6 Mandrels

Diunggah oleh

EduardoWireDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

6 Mandrels

Diunggah oleh

EduardoWireHak Cipta:

Format Tersedia

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Mandrel Catalog

Introduction:

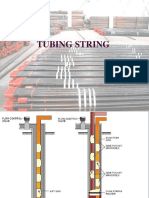

Side Pocket Mandrels:

The original side pocket mandrel was introduced in 1954, since then these mandrels

have come a long way and have suffered various design changes as well as being

adapted to different applications. Side pocket mandrels basically act as receivers for

the different valve types supplied by BINNING OIL TOOLS. These valves are held

inside a specially designed pocket the configuration of which will change depending

on the application desired.

Since 1954 to date, there is an ever increasing number of mandrel designs and

options offered, from oval mandrels to round solid bar mandrels designed for high

pressure applications. Different alloys are used in their construction being AISI4130

the standard material, but upon request 13Cr,Super 13 Cr, 9Cr and other alloy

materials or combination of materials may be supplied to ensure a long lasting and

trouble free operation in your well.

Mandrels are supplied as standard in AISI 4130 carbon steel with a As per API Spec

hardness, low heat treat mandrels may be supplied with a hardness of up to 22 HRC

to comply with NACE MR0175 specifications for stress corrosion cracking resistant

metallic materials.

Standard configuration is box-box but different configurations as well as thread types

may be supplied ranging from a 2 3/8 to 7 connections.

BINNING OIL TOOLS supplies three basic mandrel lines:

Section 1

Side Pocket Mandrels: Oval and round for use with wireline retrievable valves

Section 2

Conventional Mandrels: For use with tubing retrievable valves

Section 3

Special application mandrels: mandrels specially designed for very specific

applications.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Section 1

Side Pocket Mandrels

All side pocket mandrels are made from AISI4130 oval seamless tubing, unless

otherwise specified, and each mandrel is hydraulically tested internally to meet

rigorous specifications after a dummy valve has been run into the pocket, as per

API Specification 11V1.

The mandrels manufactured are periodically checked for external pressure as per

API Spec. 11V1.

The mandrels are always described first with the thread nomenclature (2 3/8 API

8RD or 3 New Vam, etc.), secondly, with the letter K for 1 pockets or M for 1

pockets, thirdly, with the letter G for a mandrel with an orienting sleeve and D

for the pocket discriminator. These mandrels are usually designed for highly

deviated wells. The last letter usually denotes a special usage or design feature

(E for chamber lift mandrel or W for a waterflood mandrel, etc.)

Round mandrels also have the letter R added to the description with the letters S,

F or B to describe standard (machined), forged o bored (high pressure) pockets.

A mandrel with a number 2 at the end of the description denotes a mandrel with a

reduced external diameter (and a slightly reduced pressure test) but which retains

at least the strength of a reduced coupling (or more) as recommended for API

Reduced Couplings.

Low heat-treated mandrels can be supplied for corrosive wells with H2S or CO2.

A simple K or M only denotes a standard mandrel with lateral outlet and without

an orienting sleeve, tool discriminator or special usage or design features.

Mandrels can be furnished in special alloys depending on working environment,

this will be easily identifiable on its denomination. For example: A 9 Chrome oval

seamless tubing will be denoted with in both the description an part number by

adding the sign 9CR in brackets at the end. (2 3/8K (9CR), in case of a 2 3/8 K

series mandrel.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

K Series Side Pocket Mandrel

BINNING OIL TOOLS K series side pocket mandrels are single 1 (25.4mm)

pocket mandrels. This is the basic side pocket mandrel design being rugged

and dependable and is used in thousands of completions world wide.

Mandrels are manufactured from oval seamless tubing with full integrally

forged ends (depending on mandrel size).

Applications:

Waterflood, gas lift, chemical injection and any other type of application

where side pocket mandrels are needed.

Main Features:

Manufactured from oval seamless tubing.

Forged ends for most sizes

Accomodates both top or bottom latch valves

Several tubing connection types available.

Box-box configuration as standard but may be supplied as Box-Pin

KW Type mandrel: Same as the K mandrel but specially designed for waterflood

or erosive environment operation, supplied with a case hardened 1 pocket.

KLW Type mandrel: This is a specially designed mandrel ti be used in waterflood

applications with 1 waterflood regulators. These mandrels are slightly longer

than standard K mandrels and are designed to accommodate the 1 valves

extra length and allow for the use of standard wire-line tools.

K-2 Type Mandrel: Same features as the K mandrels but with a reduced OD and

a reduced test pressure. Design has been oriented to maintaining the standard

drift while reducing the maximum OD.

KLT Type Mandrel: A full bore mandrel with a 1 pocket connected to an auxiliary

1 or 1 slip joint for use with a 1 or 1 parallel gas injection line to the

surface.

These gas lift installations are required when the well casing is in bad condition,

pre slotted casing has been run, long perf intervals want to be produced and

running a packer may be impractical or for spotting chemicals through a chemical

injector valve, etc.

NOTE: An expansion joint (slip-joint) is needed for each mandrel to connect the

auxiliary gas injection line.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

KE Type Mandrel : A K series mandrel specially designed for chamber lift

applications. The pocket in this mandrel series is equipped with a bottom exit

threaded port where the packer by pass is threaded onto.

Communication to the tubing through the pocket allows for high pressure gas

injected down the tubing to pass through the gas lift valve and into the

chamber.

Engineering Specifications:

Tubing

Size

Des-

cription

Part N Max

O.D.

Min

I.D.

Drift

I.D.

Test Pressure

Standard Service Corrosive Service

Internal External Internal External

2 3/8 K

K-2

KE

KE-2

KW

KLW

KLT

KLT-2

20-K-101

20-K-111

20-K-104

20-K-105

20-K-107

20-K-108

20-K-106

20-K-116

4.25

4.133

4.25

4.133

4.25

4.25

4.750

4.625

1.995

1.995

1.995

1.995

1.995

1.995

1.995

1.995

1.901

1.901

1.901

1.901

1.901

1.901

1.901

1.901

7500psi 6000psi 6000psi 5000psi

2 7/8 K

K-2

KE

KE-2

KW

KLW

KLT

KLT-2

25-K-121

25-K-131

25-K-124

25-K-125

25-K-127

25-K-128

25-K-126

25-K-136

4.710

4.626

4.710

4.626

4.710

4.710

5.126

5.055

2.441

2.441

2.441

2.441

2.441

2.441

2.441

2.441

2.347

2.347

2.347

2.347

2.347

2.347

2.347

2.347

3 K

K-2

30-K-148

30-K-141

5.500

5.343

2.992

2.992

2.867

2.867

Note: Test pressures may vary depending on connection type or alloy.

Standard service is understood as AISI4130 low carbon seamless tube heat treated to

HHT Specs.

Corrosive service is understood as AISI4130 low carbon seamless tube heat treated to

22 HRC under NACE MR0175 specifications for stress corrosion cracking resistant

materials.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

KGD Series Side Pocket Mandrel

BINNING OIL TOOLS KGD are based on the K series design but

incorporate an orienting sleeve as well as a tool discriminator above the

pocket to exclude larger slickline tools and prevent them hanging up in

highly deviated wells. The orienting sleeve aids in the positive alignment of

a specially designed kickover tool.

Applications:

Waterflood, gas lift, chemical injection and any other type of

application where side pocket mandrels are needed.

Deviated or vertical wells where precise alignment of kickover tool is

desired to ease insertion and retrieval operations.

Main Features:

Manufactured from oval seamless tubing.

Forged ends for most sizes

Accomodates both top or bottom latch valves

Several tubing connection types available.

Box-box configuration as standard but may be supplied as Box-Pin

Orienting sleeve which guarantees positive alignment of slickline tools

Pocket discriminator which ensures larger tools do not hang up on

the pocket and are deviated to the well bore.

KGD-2 Type Mandrel: Same features as the KGD mandrels but with a

reduced OD and a reduced test pressure. Design has been oriented to

maintaining the standard drift while reducing the maximum OD.

KGDLT Type Mandrel: A full bore mandrel with a 1 pocket connected to an

auxiliary 1 or 1 slip joint for use with a 1 or 1 parallel gas injection line

to the surface.

These gas lift installations are required when the well casing is in bad

condition, pre slotted casing has been run, long perf intervals want to be

produced and running a packer may be impractical or for spotting chemicals

through a chemical injector valve, etc.

NOTE: An expansion joint (slip-joint) is needed for each mandrel to connect

the auxiliary gas injection line.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

KGE Type Mandrel : A K series mandrel specially designed for chamber lift

applications. The pocket in this mandrel series is equipped with a bottom exit

threaded port where the packer by pass is threaded onto. Communication to the

tubing through the pocket allows for high pressure gas injected down the tubing to

pass through the gas lift valve and into the chamber.

Engineering Specifications:

Tubing

Size

Description Part

N

Max.

O.D.

Min

I.D.

Drift

I.D.

Test Pressure

Standard Service Corrosive Service

Internal External Internal External

2 3/8 KGD

KGD-2

KGDLT-2

20-K-103

20-K-113

20-K-115

4.250

4.133

4.650

1.995

1.995

1.995

1.901

1.901

1.901

7500psi 6000psi 6000psi 5000psi

2 7/8 KGD

KGD-2

KGDLT-2

25-K-123

25-K-133

25-K-139

4.710

4.626

5.055

2.441

2.441

2.441

2.347

2.347

2.347

3 KGD

KGD-2

30-K-146

30-K-143

5.500

5.343

2.992

2.992

2.867

2.867

Note: Test pressures may vary depending on connection type or alloy.

Standard service is understood as AISI4130 low carbon seamless tube heat treated as per

API Spec.

Corrosive service is understood as AISI4130 low carbon seamless tube heat treated to 22

HRC under NACE MR0175 specifications for stress corrosion cracking resistant materials.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

M Series Side Pocket Mandrel

BINNING OIL TOOLS M series side pocket mandrels are single 1

(38.1mm) pocket mandrels. This is the basic side pocket mandrel design

being rugged and dependable an is used in thousands of completions world

wide. Mandrels are manufactured from oval seamless tubing with full

integrally forged ends (depending on mandrel size).

Applications:

Waterflood, gas lift, chemical injection and any other type of application

where side pocket mandrels are needed.

Main Features:

Manufactured from oval seamless tubing.

Forged ends for most sizes

Accomodates both top or bottom latch valves

Several tubing connection types available.

Box-box configuration as standard but may be supplied as Box-Pin

MW Type mandrel: Same as the M mandrel but specially designed for

waterflood or erosive environment operation, supplied with a case hardened

1 1/2 pocket.

M-2 Type Mandrel: Same features as the M mandrels but with a reduced OD

and a reduced test pressure. Design has been oriented to maintaining the

standard drift while reducing the maximum OD.

MLT Type Mandrel: A full bore mandrel with a 1 1/2 pocket connected to an

auxiliary 1 or 1 slip joint for use with a 1 or 1 parallel gas injection line

to the surface.

These gas lift installations are required when the well casing is in bad condition,

pre slotted casing has been run, long perf intervals want to be produced and

running a packer may be impractical or for spotting chemicals through a

chemical injector valve, etc.

NOTE: An expansion joint (slip-joint) is needed for each mandrel to connect the

auxiliary gas injection line.

ME Type Mandrel : A M series mandrel specially designed for chamber lift

applications. The pocket in this mandrel series is equipped with a bottom exit

threaded port where the packer by pass is threaded onto. Communication to

the tubing through the pocket allows for high pressure gas injected down the

tubing to pass through the gas lift valve and into the chamber.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

MKW Type Mandrel: The MKW type mandrel is a mandrel with a 1 pocket

welded in a K type vessel with a reduced bore. It is normally required by those who

need to run a 1 diameter waterflood regulator in 5 casing with 2 7/8 tubing.

The 1 pocket is case hardened at the lateral exit to withstand water erosion

better. Note: Due to reduced ID a L type kickover tools with a maximum OD

retracted of 1.850 or a K type kicover tool with flexible arms should be used in

these mandrels.

Engineering Specifications:

Tubing

Size

Descrip

tion

Part N Max.

O.D.

Min I.D. Drift

I.D.

Test Pressure

Standard Service

Corrosive Service

Internal External Internal External

2 3/8 M

M-2

ME

ME-2

MW

20-M-161

20-M-171

20-M-164

20-M-174

20-M-166

4.740

4.626

4.740

4.626

4.740

1.995

1.995

1.995

1.995

1.995

1.901

1.901

1.901

1.901

1.901

7500psi 6000psi 6000psi 5000psi

2 7/8 M

M-2

ME

MKW

MW

MKW-2

25-M-181

25-M-182

25-M-184

25-M-186

25-M-187

25-M-195

5.500

5.500

5.500

4.710

5.500

4.626

2.441

2.441

2.441

1.900

2.441

1.900

2.347

2.347

2.347

1.900

2.347

1.900

3 M

M-2

30-M-191

30-M-201

5.968

5.750

2.992

2.992

2.867

2.867

4 M

MW

45-M-458

45-M-445

7.031

7.031

3.958

3.958

3.833

3.833

Note: Test pressures may vary depending on connection type or alloy.

Standard service is understood as AISI4130 low carbon seamless tube heat treated to

As per API Spec.

Corrosive service is understood as AISI4130 low carbon seamless tube heat treated to

22 HRC under NACE MR0175 specifications for stress corrosion cracking resistant

materials.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

MGD Series Side Pocket Mandrel

BINNING OIL TOOLS MGD are based on the M series design but

incorporate an orienting sleeve as well as a tool discriminator above the

pocket to exclude larger slickline tools and prevent them hanging up in

highly deviated wells. The orienting sleeve aids in the positive alignment of

a specially designed kickover tool.

Applications:

Waterflood, gas lift, chemical injection and any other type of

application where side pocket mandrels are needed.

Deviated or vertical wells where precise alignment of kickover tool is

desired to ease insertion and retrieval operations.

Manufactured from oval seamless tubing.

Forged ends for most sizes

Several tubing connection types available.

Box-box configuration as standard but may be supplied as Box-Pin

Orienting sleeve which guarantees positive alignment of slickline tools

Pocket discriminator which ensures larger tools do not hang up on

the pocket and are deviated to the well bore.

Main Features:

MGD-2 Type Mandrel: Same features as the MGD mandrels but with a

reduced OD and a reduced test pressure. Design has been oriented to

maintaining the standard drift while reducing the maximum OD.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Engineering Specifications:

Tubing

Size

Descrip

tion

Part N Max.

O.D.

Min

I.D.

Drift

I.D.

Test Pressure

Standard Service Corrosive Service

Internal External Internal External

2 3/8 MGD

MGD-2

MGDW

20-M-163

20-M-173

20-M-168

4.740

4.626

4.740

1.995

1.995

1.995

1.901

1.901

1.901

7500psi 6000psi 6000psi 5000psi

2 7/8 MGD

MGD-2

MGDW

25-M-183

25-M-170

25-M-194

5.500

5.396

5.500

2.441

2.441

2.441

2.347

2.347

2.347

3 MGD

MGD-2

30-M-199

30-M-203

5.968

5.750

2.992

2.992

2.867

2.867

4 MGD 45-M-444 7.031 3.958 3.833

7 MGD 70-M-470 9.375 6.184 6.059

Note: Test pressures may vary depending on connection type or alloy.

Standard service is understood as AISI4130 low carbon seamless tube heat treated to

As per API Spec.

Corrosive service is understood as AISI4130 low carbon seamless tube heat treated

to 22 HRC under NACE MR0175 specifications for stress corrosion cracking resistant

materials.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

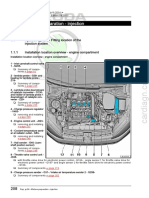

Round High Pressure Side Pocket Mandrels

BINNING OIL TOOLS R series side pocket mandrels are single pocket

high pressure mandrels. The design of these mandrels are the based on

standard side pocket mandrels design which have proven rugged and

dependable being used in thousands of completions world wide.

Applications:

High pressure gas-lift, chemical injection, waterflood and other

applications.

Round geometry ensures a high burst/collapse resistance

Solid body type mandrels

Accomodates both top or bottom latch valves (in the KR version)

Several tubing connection types available.

Box-pin configuration as standard but may be supplied as Box-box

Main Features:

KR Type mandrel: Solid body 1 side pocket mandrel. Round geometry ensure

superior burst/collapse pressures resistance.

KGDR Type mandrel:. are based on KR series design but incorporate an

orienting sleeve as well as a tool discriminator above the pocket to exclude

larger slickline tools and prevent them hanging up in highly deviated wells.

The orienting sleeve aids in the positive alignment of a specially designed

kickover tool.

MR Type Mandrel: Solid body 1 1/2 side pocket mandrel. Round geometry

ensure superior burst/collapse pressures resistance.

MGDR Type mandrel:. are based on MR series design but incorporate an

orienting sleeve as well as a tool discriminator above the pocket to exclude

larger slickline tools and prevent them hanging up in highly deviated wells.

The orienting sleeve aids in the positive alignment of a specially designed

kickover tool.

In most sizes round geometry offers a reduced OD.

Other pocket configurations are available upon request.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Engineering Specifications:

Tubing

Size

Description Part N Max.

O.D.

Min

I.D.

Drift

I.D.

Test Pressure

Standard Service Corrosive Service

Internal External Internal External

4 KGDRS

KGDRF

KGDRB

45-K-452

45-K-453

45-K-258

5.987

5.987

5.987

3.958

3.958

3.958

3.833

3.833

3.833

11000

11000

12500

10000

10000

12000

6500

6500

7500

6000

6000

6500

MGDRS

MGDRF

MGDRB

45-M-454

45-M-455

45-M-460

7.250

7.250

7.250

3.958

3.958

3.958

3.833

3.833

3.833

9500

9500

11000

9000

9000

10000

6500

6500

8500

6000

6000

7500

5 MGDRS

MGDRF

MGDRB

55-M-456

55-M-208

55-M-457

7.810

7.810

7.810

4.778

4.778

4.778

4.653

4.653

4.653

9500

9500

11000

8500

8500

10000

6500

6500

7000

6000

6000

6500

Note: Test pressures may vary depending on connection type or alloy.

Standard service is understood as AISI4130 low carbon seamless tube heat treated to As

per API Spec.

Corrosive service is understood as AISI4130 low carbon seamless tube heat treated to

22 HRC under NACE MR0175 specifications for stress corrosion cracking resistant

materials.

TYPE B TYPE F TYPE S

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Conventional Mandrels

BINNING OIL TOOLS C series conventional mandrels are specially designed

to be used with tubing retrievable valves.This is the basic side pocket mandrel

design being rugged and dependable and is used in thousands of completions

world wide. Mandrels are manufactured from one-piece seamless pup joints.

Applications:

Waterflood, gas lift, chemical injection and any other type of application

where mandrels are needed.

Manufactured from seamless one piece pup joints.

Forged ends.

Accommodate all tubing retrievable valves and check-valves

Several tubing connection types available.

Box-pin configuration as standard (coupling is used)

All mandrels fully drifted and hydro tested.

Main Features:

CO Type mandrel: Conventional tubing retrievable mandrel with connecting lug

where valve or check is threaded and a protective top lug to prevent valve damage

during running or retrieving procedures. Designed for 1, 1 and 5/8 valves.

COB Type mandrel: Similar to CO type but with the addition of two steel plates

welded parallel to valve designed to offer extra protection of installed devices.

COF Type Mandrel: Similar to the CO mandrel but the pocket is near the middle of

the mandrel and is designed for annular flow or fluid operated valves.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

COLT Type Mandrel: Design is based on the CO mandrels but this mandrel

incorporates a side pipe connected to the pocket through which gas is injected in

side pipe gas lift designs where casing or long perforated intervals prove

standard gas lift as inefficient.

Tubing Size Description Part N Max.

O.D.

Valve

dia.

Test Pressure

2 3/8 EUE CO06

CO10

CO10B

CO15

CO15B

COF10

20-CO-750

20-CO-751

20-CO-765

20-CO-752

20-CO-766

20-CO-753

3.57

3.78

3.78

4.38

4.38

4.10

5/8

1

1

1

1

1

6000psi

2 3/8 NUE CO06

CO10

CO10B

CO15

CO15B

COF10

20-CO-760

20-CO-761

20-CO-785

20-CO-762

20-CO-786

20-CO-763

3.07

3.69

3.69

4.29

4.29

4.01

5/8

1

1

1

1

1

6000psi

2 7/8EUE C010

C010B

CO15

CO15B

COF10

COF15

25-CO-770

25-CO-769

25-CO-771

25-CO-767

25-CO-772

25-CO-773

4.33

4.33

4.92

4.92

4.70

5.26

1

1

1

1

1

1

6000psi

3 EUE CO10

CO10B

CO15

CO15B

30-CO-780

30-CO-787

30-CO-781

30-CO-788

5.06

5.06

5.66

5.66

1

1

1

1

6000psi

Note: Test pressures may vary depending on connection type or alloy.

Standard service is understood as N80-L80 low carbon seamless tube heat treated as per

API Spec.

Corrosive service is understood as heat treated to 22 HRC under NACE MR0175

specifications for stress corrosion cracking resistant materials.

Engineering Specifications:

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Concave and annular mandrels

BINNING OIL TOOLS special application conventional mandrel product line offers

a wide range of designs for custom built applications such as, chamber, macaroni,

coiled tubing, slim hole or pack-off applications.

Applications:

Gas lift, chemical injection and any other type of application where

mandrels are needed where small ODs are required.

Wide range of options, sizes and configurations

Carbon steel or high alloys available.

Accommodate standard conventional valves.

Several tubing connection types available.

Special custom made designs available to adapt to your completion needs.

All mandrels fully drifted and hydro tested.

Main Features:

Concave Type Mandrel: Restricted flow mandrels used in macaroni and pack-

off type gas-lift completions. These concave mandrels with NPT screwed

connections are made to receive standard conventional valves. This mandrel

series is used in applications where tubing flow is required. Mandrel flow

restriction must be considered when selecting.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Annular Small Tubing Production Mandrel: Mandrels specially designed for

macaroni type completions where gas is injected down the inner string,

through a conventional gas lift valve and up the annulus. This is commonly

used in coiled tubing gas lift application with the appropriate connectors.

Snorkel Type Mandrel: Specially designed, restricted flow mandrel used

only as the bottom mandrel in Macaroni type Gas Lift Chamber Completions.

The NPT screwed connection are made to receive a 1 o.d. type N-10

Gas Lift Valve.

Recommended for use with a type L seating nipple.

PRODUCT CATALOG 2009

www.binning-oil-tools.com.ar

Engineering Specifications Concave and Annular Mandrels

Tubing Size Description Part N Max.

O.D.

Valve

dia.

Test

Pressure

1 EUE

1 NUE

1 EUE

1 NUE

CON10

CON10

CON10

CON10

10-CON-600

10-CON-601

12-CON-602

15-CON-603

1.900

1.660

2.200

2.200

1

1

1

1

3000psi

1 NUE

1 EUE

1 NUE

ANP10

AN10

AN10

10-AN-210

12-AN-212

15-AN-215

1.850

2.200

2.500

1

1

1

3000psi

Engineering Specifications Snorkel Mandrels

Tubing

Size

Description Part N Max.

O.D.

Valve

dia.

Test Pressure Dip Tube

1 EUE

1 NUE

1 EUE

1 NUE

1 NUE

SN10

SN10

SN10

SN10

SN10

10-SN-225

10-SN-220

12-SN-221

12-SN-222

15-SN-223

1.660

1.875

2.296

2.296

2.368

1

1

1

1

1

3000psi

1 NUE

1 NUE

1NUE

1NUE

Note: Test pressures may vary depending on connection type or alloy.

Other configurations and sizes are available upon request.

Anda mungkin juga menyukai

- CIP Handbook v1 PDFDokumen84 halamanCIP Handbook v1 PDFThiagoSilvaOliver100% (4)

- 3 - Presentation - John Crane - Fishing Fiberglass Rods in The 21st CenturyDokumen31 halaman3 - Presentation - John Crane - Fishing Fiberglass Rods in The 21st Centuryrolando100% (1)

- Welltec Corporate Presentation - PDFDokumen18 halamanWelltec Corporate Presentation - PDFzapspaz0% (1)

- Fundamentals and Applications of Bionic Drilling FluidsDari EverandFundamentals and Applications of Bionic Drilling FluidsBelum ada peringkat

- As 1228-2006 Pressure Equipment - BoilersDokumen9 halamanAs 1228-2006 Pressure Equipment - BoilersSAI Global - APAC25% (4)

- Astm - A761 A761m 04 (2009)Dokumen8 halamanAstm - A761 A761m 04 (2009)nugroho teguhBelum ada peringkat

- Appendix 2 - Onshore Pipeline Design BasisDokumen22 halamanAppendix 2 - Onshore Pipeline Design BasisUyavie Obonna83% (6)

- 02 Samss 012Dokumen9 halaman02 Samss 012slan79bisBelum ada peringkat

- Method Statement-Fit-Out WorksDokumen18 halamanMethod Statement-Fit-Out WorksВиссам АбдинBelum ada peringkat

- C 06.C Wellhead DesignDokumen6 halamanC 06.C Wellhead DesignJose David Hernandez OteroBelum ada peringkat

- PPE I PR 005Dokumen11 halamanPPE I PR 005MahanderOadBelum ada peringkat

- Fs2 Isolation Barrier ValveDokumen12 halamanFs2 Isolation Barrier Valvehamed66652Belum ada peringkat

- Wellhead Products Catalog vFEB2015 PDFDokumen20 halamanWellhead Products Catalog vFEB2015 PDFRatnakar PatilBelum ada peringkat

- Basic Understanding of Oil Well Casing and TubingDokumen21 halamanBasic Understanding of Oil Well Casing and TubingmanibabuBelum ada peringkat

- 11 SSFC PDFDokumen50 halaman11 SSFC PDFChaib MaamarBelum ada peringkat

- Winch Operators Slickline Cased Hole Analog PanelDokumen2 halamanWinch Operators Slickline Cased Hole Analog PanelHenry FuentesBelum ada peringkat

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDokumen8 halamanBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightBelum ada peringkat

- Orifice Meter & Barton RecorderDokumen46 halamanOrifice Meter & Barton RecorderNoor AliBelum ada peringkat

- Casing LeaksDokumen8 halamanCasing LeaksDavid LuhetoBelum ada peringkat

- Mandrel Hangers 01Dokumen1 halamanMandrel Hangers 01arianaseriBelum ada peringkat

- Model E Hydraulic Setting ToolDokumen1 halamanModel E Hydraulic Setting ToolrezaBelum ada peringkat

- Fill Only The Yellow Cells !: Pump Rate Pump RateDokumen3 halamanFill Only The Yellow Cells !: Pump Rate Pump RateCristian BarbuceanuBelum ada peringkat

- Well Intervention CoilHose A4Dokumen2 halamanWell Intervention CoilHose A4William EvansBelum ada peringkat

- Locating A Tubing LeakDokumen12 halamanLocating A Tubing LeakEhab MarzoqBelum ada peringkat

- Ring Type Joint Gaskets Styles: R, RX, BXDokumen2 halamanRing Type Joint Gaskets Styles: R, RX, BXiswantmachooBelum ada peringkat

- 05-0049 Rev 2 TD Tubing Head TB 3Dokumen2 halaman05-0049 Rev 2 TD Tubing Head TB 3Anonymous F2tu2TrzVtBelum ada peringkat

- OptiSleeve Sliding SleeveDokumen3 halamanOptiSleeve Sliding SleeveRichard More LeonBelum ada peringkat

- Tubing StringDokumen32 halamanTubing StringKAORU AmaneBelum ada peringkat

- Packer CupDokumen2 halamanPacker Cupmiguel mendozaBelum ada peringkat

- 4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description FeaturesDokumen1 halaman4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description Featureshamed1725Belum ada peringkat

- Wellbore Integrity Restoration Services Brochure PDFDokumen8 halamanWellbore Integrity Restoration Services Brochure PDFDavid LuhetoBelum ada peringkat

- CT D - Ploy Velocity StringDokumen2 halamanCT D - Ploy Velocity StringAlejandro MonroyBelum ada peringkat

- Weatherford CORODDokumen6 halamanWeatherford CORODclass 96Belum ada peringkat

- Basic Coiled Tubing Course Part 1Dokumen105 halamanBasic Coiled Tubing Course Part 1Es BahBelum ada peringkat

- Completion ComponentsDokumen28 halamanCompletion ComponentsnabiBelum ada peringkat

- CT Hydraulic JarsDokumen2 halamanCT Hydraulic JarsAde RiantoBelum ada peringkat

- Tubing ManDokumen30 halamanTubing ManГалинаBelum ada peringkat

- Cement Dump BailerDokumen2 halamanCement Dump BailerfelipeBelum ada peringkat

- Corrosion IntroductionDokumen95 halamanCorrosion IntroductionDavitxu1Belum ada peringkat

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDokumen6 halaman29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaBelum ada peringkat

- Completion Fluid 2Dokumen45 halamanCompletion Fluid 2Waled Fekry100% (2)

- Acid TunnelingDokumen3 halamanAcid TunnelingFisher YohannesBelum ada peringkat

- DHSV WeatherfordDokumen23 halamanDHSV WeatherfordRonald Lucas Silva Lefundes OliveiraBelum ada peringkat

- Microsoft Word - Slickline Mechanical CapibilitiesDokumen7 halamanMicrosoft Word - Slickline Mechanical CapibilitiesRangga DraApBelum ada peringkat

- TTS Catalog 2012Dokumen65 halamanTTS Catalog 2012hantaodulut100% (1)

- 1PackerSystem PackerAccessories&tools PDFDokumen21 halaman1PackerSystem PackerAccessories&tools PDFAnand aashishBelum ada peringkat

- Catalogue: Flow Control EquipmentDokumen19 halamanCatalogue: Flow Control EquipmentFranklin NavarroBelum ada peringkat

- Wireline (Rev.15.8.12)Dokumen5 halamanWireline (Rev.15.8.12)hBelum ada peringkat

- Casing Head Housings 01Dokumen1 halamanCasing Head Housings 01arianaseriBelum ada peringkat

- MSASDokumen2 halamanMSASFeby ZulkarnainBelum ada peringkat

- Powerstroke Drilling Jar: Instruction Manual 4250Dokumen24 halamanPowerstroke Drilling Jar: Instruction Manual 4250Foros IscBelum ada peringkat

- Cavins Double Action Tubing PumpDokumen2 halamanCavins Double Action Tubing PumpHassan KhalidBelum ada peringkat

- Tubing Cutter Radial Cutting TorchDokumen2 halamanTubing Cutter Radial Cutting Torcharvandi_mahryBelum ada peringkat

- Homco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealDokumen8 halamanHomco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealHamed NazariBelum ada peringkat

- Shell Wireline Downhole Tools ToolkitDokumen21 halamanShell Wireline Downhole Tools ToolkitLuqman ZamanBelum ada peringkat

- Beam Pumping System For Deep High-Volume WellsDokumen16 halamanBeam Pumping System For Deep High-Volume WellsIri PelaezBelum ada peringkat

- 4-06 Tandem Side Loading Stripper PackerDokumen14 halaman4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERBelum ada peringkat

- 3 - Arenas Curables y ActivadoresDokumen52 halaman3 - Arenas Curables y ActivadoresPablo SotoBelum ada peringkat

- Introduction To OCTG: API Steel Grades Handout 03Dokumen4 halamanIntroduction To OCTG: API Steel Grades Handout 03AHMEDBelum ada peringkat

- Trinity Plugs For Well CompletionDokumen50 halamanTrinity Plugs For Well CompletionEspion BenBelum ada peringkat

- SLK-PR-06.00 Procedure For Tubing PuncherDokumen3 halamanSLK-PR-06.00 Procedure For Tubing PuncherDonald TchiroueBelum ada peringkat

- Water Control BasicsDokumen40 halamanWater Control BasicstonyBelum ada peringkat

- Production Logging and Its Implementation: A Technical ReviewDokumen10 halamanProduction Logging and Its Implementation: A Technical ReviewghufranBelum ada peringkat

- CatalogDokumen120 halamanCatalogTaras ByloBelum ada peringkat

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsDari EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsBelum ada peringkat

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDari EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsBelum ada peringkat

- Bhel Guide: Hydro GeneratorsDokumen29 halamanBhel Guide: Hydro GeneratorsDeepen SharmaBelum ada peringkat

- 6 Great Benefits of Using Carbon Steel Pipe: In, byDokumen3 halaman6 Great Benefits of Using Carbon Steel Pipe: In, byMarnel Roy MayorBelum ada peringkat

- Concrete ManholesDokumen14 halamanConcrete ManholesnijasBelum ada peringkat

- Product Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)Dokumen7 halamanProduct Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)srmohapatra5086100% (1)

- Procurement (MEP VENDERS)Dokumen4 halamanProcurement (MEP VENDERS)Skylink Estimation TeamBelum ada peringkat

- TD-ST-MAST-100-004-EN V2.00 MAST-A MAST-V MAST-H Installation Manual-EN PDFDokumen20 halamanTD-ST-MAST-100-004-EN V2.00 MAST-A MAST-V MAST-H Installation Manual-EN PDFBam BA100% (1)

- Australia QLD Mining IECEx SIMTARS E-TYPE T3CDS TE1FUDokumen11 halamanAustralia QLD Mining IECEx SIMTARS E-TYPE T3CDS TE1FUUmar FarooqBelum ada peringkat

- 1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsDokumen6 halaman1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsHenry HoyosBelum ada peringkat

- BSI ListDokumen158 halamanBSI ListAndie AviBelum ada peringkat

- S and S Emissionssensorscatalog 2021Dokumen20 halamanS and S Emissionssensorscatalog 2021Eduardo SantanaBelum ada peringkat

- 39 Roof Panel Penetration DetailDokumen1 halaman39 Roof Panel Penetration DetailAhmed Saber NassarBelum ada peringkat

- Progress Piping GCC CaCo3Dokumen66 halamanProgress Piping GCC CaCo3Alif Rahmat FebriantoBelum ada peringkat

- 19.2 Data Sheet Soluforce RLPDokumen6 halaman19.2 Data Sheet Soluforce RLPElkin DJBelum ada peringkat

- quotation of PVC wall panel production line 1条线 2set mouldDokumen11 halamanquotation of PVC wall panel production line 1条线 2set mouldarg3112Belum ada peringkat

- Technical SpecificationDokumen15 halamanTechnical SpecificationKiesha SantosBelum ada peringkat

- Pipe Body Data: NotesDokumen1 halamanPipe Body Data: Notessica1234Belum ada peringkat

- Manhole RothengaranparseDokumen4 halamanManhole RothengaranparseImoneBoltenBelum ada peringkat

- SM SeriesDokumen36 halamanSM SeriesGiorgiana RosuBelum ada peringkat

- VMP E16 E01 V00Dokumen36 halamanVMP E16 E01 V00Marian StatacheBelum ada peringkat

- Method of Statement Cable LayingDokumen2 halamanMethod of Statement Cable LayingKo ZayBelum ada peringkat

- 30HX 5PDDokumen76 halaman30HX 5PDThành CôngBelum ada peringkat

- TunnelingDokumen54 halamanTunnelingDhila Kurokawa Chii100% (1)

- CJZC Engine InjectionDokumen32 halamanCJZC Engine InjectionDanielBelum ada peringkat

- ITEM 1.16 Blowers For Aeration TankDokumen491 halamanITEM 1.16 Blowers For Aeration TankChad HuntBelum ada peringkat