QB PSC Unit-I

Diunggah oleh

Manigandan Priya0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

35 tayangan4 halamanhi

Judul Asli

QB PSC UNIT-I

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inihi

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

35 tayangan4 halamanQB PSC Unit-I

Diunggah oleh

Manigandan Priyahi

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

Unit I Introduction Theory & behaviour Two marks

1. Explain the term Prestressed Concrete

Prestressed concrete is basically a concrete in which internal stresses of suitable magnitude and

distribution are introduced so that the stresses resulting from external loads are counteracted to a desired

degree.

2. How the prestressing is imparted into R.C. Structures?

In R.C. Structural members, the prestressing is commonly introduced by tensioning the steel

reinforcement.

3. Explain the principle of prestressing?

The principle of prestressing is that when the system is expected to have tensile stresses due to external

loads, a pre-compression can be given to the system to a desired level even before the application of the

external loads. Then the tension developed due to the external loads will get largely nullified by the

initially applied compression.

Examples (i) force fitting of metal bands on wooden barrels. (ii) pre-tensioning the spokes in a bicycle

wheel.

4. Classify the prestressed concrete structures?

Prestressed concrete structures are broadly classified into two types. They are as follows

(i) Pretensioned prestressed concrete

(ii) Post tensioned prestressed concrete

5. Explain pretensioning and post tensioning in prestressed concrete?

(i)Pretensioned prestressed concrete

Pretensioned is a method of prestressing a concrete in which the tendons are tensioned before the concrete

is placed. In this method, the prestress is imparted to concrete by bond between the steel and concrete

(ii)Post tensioned prestressed concrete

Post tensioned is a method of prestressing concrete by tensioning the tendons against hardened concrete.

In this method prestress is imparted to concrete by bearing action.

6. Define anchorage zone

Anchorage zone is defined as the zone within which the force gets uniformly distributed on to the

structural element.

7. What are Tendons in prestressed concrete?

Tendons are the stretched element used in a concrete member of structure to impart prestress to the

concrete. Generally, high tensile steel wires, bars or strands are used as tendons.

Unit I Introduction Theory & behaviour Two marks

8. What is meant by Anchorage? What are the different types of anchorages used?

Anchorage is a device generally used to enable the tendon to impart and maintain prestress in the

concrete. The commonly used anchorages are

(i)Freyssinet, (ii)Magnel Blaton,(iii)Gifford-Udall,(iv)LeeMcCall,(v)Leonhardt-Baur,(vi) Dywidag,

(vii)Roebling (viii) BBRV systems

9. What is the need for High strength steel and concrete in prestressed concrete?

The early attempts to use mild steel in prestressed concrete were not successful as a working stress

of 120 N/mm

2

in mild steel is more or less completely lost due to elastic deformation, creep and

shrinkage of concrete.

The normal loss of stress in steel is generally about 100 to 240 N/mm

2

, if this loss is to be small

portion of the initial stress, the stress in the initial stages must be very high, about 1200 to 2000

N/mm

2

. These high stress ranges are possible only with the use of high strength steel.

High strength concrete is less liable to shrinkage cracks, and has a higher modulus of elasticity and

smaller ultimate creep strain, resulting in a smaller loss of prestress in steel.

The use of High strength concrete results in the reduction in the cross sectional dimensions of

prestressed concrete structural elements.

With a reduced dead weight of the material, long span becomes technically as well as economically

practicable.

10. What are the materials required for prestressing concrete?

The main materials required are as follows

High strength concrete

High strength steel

11. What is creep and shrinkage of concrete?

The creep in concrete is the progressive increase in the inelastic deformation of concrete under sustained

stress component. Shrinkage of concrete is the contraction of concrete on drying.

12. What are the different stages of loading?

The stages of loading are as follows

Initial loading (i) during tensioning of steel (ii) at transfer of prestress to concrete

Intermediate loading it includes the loads during transportation of the prestressed members

Final loading (i) at service during operation (ii) at ultimate during extreme conditions

Unit I Introduction Theory & behaviour Two marks

13. List the Advantages of prestressing

(i) The section remains uncracked under service loads

Reduction of steel corrosion which increases durability.

Full section is utilized as high stiffness and less deformations

Increase in shear capacity and improved resilience under dynamic and fatigue loading

Suitable for liquid retaining structures and pressure vessels

(ii) High span to depth ratios

Larger spans are possible with prestressing (buildings with large column free spaces)

Reduction in self-weight results in slender section

More aesthetic and more economical sections

(iii) Suitable for precast construction

Rapid construction.

Better quality control

Reduced maintenance

Suitable for repetitive construction

Reduction of formwork

Availability of standard shapes

14. What are the Limitations of prestressing?

Prestressing requires skilled technology hence it is not common as reinforced concrete

The use of high strength materials is costly

There is additional cost in auxiliary equipments

There is need for quality control and inspection

15. What are the types of prestressing?

(i) Source of prestressing force a)hydraulic prestressing b)mechanical prestressing c) electrical

prestressing d) chemical prestressing

(ii) External or internal prestressing

(iii) Pretensioning or post tensioning

(iv) Linear prestressing or circular prestressing

(v) Full, limited or partial prestressing

(vi) Uniaxial, biaxial or multi axial prestressing

(vii) Concentric or eccentric prestressing

Unit I Introduction Theory & behaviour Two marks

16. Compare reinforced concrete and prestressed concrete

In reinforced concrete, concrete and steel are combined such that concrete resists compression and steel

resists tension. This is a passive combination of the two materials

In prestressed concrete, high strength concrete and high strength steel are combined such that the full

section is effective in resisting tension and compression. This is a active combination of the two materials.

17. Define creep co-efficient

Creep co-efficient is defined as the ratio of the ultimate creep strain to the elastic strain.

Creep co-efficient values Age in days

2.2 7

1.6 28

1.1 360(one year)

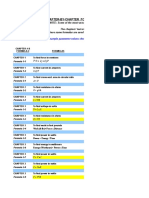

18. List the losses of prestress

S.No Pretensioning Post tensioning

1

Elastic deformation of

concrete

No such losses if simultaneously stressed the wires but if successively tensioned

there will be a loss of prestress due to elastic deformation of concrete

2

Relaxation of stress in

steel

Relaxation of stress in steel

3 Shrinkage of concrete Shrinkage of concrete

4 Creep of concrete Creep of concrete

5 Friction

6 Achorage slip

Anda mungkin juga menyukai

- Detailing of Reinforcement in Concrete Structures-17Dokumen328 halamanDetailing of Reinforcement in Concrete Structures-17Ahmed Refaey76% (17)

- Control and On-Off Valves GuideDokumen87 halamanControl and On-Off Valves Guidebaishakhi_b90100% (3)

- Strength Through Wizardry: Prestressing TechniqueDokumen6 halamanStrength Through Wizardry: Prestressing TechniqueMayankMehrotraBelum ada peringkat

- Aluminium GMAW GuideDokumen32 halamanAluminium GMAW GuideDaniel Salinas100% (2)

- PDFDokumen268 halamanPDFFaisal Nasim0% (1)

- Introduction to Prestressed Concrete Design and MaterialsDokumen10 halamanIntroduction to Prestressed Concrete Design and MaterialsSasi HoneyBelum ada peringkat

- HTML Project RestaurantDokumen8 halamanHTML Project RestaurantSandeep Chowdary0% (1)

- PSC Lecture NotesDokumen32 halamanPSC Lecture NotesHaider Shah100% (1)

- Battery Testing and MaintenanceDokumen23 halamanBattery Testing and MaintenanceMormor Omerta0% (1)

- 4th Semester RCC Notes 170745Dokumen32 halaman4th Semester RCC Notes 170745Santosh67% (3)

- 02.prestressed Concrete PresentationDokumen15 halaman02.prestressed Concrete PresentationAR1941MUBBASHIRA LAKDAWALABelum ada peringkat

- Provide A Brief History of Prestressed ConcreteDokumen8 halamanProvide A Brief History of Prestressed Concretehasif21100% (1)

- Pre StressingDokumen5 halamanPre StressingAakriti VermaBelum ada peringkat

- Elastic, Plastic and Yield Design of Reinforced StructuresDari EverandElastic, Plastic and Yield Design of Reinforced StructuresBelum ada peringkat

- 4 - Prestressed ConcreteDokumen12 halaman4 - Prestressed ConcreteIsaac Jeb100% (1)

- Post Tension IngDokumen25 halamanPost Tension IngakhilbmittalBelum ada peringkat

- Prestress Lecture NotesfsfsfsDokumen153 halamanPrestress Lecture NotesfsfsfsAlzhammer ManupacBelum ada peringkat

- Volume 1 Drafting Design and Presentation StandardsDokumen328 halamanVolume 1 Drafting Design and Presentation StandardsAntonio Herrera PérezBelum ada peringkat

- Design of Composite BridgeDokumen10 halamanDesign of Composite BridgeHarold Jackson MtyanaBelum ada peringkat

- Materials and Jacketing TechniqueDokumen5 halamanMaterials and Jacketing TechniqueHoussam Al MoussawiBelum ada peringkat

- Saudi Arabia Power StationDokumen108 halamanSaudi Arabia Power StationEhab HarbBelum ada peringkat

- MCQ in Services MarketingDokumen83 halamanMCQ in Services Marketingbatuerem0% (1)

- Primary Mathematics Book 5Dokumen87 halamanPrimary Mathematics Book 5joseph kunikina0% (1)

- Nabor, Jeanfred G. BSCE-5,151578 Pre-Test Examination: Elective Ii: Module-1 PCDDokumen3 halamanNabor, Jeanfred G. BSCE-5,151578 Pre-Test Examination: Elective Ii: Module-1 PCDPalabyo NaborBelum ada peringkat

- Husana, Thessaly Aubrey S. - Bt115 - Research No. 2aDokumen19 halamanHusana, Thessaly Aubrey S. - Bt115 - Research No. 2aThessaly HusanaBelum ada peringkat

- Construction TechDokumen13 halamanConstruction Techengsam777Belum ada peringkat

- Figure-Prestressing of Concrete Beams by Mild Steel RodsDokumen4 halamanFigure-Prestressing of Concrete Beams by Mild Steel RodsJaneeshVargheseBelum ada peringkat

- Principles of Reinforced and Prestressed Concrete: Module inDokumen46 halamanPrinciples of Reinforced and Prestressed Concrete: Module inHatsuieeBelum ada peringkat

- V2 I20 10Dokumen7 halamanV2 I20 10Anu PathakBelum ada peringkat

- Rohit. S. DasariDokumen9 halamanRohit. S. DasarirohitBelum ada peringkat

- Prestresed Concrete Post Tensioning PDFDokumen27 halamanPrestresed Concrete Post Tensioning PDFSathya GajjalaBelum ada peringkat

- Design and Behavior of Prestressed Concrete StructuresDokumen268 halamanDesign and Behavior of Prestressed Concrete StructuresMageshBelum ada peringkat

- PSC UNIT-1Dokumen49 halamanPSC UNIT-1madhu sreeBelum ada peringkat

- Prestressed ConcreteDokumen123 halamanPrestressed ConcreteArunavBelum ada peringkat

- Prestressing Concept, Materials and Prestressing SystemDokumen95 halamanPrestressing Concept, Materials and Prestressing SystemTinzar LattBelum ada peringkat

- Design of Steel Structure: 5. Snow LoadDokumen7 halamanDesign of Steel Structure: 5. Snow Loadsuraj kumarBelum ada peringkat

- Structural Steel Design LRFD ApproachDokumen16 halamanStructural Steel Design LRFD ApproachSureshbabu NarayanasamyBelum ada peringkat

- NotesDokumen19 halamanNotesvenkatdasBelum ada peringkat

- Ce DesignDokumen6 halamanCe DesignJhona PancitoBelum ada peringkat

- Prestress BasicDokumen70 halamanPrestress Basickingsaurabh1234Belum ada peringkat

- Prestressed Concrete Design 2020Dokumen21 halamanPrestressed Concrete Design 2020Edzel RenomeronBelum ada peringkat

- Notes On Prestressed ConcreteDokumen42 halamanNotes On Prestressed ConcreteSushant DahalBelum ada peringkat

- Prestressed Concrete StructuresDokumen32 halamanPrestressed Concrete StructuresMâjñù MâjñúBelum ada peringkat

- Question & Answer - 20marks ADokumen62 halamanQuestion & Answer - 20marks AIswaryaBelum ada peringkat

- MMBC Prestressed ConcreteDokumen1 halamanMMBC Prestressed ConcreteNiveditha jBelum ada peringkat

- RCD PLATE1 IntoductionDokumen6 halamanRCD PLATE1 IntoductionEugene TongolBelum ada peringkat

- Reinforced Concrete Design Module OverviewDokumen7 halamanReinforced Concrete Design Module OverviewNiel John BaquilarBelum ada peringkat

- 1.introduction To Pre Stressed Concrete StructuresDokumen9 halaman1.introduction To Pre Stressed Concrete Structures8986103tBelum ada peringkat

- كونكريت كورس اولDokumen181 halamanكونكريت كورس اولمحمد حسن محمد حسنBelum ada peringkat

- Prestressed Concrete STRUCTURES 1) Advantages of Prestressed ConcreteDokumen2 halamanPrestressed Concrete STRUCTURES 1) Advantages of Prestressed ConcreteKannan CrBelum ada peringkat

- BT 5 Module 2Dokumen4 halamanBT 5 Module 2Sun FlowerBelum ada peringkat

- Prestressed Concrete - Lecture 1 & 2Dokumen69 halamanPrestressed Concrete - Lecture 1 & 2Banda RajeshBelum ada peringkat

- Tos Vii Unit 01 & 02dfhtgfijkDokumen20 halamanTos Vii Unit 01 & 02dfhtgfijkKanak YadavBelum ada peringkat

- Ib 39Dokumen19 halamanIb 39Rup JoshiBelum ada peringkat

- SV 1Dokumen27 halamanSV 1Syed Imaduddin ZubairBelum ada peringkat

- Enhancement Properties of Circular Column With The Help of Compression Members Increase Their DuctilityDokumen5 halamanEnhancement Properties of Circular Column With The Help of Compression Members Increase Their DuctilityEditor IJTSRDBelum ada peringkat

- Module 1 PRESTRESSED CONCRETE Basic ConceptsDokumen10 halamanModule 1 PRESTRESSED CONCRETE Basic ConceptsJay BarotBelum ada peringkat

- CIVIL INTERSHIP REPORTDokumen17 halamanCIVIL INTERSHIP REPORTEBIN JACOB ANISH CE A 16-20Belum ada peringkat

- Ce2404 Pcs NotesDokumen49 halamanCe2404 Pcs NotesChockalingamBelum ada peringkat

- Chapter 4 Pre-Stressed ConcreteDokumen23 halamanChapter 4 Pre-Stressed ConcreteDdeqz Elina Bueno IBelum ada peringkat

- Pre-Stressed Elective EngineeringDokumen7 halamanPre-Stressed Elective EngineeringJonas FernandezBelum ada peringkat

- Prestressed Concrete: 2Nd Semester 2020-2021Dokumen7 halamanPrestressed Concrete: 2Nd Semester 2020-2021Nino MontaBelum ada peringkat

- Students' Reinforced Concrete DictionaryDokumen5 halamanStudents' Reinforced Concrete DictionaryKWUPASENABelum ada peringkat

- PSC Box Girder ReportDokumen34 halamanPSC Box Girder ReportAshish GBelum ada peringkat

- 1 Prestressed ConcreteDokumen8 halaman1 Prestressed ConcreteWiy Guom0% (1)

- Reinforced Concrete Design by Professor Anthony Kwame DansoDokumen131 halamanReinforced Concrete Design by Professor Anthony Kwame DansoBadu Evans NyiayeBelum ada peringkat

- Design of Steel and Timber Structures Examples PDFDokumen78 halamanDesign of Steel and Timber Structures Examples PDFsamson100% (3)

- PCDokumen491 halamanPCVaibhav Gorad100% (2)

- 34 Ono PDFDokumen44 halaman34 Ono PDFManigandan PriyaBelum ada peringkat

- Mechanical Projects by StudentsDokumen42 halamanMechanical Projects by StudentsManigandan PriyaBelum ada peringkat

- Mechanical Projects by StudentsDokumen42 halamanMechanical Projects by StudentsManigandan PriyaBelum ada peringkat

- All Heat Transfer Lectures1Dokumen19 halamanAll Heat Transfer Lectures1Giovani Renato ZontaBelum ada peringkat

- All Heat Transfer Lectures1Dokumen19 halamanAll Heat Transfer Lectures1Giovani Renato ZontaBelum ada peringkat

- Admin Interview Questions and Answers - Robert HalfDokumen2 halamanAdmin Interview Questions and Answers - Robert HalfWaqqas AhmadBelum ada peringkat

- Shivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursDokumen4 halamanShivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursSHIVAM TAYALBelum ada peringkat

- Deutz 1013Dokumen3 halamanDeutz 1013Retno Pudji LestariBelum ada peringkat

- GPT 1-15 LineBackerDokumen4 halamanGPT 1-15 LineBackerazadeazBelum ada peringkat

- Virginia Transformer - Developments in Traction TransformersDokumen10 halamanVirginia Transformer - Developments in Traction TransformersTshepo Sharky SebeBelum ada peringkat

- 7.qad-Dpr-11 ImteDokumen4 halaman7.qad-Dpr-11 ImteDhinakaranBelum ada peringkat

- Unit4questions 100415042439 Phpapp01Dokumen4 halamanUnit4questions 100415042439 Phpapp01Mohamad HishamBelum ada peringkat

- August 2017Dokumen72 halamanAugust 2017Treatment Plant Operator MagazineBelum ada peringkat

- Types of Commercial CellDokumen4 halamanTypes of Commercial CellDaveBelum ada peringkat

- Dissertation ErsatzteilmanagementDokumen7 halamanDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- Documentation of Xabe - FFmpegDokumen11 halamanDocumentation of Xabe - FFmpegTomasz ŻmudaBelum ada peringkat

- Digital Logic and Microprocessor Design With Interfacing 2nd Edition Hwang Solutions ManualDokumen27 halamanDigital Logic and Microprocessor Design With Interfacing 2nd Edition Hwang Solutions Manualdacdonaldnxv1zq100% (27)

- bbk-lt2614-lt3214 Service Manual PDFDokumen42 halamanbbk-lt2614-lt3214 Service Manual PDFrj arcinasBelum ada peringkat

- The Top 200 International Design Firms - ENR - Engineering News Record - McGraw-Hill ConstructionDokumen4 halamanThe Top 200 International Design Firms - ENR - Engineering News Record - McGraw-Hill ConstructiontarekhocineBelum ada peringkat

- Saint Louis University Baguio City Principal'S Recommendation FormDokumen1 halamanSaint Louis University Baguio City Principal'S Recommendation FormnidzBelum ada peringkat

- حل جميع المعادلات الكهربائيةDokumen60 halamanحل جميع المعادلات الكهربائيةGandhi HammoudBelum ada peringkat

- Fundamentals 2014Dokumen959 halamanFundamentals 2014Angelo Vittorio VettorazziBelum ada peringkat

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFDokumen6 halamanDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- Touch Screen TechnologyDokumen18 halamanTouch Screen TechnologySmîlērBelum ada peringkat

- Introduction To Windows PDFDokumen24 halamanIntroduction To Windows PDFRaymoon Twopass DaysBelum ada peringkat

- KernelDokumen326 halamanKernelSkyezine Via Kit FoxBelum ada peringkat

- D72140GC10 46777 UsDokumen3 halamanD72140GC10 46777 UsWilliam LeeBelum ada peringkat