stone IndiaDokumen20 halamanStone Indiapoonam_ranee3934Belum ada peringkat

- Civil Engineers GuideDokumen46 halamanCivil Engineers GuideSrinivasan Reddy88% (17)

- Wood Mosaic Price List NewDokumen8 halamanWood Mosaic Price List Newpoonam_ranee3934Belum ada peringkat

- Concrete Construction: Estimate The Cost ofDokumen12 halamanConcrete Construction: Estimate The Cost ofYay B. GicoBelum ada peringkat

- India - Cosmetics Imports & Regulatory AspectsDokumen6 halamanIndia - Cosmetics Imports & Regulatory AspectsSuruchi ChopraBelum ada peringkat

- Civil SpecificationsDokumen65 halamanCivil SpecificationsmrkssastryBelum ada peringkat

- NGP Section 04Dokumen4 halamanNGP Section 04poonam_ranee3934Belum ada peringkat

- DSR (Delhi Schedule Rate) 2013Dokumen550 halamanDSR (Delhi Schedule Rate) 2013c2anBelum ada peringkat

- Comparison of Traditional and Modern Rajasthan HousesDokumen11 halamanComparison of Traditional and Modern Rajasthan Housesaishwarya raniBelum ada peringkat

- Prefabricated Structures - Lecture Notes, Study Material and Important Questions, AnswersDokumen4 halamanPrefabricated Structures - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVBelum ada peringkat

- t220 Building Drawing n3 QP Aug 2014Dokumen8 halamant220 Building Drawing n3 QP Aug 2014Balungile0% (1)

- Architectural Drawing of Proposed Three Storey BuildingDokumen7 halamanArchitectural Drawing of Proposed Three Storey BuildingMuhammad Wazim AkramBelum ada peringkat

- Build Up Rate of BrickworksDokumen16 halamanBuild Up Rate of BrickworksFBelum ada peringkat

- Cree LED Lighting Quick Product Guide Brochure PDFDokumen18 halamanCree LED Lighting Quick Product Guide Brochure PDFtonyeldBelum ada peringkat

- SFSRTS - 2017 (Printable 1 Page) PDFDokumen244 halamanSFSRTS - 2017 (Printable 1 Page) PDFyunying21Belum ada peringkat

- Eco Joist Tech ManualDokumen43 halamanEco Joist Tech ManualkokulBelum ada peringkat

- WickesDokumen180 halamanWickesBasant ShamsBelum ada peringkat

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Dokumen1 halamanProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanBelum ada peringkat

- Kerakoll ProductsDokumen14 halamanKerakoll ProductsArmaanBelum ada peringkat

- Proposed Construction of Two-Story Multi-Purpose Hall / SK HallDokumen1 halamanProposed Construction of Two-Story Multi-Purpose Hall / SK HallEli PascualBelum ada peringkat

- Long Span StructuresDokumen8 halamanLong Span Structures1707 Bhitale SiddharthBelum ada peringkat

- Lavabo - Disegni TecniciDokumen12 halamanLavabo - Disegni TecniciaBelum ada peringkat

- Osram Dimmers 1Dokumen4 halamanOsram Dimmers 1BasBelum ada peringkat

- RCC Slab 2'Dokumen121 halamanRCC Slab 2'Nuwan AththanayakaBelum ada peringkat

- Pula, DA - No Concurr-4Dokumen1 halamanPula, DA - No Concurr-4Scott WayneBelum ada peringkat

- Bridge EngineeringDokumen93 halamanBridge EngineeringGokul KannanBelum ada peringkat

- Nalanda BOQDokumen75 halamanNalanda BOQmikky_kumarBelum ada peringkat

- Revit 2023 Architecture Certified Professional Exam Study GuideDokumen53 halamanRevit 2023 Architecture Certified Professional Exam Study GuideRoberto David Perez Leon100% (1)

- Lux FormulaDokumen3 halamanLux FormulaKrishna PATELBelum ada peringkat

- Design of Hotel PDFDokumen67 halamanDesign of Hotel PDFIssam Saleh100% (1)

- Cast-in-Place Posttensioned Prestressed Concrete Girder BridgesDokumen18 halamanCast-in-Place Posttensioned Prestressed Concrete Girder BridgesglaydelleBelum ada peringkat

- Loading On TankDokumen24 halamanLoading On TankHariHaranBelum ada peringkat

- Unit 5 ESCDokumen11 halamanUnit 5 ESCPRASHANTH REDDY MUNGIBelum ada peringkat

- Minoan and Ethruscan ArchitectureDokumen15 halamanMinoan and Ethruscan ArchitectureMSTEM-H Rafael, MarkBelum ada peringkat

- Pricelist BRC PDFDokumen1 halamanPricelist BRC PDFit.rsudjatipadangBelum ada peringkat

- KT6867188 - 102 Myers DR, Hartly DE 19953Dokumen158 halamanKT6867188 - 102 Myers DR, Hartly DE 19953Jeff EarlsBelum ada peringkat

- Dupa SummaryDokumen2 halamanDupa SummaryNeil Dahab67% (3)