SAIC & SATR - Instrumentation

Diunggah oleh

Adel KlkHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SAIC & SATR - Instrumentation

Diunggah oleh

Adel KlkHak Cipta:

Format Tersedia

Storage, Handling, and Preservation

A10

The manufacturer's storage, handling and preservation instructions to be

followed.

Schedule Q,

Att, IV, Sec 5.

A9

A8

Verify that the contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier

locations as required by the inspection level assigned for the materials

and equipment identified in SAER-1972 Inspection Requirements.

Schedule Q

Attachment llI

Sec 1.2

A7

Traceability - Instrumentation materials shall be traceable from the

manufacturer and supplier through delivery, storage, fabrication,

erection, installation, repair, modification and use.

Schedule "Q"

Attachment lV

Sec. 3.3

A6

QC Before Installation - Instrumentation materials shall conform to all

applicable requirements, standards, and specifications prior to release to

be used as part of the work.

Schedule "Q"

Attachment lV

Sec 7.1

A5

Free of Damage - Instrumentation materials shall be free of damage. All

Incoming material shall be visually inspected for damage and

conformance to all applicable inspection releases with Material Test

Report (MTR).

Schedule "Q"

Attachment lV

Sec 7.1

Schedule "G"

Sec. 4.1

A4

As Designed - Instrumentation materials shall be in accordance with the

Saudi Aramco-approved project-specific design drawings, diagrams,

schedules, lists, databases, and associated documents.

Schedule "G"

Sec. 4.1

A3 New and Unused - Instrumentation materials shall be new and unused.

A2

Identification - Instrumentation materials shall be identified by using tags,

stamps, color coding, stencils or labels. The location and method of

identification shall not affect the function or quality of the materials.

Schedule "Q"

Attachment lV

Sec. 3.2

A1 Review Quality Documentation for Material Receiving.

Schedule Q,

Att, IV, Sec. 3.1.

FAIL N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE PASS

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJ ECT TITLE WBS / BI / J O NUMBER CONTRACTOR / SUBCONTRACTOR

Level- Switches- Material Receiving. SAIC-J-6309 1-Oct-05 INST

PLANT NO. EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

A Document Review and Certification

C1

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags / labels

and nameplates, and shipment checked for damage, prior to acceptance

of the shipment

Schedule Q,

Att IV, Sec. 7.1.

SAES-J -300,

Sec.11.1.1

SAES-J -002,

Sec. 7

C Material Requirements

C2 Verify that all the instruments are from technically acceptable vendors

C3

Emergency Shutdown

A dedicated float or displacer type level switch shall be used whenever

analog level transmitters are not practical for the intended process.

Page 1 of 4

Internal displacement switches shall not be used for installation in

refrigerated LPG tanks or similar low temperature applications.

SAES-J -300,

Sec.11.3.2

C14

For non-corrosive service, a magnet-type actuated switch is acceptable.

Switches with packed gland connections between float and switch shall

not be used.

SAES-J -300,

Sec.11.2.1

C15

Internal displacement switches shall have a steel flange for top mounting

on vessel. Cast iron flanges shall not be used. Flange rating shall be

equal to or higher than the vessel design pressure and temperature, but

shall be minimum ASME class 150. Displacer and cable material shall

be type 316 stainless steel. However, other displacer materials may be

used if required by process conditions.

SAES-J -300,

Sec.11.3.1

C12

On-Off Control

Internal tandem type displacement switches may be used for start-stop

of pumps, open-close control of valves, initiation of high-low alarms, or

combinations of these functions.

C13

External level switches shall be supplied with steel float chambers,

having a flanged closure for internal inspection. The minimum flange

rating for the float chamber shall be ASME class 300. Float and trim

material shall be 316 stainless steel or as otherwise specified in the

instrument specification sheet. Process connections shall be minimum 1

inch NPT.

SAES-J -300,

Sec.11.2.1

SAES-J -300,

Sec.11.1.3

C11

Alarms

Secondary devices, actuated by the output of a level transmitter, may be

used for alarms.

SAES-J -300,

Sec.11.1.2

C8

For non-corrosive service, a magnet-type actuated switch is acceptable.

Switches with packed gland connections between float and switch shall

not be used.

SAES-J -300,

Sec.11.2.1

C10

C9

Internal displacement switches shall have a steel flange for top mounting

on vessel. Cast iron flanges shall not be used. Flange rating shall be

equal to or higher than the vessel design pressure and temperature, but

shall be minimum ASME class 150. Displacer and cable material shall

be type 316 stainless steel. However, other displacer materials may be

used if required by process conditions.

SAES-J -300,

Sec.11.3.1

C16

C7

External level switches shall be supplied with steel float chambers,

having a flanged closure for internal inspection. The minimum flange

rating for the float chamber shall be ASME class 300. Float and trim

material shall be 316 stainless steel or as otherwise specified in the

instrument specification sheet. Process connections shall be minimum 1

inch NPT.

SAES-J -300,

Sec.11.2.1

FAIL N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE PASS

Internal displacement switches shall not be used for installation in

refrigerated LPG tanks or similar low temperature applications.

Installation Inspection

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJ ECT TITLE WBS / BI / J O NUMBER CONTRACTOR / SUBCONTRACTOR

Level- Switches- Material Receiving. SAIC-J-6309 1-Oct-05 INST

SAES-J -300,

Sec.11.3.2

C6

On-Off Control

Internal tandem type displacement switches may be used for start-stop

of pumps, open-close control of valves, initiation of high-low alarms, or

combinations of these functions.

SAES-J -300,

Sec.11.1.3

C5

Alarms

Secondary devices, actuated by the output of a level transmitter, may be

used for alarms.

SAES-J -300,

Sec.11.1.2

Material Inspection

C4

Vendor to provide certification that the device materials, in wet sour

service, comply with the requirements of NACE MR0175.

SAES-J -300,

Sec.11.2.3

Page 2 of 4

FAIL N/A RE-INSP DATE

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE PASS

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJ ECT TITLE WBS / BI / J O NUMBER CONTRACTOR / SUBCONTRACTOR

Level- Switches- Material Receiving. SAIC-J-6309 1-Oct-05 INST

6. Attachment "A" Saudi Aramco Library Drawings, DC-950047 and DC-950048

ATTACHMENTS:

2. Schedule Q -- Quality Requirements (Pro Forma Contract), November 2003

4. SAES-J -300, Level, 30 April.2003.

3. SAES-J -002,Technically acceptable instruments, 29 Feb 2004.

5. NACE MR0175. Petroleum and Natural Gas industries materials for use in H2S containing environment in oil and gas production

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), J uly 1993

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

Work Verified

Saudi Aramco

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

f

PMT Representative

T&I Witnessed

Name, Initials and Date:

Contractor / Third-Party

QC Record Reviewed

REFERENCE DOCUMENTS:

NOTES:

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

C17

Each external float switch shall have its own individual vessel or

standpipe connections. The float or displacer chamber shall be installed

with the longitudinal axis vertical. For details of typical installations refer

to Attachment "A" Saudi Aramco Library Drawings, DC-950047 and DC-

950048

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

indicates compliance with appropriate standards or performance in a specified manner.

Technician Performing Test*

Name, Title, Department,

Company, Initials and

Date:

Work Verified T&I Witnessed QC Record Reviewed

QC Inspector PID Representative

Test Performed Successfully and Results are Acceptable:

QC Supervisor Proponent and Others

Name, Initials and Date:

Witnessed Test Work / Rework May Proceed

Name, Initials and Date:

Y =YES N =NO F =FAILED *Person Responsible for Implementation of Test and Analysis of Results

QC Record Reviewed Work Verified

Name, Sign and Date:

Quality Record Approved:

Name, Organization,

Initials and Date:

T&I Witnessed

C18

Internal displacement switches shall not be used for installation in

refrigerated LPG tanks or similar low temperature applications.

SAES-J -300,

Sec.11.3.2

SAES-J -300,

Sec.11.4.1

C19

Internal displacer switches shall be flange-mounted on top of the vessel.

A mating flange shall be provided on the vessel. Clearance shall be

provided for removal of the displacers. An internal stilling well shall be

required for applications where liquid turbulence is excessive. The inside

diameter of the stilling well shall be at least 25 mm larger than the

displacer diameter. The stilling well shall be open at the bottom end and

shall have a vent hole located above maximum level.

SAES-J -300,

Sec.11.4.2

C20

Internal displacement Level switch contacts shall be hermetically sealed

or totally encapsulated. Switch contacts shall be wired in a fail-safe, de-

energize to trip design. For example, contacts shall be closed during

normal process levels. The contacts shall open at abnormal levels, to

alarm or shutdown

SAES-J -300,

Sec.11.4.2

Page 3 of 4

SAIC-J-6309 1-Oct-05

Attachment 1 Liquid level Gauge Glasses Instrument

Piping Details Library Dwg. DB 950046

Level- Switches- Material Receiving. INST

SAUDI ARAMCO ID/PID - 4/14/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

Page 4 of 4

Anda mungkin juga menyukai

- SATR-J-6601 Rev 0 PDFDokumen4 halamanSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- SATR-J-6503 - Rev 0 PDFDokumen5 halamanSATR-J-6503 - Rev 0 PDFAdel KlkBelum ada peringkat

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Dokumen11 halamanDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiBelum ada peringkat

- Saudi Aramco Test ReportDokumen5 halamanSaudi Aramco Test Reportkarthi51289Belum ada peringkat

- Saudi Aramco Pre-Commissioning FormDokumen2 halamanSaudi Aramco Pre-Commissioning Formmahdi_gBelum ada peringkat

- KP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Dokumen3 halamanKP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Utku Can KılıçBelum ada peringkat

- ELT-01-CQ-PC-0001 Construction Inspection and Test Plan Procedure - R0Dokumen13 halamanELT-01-CQ-PC-0001 Construction Inspection and Test Plan Procedure - R0jorgekarlosprBelum ada peringkat

- SAIC & SATR - InstrumentationDokumen8 halamanSAIC & SATR - InstrumentationAdel KlkBelum ada peringkat

- Inst IndexDokumen3 halamanInst IndexblessonfrancisBelum ada peringkat

- E2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13Dokumen27 halamanE2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13rosy_vereniceBelum ada peringkat

- J 16Dokumen29 halamanJ 16Rochdi SahliBelum ada peringkat

- Cable Tray InstallationDokumen1 halamanCable Tray InstallationNaeemBelum ada peringkat

- BCD3-315-48-DS-4-001-00 Data Sheet For Fiber Optic Cable - Rev 1Dokumen7 halamanBCD3-315-48-DS-4-001-00 Data Sheet For Fiber Optic Cable - Rev 1rofingi ajiBelum ada peringkat

- Amnit in 300 Wir 1003 Ded C Junction Box Schedule AppDokumen46 halamanAmnit in 300 Wir 1003 Ded C Junction Box Schedule Appzaraki kenpachiBelum ada peringkat

- 34 Samss 118 PDFDokumen9 halaman34 Samss 118 PDFCherukunnon JubuBelum ada peringkat

- FLRE-InS-RFQ-012 RFQ For Instrument Erector Rev.1Dokumen16 halamanFLRE-InS-RFQ-012 RFQ For Instrument Erector Rev.1Sugeng Wahyudi100% (3)

- D62 - 740 - 3 - C4-Pressure Gauge General Arrangement Drawing PDFDokumen6 halamanD62 - 740 - 3 - C4-Pressure Gauge General Arrangement Drawing PDFSoumiyaBelum ada peringkat

- Itp Forabove Grade and Embedded Conduits Rev. 0Dokumen6 halamanItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- SATR-J-6505-Rev 0 PDFDokumen5 halamanSATR-J-6505-Rev 0 PDFAdel KlkBelum ada peringkat

- Valve SizeDokumen9 halamanValve Sizesajjadn9Belum ada peringkat

- Tender For Annual Maintenance Contract For Distributed Control System and Programmable Logic Control atDokumen118 halamanTender For Annual Maintenance Contract For Distributed Control System and Programmable Logic Control atrpshvjuBelum ada peringkat

- 04 Samss 002Dokumen11 halaman04 Samss 002hamedm1998100% (1)

- Sa P 033Dokumen3 halamanSa P 033Haleem Ur Rashid BangashBelum ada peringkat

- PP in Ii 001Dokumen15 halamanPP in Ii 001Dav EipBelum ada peringkat

- Loop Check and ValveDokumen1 halamanLoop Check and ValveMohd A IshakBelum ada peringkat

- National Oil Corporation: Rev Date Description Checked ApprovedDokumen37 halamanNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliBelum ada peringkat

- Saudi Arabian Oil Company: Instrument Specification Sheet Level SwitchesDokumen1 halamanSaudi Arabian Oil Company: Instrument Specification Sheet Level SwitchesDineshBelum ada peringkat

- 2-Test Pack Cover SheetDokumen1 halaman2-Test Pack Cover SheetPintu KumarBelum ada peringkat

- MRB 2100580 ADokumen330 halamanMRB 2100580 AMuthu SaravananBelum ada peringkat

- IDBC-TS-VDPID-T84596-NI0961-876 Rev 0 - PID Drawing For Nitrogen Vaporizer PKGDokumen3 halamanIDBC-TS-VDPID-T84596-NI0961-876 Rev 0 - PID Drawing For Nitrogen Vaporizer PKGAndiWSutomoBelum ada peringkat

- National Oil Corporation: Rev Date Description Checked ApprovedDokumen11 halamanNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliBelum ada peringkat

- National Oil Corporation: Rev Date Description Checked ApprovedDokumen37 halamanNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliBelum ada peringkat

- 305.icm-Ou-11.07 Programmable Logic ControllerDokumen28 halaman305.icm-Ou-11.07 Programmable Logic ControllerTpBelum ada peringkat

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDokumen11 halamanSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListEswari AnandBelum ada peringkat

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Penetrant Inspection Test Procedure B-QAC-PRO-210-39160Dokumen12 halamanAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Penetrant Inspection Test Procedure B-QAC-PRO-210-39160ZaidiBelum ada peringkat

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Dokumen25 halamanAin Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiBelum ada peringkat

- CHECK-LIST PR-03 P&ID - Fr.enDokumen6 halamanCHECK-LIST PR-03 P&ID - Fr.enYousef SalahBelum ada peringkat

- 29008.eng - Cpi.std - Qualification Requirements For Painting SystemsDokumen34 halaman29008.eng - Cpi.std - Qualification Requirements For Painting SystemsMatteo100% (1)

- Electrical Tray InstallationDokumen4 halamanElectrical Tray InstallationClinton OlivierBelum ada peringkat

- Honeywell Prover PDFDokumen12 halamanHoneywell Prover PDFMelina SbhBelum ada peringkat

- Servo Gauge TI00452G08EN06.14Dokumen41 halamanServo Gauge TI00452G08EN06.14jeduardo2325Belum ada peringkat

- Cable Connection List - Power & Control Cables-Ammonia Storage Plant # 90Dokumen18 halamanCable Connection List - Power & Control Cables-Ammonia Storage Plant # 90Sandeep GuptaBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen8 halamanSaudi Aramco Inspection Checklistnisha_khan0% (1)

- E02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaDokumen6 halamanE02-E02 Rev 3 Jun 2017 Selection of Elec Equip in Hazardous AreaSALMANBelum ada peringkat

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDokumen4 halamanSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDokumen136 halaman5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarBelum ada peringkat

- I&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Dokumen16 halamanI&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Mohd Sami UddinBelum ada peringkat

- SAIC-J - 6501 - Rev 0Dokumen7 halamanSAIC-J - 6501 - Rev 0Adel KlkBelum ada peringkat

- Work Method Statement: Installation of Site Perimeter FencingDokumen9 halamanWork Method Statement: Installation of Site Perimeter FencingStansilous Tatenda NyagomoBelum ada peringkat

- Section-V-technical Specification 20130610 103851Dokumen195 halamanSection-V-technical Specification 20130610 103851Suraj Yedla100% (1)

- 18-SAMSS-493 - Two Part Polyurethane Duct SealantDokumen5 halaman18-SAMSS-493 - Two Part Polyurethane Duct Sealantmedication abbasBelum ada peringkat

- Vendor Document / Document Front Sheet: Diesel Engine Generator Set Overall Piping & Instrumentation DiagramDokumen11 halamanVendor Document / Document Front Sheet: Diesel Engine Generator Set Overall Piping & Instrumentation Diagramshoghi wisesa100% (1)

- 175 140500Dokumen2 halaman175 140500Abu Anas M.SalaheldinBelum ada peringkat

- Electrode Test Record E6010Dokumen9 halamanElectrode Test Record E6010Veeraraghavan GuruBelum ada peringkat

- ITP InstrumentationDokumen9 halamanITP InstrumentationzhangyiliBelum ada peringkat

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Dokumen14 halamanAin Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiBelum ada peringkat

- Method of Statement For RadiationDokumen4 halamanMethod of Statement For RadiationFiras AlbaweiBelum ada peringkat

- STOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetDokumen13 halamanSTOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetAHMED AMIRABelum ada peringkat

- SAT Procedure DCI JK5 - Fire Fighting Rev. 2Dokumen14 halamanSAT Procedure DCI JK5 - Fire Fighting Rev. 2Awaludin Angga WBelum ada peringkat

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDokumen2 halamanSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkBelum ada peringkat

- Inverter-Based Resource Performance Guideline NERCDokumen97 halamanInverter-Based Resource Performance Guideline NERCSubhadeep PaladhiBelum ada peringkat

- Kelada, Buire JCGE22Dokumen7 halamanKelada, Buire JCGE22Adel KlkBelum ada peringkat

- Low Voltage Ride ThroughDokumen11 halamanLow Voltage Ride ThroughAdel KlkBelum ada peringkat

- Power Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageDokumen7 halamanPower Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageAdel KlkBelum ada peringkat

- PDS in ElectricalDokumen16 halamanPDS in ElectricalPepe Garcia EstebezBelum ada peringkat

- Inverter Topologies and Control Structure in Photovoltaic Applications: A ReviewDokumen24 halamanInverter Topologies and Control Structure in Photovoltaic Applications: A ReviewKrishna PrasathBelum ada peringkat

- INFOSTEEL - Guide To Protection of Steel Against CorrosionDokumen8 halamanINFOSTEEL - Guide To Protection of Steel Against CorrosionA87_navjBelum ada peringkat

- 400-200 KV Substation DesignDokumen62 halaman400-200 KV Substation DesignMousum91% (22)

- Headlines DL - NERC 2013 Annual Report - Final - WebDokumen31 halamanHeadlines DL - NERC 2013 Annual Report - Final - WebAdel KlkBelum ada peringkat

- Guide To Protection of Steel Against CorrosionDokumen9 halamanGuide To Protection of Steel Against CorrosionAdel KlkBelum ada peringkat

- Reactive Power and Fuel CalculationDokumen10 halamanReactive Power and Fuel CalculationAdel KlkBelum ada peringkat

- 3 4 GIZ17 XXX Presentation Clemens HoffmannDokumen20 halaman3 4 GIZ17 XXX Presentation Clemens HoffmannAdel KlkBelum ada peringkat

- Network Design Manual v7.7Dokumen194 halamanNetwork Design Manual v7.7somchak2000100% (3)

- Cooling Tower Thermal DesignDokumen106 halamanCooling Tower Thermal Designxuense100% (4)

- Reactive Energy CompensationDokumen38 halamanReactive Energy Compensationcyo3fffBelum ada peringkat

- CFB PresentationDokumen48 halamanCFB PresentationSam100% (3)

- Transmission System Performance Analysis For High-Penetration Photovoltaics PDFDokumen77 halamanTransmission System Performance Analysis For High-Penetration Photovoltaics PDFkm11kartalBelum ada peringkat

- Transmission LineDokumen2 halamanTransmission LineAdel KlkBelum ada peringkat

- Transmission LineDokumen2 halamanTransmission LineAdel KlkBelum ada peringkat

- Design of EHV SubstationDokumen66 halamanDesign of EHV SubstationMadanasekhar Tadimarri100% (1)

- Lesson Learned From Int - Wind Integration StudiesDokumen109 halamanLesson Learned From Int - Wind Integration StudiesAdel KlkBelum ada peringkat

- Grid Code China Vs Amerca5Dokumen50 halamanGrid Code China Vs Amerca5Adel KlkBelum ada peringkat

- Modeling and Control of Wind Power System PDFDokumen212 halamanModeling and Control of Wind Power System PDFAdel Klk50% (2)

- 3 Day1 - Plant Operation Modes RAF - HandoutDokumen23 halaman3 Day1 - Plant Operation Modes RAF - HandoutAdel KlkBelum ada peringkat

- 3 Fulfillment of Grid CodeDokumen21 halaman3 Fulfillment of Grid CodeAdel KlkBelum ada peringkat

- 3 2 GIZ17 XXX Presentation Sandip SharmaDokumen49 halaman3 2 GIZ17 XXX Presentation Sandip SharmaAdel KlkBelum ada peringkat

- 3 3 GIZ17 XXX Presentation J HenkelDokumen28 halaman3 3 GIZ17 XXX Presentation J HenkelAdel KlkBelum ada peringkat

- NERC Balancing and Frequency Control 040520111Dokumen53 halamanNERC Balancing and Frequency Control 040520111pongpumBelum ada peringkat

- 3 1 GIZ17 XXX Presentation Ernesto HuberDokumen36 halaman3 1 GIZ17 XXX Presentation Ernesto HuberAdel KlkBelum ada peringkat

- Blackout PreventionDokumen8 halamanBlackout PreventionAdel KlkBelum ada peringkat

- Medical Devices RegulationsDokumen59 halamanMedical Devices RegulationsPablo CzBelum ada peringkat

- Yamaha F200 Maintenance ScheduleDokumen2 halamanYamaha F200 Maintenance ScheduleGrady SandersBelum ada peringkat

- Expected MCQs CompressedDokumen31 halamanExpected MCQs CompressedAdithya kesavBelum ada peringkat

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDokumen2 halamanPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalBelum ada peringkat

- Indirect Teaching Strategy??: Name: Topic: Under SupervisionDokumen9 halamanIndirect Teaching Strategy??: Name: Topic: Under SupervisionSeham FouadBelum ada peringkat

- Cinnamon Peelers in Sri Lanka: Shifting Labour Process and Reformation of Identity Post-1977Dokumen8 halamanCinnamon Peelers in Sri Lanka: Shifting Labour Process and Reformation of Identity Post-1977Social Scientists' AssociationBelum ada peringkat

- D6a - D8a PDFDokumen168 halamanD6a - D8a PDFduongpn63% (8)

- Enumerator ResumeDokumen1 halamanEnumerator Resumesaid mohamudBelum ada peringkat

- Software Hackathon Problem StatementsDokumen2 halamanSoftware Hackathon Problem StatementsLinusNelson100% (2)

- Analysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)Dokumen11 halamanAnalysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)AJHSSR JournalBelum ada peringkat

- RWJ Corp Ch19 Dividends and Other PayoutsDokumen28 halamanRWJ Corp Ch19 Dividends and Other Payoutsmuhibbuddin noorBelum ada peringkat

- Applications of MathematicsDokumen35 halamanApplications of MathematicsRamdas Sonawane100% (1)

- QP 4Dokumen4 halamanQP 4Yusra RaoufBelum ada peringkat

- Press Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFDokumen6 halamanPress Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFJay ShahBelum ada peringkat

- Nasoya FoodsDokumen2 halamanNasoya Foodsanamta100% (1)

- 254 AssignmentDokumen3 halaman254 AssignmentSavera Mizan ShuptiBelum ada peringkat

- S 101-01 - PDF - User Interface - Computer MonitorDokumen130 halamanS 101-01 - PDF - User Interface - Computer Monitormborghesi1Belum ada peringkat

- Faculty of Business and Law Assignment Brief Mode E and R RegulationsDokumen4 halamanFaculty of Business and Law Assignment Brief Mode E and R RegulationsSyeda Sana Batool RizviBelum ada peringkat

- Labor Law 1Dokumen24 halamanLabor Law 1Naomi Cartagena100% (1)

- Perhitungan Manual Metode Correlated Naïve Bayes Classifier: December 2020Dokumen6 halamanPerhitungan Manual Metode Correlated Naïve Bayes Classifier: December 2020andreas evanBelum ada peringkat

- OOPS Notes For 3rd Sem ALL ChaptersDokumen62 halamanOOPS Notes For 3rd Sem ALL Chaptersabhishek singh83% (6)

- Pyro ShieldDokumen6 halamanPyro Shieldmunim87Belum ada peringkat

- Key Features of A Company 1. Artificial PersonDokumen19 halamanKey Features of A Company 1. Artificial PersonVijayaragavan MBelum ada peringkat

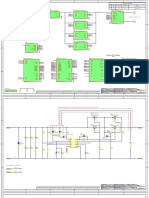

- Scheme Bidirectional DC-DC ConverterDokumen16 halamanScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaBelum ada peringkat

- COVID Immunization Record Correction RequestDokumen2 halamanCOVID Immunization Record Correction RequestNBC 10 WJARBelum ada peringkat

- Tank Emission Calculation FormDokumen12 halamanTank Emission Calculation FormOmarTraficanteDelacasitosBelum ada peringkat

- Triplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionDokumen2 halamanTriplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionMaz Ariez EkaBelum ada peringkat

- IBMC Competition Booklet 2013Dokumen40 halamanIBMC Competition Booklet 2013Rollins Center at BYUBelum ada peringkat

- Modeling and Fuzzy Logic Control of A Quadrotor UAVDokumen5 halamanModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rBelum ada peringkat

- A.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdDokumen6 halamanA.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdCharisse SarateBelum ada peringkat