Flood-Resistant Construction Guide

Diunggah oleh

my.dear.sirHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Flood-Resistant Construction Guide

Diunggah oleh

my.dear.sirHak Cipta:

Format Tersedia

Flood-Resistant Construction Guide

(800) 999-5099 | www. strongti e.com

Inst al l i ng Si mpson Strong-Ti e

Connectors i n Fl ood-Prone Regi ons

Flood-Resistant Construction Guide

MITIGATING FLOOD DAMAGE

Unlike earthquakes, tornadoes, and hurricanes, ooding is a natural disaster that commonly occurs throughout all regions of

North America. While the causes tend to be different depending on the region, oods cause billions of dollars in damage annually

to structures near the coast as well as inland.

Flood Design

In ood-prone regions, it is important to design structures to resist the forces encountered during a ood.

The movement of water and debris can also result in several design considerations unique to oods.

HYDROSTATIC FORCES

Lateral or vertical forces resulting

from standing or slow-moving water

in contact with a structure. Lateral

loads can occur when a vertical wall

has ood water on one side and is

not ooded on the other side. Vertical

(buoyancy) loads occur when elements

of the structure displace ood waters.

Non-Flooded

Area

HYDRODYNAMIC FORCES

Lateral forces typically resulting from

water moving at a moderate to high

speed in contact with a structure.

Lateral loads are created when the

structure is impacted by the moving

water and drag forces are created as

the water moves around the structure.

IMPACT FORCES

Lateral forces resulting from debris,

ice and other objects carried by

oodwaters impacting a structure.

WAVE FORCES

Lateral or vertical forces resulting

from breaking and non-breaking

waves striking the structure. Vertical

uplift loads occur when waves peak

or run-up against a structure.

SCOUR

The removal of soil, sand or ll material

by moving water that can result in the

loss of bearing capacity or anchoring

capacity of the foundation.

2

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

High Wind Design

Flooding is often caused by storms that can also bring damaging winds.

High winds create uplift and lateral forces that can damage structures. Uplift

forces can lift a structure, therefore they must be transferred down to the

foundation to prevent damage. Several connections throughout the structure

are required to create a continuous load path to resist uplift loads.

In addition to its uplift forces, high wind also imposes lateral forces that can

make a structure rack, slide, or overturn. Additional steps must be taken to

resist these loads and ensure that the structure will remain strong. This is

done by adding bracing, shearwalls and connectors.

Large openings along wall lines, such as windows and doors, create

structural challenges in resisting these lateral loads. This is especially true

at garage fronts. Such openings often do not leave a large enough wall

section to provide sufcient strength. These applications will require the

use of prefabricated panels to meet the load requirements.

For more information on the effects of high wind, please refer to the

Simpson Strong-Tie

High Wind-Resistant Construction catalog and the

Companion to the 2001 AF&PA Wood Frame Construction Manual for

Wind Design.

Resources and Links

Guidelines referred to here can be found

in documents published by the Federal

Emergency Management Administration

(FEMA) and other organizations.

DHS-FEMA

National Flood Insurance Program

www.oodsmart.gov

FEMA

www.fema.gov/library

Home Builders Guide to Coastal

Construction (FEMA 499)

- Fact Sheet No. 10: Load Paths

- Fact Sheet No. 17: Use of Connectors

- Fact Sheet No. 28: Decks, Pools,

and Accessory Structures

- Fact Sheet No. 30: Repairs,

Remodeling, Additions, and

Retrotting

Coastal Construction Manual

(FEMA P-55)

Local Ofcials Guide for Coastal

Construction (FEMA P-762)

Wind Retrot Guide for Residential

Buildings (FEMA P-804)

Recommended Residential (foundation)

Construction for Coastal Areas

(FEMA P-550)

AMERICAN SOCIETY OF

CIVIL ENGINEERS

www.asce.org

Flood Resistant Design and

Construction (ASCE 24)

Minimum Design Loads for Buildings

and Other Structures (ASCE 7)

INSTITUTE FOR BUSINESS

AND HOME SAFETY

www.disastersafety.org

Fortied for Safer Living guide

SIMPSON STRONG-TIE

High Wind-Resistant Construction

catalog (C-HW)

Companion to the 2001 AF&PA

Wood Frame Construction Manual

for Wind Design (T-01WFCM)

Anchoring Solutions for

Simpson Strong-Tie

Connectors

in Wind and Low-Seismic Regions

technical bulletin (T-ANCHORSPEC)

3

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

CONTINUOUS LOAD PATH:

MAKING STRUCTURES SAFER IN FLOOD-PRONE AREAS

Following current building codes and installing

structural connectors and fasteners used in a

continuous-load-path system can effectively

contribute to mitigating damage caused by

coastal storm surge, ooding and wind.

When this system of connections is designed

properly, loads are transferred throughout

the structure and into the foundation. The

accompanying graphic illustrates how the

continuous load path extends from the roof

sheathing/frame down to the foundation.

ASCEs Flood Resistant Design and Construction

(ASCE 24) is referenced in the International

Building Code (IBC) and states that the

structure, including anchorage and connections,

shall be designed to resist effects of vertical

loads, including uplift and lateral loads ....

This document will focus on the load path from

the foundation up to and including the rst-oor

studs (links 6, 7 and 8 in the accompanying

graphic). For links, 1-5, refer to the Simpson

Strong-Tie

High Wind-Resistant Construction

catalog (C-HW12) and the companion to the

2001 AF&PA Wood Frame Construction Manual

for Wind Design (T-01WFCM08).

Wall

Joist

Bolts

Sheathing

Steel Plate

(each side)

Pile

Link 7

Link 8

Link 6

Wood Structure

on Wood Piles

Courtesy: FEMA

4

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

Appendix of Terms

Floodplain

Any land area susceptible to partial or complete

inundation by water from any source.

Flood Hazard Area

Area subject to ooding.

Floodway

Channel and that portion of the oodplain reserved to

hold the base ood without cumulatively increasing the

water surface elevation more than a designated height.

Base Flood Elevation (BFE)

Elevation of ooding, including wave height, having a

1% chance of being equaled or exceeded in a given year

(26% chance in 30 years). BFE is generally the elevation

used by the National Flood Insurance Program to map

Special Flood Hazard Areas.

Freeboard

An additional amount of height above the Base Flood

Elevation (BFE) used as a factor of safety in determining

the level at which a structures lowest oor must be

elevated or ood-proofed to be in accordance with state

or community oodplain management regulations.

Design Flood Elevation (DFE)

Elevation of ooding, including wave height, used for

design. Generally equal to the BFE plus freeboard as

determined by the authority having jurisdiction and/or

the property owner.

X Zone

Areas where the ood hazard is lower than that in the

Special Flood Hazard Area. Flood insurance is not mandatory.

However, 20% of all ood insurance claims occur in these

zones.

Special Flood Hazard Area (SFHA)

Land in the oodplain subject to a 1% or greater chance of

ooding in any given year. This is a FEMA-identied, high-risk

ood area where ood insurance is mandatory for properties

that have a mortgage or loan by a federally regulated nancial

institution.

A Zone

Special Flood Hazard Area that is subject to ooding from

riverine or coastal sources where the waves are less than

3 feet high.

V Zone

Coastal Special Flood Hazard Area extending from offshore

to an inland limit of a primary frontal dune along an open coast

and any other area subject to high-velocity wave action where

wave heights or wave runup depths are 3 feet or higher.

LiMWA

Limit of Moderate Wave Action

MoWA

Moderate Wave Action

MiWA

Minimal Wave Action

Courtesy: FEMA

ZONES

5

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

Corrosion

Considerations

Metal corrosion is an important

consideration when building structures in

ood-prone areas. If an environment causes

metal to corrode to a level where galvanized

hardware will not retain its strength through

the useful life of the structure, stainless-

steel connectors are recommended. These

environments would include areas where

salt air or chlorides are present. Chlorides

often result from de-icing salts, salts used

to melt snow, coastal salt fog, mist or

spray. The Simpson Strong-Tie minimum

recommendation is type 316 stainless steel

connectors and fasteners for use in ocean-

salt air and other chloride environments.

While stainless steel provides the greatest

resistance to corrosion, ASCE 24-05

sections 5.2.2.1 and 5.2.2.2 for corrosive

and non-corrosive environments,

respectively, address the use of other

coatings as indicated:

5.2.1 Metal Connectors and Fasteners

Metal plates, connectors, screws, bolts,

nails and other fasteners exposed to direct

contact by ood water, precipitation or

wind-driven water shall be stainless steel

or hot-dip galvanized (HDG) in accordance

with ASTM A123, ASTM A153, ASTM A653.

5.2.2.1 Corrosive Environments

... exposed to salt water, salt spray or other

corrosive agents ... straps and anchoring

devices shall be stainless steel or hot-dip

galvanized after fabrication ...

5.2.2.2 Noncorrosive Environments

... exposed ... straps and anchoring devices

shall be stainless steel or hot-dip galvanized

after fabrication.

RAISED FOUNDATIONS

In V zones, structures are built on raised foundations to mitigate potential

damage caused by hydrostatic and hydrodynamic loads as well as

accompanying debris and scour. These structures are typically built with

either wood piles or masonry/concrete piers that support oor beams.

In each scenario, a continuous load path of connections throughout the

structure is vital to resist ood loads.

ASCE 24-05 Section 4.5.6.6 governs the

connection between the wood pile and

the oor beam.

To maintain a continuous load path up

from the piles/piers, beam-to-oor

and oor-to-wall, connections

are needed to resist both

lateral and vertical forces

caused by ooding.

MTS12

PS418

LTS12

A35

LTS12

Beam-to-Floor

Connections

To achieve full holdown

capacity through bearing

of the plate, a larger

BP1 must be used in

combination with a BP

5

8

CS16

HTT4

with BP

PS720

(PS218, PS418

similar)

RFB#5x16

MTS16

(LTS, HTS

similar)

BP1

BP

5

8

Consult with

Designer prior to

drilling through

the beam

MST37

Beam/Floor-to-Wall

Connections

6

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Typical CCQM Installation

Min. (4)

#7 vertical

rebar (total

for pier)

Typical ECCLQM Installation

Min. (4)

#7 vertical

rebar (total

for pier)

Typical CCTQM Installation

Min. (4)

#7 vertical

rebar (total

for pier)

Flood-Resistant Construction Guide

RAISED FOUNDATIONS (cont.)

To maintain a continuous load path between concrete/masonry piers and oor systems, beam seats or column caps provide

the required resistance to ood forces.

Concrete

Pier

Typical GLB Installation

7

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

SOLID FOUNDATIONS

Solid foundations can be used for structures

located outside of a V Zone. Structures located

away from the coastline are subject to lesser

hydrodynamic loads, impact forces (debris)

or scour than shoreline buildings.

Flood water buildup on the exterior of a

foundation wall applies inward pressure on

the wall. As a result, section 2.6 of ASCE 24-05

states that foundation walls that enclose an

area below the DFE ... shall contain openings

to allow for automatic entry and exit of

oodwaters during design ood conditions.

These ood openings will allow the water to

ow through the openings into a non-living

area to equalize the pressure. In addition,

to ensure that the structure remains securely

fastened to the foundation, it must be

designed with foundation-to-sill plate and

sill plate-to-rim joist connections. These

Simpson Strong-Tie

connectors provide

resistance to vertical loads per section

1.5.5 of ASCE 24-05.

Mudsill

MASA

MAB23

SSP

(DSP similar)

MSTA18

CS16

MTS16

Bearing plates

required for uplift

(model LBPS

1

2

or LBPS

5

8)

Mudsill

TITEN HD

Anchor

(Available in a mechanically

galvanized finish)

A23

Optional

Typical FJA Installation

Foundation to Joist

8

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

DECKS

Decks require strong connections to columns/piles

and footings as well as to the adjacent structure in

order to resist the various loads caused by a ood.

Without proper connections, a deck can tear away and

become a hazard to downstream people and structures

as it is swept along by ood waters. In sections 9.1

and 9.2 of the ASCE 24-05, several guidelines that

address deck connections to the house are provided

based on the coastal ood zone in which the structure

is located. If a deck is not attached to the structure,

it should be designed in accordance with section 4.8.

Several Simpson Strong-Tie

posts and column bases

are specically designed to resist lateral loads between

the post and concrete foundation. Depending on loads,

these connectors can provide the required lateral

resistance. The particular ood zone can also affect

how to best connect decks to structures or the

foundation. For example, in V Zones, decks are

required to be attached to piles and the deck is

mandated to be elevated above the required ood

elevation. Section 4.5.7 of ASCE 24-05 states

... where founded on erodible soils, supports shall

extend to at least 10 ft. below mean water level or

shall be ... anchored by a pile, spread footing ...

meeting the requirements of Section 4.5.1 In other

coastal ood areas, concrete footings are acceptable

but should be deep enough to resist erosion and

scour from ood waters.

For additional deck-specic construction information,

visit www.strongtie.com and download a .pdf copy of

our Deck Framing Connection Guide (F-DECKCODE).

PORCHES

Similar to decks, porches require a solid connection between the supporting

columns/posts and the substructure to avoid collapse. In ood-prone areas, most

of these connections will be cast-in-place solutions, similar to those for decks.

Installing these types of connectors will help avoid many of the common reasons

for porch collapses, such as posts washing away from hydrodynamic loads or scour.

ABW44

1" Standoff satises code

requirem

ents

3

12" E

m

b

e

d

.

(P

B

S

4

4

A

)

5

" E

m

b

e

d

.

(P

B

S

6

6

)

2

" M

in

.

S

id

e

c

o

v

e

r

PBS44A

(PBS66 similars)

3" Min.

Sidecover

3" Min.

Sidecover

CBSQ-SDS2

ABU44

Post-to-Beam Connections

CCQ44SDS2.5

Post-to-Concrete Deck/Porch Connections

ECCLRQMD-KT

Ideal for applications where a member

is needed off the corner of the structure,

such as a deck beam.

Beam-to-Joist Connections

MTS12

(LTS and HTS

similar)

9

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

BOARDWALKS

Boardwalks must be designed to resist the

design loads described in ASCE 7 as well as the

requirements of ASCE 24. The following details

provide several connectors between beams and

their supports to resist the design loads. When

designing in ood zones, smaller hurricane ties

may be inadequate for joist-to-beam or beam-to-

support connections. To resist the loads imposed

by ood waters, straps and connectors that

engage most of the height of the wood members

can greatly reduce the potential for wood failure

from cross-grain tension.

H10A 2x Joist

Beam

Joist-to-Beam Connections

H10A-2

Beam

Double 2x

Joist

A34 H8

Joist

Beam

A34 MTS12

FJA installed with

1

2" dia. through bolts

A34

Beam-to-Beam Connections

10

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

Flood-Resistant Construction Guide

BOARDWALKS (cont.)

H8 A34

5

8" dia. threaded rod

installed with SET-XP

or AT-XP

anchoring

adhesive and BP

5

8-3

FJA installed with

1

2" dia. through bolts and

1

2" dia. threaded rod with SET-XP

or AT-XP

anchoring adhesive

Beam-to-Concrete Nailer Connections

FJA installed with

1

2" dia. through bolts and

1

2" dia. threaded rod with SET-XP

or AT-XP

anchoring adhesive

DTT2 installed with

1

2" dia. threaded rod and SET-XP

or AT-XP

anchoring adhesive

Beam-to-Concrete Pile Cap Connections

11

F

-

C

-

F

L

O

O

D

C

O

N

1

3

2

0

1

3

S

i

m

p

s

o

n

S

t

r

o

n

g

-

T

i

e

C

o

m

p

a

n

y

I

n

c

.

800-999-5099

www.strongtie.com

This ier is effective until June 30, 2015, and reects information available as of July 1, 2013.

This information is updated periodically and should not be relied upon after June 30, 2015; contact

Simpson Strong-Tie for current information and limited warranty or see www.strongtie.com.

2013 Simpson Strong-Tie Company Inc. P.O. Box 10789, Pleasanton, CA 94588 F-C-FLOODCON13 7/13 exp. 6/15

Flood-Resistant Construction Guide

Available Finishes/Materials

1. A full list of corrosion reistant products is available at

www.strongtie.com/corrosion.

2. Products noted are available in multiple sizes. Replace

## in the model number with sizes from our current

Wood Construction Connectors catalog.

FASTENERS

Type 316 Stainless-Steel Annular Ring-Shank Nails

Industry studies have shown smooth-shank stainless-steel nails have lower

withdrawal capacity compared to smooth-shank carbon-steel nails. When

using stainless-steel connectors, the annular-ring-shank nails in the tables

below may be used in place of the specied smooth-shank stainless-steel

nails. See engineering letter L-F-SSNAILS at www.strongtie.com for nail

replacement chart and other related information.

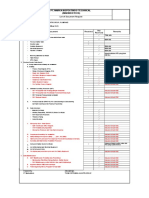

CONNECTORS

33 Paper Tape, Full Round Head,

Ring Shank Structural-Connector Nails

Hand-Drive Common, Annular Ring Shank Nails

Nail

Size

Model

Prefix

Shank

Dia.

(in.)

Head

Dia.

(in.)

Approx.

Count

per lb.

1 lb.

Model

No.

5 lb.

Model

No.

25 lb.

Bucket

Model

No.

8dx1

1

2" SSNA8 0.134

5

16 147 SSNA8D SSNA8D5 SSNA8DB

8dx2

1

2" SSA8D 0.134

5

16 94 SSA8DD SSA8D5 SSA8DB

10dx1

1

2" SSNA10 0.147

5

16 126 SSNA10D SSNA10D5 SSNA10DB

10dx3" SSA10D 0.147

5

16 66 SSA10DD SSA10D5 SSA10DB

16dx3

1

2" SSA16D 0.161

11

32 44 SSA16DD SSA16D5 SSA16DB

Nail

Size

Model

No.

Diameter (in.)

Carton

Quantity

Shank Head

10dx1

1

2" T9A150MCN 0.148 0.281 1500

10dx2

1

2" T9A250MCN 0.148 0.281 1000

ZMAX

HDG

Type 316

Stainless Steel

ANGLES

A34Z A34SS

A35Z A35SS

POST BASES

ABU##Z

2

ABU##SS

2

ABW##Z

2

CBSQ##-SDS2HDG

2

CBSQ##SS

2

PBS44AZ PBS44AHDG

PBS66HDG

COLUMN CAPS

CCQ##-SDS2.5HDG

2

CCQ##SS-SDS2.5

2

ECCQ##-SDS2.5HDG

2

ECCQ##SS-SDS2.5

2

CCQM##-SDSHDG

2

CCTQM##-SDSG

2

ECCLQM##G-KT

2

ECCLQMD##GX-KT

2

BEARING PLATES

LBP##Z

2

LBPS##Z

2

BP ##HDG

2

BP ##-3HDG

2

STRAPS

MSTA##Z

2

MSTA##SS

2

MST##HDG

2

CS16Z CS16SS

PS##

2

TIES

FJAHDG

H8Z H8SS

H10AZ H10ASS

H10A-2Z

LTS12SS

LTS18SS

MTS12Z MTS12SS

MTS16Z

MTS20Z MTS20SS

HTS20Z

SSPZ

DSPZ

MUDSILL ANCHORS

MAB23Z

MASAZ

TENSION TIES

DTT2Z DTT2SS

HTT4HDG

THREADED ROD

RFB ##HDG

2

Anda mungkin juga menyukai

- Songs That Relate To HamletDokumen12 halamanSongs That Relate To Hamletapi-31405016033% (9)

- Cmu Block Wall DetailDokumen2 halamanCmu Block Wall DetailAbdulBari100% (1)

- JSA Lifting OperationsDokumen4 halamanJSA Lifting OperationsCristina Rican100% (1)

- Hazard Map PresentationDokumen35 halamanHazard Map Presentationwilliam edzar b. lipit50% (2)

- ASCE 24-14 Highlights-20150100 Rev2 PDFDokumen6 halamanASCE 24-14 Highlights-20150100 Rev2 PDFcvimer01Belum ada peringkat

- How To Calculate The Total Load On The FootingDokumen7 halamanHow To Calculate The Total Load On The Footingram_babu_59100% (3)

- Types of CracksDokumen3 halamanTypes of CracksShativel ViswanathanBelum ada peringkat

- 2015 NDSDokumen88 halaman2015 NDSEric Forman100% (1)

- Drainage Systems in Retaining WallsDokumen9 halamanDrainage Systems in Retaining WallsAlex Tituaña100% (2)

- How To Design A Flat Roof PDFDokumen3 halamanHow To Design A Flat Roof PDFMaria Rose Giltendez - BartianaBelum ada peringkat

- NHA HousingDokumen95 halamanNHA HousingGarry Yan DiazBelum ada peringkat

- Lateral Force CollectorsDokumen11 halamanLateral Force Collectorsx620Belum ada peringkat

- Lintel DesignDokumen7 halamanLintel DesignDan AielloBelum ada peringkat

- FEMA TB5 508 Rev03132020Dokumen53 halamanFEMA TB5 508 Rev03132020grahambrasicBelum ada peringkat

- Repair and RehabilitationDokumen115 halamanRepair and RehabilitationBala Subramanian0% (1)

- ArticledesignandconstructionofliquidtightconcretestrucDokumen3 halamanArticledesignandconstructionofliquidtightconcretestrucalbertoxinaBelum ada peringkat

- Tek 10-03Dokumen4 halamanTek 10-03Thai DamBelum ada peringkat

- Traditional Timber Repairs PDFDokumen3 halamanTraditional Timber Repairs PDFcarlmorganBelum ada peringkat

- 02-Tensinet - Engineering Fabric ArchitectureDokumen18 halaman02-Tensinet - Engineering Fabric ArchitecturebatteekhBelum ada peringkat

- Mitek ManualDokumen124 halamanMitek ManualTuroyBelum ada peringkat

- TFEC 4 2020 Design Guide For Timber Roof TrussesDokumen72 halamanTFEC 4 2020 Design Guide For Timber Roof TrussesEinBelum ada peringkat

- Chapter 12 Retaining WallDokumen100 halamanChapter 12 Retaining WallLiu ZhenguoBelum ada peringkat

- Chapter 5 MortarDokumen6 halamanChapter 5 MortarSabrina AlyaBelum ada peringkat

- Why Install A Skillion Roof?: Ridge PitchDokumen2 halamanWhy Install A Skillion Roof?: Ridge PitchTeodoro Miguel Carlos IsraelBelum ada peringkat

- Chapter 4.2 Building Near TreesDokumen40 halamanChapter 4.2 Building Near TreesDan Thompson67% (3)

- ACI 530-13 8.2.4, NSCP 707.3.2 Allowable Axial Compressive StressDokumen1 halamanACI 530-13 8.2.4, NSCP 707.3.2 Allowable Axial Compressive StressLhester NavascaBelum ada peringkat

- Concrete Masonry Fire Resistance June 2016Dokumen4 halamanConcrete Masonry Fire Resistance June 2016Hendrix TilloBelum ada peringkat

- Concrete Slab Repair PDFDokumen6 halamanConcrete Slab Repair PDFZac Francis Daymond100% (1)

- Guidelines For Masonry and Stucco: E M S IDokumen12 halamanGuidelines For Masonry and Stucco: E M S IFare NienteBelum ada peringkat

- Industrial Floors and Pavements in Australia A Critical Overview of Current Design MethodsDokumen9 halamanIndustrial Floors and Pavements in Australia A Critical Overview of Current Design Methodsmehdi_hoseineeBelum ada peringkat

- Braced Wall PanelsDokumen10 halamanBraced Wall PanelsMike LojoBelum ada peringkat

- Topic1 3 Foundations Footings 13Dokumen19 halamanTopic1 3 Foundations Footings 13Hussein JaberBelum ada peringkat

- TFEC Timber Design Guide 17 Fire Resistance of Mass Timber StructuresDokumen6 halamanTFEC Timber Design Guide 17 Fire Resistance of Mass Timber StructuresVelmohanaBelum ada peringkat

- CIP 6 Joints in Concrete Slaabs On Grade PDFDokumen2 halamanCIP 6 Joints in Concrete Slaabs On Grade PDFAli ParvezBelum ada peringkat

- Load Assumtions For Buildings PDFDokumen25 halamanLoad Assumtions For Buildings PDFJose LuisBelum ada peringkat

- Building DefectsDokumen41 halamanBuilding DefectsVaibhav HireraddiBelum ada peringkat

- ASCE 7-22 CH 18 - For PC - SouDokumen57 halamanASCE 7-22 CH 18 - For PC - SousharethefilesBelum ada peringkat

- Concrete SolutionDokumen6 halamanConcrete SolutionMohamed KhanBelum ada peringkat

- Unit-Ii: Timber: Building Construction - VDokumen71 halamanUnit-Ii: Timber: Building Construction - VKittur AkshayBelum ada peringkat

- Structural Building Defects - Crack in FoundationDokumen4 halamanStructural Building Defects - Crack in Foundationmyrayaya100% (1)

- Design of Stiffened Slabs-On-grade On Shrink-SwellDokumen23 halamanDesign of Stiffened Slabs-On-grade On Shrink-SwelljoneBelum ada peringkat

- Raft Foundation WWW - BuildinghowDokumen3 halamanRaft Foundation WWW - Buildinghowvarma369vina50% (2)

- 2009 - Forensic of Fire StructuresDokumen7 halaman2009 - Forensic of Fire StructuresivanBelum ada peringkat

- Chapter 17Dokumen20 halamanChapter 17Jack TaylorBelum ada peringkat

- Aitc - 119-96 American Institute of Timber Construction PDFDokumen39 halamanAitc - 119-96 American Institute of Timber Construction PDFECC100% (1)

- Masonry Design PDFDokumen28 halamanMasonry Design PDFnanaamoakoBelum ada peringkat

- Footing Design As Per AstmDokumen102 halamanFooting Design As Per AstmZankar R ParikhBelum ada peringkat

- Home Home: 318 Historical ACI Building Code Requirements (1908-2005)Dokumen3 halamanHome Home: 318 Historical ACI Building Code Requirements (1908-2005)newbie_101Belum ada peringkat

- Axial Load Carrying Capacty of Corroded RC ColumnDokumen11 halamanAxial Load Carrying Capacty of Corroded RC Columnvlad lupasteanuBelum ada peringkat

- Full DocumentDokumen381 halamanFull DocumentMike HarperBelum ada peringkat

- Design of Diaphram & Shear WallsDokumen36 halamanDesign of Diaphram & Shear WallsChidi HenryBelum ada peringkat

- Wood Shear Wall Examples SeismicDokumen40 halamanWood Shear Wall Examples SeismicgullipalliBelum ada peringkat

- Detailing of Concrete Masonry-Solid-Units-140mmDokumen40 halamanDetailing of Concrete Masonry-Solid-Units-140mmbrian1mugadzaBelum ada peringkat

- Building On LandfillDokumen19 halamanBuilding On LandfillAlbi AlboBelum ada peringkat

- Indian AwakeningDokumen12 halamanIndian AwakeningVinod GandhiBelum ada peringkat

- Ncma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BDokumen6 halamanNcma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BjerryBelum ada peringkat

- BSS502 Construction Technology 1Dokumen63 halamanBSS502 Construction Technology 1PATCADS STRUCTURAL SOLUTIONSBelum ada peringkat

- Vulcraft Bar Joist CatalogDokumen129 halamanVulcraft Bar Joist CatalogKris MossBelum ada peringkat

- Tpic 2011Dokumen85 halamanTpic 2011garycwkBelum ada peringkat

- The Evolution of Masonry Bridge Assessment MethodologiesDokumen18 halamanThe Evolution of Masonry Bridge Assessment Methodologiesmoug_thBelum ada peringkat

- Gravity CantileverDokumen3 halamanGravity Cantileverfaroukm91Belum ada peringkat

- Minimum Reinforcement in Concrete MembersDari EverandMinimum Reinforcement in Concrete MembersPenilaian: 3 dari 5 bintang3/5 (2)

- An Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberDari EverandAn Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberPenilaian: 5 dari 5 bintang5/5 (1)

- Bioinformatics CompaniesDokumen18 halamanBioinformatics Companiesmy.dear.sirBelum ada peringkat

- X-Chip: Map Proteins/Histone Modifications To Genomic LociDokumen1 halamanX-Chip: Map Proteins/Histone Modifications To Genomic Locimy.dear.sirBelum ada peringkat

- Tezpur University: Ocean and Atmospheric Science and Technology Cell (OASTC)Dokumen1 halamanTezpur University: Ocean and Atmospheric Science and Technology Cell (OASTC)my.dear.sirBelum ada peringkat

- Walk in Int SRF 9jul14Dokumen1 halamanWalk in Int SRF 9jul14my.dear.sirBelum ada peringkat

- Automated High-Dimensional Flow Cytometric Data Analysis: A A, 1 B, 1 A, 1 C A, D D B, e A A, d,2 A, D, F, 3 A, 2,3Dokumen6 halamanAutomated High-Dimensional Flow Cytometric Data Analysis: A A, 1 B, 1 A, 1 C A, D D B, e A A, d,2 A, D, F, 3 A, 2,3my.dear.sirBelum ada peringkat

- Biodata - SL SahooDokumen18 halamanBiodata - SL Sahoomy.dear.sirBelum ada peringkat

- Call For Proposals Under Molecular Electronics, Conducting Polymers and Non-Invasive and Other Bio-SensorsDokumen1 halamanCall For Proposals Under Molecular Electronics, Conducting Polymers and Non-Invasive and Other Bio-Sensorsmy.dear.sirBelum ada peringkat

- Nominations Invited For Shanti Swarup Bhatnagar Prizes For Science and Technology - 2014Dokumen1 halamanNominations Invited For Shanti Swarup Bhatnagar Prizes For Science and Technology - 2014my.dear.sirBelum ada peringkat

- Syllabus For 2-Year Semester in M.sc. (Zoology), University of CalcuttaDokumen41 halamanSyllabus For 2-Year Semester in M.sc. (Zoology), University of Calcuttamy.dear.sir100% (2)

- Dec PG Prospectus 2011 BerhampurDokumen34 halamanDec PG Prospectus 2011 Berhampurmy.dear.sirBelum ada peringkat

- Algal Bioactive Diversities Against Pathogenic MicrobesDokumen8 halamanAlgal Bioactive Diversities Against Pathogenic Microbesmy.dear.sirBelum ada peringkat

- Boyscast Fellowship For The Year 2004-05Dokumen6 halamanBoyscast Fellowship For The Year 2004-05my.dear.sirBelum ada peringkat

- FP Facts 09 Flood Resistant DesignDokumen2 halamanFP Facts 09 Flood Resistant Designlaurenjia100% (1)

- Detailed LPDokumen6 halamanDetailed LPLiewenzBelum ada peringkat

- 10 Steps To Disaster PreparednessDokumen2 halaman10 Steps To Disaster PreparednessAmir LMBelum ada peringkat

- Module 4CCDRMDokumen7 halamanModule 4CCDRMLadee KharryleBelum ada peringkat

- MakingTheGeologic EbookDokumen264 halamanMakingTheGeologic Ebookcraigzeroone100% (1)

- Determination of Modification Factor R For Seismic Design of Pressure Vessels Using ASME and EurocodesDokumen11 halamanDetermination of Modification Factor R For Seismic Design of Pressure Vessels Using ASME and Eurocodesoscargon19Belum ada peringkat

- GCSE Revision GuideDokumen86 halamanGCSE Revision GuideJamie WeeksBelum ada peringkat

- Unit 7 - Strategic Information Systems: Data Security Session 7Dokumen11 halamanUnit 7 - Strategic Information Systems: Data Security Session 7Career and EducationBelum ada peringkat

- Dokumen List Re - SkpiDokumen2 halamanDokumen List Re - SkpiarisBelum ada peringkat

- School Prepareness and Response Measures in Connection With El Nino (District Data)Dokumen35 halamanSchool Prepareness and Response Measures in Connection With El Nino (District Data)Amarah Christian MatthewBelum ada peringkat

- DLL DRRR Week 4 - 2020Dokumen3 halamanDLL DRRR Week 4 - 2020Rizalyn Garcia100% (2)

- Research Chapter 1Dokumen9 halamanResearch Chapter 1Mark Anthony BalaneBelum ada peringkat

- 916888ger PDFDokumen19 halaman916888ger PDFRoach Gabriele SandersonBelum ada peringkat

- Saint Research EditedDokumen41 halamanSaint Research EditedemrolaineBelum ada peringkat

- Types of Volcanoes Guided NotesDokumen3 halamanTypes of Volcanoes Guided Notesapi-264099976Belum ada peringkat

- Question G 7Dokumen6 halamanQuestion G 7Hadi Iz'aanBelum ada peringkat

- Bhopal Gas TragedyDokumen1 halamanBhopal Gas TragedyaBelum ada peringkat

- West of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFDokumen6 halamanWest of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFDave Moreno100% (1)

- The Aesthetic AttitudeDokumen3 halamanThe Aesthetic AttitudePantatNyanehBurikBelum ada peringkat

- Jose Cangco: Topic: (Common Carriers - in General-Nature and Basis of Liability - Article 1733) (Cruz, Anton)Dokumen65 halamanJose Cangco: Topic: (Common Carriers - in General-Nature and Basis of Liability - Article 1733) (Cruz, Anton)Jovanni BajanBelum ada peringkat

- SIKAP Extension Request TemplateDokumen11 halamanSIKAP Extension Request TemplateDix Ty100% (1)

- Traders JuneDokumen71 halamanTraders Junemustafa-ahmedBelum ada peringkat

- Chandamama 1983-09Dokumen68 halamanChandamama 1983-09varnamala100% (1)

- Azerbaijan Seismic MapDokumen1 halamanAzerbaijan Seismic MapHüseyin Ekici0% (1)

- Calculation of Blast Loads For Application To Structural ComponentsDokumen58 halamanCalculation of Blast Loads For Application To Structural ComponentsPatran60% (5)

- Example Reso On Moa BDRRMCDokumen2 halamanExample Reso On Moa BDRRMCHanume EmunahBelum ada peringkat

- EOHSMS-05-F01 Incident & Accident Investigation Report FormDokumen4 halamanEOHSMS-05-F01 Incident & Accident Investigation Report FormLisa SwansonBelum ada peringkat