ARC5 Conversion Phil AD5X

Diunggah oleh

Cliff Miller0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

202 tayangan9 halamanARC-5 Command Set SCR-274N Military WW2 Aircraft Radio

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniARC-5 Command Set SCR-274N Military WW2 Aircraft Radio

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

202 tayangan9 halamanARC5 Conversion Phil AD5X

Diunggah oleh

Cliff MillerARC-5 Command Set SCR-274N Military WW2 Aircraft Radio

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 9

Bring That ARC-5/BC-45X Receiver Back To Life

Phil Salas AD5X

Introduction

The old military ARC-5/BC-45X series of receivers were used with a matching

transmitter in B-17 and B-24 bombers (typically 2-3 pairs) and P-38 fighters (one pair),

and probably other aircraft during WWII (Figure 1).

Figure 1: ARC-5 Equipment in a B-17 Bomber

The BC-453 (190-550KHz, the old Q5er), the BC-454 (3-6 MHz), and the BC-455 (6-9.1

MHz) receivers were very popular with hams in the 1950s and 1960s, as they were

readily available and inexpensive. In the mid-60s I paid $5 for a brand new BC-455

receiver. It was surprisingly sensitive and stable, and I used it as my primary 40 meter

receiver for a year or so. Unfortunately, I dont know what ever happened to that

receiver. But I recently picked up both a BC-454 and a BC-455. After studying the on-

line conversions and schematics, I decided to try to document the conversion so as to

make it easier for the average ham.

Receiver Modifications

These receivers use 6-tubes with 12-volt filaments. The tubes are paired-up and each

pairs filaments wired in series so as to operate from 26VDC. The receivers need a 125-

250VDC high voltage source for the tube plates. The plate current requirement is less

than 100ma, and the filament requirement is 1.5-amps. Other than a suitable power

supply, these receivers are pretty much self-contained, so getting them up and running

requires minimal effort. Basically, you need to figure out how to power it, replace the

old paper and electrolytic capacitors, and add a headphone jack, a BFO ON/OFF switch

and a volume control.

First replace the three 0.22uf, the twelve 0.05uf, and the three electrolytic (5uf, 8uf and

15uf) capacitors with modern capacitors. After 60+ years, these capacitors are almost

certainly leaky, shorted or open. And these capacitors are large and take up a lot of room.

It is much easier to continue the wiring modifications when you free-up more internal

room. I used 10uf electrolytics for both the 5- and 8uf capacitors, and a 22uf electrolytic

for the 15uf capacitor. Except for the 22uf capacitor, all capacitors should be rated at

250VDC or higher. The 22uf capacitor can be rated at 100VDC. Also, C24 (200pf) in

my unit was a paper capacitor, so I replaced this as well. Remove the existing capacitors

one at a time starting at C16 and moving counterclockwise. Snip the wires right at the

capacitors, then mount the replacement capacitors on terminal strips using the original

capacitor mounting locations. Solder the snipped-off existing wires to the new capacitors

on the terminal strips. The terminal strips have 5-positions, including ground. I snipped

off unused terminals just to make things a little neater.

Next remove L14. One wire on L14 connects to Pin 6 on the rear connector. Completely

remove this wire as well. The other wire on L14 goes to Pin 7 on the front panel. Move

the L14 end of this wire to the secondary of T1, the audio output transformer. We will

use this wire to bring audio to the front panel. The secondary is connected to Pin 2 of the

rear connector, but this rear connector will no longer be used. L15 is left in place, and

provides some plate voltage filtering.

The next task is to rewire the filaments in parallel so the tubes will run on +13.8VDC.

First remove the following wires:

1) Remove the wire from 12A6 Pin 7 to 12SR7 Pin 7

2) Remove the wire from the left 12K8 Pin 2 to the bottom-left 12SK7 Pin 7.

Figure 2 shows the bottom view/tube socket locations of the receiver and the re-wired

filaments. The black wires are existing, and the red wires are new. Double-check that

the filament wiring is as shown, and no other wires are attached to the tube filament pins.

It is important to verify the orientation of the tube sockets, as some receivers may have

one of the sockets rotated differently. Also, some receivers have a 12FS7 for the bottom-

right/middle tube instead of the 12SK7. The filament pins are different on the 12SF7

(pins 7 & 8).

Figure 3: Bottom view of the re-wired and re-capped receiver

I used a Powerpole connector for the 13.8VDC filament input, and a 2-pin male Molex

connector for the plate voltage input. I replaced the rear multi-pin connector with my

own connector mounting bracket built from a 1.8 x 1.2 piece of pc board material and a

nibbling tool, and half of a PowerPole mounting bracket (Figure 4).

Figure 2: Component placements and filament wiring

C24

200pf

Rear

Front

C15

2x0.056uf

C32

10uf

C6

3x0.056uf

C16

3x0.22uf

C7

3x0.056uf

C30

22uf

C44

3x0.056uf

C5

10uf

1

1

12SF

7

12SK7

1

12SK7

1

12K8

1

12A6

1

12SR7

12SK7

L14

L15

1 resistor

+13.8VDC IN

Figure 4: Rear panel filament and HV connector assembly

After adding the DC connector assembly, wire the 1-ohm 3-watt resistor in series with

the 13.8VDC input to drop the filament voltage to 12VDC. You can see the resistor in a

2-terminal strip near the bottom middle of Figure 3.

Figures 5 and 6 show the front panel connector and component wiring diagrams. A 50K

linear-taper (NOT audio-taper) potentiometer is used for the audio gain. A 1000:8 ohm

audio transformer more closely matches the ARC-5 audio output to modern headphones.

Figure 7 shows the internal wiring. The transformer is hot-glued to the panel, and also

held in place by some of the wiring. I tinned the ARC-5 connector pins and then just lap-

soldered the wires from the front panel controls to the connector pins. Figure 8 shows the

headphone jack, potentiometer and BFO switch mounted on the front panel.

Figure 5: Front Panel Connector

(Viewed from front)

1

2

3

4

5

6

7

8

Figure 6: Front Panel

component wiring

50K Linear

1

2

ON

BFO

5

1K:8

XFMR

7

Phones

Figure 7: Internal front-panel wiring

Figure 8: Front Panel Controls

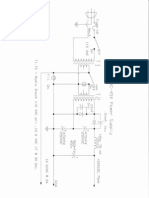

For the plate supply I used the full-wave rectified output of a 13.8VDC/120VAC inverter

(Figure 9). Any inexpensive inverter can be used do to the low plate current requirement

(check 120VAC inverters on eBay). You can either build the rectifier circuitry directly

into the inverter, or use an external rectifier assembly. Besides being easy to build, this

inverter also provides isolation from the AC line!

Tuning Shaft

A final problem with these receivers is the recessed -splined tuning shaft which

requires a special knob. These knobs are hard to find, and are expensive if you do find

one. My BC-454 receiver had the special tuning knob but the BC-455 didnt. So I built a

very effective shaft adapter/extension that is easy to reproduce. All you need is a short

piece of 3/16 ID plastic tubing, a OD aluminum rod, and a 3/8NPT brass cap from

your local hardware store. Figure 10 shows the individual shaft parts before assembly

(top), the final shaft adapter (bottom left), the drilled 3/8NPT cap (bottom right), and the

hard-to-find ARC-5 tuning knob (left).

Figure 10: Shaft Adapter (bottom left)

To make the shaft adapter, mix up a small dab of 2-part epoxy and lightly coat the first

0.2 of one end of the rod. Force the 3/16 ID plastic tubing over this end of the

120uf

350VDC

+

68K

1W

+

170VDC

-

13.8VDC/120VAC

Inverter

+

13.8VDC

-

Figure 9: High Voltage DC Power Supply

rod so it overlaps 0.2 of the aluminum rod. When the epoxy has cured, cut the tubing

and aluminum rod as shown in Figure 11.

Now align the open end of the plastic tube with the splined shaft and push the new shaft

adapter into place. This takes a little effort at first, and then it almost snaps in place. Put

a knob on the shaft and verify that tuning works well. Next, pull the shaft

adapter/extension off the radio and put just a small amount of epoxy into the open end of

the plastic tubing with a toothpick. Then push the shaft adapter/extension back over the

splined tuning shaft. To help support the shaft, I used a 3/8NPT brass plumbing cap with

a shaft clearance hole drilled in the center. As the 3/8NPT brass cap is slightly larger

than the ARC-5 shaft collar, wrap a few turns of black electrical tape over the shaft

collar. Now you can screw the brass cap over the shaft adapter and the radio shaft collar.

Figure 12 shows the new shaft adapter in place.

Figure 12: Shaft Adapter in place

0.2 0.3

0.80

OD AL Bar 3/16 ID Plastic Tube

Figure 11: Shaft Adapter/Extension

The knob I used is an Eagle 1.75 diameter spinner tuning knob available from Mouser

Electronics (part number 450-1755). Figure 13 shows the front of my BC-455 receiver

with the new knob on the shaft adapter.

Figure 13: New tuning knob in place on authors BC-455

Conclusion

Re-building an ARC-5 receiver is one of the easier boat anchor restorations you can take

on. Because so many of these receivers were built during WWII, they are still available

on on-line auction sites at reasonable prices. When finished, you will wind up with a

sensitive receiver that is both an interesting topic of discussion, as well as a nostalgic trip

back to our youth (for some of us).

Table 1 Components needed for ARC-5 conversion and powering

QTY Description Mouseer Part Number

1 Molex 2-pin recept. 538-03-06-1022

2 Molex 0.062 sockets 538-02-06-1103

1 Molex 2-pin plug 538-03-06-2024

2 Molex 0.062 pins 538-02-06-2103

1 68K 1-watt resistor 594-5073NW-68K00J $0.16

1 0.375A in-line fuse 576-0251.375MXL

12 0.056uf 250V caps 5989-250V.056-F

1 22uf 100V cap. 647-UVR2A220MED $0.30

2 10uf 250V caps. 647-UVR2E100MPD $0.39

1 200pf 1KV capacitor 75-562R10TST20

1 50K linear pot 313-2000F-50K

1 1 ohm 3-watt resistor 594-5093NW-1R000J

1 8/1000 ohm xfmr 42TL013-RC

10 Terminal Strip 158-1005

1 120uf/350V cap. 661-EKXJ351ELL121MLP

1 Bridge rectifier 625-W04G-E4

3 0.22uf 250 810-FK20X7R2E224K

1 1/8 stereo jack 161-3402-E

1 SPDT switch 108-1MS1T2B3M1QE-EVX

1 set PowerPole

TM

mounting bracket 879-1462G1

2 Black PowerPole

TM

connector & contact 879-1330G4

2 Red PowerPole

TM

connector & contact 879-1330

1 13.8V/120V inverter eBay

Anda mungkin juga menyukai

- ARC5 Conversion Revision BDokumen4 halamanARC5 Conversion Revision BCliff MillerBelum ada peringkat

- PWMcircuit 08Dokumen10 halamanPWMcircuit 08kcarringBelum ada peringkat

- 450 Watt 6m Amplifier: Chris, G3WOS - July 1993Dokumen10 halaman450 Watt 6m Amplifier: Chris, G3WOS - July 1993Adrian DrakesBelum ada peringkat

- Yaesu FT 736r Ps RepairDokumen9 halamanYaesu FT 736r Ps RepairBravo KiloBelum ada peringkat

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDari EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsPenilaian: 3 dari 5 bintang3/5 (2)

- Surplus Radio Conversion Manual Vol2Dokumen127 halamanSurplus Radio Conversion Manual Vol2ygiannarakis100% (1)

- Build A Four Transistor Metal DetectorDokumen19 halamanBuild A Four Transistor Metal Detectorkamelferes100% (1)

- A Look at The Yaqin MC100BDokumen24 halamanA Look at The Yaqin MC100BRoi Rey100% (1)

- Quad 606 MK I II 707 and 909 Upgrade Revision Manual V2.6Dokumen13 halamanQuad 606 MK I II 707 and 909 Upgrade Revision Manual V2.6Edwin Petallar ApareceBelum ada peringkat

- Dynamull Driver Board St-70: Classic Valve DesignDokumen13 halamanDynamull Driver Board St-70: Classic Valve DesignyehkanghuiBelum ada peringkat

- DynaMull Docs PDFDokumen13 halamanDynaMull Docs PDFmohamadazareshBelum ada peringkat

- 400W Rms Hexfet Mosfet Symmetrical AmplifierDokumen10 halaman400W Rms Hexfet Mosfet Symmetrical Amplifieralbedo367Belum ada peringkat

- Ant 965Dokumen3 halamanAnt 965Anonymous zZ36IbdkixBelum ada peringkat

- Modification To AMP REV1Dokumen14 halamanModification To AMP REV1augustinetezBelum ada peringkat

- Neve SchematicsDokumen17 halamanNeve SchematicsLucas RossoBelum ada peringkat

- Neve BA283 Class A Gain-Stage Building Block For Preamps - Design Info Document2Dokumen17 halamanNeve BA283 Class A Gain-Stage Building Block For Preamps - Design Info Document2crackintheshatBelum ada peringkat

- IC Guitar AmpDokumen3 halamanIC Guitar AmpSteven Howell100% (1)

- PRC 320 PsuDokumen2 halamanPRC 320 PsuutammarryBelum ada peringkat

- Dentron MLA-2500 GI7B Modification Procedure 3Dokumen27 halamanDentron MLA-2500 GI7B Modification Procedure 3david bonilla pinoBelum ada peringkat

- Firefly PCB Guide 8Dokumen16 halamanFirefly PCB Guide 8Renier Orlando BlancoBelum ada peringkat

- Preamp PDFDokumen9 halamanPreamp PDFjohandry84Belum ada peringkat

- Automatic Siren Kit: Elenco Electronics, IncDokumen8 halamanAutomatic Siren Kit: Elenco Electronics, IncCiro GiordanoBelum ada peringkat

- Art AcpDokumen12 halamanArt AcpTrungKiênTrầnBelum ada peringkat

- Beko 14.2 Chassis Full TV SMDokumen34 halamanBeko 14.2 Chassis Full TV SMJosep Maria Bargallo MoyaBelum ada peringkat

- Apex - 460 - Tube Condenser Mic ModsDokumen48 halamanApex - 460 - Tube Condenser Mic ModsTom VenagliaBelum ada peringkat

- Sese80 Manual (1) Rev2Dokumen10 halamanSese80 Manual (1) Rev2Putri AristaBelum ada peringkat

- Converting The Collins 516FDokumen4 halamanConverting The Collins 516Fk6may100% (1)

- Restoration of My Atwater Kent Model 40 Radio SetDokumen25 halamanRestoration of My Atwater Kent Model 40 Radio SetRandom73100% (9)

- Building The Geotech Baracuda (Rev-A)Dokumen19 halamanBuilding The Geotech Baracuda (Rev-A)ford50% (2)

- Induction Cooker TeardownDokumen14 halamanInduction Cooker TeardownNguyễn Hồng DươngBelum ada peringkat

- Twin Loop Treasure Seeker: Robert and David CroneDokumen5 halamanTwin Loop Treasure Seeker: Robert and David CronesafdsfdBelum ada peringkat

- Metal Detector ReportDokumen13 halamanMetal Detector ReportAnonymous ytZsBOVBelum ada peringkat

- "Dynamutt" Driver Board: For The Dynaco St-70Dokumen15 halaman"Dynamutt" Driver Board: For The Dynaco St-70azornBelum ada peringkat

- The Scrounger A Ham Radio Transmitter ProjectDokumen18 halamanThe Scrounger A Ham Radio Transmitter ProjectRandom73Belum ada peringkat

- Dynaco PAS RIAA EQ Correction ModDokumen4 halamanDynaco PAS RIAA EQ Correction ModGoran PatarakoskiBelum ada peringkat

- AM Receiver: Home Analysis Help Media Links PracticalDokumen10 halamanAM Receiver: Home Analysis Help Media Links PracticalĐinh Văn HiếuBelum ada peringkat

- High Frequency Function Generator With The Maxim MAX038Dokumen11 halamanHigh Frequency Function Generator With The Maxim MAX038JCBelum ada peringkat

- Four Output IsolatedDokumen4 halamanFour Output IsolatedDiego Marcelo Terrazas VBelum ada peringkat

- New PA For Yaesu Tf101Dokumen2 halamanNew PA For Yaesu Tf101Federico LavolpeBelum ada peringkat

- Building An AnalogDokumen10 halamanBuilding An AnalogRosita AzzamBelum ada peringkat

- McCoy VFODokumen17 halamanMcCoy VFOFrancisco J. Aguilera HiguereyBelum ada peringkat

- McCoy VFO PDFDokumen17 halamanMcCoy VFO PDFFrancisco J. Aguilera HiguereyBelum ada peringkat

- TF 407 & TF 410 Installation Manual: DescriptionDokumen2 halamanTF 407 & TF 410 Installation Manual: Descriptionprasad357Belum ada peringkat

- RX RegenDokumen8 halamanRX RegenhgbarieroBelum ada peringkat

- Beaver InstructionsDokumen29 halamanBeaver InstructionsMyles de BastionBelum ada peringkat

- The Birth of The TS2019-PP80 AmplifierDokumen26 halamanThe Birth of The TS2019-PP80 AmplifierIldo ParnowBelum ada peringkat

- AV1000 + Assembly + ManualDokumen22 halamanAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- WWW Usefulcomponents ComDokumen8 halamanWWW Usefulcomponents Comjg94419625Belum ada peringkat

- R-390A SSB ModDokumen6 halamanR-390A SSB ModYiannis GiannarakisBelum ada peringkat

- Photograph High Voltage Power Supply Shown With Optional 24 VAC TransformerDokumen8 halamanPhotograph High Voltage Power Supply Shown With Optional 24 VAC TransformerdughirBelum ada peringkat

- NS-40 - "None Simpler" 40 Meter QRP TransmitterDokumen6 halamanNS-40 - "None Simpler" 40 Meter QRP Transmitterglue2Belum ada peringkat

- Avr400 Service ManualDokumen34 halamanAvr400 Service ManualwatteaucarBelum ada peringkat

- Build An AM Radio Transmitter PDFDokumen8 halamanBuild An AM Radio Transmitter PDFΔημητριος ΣταθηςBelum ada peringkat

- ADA MN3007 Rev5 Jan2010 Documentation Rev20120225Dokumen12 halamanADA MN3007 Rev5 Jan2010 Documentation Rev20120225ismaelsleiferBelum ada peringkat

- 01-Building A 1929 Style Hartley TransmitterDokumen4 halaman01-Building A 1929 Style Hartley Transmittermax_orwell100% (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDari EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileBelum ada peringkat

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Dari EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Penilaian: 4.5 dari 5 bintang4.5/5 (3)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsDari EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsBelum ada peringkat

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusDari EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusPenilaian: 3 dari 5 bintang3/5 (1)

- The ARC-5'Er Power SupplyDokumen6 halamanThe ARC-5'Er Power SupplyCliff MillerBelum ada peringkat

- SCR274 Radio Operators ManualDokumen32 halamanSCR274 Radio Operators ManualCliff Miller100% (1)

- Dave Stinson ARC 5 InfoDokumen8 halamanDave Stinson ARC 5 InfoCliff MillerBelum ada peringkat

- Compilation of CQ Articles On ARC 5 Command SetsDokumen137 halamanCompilation of CQ Articles On ARC 5 Command SetsCliff MillerBelum ada peringkat

- ARC 5 Receiver Power SupplyDokumen1 halamanARC 5 Receiver Power SupplyCliff MillerBelum ada peringkat

- ARC-5 Alignment ProcedureDokumen56 halamanARC-5 Alignment ProcedureCliff MillerBelum ada peringkat

- ARC 5 Command Set RoundupDokumen8 halamanARC 5 Command Set RoundupCliff MillerBelum ada peringkat

- ARC 5 Receiver Power Supply 3Dokumen1 halamanARC 5 Receiver Power Supply 3Cliff MillerBelum ada peringkat

- A User Guide To ARC Command Set ReceiversDokumen34 halamanA User Guide To ARC Command Set ReceiversCliff MillerBelum ada peringkat

- Tricking Out HF 9x20 LatheDokumen48 halamanTricking Out HF 9x20 LatheCliff Miller100% (2)

- Black Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonDokumen44 halamanBlack Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonmarcBelum ada peringkat

- Sunfix Blue SPRDokumen7 halamanSunfix Blue SPRDyeing 2 Wintex100% (2)

- EI6704: UNIT 5 NotesDokumen19 halamanEI6704: UNIT 5 NotesMadhu MithaBelum ada peringkat

- Department of Mechanical EnginneringDokumen11 halamanDepartment of Mechanical EnginneringViraj SukaleBelum ada peringkat

- Cad, CamDokumen16 halamanCad, CamRakhi Mol BVBelum ada peringkat

- Biology Unit 4Dokumen44 halamanBiology Unit 4Mohammad KhanBelum ada peringkat

- Sdo Tle Grade 8 Dressmaking 2nd Q Week 1 8 1Dokumen64 halamanSdo Tle Grade 8 Dressmaking 2nd Q Week 1 8 1Maggie De jesusBelum ada peringkat

- Regulatory Framework For Water Dams in QuebecDokumen2 halamanRegulatory Framework For Water Dams in QuebecRaveeBelum ada peringkat

- Schrodinger Wave EquationsDokumen6 halamanSchrodinger Wave EquationsksksvtBelum ada peringkat

- Steam Purity Considerations For New TurbinesDokumen46 halamanSteam Purity Considerations For New Turbinesomertrik100% (1)

- 2020 Landfill Capacity Calculation Work SheetDokumen4 halaman2020 Landfill Capacity Calculation Work SheetLYBelum ada peringkat

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDokumen10 halamanSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaBelum ada peringkat

- Red Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFDokumen1 halamanRed Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFCintiah KenedyBelum ada peringkat

- API 571 Quick ReviewDokumen32 halamanAPI 571 Quick ReviewMahmoud Hagag100% (1)

- Money, Interest, and Inflation: Answers To CheckpointsDokumen16 halamanMoney, Interest, and Inflation: Answers To Checkpointsb96309Belum ada peringkat

- BHS Inggris 2021Dokumen6 halamanBHS Inggris 2021Muhammad FirmanBelum ada peringkat

- Brochure ISDokumen4 halamanBrochure ISJAYESH VIKRAM RastogiBelum ada peringkat

- BIOC32 Practice QuestionsDokumen7 halamanBIOC32 Practice QuestionsLydia DuncanBelum ada peringkat

- Recipes G.garvin Copy1 Scribd 5Dokumen7 halamanRecipes G.garvin Copy1 Scribd 5Peggy Bracken StagnoBelum ada peringkat

- History of Costa RicaDokumen2 halamanHistory of Costa Ricakrishnan MishraBelum ada peringkat

- Definition of Logistics ManagementDokumen4 halamanDefinition of Logistics ManagementzamaneBelum ada peringkat

- EASL 2021 Version 4 NewDokumen691 halamanEASL 2021 Version 4 NewGupse Köroğlu AdalıBelum ada peringkat

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsDokumen21 halamanEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoBelum ada peringkat

- Origami Undergrad ThesisDokumen63 halamanOrigami Undergrad ThesisEduardo MullerBelum ada peringkat

- CA InsideDokumen1 halamanCA InsideariasnomercyBelum ada peringkat

- Mits Chocolates: Let The Life Be More Sweet'Dokumen30 halamanMits Chocolates: Let The Life Be More Sweet'Azaz NathaniBelum ada peringkat

- Handbook (P)Dokumen224 halamanHandbook (P)Joe80% (5)

- The Practice of Veterinary Anesthesia - Small Animals, Birds, Fish, and ReptilesDokumen382 halamanThe Practice of Veterinary Anesthesia - Small Animals, Birds, Fish, and ReptilesMárcio MoreiraBelum ada peringkat

- Embedded Systems:: Hacking of Electronic EquipmentsDokumen76 halamanEmbedded Systems:: Hacking of Electronic EquipmentsKailashi Chandra SekharBelum ada peringkat

- Balmatech Go Ep Tds 2022-03 GBDokumen2 halamanBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadBelum ada peringkat