Gall5231328512232fip PDF

Diunggah oleh

Andres CortezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gall5231328512232fip PDF

Diunggah oleh

Andres CortezHak Cipta:

Format Tersedia

HEATSHRINKABLE SHEETS

ManufacturerStatement&ProductdataSheets

ThisSectionincludestheTechnicaldatasheets,safetyData

Sheets,andInstallationInstructions.

Fip

Fip

fip

CANUSA-CPS

CSS

CANUSA-CPS

CSS

CANUSA-CPS

CSS-2

Canusa is registered to ISO 9001:2008.

APD-NA-rev024

CANUSA-CPS

CSC

CFS

CSC-X

Reh

a

b

Sleeves

G

TS-80

G

TS-65

G

TS-H

T

G

TS-PP

H

igh

Shrink

Sleeves

KLO

X/PM

O

F

PM

O

/W

LO

X

PM

A

LRKN

Casing

Snap

Fit

(CSF/CSK

)

W

ra

p

id

Sle

e

ve

C

a

n

u

sa

Tu

b

e

C

a

n

u

sa

W

ra

p

Su

p

e

rse

a

l

Su

p

e

rC

a

se

O

ffs

h

o

r

e

P

r

o

d

u

c

ts

M

IS

IN

R-110

PLX

CSS

CSS-2

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

CFS

CFS

SUPERSEAL

CANUSA-CPS

SUPERSEAL

TBK

TBK

Directional Drilling

Kits

TBK-PP

CANUSA-CPS

CANUSA-CPS

CANUSA-CPS

G

TS-PP

A

Q

W

AQUA-SHIELD

AQUA-SHIELD

A

Q

W

-FF

AQUA-SHIELD

A

qua-Shield

F

la

g

s

h

ip

P

r

o

d

u

c

ts

G

T

S

&

P

o

ly

p

r

o

p

y

le

n

e

P

r

o

d

u

c

ts

P

r

e

-

In

s

u

la

te

d

P

r

o

d

u

c

ts

W

rapid

Sleeve

W

a

te

r

P

ip

e

lin

e

P

r

o

d

u

c

ts

L

iq

u

id

E

p

o

x

y

P

r

o

d

u

c

ts

H

B

E-9

5

H

B

E-H

T

H

B

E-FE

Spray Grade

Brush Grade

Spray Grade

Brush Grade

M

elt

Stick

Pipeline

Repair

Products

CRP

M

astic

Filler

CANUSA-CPS

CANUSA-CPS

H

CA/H

CO

W

rapid

Tape

CANUSA-CPS

V

E

C

o

a

t

i

n

g

s

G

T

S

-

V

E

W

r

a

p

i

d

B

o

n

d

W

r

a

p

i

d

C

o

a

t

G

TS-PP-100

CANUSA-CPS

G

TS-PE

Canusa-CPS is a leading manufacturer of

specialty pipeline coatings which, for over

30 years, have been used for sealing and

corrosion protection of pipeline joints and

ot her subst r at es. Canusa hi gh

performance products are manufactured

to the highest quality standards and are

available in a number of configurations to

accommodate your specific project

applications.

CanusaWrap is a wraparound sleeve

with a separate closure designed for

corrosion protection of buried and

exposed steel pipelines. CanusaWrap is

supplied in bulk rolls consisting of a

crosslinked polyolefin backing, coated

with a protective heat activated adhesive.

Once installed, the system effectively

bonds and protects steel substrates and

common main line pipe coatings including

polyethylene and fusion bonded epoxy.

CanusaWrap provides excellent resis-

tance to cathodic disbondment resulting in

effective long term corrosion protection.

The high performance crosslinked

backing, in combination with a broad

range of adhesives, can be engineered for

regular or high stress environments. Once

installed, CanusaWrap provides the

structural integrity of a seamless tube, and

provides the substrate with durable

protection against abrasion and chemical

attack.

Long-Term Corrosion Protection

Product Description

Features & Benefits

CanusaWrap

Two-piece protective bulk roll with separate closure

Flexibility on the Job Site

Easy Field Installation

Since CanusaWrap is supplied in bulk

rolls, just-in-time customized lengths can

be quickly cut in the field to protect any

pipe size. This flexibility results in reduced

inventories and cost savings on the job

site. CanusaWrap is also available in a

high shrink ratio for high profile joint

protection. Consult the High Shrink data

sheet or your Canusa representative for

additional information.

CanusaWrap can be installed quickly

and easily in most environments. Since no

special taping, priming or operator

equipment is required, product installation

is quick and labour costs are kept to a

minimum. CanusaWrap and the closure

seals are available in yellow with a

thermochromic indicator and a patented

Windoweld feature which visually con-

firms optimuminstallation.

CANUSA-CPS is registered to . ISO 9001:2008

Y

e

llo

w

B

a

c

k

in

g

B

la

ck

B

a

ckin

g

Configurations

Configurations

Applications

Product Data Sheet Product Data Sheet

CanusaWrap

Girth-Weld Joints

Oil & Gas

Pre-Insulated Pipes

Water Pipelines

Temperature Range

Pipe Sizes

55 - 1520 (2 - 60)

up to 80C (176F)

2-Layer

Standard Shrink

C

A

N

U

SA

-C

PS

C

A

N

U

S

A

-C

P

S

Polypropylene

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusas written instructions. Since

many installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith. Canusas liability is stated in

the standard terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a guide and is subject to change without

notice. This installation guide supersedes all previous installation guides on this product. E&OE

PDS-CW-rev014 Printed on recycled paper. Recyclable.

www.canusacps.com

The product selection chart shown here is intended as a guide for standard products.

Consult your Canusa representative for specific projects or unique applications.

The following are typical values based on Black, Heavy Duty (L) Sleeves.

CanusaWrap

How To Order:

(50, 100 ft) 15, 30 m

Bulk Roll Lengths: 30 m 15 m up to 600 mm width: (100ft), above 600 mm width: (50ft)

W - Bulk Roll

B - Bulk Roll designation B - Bulk Roll

C - Closure Seal Configuration

Sleeve / Closure Width

Colour ZZ-BK, WW, YE BK ZZ-BK, YE

0.65mm (27 mils) 0.6mm (32 mils) 0.8mm (32 mils)

W- n/a H-0.35mm (14mils) S-0.75 mm (30mils)

T - 0.6 mm (25 mils) L - 0.9 mm (36 mils)

1.25 mm (50 mils)

Bulk Roll Length

Bulk Roll Designation

Backing (thickness as supplied)

Adhesive (thickness as supplied)

WLO-B 450-30 BK

D

i

m

e

n

s

i

o

n

s

&

O

r

d

e

r

i

n

g

I

n

f

o

BK- YE- Black, Yellow

Bulk Roll Ordering Options Closure Seal Options

CLW-B 100-15 ZZ

Weldable Closure

CLH-B XXX-15 BK

Hot Melt Closure

CLS-B 100-15 ZZ

Butyl Adhesive Closure

Regular Thickness (T) Heavy Duty Thickness (L)

300, 450, 600, 900mm, (12, 18, 24, 36)

Bulk:15,30 m (50,100 ft) Precut: 300,450,600,900mm, (12,18,24,36)

100mm (4) 100mm (4) 115, 150mm (4,6)

The above represents standard ordering options Consult your Canusa representative for any unique project requirements, including pre-cut sleeves or closures.

A

d

h

e

s

i

v

e

B

a

c

k

i

n

g

S

l

e

e

v

e

Celsius

110

90

70

50

30

Fahrenheit

230

194

158

122

86

Mastic Adhesives Hot Melt Adhesives

Pipeline

Operating

Temperature

S

l

e

e

v

e

O

p

e

r

a

t

i

n

g

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

Product Selection Guide

Typical Product Properties

100 (212)

8 (12)

.93

20 (2900)

600

46

45

10

27

--

--

15 (9)

8 (5)

6

0.05

-40 (-40)

--

17

90 (194)

30 (44)

.93

20 (2900)

600

46

45

10

20

pass

pass

55 (31)

50 (29)

6

0.05

5 (23)

--

17

77 (171)

40 (58)

.93

20 (2900)

600

46

45

10

20

pass

pass

79 (45)

70 (40)

8

0.05

-20 (-4)

--

17

102 (216)

40 (58)

.93

24 (3480)

700

48

35

10

27

pass

pass

80 (46)

65 (37)

8

0.05

-14 (7)

C30

17

102 (216)

40 (58)

.95

24 (3480)

700

52

30

10

20

pass

pass

80 (46)

65 (37)

7

0.05

-14 (7)

C30

18

PE, PP, FBE, PU, Coal tar, Bitumen,

50 (122)

fair

fair

fair

60 (140)

fair

fair

fair

65 (150)

good

good

good

75 (167)

good

good

good

75 (167)

good

good

good

90 (195)

good

good

good

PE, PP, FBE

Test Standard

ASTM E28

DIN 30 672 M

ASTM D792

ASTM D638

ASTM D638

ASTM D2240

ASTM D1044

ASTM D257

ASTM D149

DIN 30 672

DIN 30 672

ASTM D1000

DIN 30 672

ASTM G8

ASTM D570

ASTM D2671C

DIN 30 672

Softening Point

Lap Shear

Specific Gravity

Tensile Strength

Elongation

Hardness

Abrasion Resistance

Volume Resistivity

Dielectric Voltage Brkdwn.

Impact *

Indentation *

Peel

Peel

Cathodic Disbondment

Water Absorption

Low Temp. Flexibility

DIN Approval *

Fully Recovered Sleeve Thickness

Fully Recovered Sleeve Thickness

T

L

Unit

C (F)

N/cm (psi)

MPa (psi)

%

Shore D

mg

ohm-cm

kV/mm

class C

class C

N/cm (pli)

N/cm (pli)

mm rad

%

C (F)

class

mm (mils)

mm (mils)

2

Minimum Installation Temperature C (F)

Resistance to Circumferential Forces

Resistance to Soil Stress

Resistance to Axial Pipe Movement

Main Line Coating Compatibility

-40C -40F -40C -40F

60 (140)

v. good

v. good

v. good

PE, FBE

90 (195)

excl

excl

excl

PE, FBE

Choose your sleeve based on Operating Temperature and Characteristics listed below.

WLG WLC WLS WLO WLON WLNN

WTNN

WLA WLAS

WTG WTC WTS WTO WTON

124 (255)

52 (75)

.95

24 (3480)

700

52

30

10

20

pass

pass

115 (66)

90 (51)

7

0.05

-15 (5)

--

2.3 (90)

2.8 (111)

18

72 (162)

60 (87)

.93

20 (2900)

600

46

45

10

20

pass

pass

50 (29)

35 (20)

13

0.05

-32 (-26)

C50

--

17

1

NN has an adhesive thickness of 1.1mm (45 mils)

3.3 (131)

2.5 (99)

3.3 (131)

1.7 mm (65 mils)

90 (194)

117 (170)

.93

24 (3480)

700

48

35

10

27

pass

pass

120 (70)

86 (50)**

11

0.05

-28 (-18)

C50

--

17

* Denotes sleeve thickness L ** backing elongation during peeling due to superior bond strength

* For higher temperature requirements refer to Canusa GTS product line.

WTON, WLON, WTNN, WLNN are available in black only.

CANUSA-CPS

SHAWCOR LTD a division of .

25 Bethridge Road

Rexdale, Ontario

M9W 1M7,

Canada

Tel: +1 (416) 743-7111

Fax: +1 (416) 743-5927

Canada U.S.A./Latin America

CANUSA-CPS

SHAWCOR INC. a division of

2408 Timberloch Place

Building C-8

The Woodlands, Texas

77380, U.S.A.

Tel: +1 (281) 367-8866

Fax: +1 (281) 367-4304

Europe/Middle East Asia/Pacific

CANUSA-CPS

a division of Canusa Systems Ltd.

Unit 3, Sterling Park

Gatwick Road

Crawley, West Sussex

England RH10 9QT

Tel: +44 (1293) 541254

Fax: +44 (1293) 541777

CANUSA-CPS

a division of .

#05-31, Blk 52, Frontier

Ubi Avenue 3

Singapore

408867

Tel: +65-6749-8918

Fax: +65-6749-8919

SHAWCOR LTD

PAGE 12 / 12

25 Bethridge Road, Toronto, Ontario, Canada M9W 1M7 Tel: (416) 743-7111 Fax: (416) 743-5927 www.canusacps.com

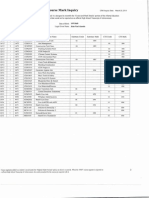

WLO/ KLO type heat-shrinkable sleeves

Table 1: Summary of Dimensions

Dimension Description

Unit of

Measure

Nominal Value

A Pipe Diameter inch Various

B Total Cutback Length mm 300

C Factory Coating -- 3LPE

D Sleeve Width mm 450

E Factory Coating Overlap mm 75

F Sleeve Length mm Various

G Closure Width (Pre-attached) mm 100

H Adhesive Thickness (as supplied) mm 1.65

I Backing Thickness (as supplied) mm 0,9

Field Joint View

Supplied Product View

Our Submittal

Water Pipelines

Wrapid Tape

Fittings

Bends

Repair & Rehab

Configurations

Applications

Girth-Weld Joints

Oil & Gas

Temperature Range

Pipe Sizes

All Sizes

up to 55C (131F)

2-Layer

Canusa-CPS is a leading manufacturer

of specialty pipeline coatings which, for

over 30 years, have been used for

sealing and corrosion protection of

pipeline joints and other substrates.

Canusa high performance products are

manufactured to the highest quality

standards and are available in a number

of configurations to accommodate your

specific project applications.

The flexibility provided by the thinner

tape dimension allows Wrapid Tapeto

effectively protect both conventional

substrates such as circular pipe as well

as irregular transitions such as elbows

and risers. Upon the application of

heat, the specially formulated adhesive

flows into all surface irregularities,

forming a protective barrier against

corrosion.

Canusa Wrapid Tape consists of a

crosslinked polyolefin backing, coated

with a protective, heat sensitive anti-

corrosion adhesive which effectively

bonds to steel substrates and common

pipeline coatings including polyethyl-

ene and fusion bonded epoxy. Upon

the application of heat, Wrapid Tape

shrinks down to fully encapsulate the

protected substrate. The product is

packaged in convenient rolls with

various widths to protect and repair

pipelines, fittings, bends, elbows and

other irregular configurations.

Wrapid Tape is quick and easy to

install. Since no special priming or

operator equipment is required,

product installation is quick and labour

costs are kept to a minimum. Unlike

conventional cold-applied tapes,

Wrapid Tape does not require the use

of high volatile primers, further mini-

mizing costs and risks to health and

safety.

Easy Installation

Saves Time &Money

Product Description

Features & Benefits

Product Data Sheet

Wrapid Tape

Primerless Crosslinked Protective Tape

Long TermProtection

Wrapid Tape is manufactured using

materials that provide high electrical

resistivity, lowwater absorption and low

moisture permeability. The unique

crosslinking process results in a

protective backing that is much tougher

than conventional tapes, more effec-

tively resisting abrasion and damage,

and thus extending the lifetime of the

substrate. Wrapid Tape can also be

double or triple wrapped for extra

mechanical protection when required.

CANUSA-CPS is registered to ISO 9001:2008.

The product selection chart shown here is intended as a guide for standard products.

Consult your Canusa representative for specific projects or unique applications.

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusas written instructions. Since many

installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith. Canusas liability is stated in the standard

terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a guide and is subject to change without notice. This installation

guide supersedes all previous installation guides on this product. E&OE

Printed on recycled paper. Recyclable.

www.canusacps.com

PDS-A4-WT-rev015

DN inches mm inches M feet M feet

25 1 50 2 2.8 9.3 2.8 9.3

40 1.5 50 2 4.0 13.2 4.6 15

50 2 50 2 5.2 17 6.2 20.3

80 3 50 2 8.5 28 10.6 34.7

100 4 50 2 12.3 40 14.8 48.6

125 5 75 3 11.1 36.4 13.6 44.6

150 6 75 3 14.3 46.9 18.3 60

200 8 100 4 16.3 53.4 20.8 68.2

250 10 100 4 23.1 75.8 30.6 100.4

300 12 100 4 30.4 99.8 40.9 134.2

>300 >12 150 6 see formula below

Minimum Installation Temperature C (F)

Resistance to Soil Stress

Main Line Coating Compatibility

Test Standard

ASTM E28

ASTM D1002

ASTM D792

ASTM D638

ASTM D638

ASTM D2240

ASTM D1044

ASTM G14

ASTM D1000

ASTM D570

ASTM G8

ASTM D149

ASTM D2671C

DIN 30 672

Softening Point

Lap Shear

Specific Gravity

Tensile Strength

Elongation

Hardness

Abrasion Resistance

Impact

Peel

Water Absorption

Cathodic Disbondment

Dielectric Voltage Brkdwn.

Low Temp. Flexibility

DIN Approval

Fully Recovered Thickness

Unit

C (F)

N/cm (psi)

MPa (psi)

%

Shore D

mg

pass/fail

N/cm (pli)

%

mm rad

kV/mm

C (F)

class

mm (mils)

2

A

d

h

e

s

i

v

e

B

a

c

k

i

n

g

T

a

p

e

Hot Melt

Nominal Pipe

Diameter

Recommended

Tape Width

Length of Tape Required

3D Bend 5D Bend

T

a

p

e

O

p

e

r

a

t

i

n

g

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

M

a

t

e

r

i

a

l

U

s

a

g

e

T

a

b

l

e

Operating Characteristics Tape Usage Guide

Typical Product Properties

HCA

60 (140)

good

PE, FBE, PU

The above table shows the typical usage for 3D and

5D bends, assuming a line coating cutback of 150

mm (6") and a 50 mm (2") overlap onto the pipe

coating.

Celsius

110

90

70

50

30

o

o

o

o

o

Fahrenheit

230

194

158

120

85

o

o

o

o

o

-40C -40F

Pipeline

Operating

Temperature

150mm

50mm

1

5

0

m

m

5

0

m

m

L

Wrapid Tape

HCO

65 (149)

good

HCC

60 (140)

fair

Bit, CT, PU, PE, PP, FBE

72 (162)

60 (87)

0.93

20 (2900)

600

46

45

pass

35 (20)

0.05

13

27

-32 (-25)

C30/C50

1.5 (60)

HCA

102 (216)

40 (58)

0.93

20 (2900)

600

46

45

pass

52 (30)

0.05

6

27

5 (23)

1.5 (60)

HCO

90 (194)

30 (44)

0.93

20 (2900)

600

46

45

pass

26 (15)

0.05

8

27

-14 (-7)

1.5 (60)

HCC

Mastic

15m (50 ft)

A - 0.75 mm (30 mils), O - , C - 0.75 mm (30 mils) 0.75 mm (30 mils)

C - 0.4 mm (16 mils)

BK YE -Black, -Yellow

50, 75, 100, 150, 200, 300 mm

(2", 3", 4", 6", 8", 12")

How To Order:

H - Tape

B - Bulk Roll Designation Bulk Roll Designation

Colour

Width of Roll

Length of Roll

HCA-B 75-15 BK

D

i

m

e

n

s

i

o

n

s

&

O

r

d

e

r

i

n

g

I

n

f

o

Wrapid Tape

The above represents standard ordering options. Consult your Canusa representative for any unique project requirements.

Backing (thickness as supplied)

Adhesive (thickness as supplied)

Configuration

CANUSA-CPS

SHAWCOR LTD a division of .

25 Bethridge Road

Rexdale, Ontario

M9W 1M7,

Canada

Tel: +1 (416) 743-7111

Fax: +1 (416) 743-5927

Canada U.S.A./Latin America

CANUSA-CPS

SHAWCOR INC. a division of

2408 Timberloch Place

Building C-8

The Woodlands, Texas

77380, U.S.A.

Tel: +1 (281) 367-8866

Fax: +1 (281) 367-4304

Europe/Middle East Asia/Pacific

CANUSA-CPS

a division of Canusa Systems Ltd.

Unit 3, Sterling Park

Gatwick Road

Crawley, West Sussex

England RH10 9QT

Tel: +44 (1293) 541254

Fax: +44 (1293) 541777

CANUSA-CPS

a division of .

#05-31, Blk 52, Frontier

Ubi Avenue 3

Singapore

408867

Tel: +65-6749-8918

Fax: +65-6749-8919

SHAWCOR LTD

For other sizes, the following formula can be used:

where L=length of area to be covered, and

W= of tape width (for 50% overlap)

Length of tape = x pipe diameter x L/W

10m (33.3 ft)

Our Submittal: 100mmx10meter Roll

CANUSA-CPS is registered to . ISO 9001:2008

Installation Guide

4

B

A

U

n

d

e

r

l

a

p

O

v

e

r

l

a

p

Cut

Sleeve

L

W

Sleeve

width

C

l

o

s

u

r

e

Pipe O.D.:

100 mm overlap

150 mm overlap

<

450mm

>450mm

(18")

(18")

overlap

Bulk Roll Closure

Corner Cuts

<450mm

Pipe O.D.

>450mm Pipe O.D.

-50mm, -25mm

-100mm, -50mm

A B

A B

WLG WTG

WLC WTC

WLS WTS

WLO WTO

WLON WTON

WLNN WTNN

WLA

WLAS

To ensure maximum performance, store

Canusa products in a dry, ventilated area. Keep

products sealed in original cartons and avoid

exposure to direct sunlight, rain, snow, dust or

other adverse environmental elements. Avoid

prolonged storage at temperatures above 35C

or below -20C Product

installation should be done in accordance with

local health and safety regulations.

(95F) (-4F).

Storage & Safety Guidelines

Pre-Heat

1

8

Bulk Roll Closure

Surface Preparation

2

Wipe clean or air blast the steel and pipe coating to

remove foreign contaminants.

Surface Preparation

5

0

m

m

+

S

le

e

v

e

+

5

0

m

m

S

le

e

v

e

W

id

t

h

Two-piece protective bulk roll with separate closure

CanusaWrap

Equipment List

3

S

O

L

V

E

N

T

S

O

L

V

E

N

T

Ensure that the PE coating edges are beveled to 30.

Clean exposed steel and adjacent pipe coating with a

solvent cleanser to remove the presence of oil,

grease, and other contaminants.

6

Surface Preparation and Pre-Heat Chart

Min. Pre-Heat Temp. Standard Sleeves Surface Preparation

SIS Standard

Minimum Preferred Preferred Minimum

M

a

s

t

i

c

H

o

t

M

e

l

t

SSPC Standard

50

60

65

75

75

90

60

90

(122)

(140)

(150)

(167)

(167)

(195)

(140)

(195)

C (F)

St2

St2

St2

St2

St2

St3

St3

St3

SP2

SP2

SP2

SP2

SP2

SP3

SP3

SP3

SP6

SP6

SP6

SP6

SP6

SP10

SP10

SP10

Sa2

Sa2

Sa2

Sa2

Sa2

Sa2

Sa2

Sa2

7

Flame Intensity & Torch Size

Use

flame intensity for pre-

heating and shrinking.

moderate to high Use flame

intensity for pre-heating

and shrinking.

moderate

Pipe O.D.

<450mm

(18")

Pipe O.D.

>450mm

(18")

Minimum Torch Size:

150,000 BTU/hr.

Minimum Torch Size:

300,000 BTU/hr.

5

These installation instructions are intended as a

guide for standard products. Consult your Canusa

representative for specific projects or unique

applications.

Part No. 99060-022

As a guideline,cut the required lengths of Sleeve material (L)and Closure material (W) from the bulk roll as follows

Ensure that the sleeve and closure are not damaged or contaminated. Trim corners as shown .

L = Coated Pipe circumference + overlap dimension W = Sleeve Width

Please see for more information on alternative cutting methods. CanusaWrap Sleeve Cutting Guideline

TM

Product Preparation Guidelines

9 10

C

A

N

U

S

A

-

C

P

S

Product Description

CanusaWrap is typically shipped in bulk rolls. The

adhesive is protected from contamination by an

inner liner. Closures are shipped either in bulk rolls

or pre-cut.

TM

Propane tank, hose, torch & regulator Appropriate

tools for surface abrasion

Knife, roller, rags &Canusa approved solvent cleanser

Digital thermometer with suitable probe

Standard safety equipment: gloves, goggles, hard hat,

etc.

Ensure that the pipe is dry before cleaning.

Prepare the steel joint area using the Surface

Preparation and Pre-Heat as a guideline. Lightly

abrade the pipe coating adjacent to the cutback

area to a distance of 50mm (2") beyond each end

of the sleeve width.

Pre-heat the joint area to the minimum required

temperature (see Surface Preparation & Pre-Heat

Chart). Using a temperature measuring device,

ensure that the correct temperature is reached on

the steel and at least 50mm(2") on each side of the

sleeve.

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusas written instructions. Since many

installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith. Canusas liability is stated in the standard

terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a guide and is subject to change without notice. This installation

guide supersedes all previous installation guides on this product. E&OE

Printed on recycled paper. Recyclable.

www.canusacps.com

IG-A4-CW-rev013

After shrinking is complete, allow the sleeve to cool for 2 hours prior to lowering and backfilling. To prevent damage to the sleeve, use selected backfill

material, (no sharp stones or large particles) otherwise an extruded polyethylene mesh or other suitable shield should be used.

CanusaWrap

1

2

1

1

2

2

Pipe O.D.:

1 torch

2 torches

<450mm

>450mm

(18")

(18")

17

20

Gently heat the closure and pat it down with a gloved hand. Repeating this procedure, move fromone side to

the other. Smooth any wrinkles by gently working themoutward fromthe centre of the closure with a roller.

While the sleeve is still hot and soft, use a hand

roller to gently roll the sleeve surface and push any

trapped air up and out of the sleeve, as shown

above. If necessary, reheat to roll out air.

Continue the procedure by also firmly rolling the

closure with long horizontal strokes from the weld

outwards.

Shrinking has been completed when the adhesive

begins to ooze at the sleeve edges all around the

circumference. Finish shrinking the sleeve with

long horizontal strokes over the entire surface to

ensure a uniformbond.

Continue heating from the centre toward one end

of the sleeve until recovery is complete. In a

similar manner, heat and shrink the remaining side.

Partially remove the release liner and gently heat

the underlap approximately 150 mm (6") from the

edge.

Wrap the sleeve loosely around the pipe, ensuring

the appropriate overlap. Gently heat the backing of

the underlap and the adhesive side of the overlap.

Press the overlap into place.

Centre the sleeve over the joint so that the sleeve

overlaps between the 10 and 2 o'clock positions.

Press the underlap firmly into place and remove the

remaining release liner.

16

11

14

13

Sleeve Installation

Inspection

15A C

B D F

18

21

12

Using the appropriate sized torch, begin at the

centre of the sleeve and heat circumferentially

around the pipe. Use broad strokes. If utilizing

two torches, operators should work on opposite

sides of pipe.

E

Visually inspect the installed sleeve for the following:

Sleeve is in full contact with the steel joint.

Adhesive flows beyond both sleeve edges.

No cracks or holes in sleeve backing.

19

2 10

Remove any release liners from the closure.

Centre the closure on the overlapping sleeve.

Press down firmly.

Backfilling Guidelines

CANUSA-CPS

SHAWCOR LTD a division of .

25 Bethridge Road

Rexdale, Ontario

M9W 1M7,

Canada

Tel: +1 (416) 743-7111

Fax: +1 (416) 743-5927

Canada U.S.A./Latin America

CANUSA-CPS

SHAWCOR INC. a division of

2408 Timberloch Place

Building C-8

The Woodlands, Texas

77380, U.S.A.

Tel: +1 (281) 367-8866

Fax: +1 (281) 367-4304

Europe/Middle East

CANUSA-CPS

a division of Canusa Systems Ltd.

Unit 3, Sterling Park

Gatwick Road

Crawley, West Sussex

England RH10 9QT

Tel: +44 (1293) 541254

Fax: +44 (1293) 541777

Asia/Pacific

CANUSA-CPS

a division of .

#05-31, Blk 52, Frontier

Ubi Avenue 3

Singapore

408867

Tel: +65-6749-8918

Fax: +65-6749-8919

SHAWCOR LTD

CANUSA-CPS is registered to . ISO 9001:2008

Installation Guide

Pre-Heat the joint area to the minimum required

temperature 60C (140F) 75C (165F)

. Using a temperature measuring

device, ensure that the correct temperature is reached

on the steel and at least 50mm(2") on each side of the

tape.

HCA: HCO:

HCC: 60C (140F)

Pre-Heat Tape Installation

8

1

Storage & Safety Guidelines Product Description

2

Canusa Wrapid Tape is supplied in 15 m length

bulk rolls, in several widths to suit the project

diameter.

HCA, HCO, HCC

Primer-less, Crosslinked, Corrosion Protection Tape.

Wrapid Tape

To ensure maximum performance, store

Canusa products in a dry, ventilated area. Keep

products sealed in original cartons and avoid

exposure to direct sunlight, rain, snow, dust or

other adverse environmental elements. Avoid

prolonged storage at temperatures above 35C

or below -20C Product

installation should be done in accordance with

local health and safety regulations.

(95F) (-4F).

Equipment List

Propane tank, hose, torch & regulator

Appropriate tools for surface abrasion

Knife, roller, rags & approved solvent cleanser

Digital thermometer with suitable probe

Standard safety equipment; gloves, goggles, hard hat, etc.

3

These installation instructions are intended as a

guide for standard products. Consult your

Canusa representative for specific projects or

unique applications.

Flame Intensity & Torch Size

4

Use

flame intensity for pre-

heating and shrinking.

moderate to high Use flame

intensity for pre-heating

and shrinking.

moderate

Pipe O.D.

<450mm

(18")

Pipe O.D.

>450mm

(18")

Minimum Torch Size:

150,000 BTU/hr.

Minimum Torch Size:

300,000 BTU/hr.

S

O

L

V

E

N

T

Part No. 99060-016

Ensure that the PE coating edges are beveled to 30.

Clean exposed steel and adjacent pipe coating with a

solvent cleanser to remove the presence of oil,

grease, and other contaminants.

Surface Preparation

HCC 60C (140F)

HCA 60C (140F)

HCO 75C (165F)

5

Ensure that the pipe is dry before cleaning. Prepare

the steel joint area to a minimumof St3 /SP3. Lightly

abrade the pipe coating adjacent to the weld area to a

distance of 50mm (2") beyond each end of the area

to be taped.

6

5

0

m

m

+Tape+50m

m

Taped Area

9

Starting at least 50mm (2") onto the pipe coating,

begin wrapping the tape around the joint, ensuring a

minimum 50% spiral overlap. Ensure that the

powdered tape side is placed onto the pipe. Remove

any plastic release liners as the product is wrapped.

S

O

L

V

E

N

T

Wipe clean or air blast the steel and pipe coating to

remove foreign contaminants.

7

50mm

HCC 60C (140F)

HCA 60C (140F)

HCO 75C (165F)

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusas written instructions. Since many

installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith. Canusas liability is stated in the standard

terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a guide and is subject to change without notice. This installation

guide supersedes all previous installation guides on this product. E&OE

Printed on recycled paper. Recyclable.

www.canusacps.com

IG-A4-WT-rev012

Wrapid Tape- HCA, HCO, HCC

Using a torch, begin at the edge of the tape and heat

circumferentially around the joint, working back to

the other edge.

Warmthe tape end and press down firmly. A hold-

down tape can be used to secure the tape end.

Continue wrapping the pipe ensuring a minimum

50%overlap.

10 11

The table at left shows the typical usage for 3D and 5D bends,

assuming a line coating cutback of 150 mm (6") and

a 50 mm (2") overlap onto the pipe coating.

DN inches mm inches m feet m feet

25 1 50 2 2.8 9.3 2.8 9.3

40 1.5 50 2 4.0 13.2 4.6 15

50 2 50 2 5.2 17 6.2 20.3

80 3 50 2 8.5 28 10.6 34.7

100 4 50 2 12.3 40 14.8 48.6

125 5 75 3 11.1 36.4 13.6 44.6

150 6 75 3 14.3 46.9 18.3 60

200 8 100 4 16.3 53.4 20.8 68.2

250 10 100 4 23.1 75.8 30.6 100.4

300 12 100 4 30.4 99.8 40.9 134.2

>300 >12 150 6 see formula at right

Nominal Pipe

Diameter

Recommended

Tape Width

Length of Tape Required

3D Bend 5D Bend

M

a

t

e

r

i

a

l

U

s

a

g

e

T

a

b

l

e

Tape Usage Guide

For other sizes, the following formula can be used:

where L=length of area to be covered, and

W= of tape width (for 50% overlap)

Length of tape = x pipe diameter x L/W

14

Backfilling Guidelines

After shrinking is complete, allow the

sleeve to cool for 2 hours prior to

lowering and backfilling. To prevent

damage to the sleeve, use selected

backfill material, (no sharp stones or

large particles). Otherwise, an extruded

polyethylene mesh or other suitable

shield should be used.

Visually inspect the taped joint for the following:

Tape is in full contact with the joint and extends

50mm (2") onto the pipe coating.

Adhesive flows at the tape edges.

No cracks or holes in the tape.

13

Inspection

150mm

50mm

1

5

0

m

m

5

0

m

m

L

12

CANUSA-CPS

SHAWCOR LTD a division of .

25 Bethridge Road

Rexdale, Ontario

M9W 1M7,

Canada

Tel: +1 (416) 743-7111

Fax: +1 (416) 743-5927

Canada U.S.A./Latin America

CANUSA-CPS

SHAWCOR INC. a division of

2408 Timberloch Place

Building C-8

The Woodlands, Texas

77380, U.S.A.

Tel: +1 (281) 367-8866

Fax: +1 (281) 367-4304

Europe/Middle East

CANUSA-CPS

a division of Canusa Systems Ltd.

Unit 3, Sterling Park

Gatwick Road

Crawley, West Sussex

England RH10 9QT

Tel: +44 (1293) 541254

Fax: +44 (1293) 541777

Asia/Pacific

CANUSA-CPS

a division of .

#05-31, Blk 52, Frontier

Ubi Avenue 3

Singapore

408867

Tel: +65-6749-8918

Fax: +65-6749-8919

SHAWCOR LTD

Mainline coating repair products for corrosion protection

Water Pipelines

Repair & Rehab

Configurations

Applications

Oil & Gas

Temperature Range

Pipe Sizes

All Sizes

up to 65C (150F)

Melt Stick

Mastic Filler

Patch

CANUSA-CPS

Epoxy

Canusa-CPS is a leading manufacturer

of specialty pipeline coatings which, for

over 30 years, have been used for

sealing and corrosion protection of

pipeline joints and other substrates.

Canusa high performance products are

manufactured to the highest quality

standards and are available in a number

of configurations to accommodate your

specific project applications.

Canusas Pipeline Repair Products are

used to add corrosion protection and/or

fill voids in damaged coatings. A full line

of products provides the flexibility to

make a variety of repairs to mainline

coatings, ranging from minor coating

damage to holidays and exposed steel.

All of Canusa's Pipeline Repair Products

offer flexibility of installation, exhibit

excellent adhesion to steel and are

compatible with common pipeline

coatings. These products also remain

permanently flexible and provide

superior resistance to moisture

infiltration, resulting in a sound corrosion

protection layer.

CRP consists of an irradiated, cross-

linked polyolefin sheet coated with a

heat-activated adhesive. It is designed

specifically for sealing and protection of

damaged pipeline coatings up to

150mm x 150mm in size. The patch

can be installed quickly with no special

tools required. The installed patch

provides a barrier to moisture and

corrosion and is resistant to abrasion

and shear forces during pipeline

installation and while in-service.

The Coating Repair Patch (CRP)

Product Description

Features & Benefits

Pipeline Repair Products

Melt Sticks (MS)

Mastic Filler (MF)

Melt Sticks are heat-activated adhesives

supplied as a rod for ease of application.

They are ideal for small coating repairs

ranging from superficial damage to

holidays and cracks up to 10mm x

10mm. Melt sticks may also be used as

a filler material below Coating Repair

Patches.

Mastic Filler is used to fill larger voids

and deep crevices in damaged coatings

prior to the application of Canusa Repair

Patches.

Note: For damage greater than 150mm

x 150mm, a new sleeve is recom-

mended.

CANUSA-CPS is registered to ISO 9001:2000.

Mastic Filler

Repair Patch

Melt Stick

CAN

USA-CPS

CANUSA-CPS

Product Data Sheet Product Data Sheet

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusas written

instructions. Since many installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith.

Canusas liability is stated in the standard terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a

guide and is subject to change without notice. This installation guide supersedes all previous installation guides on this product. E&OE

Printed on recycled paper. Recyclable.

www.canusacps.com

PDS-A4-PRP-rev013

The product selection chart shown here is

intended as a guide for standard products.

Consult your Canusa representative for

specific projects or unique applications.

Pipeline Repair Products

Celsius

110

90

70

50

30

Fahrenheit

230

194

158

122

86

P

i

p

e

l

i

n

e

O

p

e

r

a

t

i

n

g

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

Pipeline Operating Temp. C (F)

Minimum Installation Temp. C (F)

Resistance to Circumferential Forces

Resistance to Soil Stress

Resistance to Axial Pipe Movement

50 (122)

75 (167)

good

good

good

CRP0

60 (140)

80 (176)

good

good

good

CRPN

A

d

h

e

s

i

v

e

B

a

c

k

i

n

g

P

a

t

c

h

Product Properties

How To Order:

Product Selection Guide

Unit Test Standard CRPO CRPN

C (F)

N/cm (psi)

MPa (psi)

%

Shore D

mg

ohm-cm

kV/mm

class C

class C

N/cm (pli)

N/cm (pli)

mm rad

%

C (F)

2

ASTM E28

DIN 30 672

ASTM D792

ASTM D638

ASTM D638

ASTM D2240

ASTM D1044

ASTM D257

ASTM D149

DIN 30 672

DIN 30 672

ASTM D1000

DIN 30 672 class C50

ASTM G8

ASTM D570

ASTM D2671-C

Softening point

Lap shear

Specific gravity

Tensile strength

Elongation

Hardness

Abrasion resistance

Volume Resistivity

Dielectric Voltage Brkdwn

Impact

Indentation

Peel to PE or Steel

Peel to PE or Steel

Cathodic Disbondment

Water Absorption

Low Temp. Flexibility

15m, 30m (50 ft, 100 ft)

N - 0.63 mm (25 mils)

65 - 0.63 mm (25 mils)

O - 1.1 mm (45 mils)

0.80 mm (32 mils)

BK-Black

150 (6) - 450 (18")

CRP-Coating Repair Patch

B-Bulk Roll

Product Designation

Configuration

Colour

Width of Roll

Length of Roll

Adhesive (thickness as supplied)

Backing (thickness as supplied)

CRPN- B 150-30 BK

Canusa Repair Patch

B - Bulk Roll

3 mm (1/8)

50 mm (2)

Configuration

Length

MF-B 50-3-7.5

Width

Thickness

Mastic Filler

Product Designation MF - Mastic Filler

300 mm (12)

1- (hot melt)

MS - Melt Stick

10 mm (3/8)

Adhesive

Product Designation

Length

MS-1 10-300

Diameter

Melt Stick

CRP65

94 (201)

245 (350)

0.93

24 (3480)

700

48

35

10

27

pass

pass

120 (70)

86 (50)

13

0.05

-26 (-18)

17

102 (216)

40 (58)

0.93

24 (3480)

700

48

35

10

27

pass

pass

80 (46)

65 (37)

8

0.05

-14 (7)

17

124 (255)

52 (75)

0.93

24 (3480)

700

48

35

10

27

pass

pass

115 (66)

90 (51)

17

0.05

-15 (5)

17

CRP65

65 (150)

90 (195)

excellent

excellent

excellent

3.0 m (10)

15 m (50)

7.5 m (25)

CANUSA-CPS

SHAWCOR LTD a division of .

25 Bethridge Road

Rexdale, Ontario

M9W 1M7,

Canada

Tel: +1 (416) 743-7111

Fax: +1 (416) 743-5927

Canada U.S.A./Latin America

CANUSA-CPS

SHAWCOR INC. a division of

2408 Timberloch Place

Building C-8

The Woodlands, Texas

77380, U.S.A.

Tel: +1 (281) 367-8866

Fax: +1 (281) 367-4304

Europe/Middle East Asia/Pacific

CANUSA-CPS

a division of Canusa Systems Ltd.

Unit 3, Sterling Park

Gatwick Road

Crawley, West Sussex

England RH10 9QT

Tel: +44 (1293) 541254

Fax: +44 (1293) 541777

CANUSA-CPS

BrederoShaw (S) Pte Ltd

101 Thomson Road

#17-01/02, United Square

Singapore

307591

Tel +65-6732-2355

Fax +65-6732-9073

ADDITIONAL MATERIALS & ITEMS TO BE PROVIDED

BY THE CONTRACTOR

1. Dry storage facilities for all materials supplied by

Canusa-CPS following manufacturers guidelines.

2. All equipment and items related to surface

preparation (including consumables).

3. Propane fuel supply requirements.

4. Sleeve installation equipment (propane torches,

digital thermometers, rollers, etc.).

5. Disposal of empty cartons and associated waste.

6. Security and assistance with visas/work permits for

specified Canusa-CPS personnel supplied for

Training Services. All related costs associated with

the visit of Canusa technician to be covered by

contractor.

7. Holiday detection voltage equipment.

8. Standard safety equipment, including safety gloves,

glasses, boots and hard hats

www.canusacps.com

Canada

U.S.A./Latin America

Europe/Middle East

Asia/Pacific

CANUSA-CPS

Bredero Shaw (S) Pte Ltd#

05-31, Blk 52, Frontier

Ubi Avenue 3

Singapore

408867

Tel: +65-6749-8918

Fax: +65-6749-8919

CANUSA-CPS

SHAWCOR LTD a division of .

25 Bethridge Road

Toronto, Ontario

M9W 1M7,

Canada

Tel: +1 (416) 743-7111

Fax: +1 (416) 743-5927

CANUSA-CPS

SHAWCOR INC. a division of

2408 Timberloch Place

Building C-8

The Woodlands, Texas

77380, U.S.A.

Tel: +1 (281) 367-8866

Fax: +1 (281) 367-4304

CANUSA-CPS

a division of Canusa Systems Ltd.

Unit 3, Sterling Park

Gatwick Road

Crawley, West Sussex

England RH10 9QT

Tel: +44 (1293) 541254

Fax: +44 (1293) 541777

Anda mungkin juga menyukai

- Canusa Wrap Benzi Termocontractibile Izolatii Conducte OtelDokumen2 halamanCanusa Wrap Benzi Termocontractibile Izolatii Conducte Oteleugen_alexutzBelum ada peringkat

- Heatshrinkable Sheets: Manufacturer Statement & Product Data SheetsDokumen15 halamanHeatshrinkable Sheets: Manufacturer Statement & Product Data SheetsariyamanjulaBelum ada peringkat

- Wrapid Sleeve PDSDokumen2 halamanWrapid Sleeve PDSjayhuacat7743Belum ada peringkat

- Pds Na Gts65hpDokumen2 halamanPds Na Gts65hpRahadianLabigaAmidarmoBelum ada peringkat

- Polyken YGIII Coating SystemDokumen2 halamanPolyken YGIII Coating SystemKyaw Kyaw AungBelum ada peringkat

- Polyken 934 TapeDokumen2 halamanPolyken 934 TapeKyaw Kyaw AungBelum ada peringkat

- WPCT Heat Shrink SleevesDokumen4 halamanWPCT Heat Shrink SleevesHamzaHashimBelum ada peringkat

- PDS Na GTS80 PDFDokumen2 halamanPDS Na GTS80 PDFAnant RubadeBelum ada peringkat

- CTRLDokumen57 halamanCTRLpbontyBelum ada peringkat

- GTS-PP-120: 3 LayerDokumen2 halamanGTS-PP-120: 3 Layershoaib1985100% (1)

- Energy Cable Accessories Epp1984 EngDokumen156 halamanEnergy Cable Accessories Epp1984 EngSathiyanathan ManiBelum ada peringkat

- Our Mission: The Coax LeaderDokumen3 halamanOur Mission: The Coax LeaderArindam BanerjeeBelum ada peringkat

- Rachem GuideDokumen156 halamanRachem GuideeliahudBelum ada peringkat

- Polyken 932 TapeDokumen2 halamanPolyken 932 TapeKyaw Kyaw AungBelum ada peringkat

- DS HLTP 60 Rev12 1107Dokumen2 halamanDS HLTP 60 Rev12 1107Luisito Aguilar RojasBelum ada peringkat

- Polyken 905 TapeDokumen2 halamanPolyken 905 TapeKyaw Kyaw AungBelum ada peringkat

- Polyken 4000 PrimerlessDokumen2 halamanPolyken 4000 PrimerlessKyaw Kyaw AungBelum ada peringkat

- DENSO 50 Heat Shrink Sleeve (DENSO 50HSS)Dokumen3 halamanDENSO 50 Heat Shrink Sleeve (DENSO 50HSS)jay2kay5793Belum ada peringkat

- Ficha Tecnica Cinta de Juntas 930-35-50Dokumen3 halamanFicha Tecnica Cinta de Juntas 930-35-50Carlos TarquinoBelum ada peringkat

- Catálogo Tecno Plastic - Material IS PDFDokumen98 halamanCatálogo Tecno Plastic - Material IS PDFsalpica0174770% (1)

- Termination KitDokumen18 halamanTermination KitJan Glen MenesesBelum ada peringkat

- VSL Threadbar SystemsDokumen16 halamanVSL Threadbar SystemsNguyen Chau LanBelum ada peringkat

- Circular Duct Attenuators: Performance Data - Open TypeDokumen3 halamanCircular Duct Attenuators: Performance Data - Open TypePaul ShermanBelum ada peringkat

- Conduits PDFDokumen12 halamanConduits PDFAnonymous PYEzEEVzBelum ada peringkat

- KE Masterflex RubberDokumen4 halamanKE Masterflex RubberBenjamin StricklandBelum ada peringkat

- Cat-CMP Cable GlandDokumen64 halamanCat-CMP Cable GlandSyahirul Alim100% (1)

- Klamflexproduct BrochureDokumen24 halamanKlamflexproduct BrochureblindjaxxBelum ada peringkat

- Waterstop PVC BalbeckDokumen7 halamanWaterstop PVC BalbeckLuis Carlos EsquivelBelum ada peringkat

- AccessoriesDokumen56 halamanAccessoriesKUNALJAYBelum ada peringkat

- ETL Pressure Relief Valves Datasheet PDFDokumen6 halamanETL Pressure Relief Valves Datasheet PDFNanasaheb PatilBelum ada peringkat

- Cleat WiringDokumen8 halamanCleat WiringHaseeb NawazBelum ada peringkat

- Enduro FRP Cable Management Systems Catalog 05-11Dokumen44 halamanEnduro FRP Cable Management Systems Catalog 05-11xaaabbb_550464353Belum ada peringkat

- PDS A4 DDXDokumen2 halamanPDS A4 DDXRahadianLabigaAmidarmo100% (1)

- Marine-Offshore Cable & Pipe Penetration DossierDokumen39 halamanMarine-Offshore Cable & Pipe Penetration DossierHonka VoxBelum ada peringkat

- Cho ThermDokumen4 halamanCho ThermGanesan SBelum ada peringkat

- Silencers CatalogDokumen14 halamanSilencers CatalogpalindapcBelum ada peringkat

- WPC120 PDFDokumen2 halamanWPC120 PDFHamzaHashimBelum ada peringkat

- Hastelloy C-276 WeldingDokumen4 halamanHastelloy C-276 WeldingClaudia MmsBelum ada peringkat

- Conasorb V Data SheetDokumen1 halamanConasorb V Data SheetAhmed AzadBelum ada peringkat

- TOLCO Pipe HangersDokumen26 halamanTOLCO Pipe HangersPaulo VeríssimoBelum ada peringkat

- Mangas PDFDokumen14 halamanMangas PDFluisfer811Belum ada peringkat

- Drawing 80H30Dokumen3 halamanDrawing 80H30kpranjal15Belum ada peringkat

- Global Transmission Sleeve: Product Data SheetDokumen2 halamanGlobal Transmission Sleeve: Product Data SheetgoumrisalimaBelum ada peringkat

- P8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Dokumen4 halamanP8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Shruti SrinivasBelum ada peringkat

- Covalence WPC100M Shrink Sleeves PDFDokumen2 halamanCovalence WPC100M Shrink Sleeves PDFJMROMANTBelum ada peringkat

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDokumen3 halamanFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- Omron Industrial Automation: G9Sa Safety Relay UnitsDokumen90 halamanOmron Industrial Automation: G9Sa Safety Relay UnitsDenyBelum ada peringkat

- Moeller Sasy 60iDokumen50 halamanMoeller Sasy 60iOscar TorresBelum ada peringkat

- 5.+cable TiesDokumen32 halaman5.+cable TiesalimalihiBelum ada peringkat

- I - Rectangular Ducts: II - Rectangular Ducts WeldedDokumen32 halamanI - Rectangular Ducts: II - Rectangular Ducts WeldedRoy Anthone Layson100% (11)

- MCTDokumen8 halamanMCTTimothy LeonardBelum ada peringkat

- FNW CommoditiesPVFSpecSalesSheetDokumen28 halamanFNW CommoditiesPVFSpecSalesSheetVishalBelum ada peringkat

- Astral Wire Guard PipesDokumen12 halamanAstral Wire Guard PipesJoanna BaileyBelum ada peringkat

- VSL Thread Bar Systems BrochureDokumen16 halamanVSL Thread Bar Systems BrochureFida GBelum ada peringkat

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDari EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerPenilaian: 5 dari 5 bintang5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Geotextiles and Geomembranes HandbookDari EverandGeotextiles and Geomembranes HandbookT.S. IngoldPenilaian: 5 dari 5 bintang5/5 (1)

- District Heating Manual For LondonDokumen83 halamanDistrict Heating Manual For LondonAndres CortezBelum ada peringkat

- Mantencion de Chimeneas PDFDokumen33 halamanMantencion de Chimeneas PDFAndres CortezBelum ada peringkat

- Heat Tracing PDS PJ314 SRM EDokumen6 halamanHeat Tracing PDS PJ314 SRM EAndres CortezBelum ada peringkat

- Vel Api603 99 Web PDFDokumen10 halamanVel Api603 99 Web PDFAndres CortezBelum ada peringkat

- Valvulas Velan bv6d Web PDFDokumen36 halamanValvulas Velan bv6d Web PDFAndres CortezBelum ada peringkat

- 6169-2 Foam Jargonbuster PDFDokumen8 halaman6169-2 Foam Jargonbuster PDFAndres CortezBelum ada peringkat

- The 523V Catalog PageDokumen1 halamanThe 523V Catalog PageAndres CortezBelum ada peringkat

- 339-0009-000S MRoyAB SpanishDokumen32 halaman339-0009-000S MRoyAB SpanishAndres CortezBelum ada peringkat

- AE Notification 2015 NPDCLDokumen24 halamanAE Notification 2015 NPDCLSuresh DoosaBelum ada peringkat

- Dating Apps MDokumen2 halamanDating Apps Mtuanhmt040604Belum ada peringkat

- Alchemy of The HeartDokumen7 halamanAlchemy of The HeartAbdul RahimBelum ada peringkat

- 2Dokumen8 halaman2Eduardo Antonio Comaru Gouveia75% (4)

- Img 20150510 0001Dokumen2 halamanImg 20150510 0001api-284663984Belum ada peringkat

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDokumen6 halamanThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Hare and Hyena: Mutugi KamundiDokumen18 halamanHare and Hyena: Mutugi KamundiAndresileBelum ada peringkat

- Case Study - Suprema CarsDokumen5 halamanCase Study - Suprema CarsALFONSO PATRICIO GUERRA CARVAJALBelum ada peringkat

- PlateNo 1Dokumen7 halamanPlateNo 1Franz Anfernee Felipe GenerosoBelum ada peringkat

- Inspección, Pruebas, Y Mantenimiento de Gabinetes de Ataque Rápido E HidrantesDokumen3 halamanInspección, Pruebas, Y Mantenimiento de Gabinetes de Ataque Rápido E HidrantesVICTOR RALPH FLORES GUILLENBelum ada peringkat

- Shri Naina Devi Aarti English 167Dokumen5 halamanShri Naina Devi Aarti English 167ratt182Belum ada peringkat

- Toh736 - 84000 The Dharani of Parnasavari PDFDokumen24 halamanToh736 - 84000 The Dharani of Parnasavari PDFJames LeeBelum ada peringkat

- 444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16Dokumen1 halaman444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16whatisBelum ada peringkat

- Genil v. Rivera DigestDokumen3 halamanGenil v. Rivera DigestCharmila SiplonBelum ada peringkat

- I. Learning Objectives / Learning Outcomes: Esson LANDokumen3 halamanI. Learning Objectives / Learning Outcomes: Esson LANWilliams M. Gamarra ArateaBelum ada peringkat

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDokumen3 halamanTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louBelum ada peringkat

- Safety Data Sheet SDS For CB-G PG Precision Grout and CB-G MG Multipurpose Grout Documentation ASSET DOC APPROVAL 0536Dokumen4 halamanSafety Data Sheet SDS For CB-G PG Precision Grout and CB-G MG Multipurpose Grout Documentation ASSET DOC APPROVAL 0536BanyuBelum ada peringkat

- Toolbox TalkDokumen14 halamanToolbox Talkcall_mustafas2361Belum ada peringkat

- SCERT Kerala State Syllabus 9th Standard English Textbooks Part 1-1Dokumen104 halamanSCERT Kerala State Syllabus 9th Standard English Textbooks Part 1-1Athulya ThondangattilBelum ada peringkat

- Ch-10 Human Eye Notes FinalDokumen27 halamanCh-10 Human Eye Notes Finalkilemas494Belum ada peringkat

- Magic Bullet Theory - PPTDokumen5 halamanMagic Bullet Theory - PPTThe Bengal ChariotBelum ada peringkat

- Pubb-0589-L-Rock-mass Hydrojacking Risk Related To Pressurized Water TunnelsDokumen10 halamanPubb-0589-L-Rock-mass Hydrojacking Risk Related To Pressurized Water Tunnelsinge ocBelum ada peringkat

- SafetyRelay CR30Dokumen3 halamanSafetyRelay CR30Luis GuardiaBelum ada peringkat

- De Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020Dokumen11 halamanDe Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020HiềnBelum ada peringkat

- How Chargers WorkDokumen21 halamanHow Chargers WorkMuhammad Irfan RiazBelum ada peringkat

- ..Product CatalogueDokumen56 halaman..Product Catalogue950 911Belum ada peringkat

- Ej. 1 Fin CorpDokumen3 halamanEj. 1 Fin CorpChantal AvilesBelum ada peringkat

- View All Callouts: Function Isolation ToolsDokumen29 halamanView All Callouts: Function Isolation Toolsمهدي شقرونBelum ada peringkat

- A Comparative Study of Public Private Life Insurance Companies in IndiaDokumen5 halamanA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalBelum ada peringkat

- Modular Q1 WK3-4Dokumen3 halamanModular Q1 WK3-4JENIFFER DE LEONBelum ada peringkat