Fire Fighting Approved Equipment

Diunggah oleh

Abdul RaoofHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fire Fighting Approved Equipment

Diunggah oleh

Abdul RaoofHak Cipta:

Format Tersedia

Dry Powder Fire Extinguishers

PRODUCT DESCRIPTION

NAFFCO stored pressure type dry powder extinguishers are characterised by their high performance,

simple method of operation and rapid fire knock down capability. They are suitable for tackling fires

involving freely burning materials, petrol, oil, gas and electrical equipment. They are ideal for vehicle &

marine risks. NAFFCO ABC powder extinguishers contain high performance powder and are one of the

most powerful powder extinguishers in the world.

FEATURES

Ideal Use: Houses, office, buildings, warehouses, farms, wood working area etc.

Note: Not recommended for use on expensive and delicate equipment like computers, etc.

*High Fire Rating Using Special ABC Powder

Monoammonium phosphate based dry chemical

agent. Capable of fighting Class A, B, C and E

fires

Kitemark certied to BS EN3

Cylinders compliance to council directive

97/23/EC (PED) and Statutory instrument 1999

No.2001 is certified by BSI (0086)

Certified by BSI under marine equipment

directive

High quality polyster paint

Controlled discharge

Brass nickel plated head valve with simple

squeeze operation

Unique gauge testing system

Unique colour coded handle and base

(Optional)

Rechargeable and easy to service

Choice of capacity from 1 to 12 Kg

MODEL NUMBER

Extinguisher Capacity

Propellant

Fire Rating

Maximum Operating Pressure

Working Pressure

Test Pressure

Total Weight

Range of Discharge

Hose Length with Nozzle

Duration of Discharge

Operating Temperature

Cylinder Material

NP1 NP2

2kg

13A 70B

14 Bar

3.7kg

5-7m

10-12 sec

N/A

1kg

8A 34B

14 Bar

1.8kg

4-5m

7-9 sec

N/A

NP3

3kg

21A 89B

14 Bar

5.8kg

6-7m

11-12 sec

395mm

NP4

4kg

21A 113B

15 Bar

16.5 Bar @ 60C

-20C to +60C

CRCA Steel Sheet

7.5kg

7-8m

13-15 sec

457mm

NP6

6kg

34A 183B

15 Bar

10 kg

6-8m

18-20 sec

534mm

NP6

6kg

43A 233B*

15 Bar

14 kg

7-8m

20-22 sec

534mm

NP9

9kg

43A 233B

15 Bar

14 kg

6-8m

22-24 sec

524mm

NP12

12kg

55A 233B

15 Bar

30 Bar

17.8 kg

6-8m

28-30 sec

617mm

1. Valve / Extn. Lever

2. Safety Pin with Chain

3. Valve Handle

4. Pressure Gauge

5. Discharge Hose

6. Syphon Tube

7. Hose Holder

8. Discharge Nozzle

9. PVC Base

Height x Diameter (in mm) 385 x 110 337 x 78 420 x 132 408 x 150 520 x 150 520 x 150 515 x 185 620 x 185

95% Nitrogen + 5% Helium

Wet Chemical Fire Extinguishers

PRODUCT DESCRIPTION

NAFFCO stored pressure type wet chemical extinguishers are used for cooking oil or fat res where the

pray gives almost immediate ame. Extinguishment happens while the wet chemical agent reacts with oil

to form a soap like lm to seal the surface of the oil and cool it down to prevent re-ignition.

Suitable for Class A re risks.

FEATURES

Water, a liquid agent only recommended for

ghting Class A Fire.

Kitemark certied to BS 7937:2000 and BSEN3

Cylinders compliance to council directive

97/23/EC (PED) and Statutory instrument 1999

No.2001 is certied by BSI (0086)

Certied by BSI under marine equipment

directive

High quality polyster paint

Thermoplastic internal coating to prevent

corrosion

Fire mist spray to prevent grease splashing

Brass nickel chrome plated head valve with

simple squeeze operation

Unique gauge testing system

Unique colour code handle and base (Optional)

Rechargeable and easy to service

Passed 35KV electrical conductivity test

1. Valve / Extn. Lever

2. Discharge Hose

3. Safety Pin with Chain

4. Valve Handle

5. Pressure Gauge

6. Hose Holder

7. Syphon Tube

8. PVC Internal Coating

9. Filter

10. Discharge Nozzle

11. PVC Base

Ideal Use: Commercial kitchens in connection with NAFFCO Pre-engineered Hood Systems

Caution: Dont use on electrical re

MODEL NUMBER

Extinguisher Capacity

Propellant

NKE 3X* NKE 2* NKE 6

3ltr 2ltr

95% Nitrogen + 5% Helium

6ltr

Fire Rating

Maximum Operating Pressure

Working Pressure

Test Pressure

Total Weight

Range of Discharge

Hose Length with Nozzle

Duration of Discharge

Operating Temperature

8A 25F 5F

10 Bar 10 Bar

11.5 Bar @ 60C 11.5 Bar @ 60C

30 Bar 30 Bar

7.2kg 4.4kg

1m 1m

30-35 sec 40-45 sec

610mm N/A

0C to +60C 0C to +60C

13A 75F

10 Bar

11.5 Bar @ 60C

30 Bar

12.5kg

1m

50-55 sec

610mm

0C to +60C

Height x Diameter (in mm) 505 x 185 420 x 110 420 x 1324

*LPCB approval only

Cabinets for Fire Hose Reel, Fire Equipments

and Breeching Inlet

PRODUCT DESCRIPTION

NAFFCO cabinets are designed to accommodate re hose reel, re ghting equipment and breeching

inlet. Fire hose reel cabinets are manufactured to comply with BSEN 671-1 standard and breeching inlet

cabinets are manufactured to comply to BS 5041-5 standard.

FEATURES

LPCB Certied

Cabinet material made of Electro

Galvanized sheet or Stainless Steel Sheet

(Full stainless steel brush or mirror nish)

Locking of cabinet is either key operated or

round handle cam latch

Cabinets are available either in surface mounted

or recessed mounted type

Cabinet door shall be solid door or glass door

(Clear glass or wired glass)

Breeching inlet cabinets are available in

horizontal or vertical version

CABINETS

6x4 Way Breeching Inlet

PRODUCT DESCRIPTION

NAFFCO breeching inlets are suitable for installation on dry risers only, in a building for re ghting

purposes, tted with inlet connection at re brigade access level and outlet connection at specied points,

which is normally dry but capable of being charged with water by pumping from re service appliances.

The breeching inlets are manufactured to comply to BS 5041 PART-3:1975 standard comprising of male

instantaneous connections complying with BS 336:2010, drain valves complying with BS 5154, PN16

rated and non-return valves.

The breeching inlets and its ttings are suitable for a normal working pressure of 10 bar and for working

temperature range from 0C to 38C.

FEATURES

BSI Kitemark & LPCB certied

Body material made of spheroidal graphite iron

to BS 1563:1997

Inlet connection and non-return valves material

made of copper alloy to BS 12163:1998

Each inlet connection is tted with non-return

valve and of spring loaded mushroom type

Each breeching inlet is painted RED internally

and externally

BILL OF MATERIAL

NDR095

Description

4 Nos. Male Instantaneous Connector Complying to BS 336

Body

Normal Working Pressure of 10 Bar

150 mm Flanged Outlet

20 Bar

BS 4504 Part : 2 : 1974 Table : 16/21

Inlet Connection & Non-Return Valves

Drain Valve

Blank Cap for Drain Valve

Blank Cap for Inlet Connector

MODEL

S. No.

Inlet Connection

1

2

Pressure Rating

Nominal Size

Test Pressure

Flange Drilling

3

4

5

Material

Spheroidal Graphite Cast Iron to BS EN 1563:1997

Copper Alloy to BS EN 12163:1998

Copper Alloy to BS EN 12163:1998

Copper Alloy to BS EN 12163:1998

Plastic

Anda mungkin juga menyukai

- Water Fire ExtinguishersDokumen4 halamanWater Fire ExtinguishersErica LindseyBelum ada peringkat

- SPRINKLER Zone Control ValveDokumen4 halamanSPRINKLER Zone Control ValveIonut SomneaBelum ada peringkat

- Dasco 1-9Dokumen9 halamanDasco 1-9Ahmed AzadBelum ada peringkat

- Installation of Sprinkler Piping SystemDokumen6 halamanInstallation of Sprinkler Piping SystemJosef MadronaBelum ada peringkat

- Refrigerant Piping Work1Dokumen13 halamanRefrigerant Piping Work1Le Manh HieuBelum ada peringkat

- Section 23 11 25 Facility Gas PipingDokumen10 halamanSection 23 11 25 Facility Gas PipingNiong DavidBelum ada peringkat

- OMM-Kandis Residences (2019) PDFDokumen38 halamanOMM-Kandis Residences (2019) PDFjo_eli_Belum ada peringkat

- Annexure 2A - Preffered Manufactures and SuppliersDokumen36 halamanAnnexure 2A - Preffered Manufactures and SuppliersMustafa313Belum ada peringkat

- Wet Riser SpecificationDokumen4 halamanWet Riser SpecificationshihabnittBelum ada peringkat

- Pabco Aluminium CladdingDokumen1 halamanPabco Aluminium CladdingJj OredinaBelum ada peringkat

- 6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFDokumen1 halaman6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFHaitham MohammadBelum ada peringkat

- Installation-Operation-Maintenance Manual For Foam Proportioning System - DPSDokumen10 halamanInstallation-Operation-Maintenance Manual For Foam Proportioning System - DPSRoshin99Belum ada peringkat

- NOVEC Testing ReportDokumen5 halamanNOVEC Testing Reportamjadjaved033148Belum ada peringkat

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDokumen24 halamanDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemssuhasBelum ada peringkat

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsDokumen6 halamanMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92Belum ada peringkat

- Vortex FP Sales Presentation IM 051214Dokumen42 halamanVortex FP Sales Presentation IM 051214Argos100% (2)

- NAFFCOInert Catalogue PDFDokumen16 halamanNAFFCOInert Catalogue PDFMac ShaikBelum ada peringkat

- Fire Alarm System Maintenance 2Dokumen3 halamanFire Alarm System Maintenance 2renvBelum ada peringkat

- Firefighting systems and equipmentDokumen23 halamanFirefighting systems and equipmentwado11Belum ada peringkat

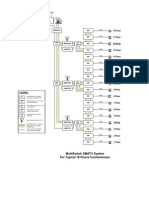

- Typical MSW SchematicDokumen1 halamanTypical MSW SchematicazanwtaBelum ada peringkat

- Xtralis Training 3Dokumen65 halamanXtralis Training 3Eduardo ParrudoBelum ada peringkat

- CRT & VPI ComparisionDokumen2 halamanCRT & VPI Comparisionbhaveshbhoi100% (1)

- Horizontal Sidewall Sprinklers Technical Data SheetDokumen6 halamanHorizontal Sidewall Sprinklers Technical Data SheetAhrian BenaBelum ada peringkat

- Carbon Dioxide Fire Suppression SystemDokumen9 halamanCarbon Dioxide Fire Suppression SystemBen Lim100% (1)

- Electrical Materials List For Construction ProjectsDokumen17 halamanElectrical Materials List For Construction Projectsmuhammad robithBelum ada peringkat

- Fire Water Tank Design RequirementsDokumen23 halamanFire Water Tank Design RequirementsWaseem Siddique100% (1)

- Ethio Telecom HQ Building Fire Suppression ValvesDokumen6 halamanEthio Telecom HQ Building Fire Suppression ValvesdiribaBelum ada peringkat

- FM200 KiddeDokumen37 halamanFM200 KiddeNguyen Van TuanBelum ada peringkat

- Standard Parts of Pipe SupportsDokumen5 halamanStandard Parts of Pipe SupportsMohit BauskarBelum ada peringkat

- Fire Fighting Systems for Oil FieldsDokumen2 halamanFire Fighting Systems for Oil FieldsSubbarayan Saravanakumar0% (1)

- 132kV XLPE Cable Accessory Factory Test ProcedureDokumen7 halaman132kV XLPE Cable Accessory Factory Test Procedurerenjithas2005Belum ada peringkat

- BOQ For Solar Water HeatersDokumen2 halamanBOQ For Solar Water Heaterssolpower_epl100% (2)

- 345 Testing THDokumen6 halaman345 Testing THDjeisonSeccoBelum ada peringkat

- Electrofusion Jointing The European WayDokumen2 halamanElectrofusion Jointing The European WayMahesh MalaiChamyBelum ada peringkat

- KSE Interview Preparation NotesDokumen47 halamanKSE Interview Preparation NotesJunaid btBelum ada peringkat

- Product Manual DCP Trolley Mounted 25-50-75 KGDokumen6 halamanProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaBelum ada peringkat

- Extcat FM200Dokumen15 halamanExtcat FM200Mohamed FawzyBelum ada peringkat

- NN 100 Nitrogen Gas Fire Suppression SystemDokumen4 halamanNN 100 Nitrogen Gas Fire Suppression SystemJulius BravoBelum ada peringkat

- Code Book Gas PipeDokumen30 halamanCode Book Gas PipeS Sinha RayBelum ada peringkat

- Supply and Installation of Firefighting and Protection System For Berth B100 Part 1Dokumen513 halamanSupply and Installation of Firefighting and Protection System For Berth B100 Part 1Mehmet DurmazBelum ada peringkat

- FIRE Fighting System in Power Plant - PPTDokumen33 halamanFIRE Fighting System in Power Plant - PPTer_jaspal100% (3)

- TEC-212200 - MET-DoR-005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200 - 1Dokumen8 halamanTEC-212200 - MET-DoR-005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200 - 1swamyBelum ada peringkat

- Mr. Slim System Pre-Commissioning and Installation Check ListDokumen4 halamanMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasBelum ada peringkat

- GFS Tank Quotation C20210514Dokumen4 halamanGFS Tank Quotation C20210514Francisco ManriquezBelum ada peringkat

- Annual Servicing, Billing Statement and QuotationDokumen43 halamanAnnual Servicing, Billing Statement and QuotationElma Alino Descartin100% (1)

- Drawings VRF SystemsDokumen2 halamanDrawings VRF Systemscalvin.bloodaxe4478Belum ada peringkat

- Junction BoxDokumen1 halamanJunction BoxIkhsan ArifBelum ada peringkat

- Safety Clearance Recommendations For TransformerDokumen6 halamanSafety Clearance Recommendations For Transformerjannumits100% (1)

- Guide to Common Fire Suppression Systems and Their ApplicationsDokumen1 halamanGuide to Common Fire Suppression Systems and Their Applicationsnvenkat.narayanBelum ada peringkat

- Medium Velocity Water Spray (MVWS) System - Electrical4UDokumen16 halamanMedium Velocity Water Spray (MVWS) System - Electrical4UkaustavBelum ada peringkat

- Kidde FM-200 Fire Suppression System SpecificationDokumen6 halamanKidde FM-200 Fire Suppression System SpecificationFi NDBelum ada peringkat

- Key Maintenance SwitchDokumen4 halamanKey Maintenance SwitchkuraimundBelum ada peringkat

- Gas Installation PDFDokumen31 halamanGas Installation PDFNelson VargasBelum ada peringkat

- Kupdf WeldingDokumen44 halamanKupdf WeldingSamayapuramBelum ada peringkat

- Panel Boards SpecificationDokumen16 halamanPanel Boards SpecificationAhmad DagamsehBelum ada peringkat

- Tanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Dokumen2 halamanTanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Paulo MaresBelum ada peringkat

- Fire Extinguisher-Naffco Kite MarkDokumen17 halamanFire Extinguisher-Naffco Kite MarkMatt TremoglieBelum ada peringkat

- Solder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PasteDokumen4 halamanSolder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PastebehzadBelum ada peringkat

- Fornovo Gas Presentation RNG 2020 03Dokumen39 halamanFornovo Gas Presentation RNG 2020 03RODIS ECHEVARRIA SALDAÑABelum ada peringkat

- Extintor Portatil CO2Dokumen2 halamanExtintor Portatil CO2CentralarmBelum ada peringkat

- Angus ProductsDokumen1 halamanAngus ProductsAbdul RaoofBelum ada peringkat

- Hydrant DetailsDokumen1 halamanHydrant DetailsAbdul RaoofBelum ada peringkat

- Drainagesystemslecturei 091022013358 Phpapp02Dokumen62 halamanDrainagesystemslecturei 091022013358 Phpapp02Abdul Raoof100% (1)

- Copper & PPRDokumen6 halamanCopper & PPRAbdul RaoofBelum ada peringkat

- Gen. FuelDokumen3 halamanGen. FuelAbdul RaoofBelum ada peringkat

- Willow GinkgoDokumen2 halamanWillow GinkgoMs. XeniBelum ada peringkat

- Pengaruh Pijat Laktasi Terhadap Produksi ASI Pada Ibu Menyusui Di Kelurahan Sendang Sari Kabupaten Asahan Tahun 2019Dokumen7 halamanPengaruh Pijat Laktasi Terhadap Produksi ASI Pada Ibu Menyusui Di Kelurahan Sendang Sari Kabupaten Asahan Tahun 2019MAS 16Belum ada peringkat

- UNESCO - Tech - Drawing - 03Dokumen90 halamanUNESCO - Tech - Drawing - 03ayariseifallahBelum ada peringkat

- (Brother Jonathan No. 6) Lt. Colonel Richard CaryDokumen5 halaman(Brother Jonathan No. 6) Lt. Colonel Richard CaryJohn U. Rees100% (1)

- Y5 Unit 2 WorksheetsDokumen38 halamanY5 Unit 2 WorksheetsLiana JohariBelum ada peringkat

- PDF 1 A Maldicao Aurea - CompressDokumen10 halamanPDF 1 A Maldicao Aurea - CompressJonathas RodriguesBelum ada peringkat

- Patronage Issues at KarlaDokumen44 halamanPatronage Issues at KarlaDh huBelum ada peringkat

- EM Waves PolarizationDokumen46 halamanEM Waves PolarizationAnik MondalBelum ada peringkat

- Beliver's Authority - Shephat PhiriDokumen110 halamanBeliver's Authority - Shephat PhiriTahpehs Phiri100% (1)

- Ibarra Character Analysis in Noli Me TangereDokumen3 halamanIbarra Character Analysis in Noli Me TangereSokchheng Phouk0% (1)

- Vocabulary 3 y 4Dokumen4 halamanVocabulary 3 y 4vivianaBelum ada peringkat

- 1200 Commonly Repeated Words in IELTS Listening TestDokumen4 halaman1200 Commonly Repeated Words in IELTS Listening TestMolka MolkanBelum ada peringkat

- Nabokov Likes DislikesDokumen3 halamanNabokov Likes DislikesFalcon PunchBelum ada peringkat

- Snow White Play ScriptDokumen9 halamanSnow White Play Scriptlitaford167% (3)

- You Dian TianDokumen5 halamanYou Dian TianWinda AuliaBelum ada peringkat

- Error Code Cannon Mp190Dokumen1 halamanError Code Cannon Mp190Hec Thor StanislaoBelum ada peringkat

- Script Story of PaulDokumen2 halamanScript Story of PaulMonica M Mercado100% (2)

- Prince Caspian Audition ScriptDokumen7 halamanPrince Caspian Audition ScriptDavid CorkillBelum ada peringkat

- Architectural Design of Public BuildingsDokumen50 halamanArchitectural Design of Public BuildingsAr SoniBelum ada peringkat

- DeskriptifDokumen5 halamanDeskriptifJonny BaristuBelum ada peringkat

- Jesus Cares For The PoorDokumen4 halamanJesus Cares For The PoorifntlybulletproofBelum ada peringkat

- Literary Movements: ..:: Syllabus 6 Semester::.Dokumen4 halamanLiterary Movements: ..:: Syllabus 6 Semester::.FARRUKH BASHEERBelum ada peringkat

- Test de Evaluare Initiala A12aDokumen2 halamanTest de Evaluare Initiala A12aRamona AndaBelum ada peringkat

- Dua Lipa - Physical LyricsDokumen2 halamanDua Lipa - Physical LyricsCarolina Jaramillo0% (2)

- TG - Music 7 - Q1&2Dokumen45 halamanTG - Music 7 - Q1&2Antazo JemuelBelum ada peringkat

- Arabia:The Untold Story, Book 1: Search For PharaohDokumen122 halamanArabia:The Untold Story, Book 1: Search For PharaohWazir Khan90% (10)

- Abecote 320: Epoxy Enamel CoatingDokumen2 halamanAbecote 320: Epoxy Enamel Coatingengramir07Belum ada peringkat

- Mass Music 2020 PDFDokumen15 halamanMass Music 2020 PDFCheryl Kelly PriceBelum ada peringkat

- Tragedy Fact SheetDokumen1 halamanTragedy Fact SheetSamBuckleyBelum ada peringkat

- Letter To The Secretary of StateDokumen3 halamanLetter To The Secretary of StateThe Guardian100% (1)