Gy2g0200d020n-Mf VP10RT

Diunggah oleh

TungstenCarbideJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gy2g0200d020n-Mf VP10RT

Diunggah oleh

TungstenCarbideHak Cipta:

Format Tersedia

1

L20.05

ar (Max.)

Re0.05

Re0.05

W

3

W3

Re L2

V

P

1

0

R

T

V

P

2

0

R

T

N

X

2

5

2

5

R

T

9

0

1

0

GY2G0200D020N-MF a a a a D 2 0.02 0.2 19.5 21.05

0224D015N-MF a a a a D 2.24 0.02 0.15 19.8 21.05

0239E020N-MF a a a a E 2.39 0.02 0.2 19.2 21.05

0250E020N-MF a a a a E 2.5 0.02 0.2 19.4 21.05

0274E020N-MF a a a a E 2.74 0.02 0.2 19.7 21.05

0300F020N-MF a a a a F 3 0.02 0.2 19.5 21.05

0300F040N-MF a a a a F 3 0.02 0.4 19.3 21.05

0318F020N-MF a a a a F 3.18 0.02 0.2 19.5 21.05

0318F040N-MF a a a a F 3.18 0.02 0.4 19.3 21.05

0324F020N-MF a a a a F 3.24 0.02 0.2 19.5 21.05

0400G020N-MF a a a a G 4 0.02 0.2 24.9 25.95

0400G040N-MF a a a a G 4 0.02 0.4 24.7 25.95

0400G080N-MF a a a a G 4 0.02 0.8 24.3 25.95

0424G020N-MF a a a a G 4.24 0.02 0.2 24.9 25.95

0475H020N-MF a a a a H 4.75 0.02 0.2 24.4 25.95

0475H040N-MF a a a a H 4.75 0.02 0.4 24.2 25.95

0475H080N-MF a a a a H 4.75 0.02 0.8 23.8 25.95

0500H020N-MF a a a a H 5 0.02 0.2 24.4 25.95

0500H040N-MF a a a a H 5 0.02 0.4 24.2 25.95

0500H080N-MF a a a a H 5 0.02 0.8 23.8 25.95

0524H020N-MF a a a a H 5.24 0.02 0.2 24.4 25.95

0600J020N-MF a a a a J 6 0.02 0.2 24.4 25.95

0600J040N-MF a a a a J 6 0.02 0.4 24.2 25.95

0600J080N-MF a a a a J 6 0.02 0.8 23.8 25.95

0631J020N-MF a a a a J 6.31 0.02 0.2 24.4 25.95

0635J020N-MF a a a a J 6.35 0.02 0.2 24.4 25.95

0635J040N-MF a a a a J 6.35 0.02 0.4 24.2 25.95

0635J080N-MF a a a a J 6.35 0.02 0.8 23.8 25.95

P

VP20RT

VP10RT

160280HB

VP20RT

VP10RT

NX2525

VP20RT

VP10RT

NX2525

M

VP20RT

VP10RT

K

VP20RT

VP10RT

VP20RT

VP10RT

S

VP20RT

VP10RT

RT9010

50 100 150 200 250 300

100

110

80

90

60

60

60

70

45

55

70

70

80

90

30

40

220

230

180

190

140

140

140

150

105

135

150

150

180

190

60

70

40 70

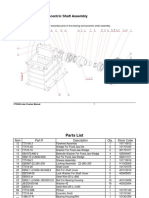

GROOVING SYSTEM

a : Inventory maintained.

Enlarged view

The sharp cutting edge is specially designed for

nish cutting and for excellent chip control. This

control prevents chips damaging the component

even during multi-functional operations. The

straight front edge ensures at bottomed

grooves.

Precision insert with MF breaker for multi-functional grooving

Efcient chip breaking

when cross-feed

machining.

Chips are controlled

when nish machining.

RECOMMENDED CUTTING SPEED (m/min)

(Note 1) VP20RT is the rst recommended grade for materials other than hardened steel.

(Note 2) For VP10RT and VP20RT, wet cutting is recommended.

Work Material Hardness Grade

Cutting Speed (m/min)

Mild Steel

(S10C, SUM22L etc)

<160HB

Carbon Steel

Alloy Steel

(SUJ2, SCr, SCM etc)

280HB<

Stainless Steel <270HB

Gray Cast Iron

Tensile Strength

<300MPa

Ductile Cast Iron

Tensile Strength

<800MPa

Heat Resistant Alloy

Titanium Alloy

Order Number

Stock

Seat

Size

Dimensions (mm)

Remarks

Coated Cermet Carbide Max.

Groove

Depth

ar

(mm)

Grooving

Width

Tolerance

Groove width corresponding to the circlip

Groove width corresponding to the circlip

Groove width corresponding to the circlip

Groove width corresponding to the circlip

Groove width corresponding to the circlip

Groove width corresponding to the circlip

2

J

H

G

F

E

D

J

H

G

F

E

D

J

H

G

F

E

D

J

H

G

F

E

D

J

H

G

F

E

D

J

H

G

F

E

D

50

40

32

25

20

3.5

3

2.5

2

1.5

1

0.5

3

2.5

2

1.5

1

0.5

3.5

3

2.5

2

1.5

1

0.5

0

0 0

0

0

0

0

0.2 0.2

0.2

0.2

0.15

0.15 0.15

0.15

0.15

0.15

0.15

0.1

0.1 0.1

0.1

0.1

0.1

0.1

0.05

0.05 0.05

0.05

0.05

0.05

0.05

0 10 20 30

0.8

0.6

0.4

0.2

0

GY2G0400G040N-MF(VP10RT)

a External Grooving

a Face Cutting off a Face Grooving

a External Turning

a Face Turning

Feed (mm/rev)

Feed (mm/rev) Feed (mm/rev)

Feed (mm/rev)

Feed (mm/rev)

S

e

a

t

S

i

z

e

S

e

a

t

S

i

z

e

S

e

a

t

S

i

z

e

R

a

d

i

a

l

D

e

p

t

h

o

f

c

u

t

(

m

m

)

R

a

d

i

a

l

D

e

p

t

h

o

f

c

u

t

(

m

m

)

: 1st recommended area

: 1st recommended area : 1st recommended area

RECOMMENDED CUTTING CONDITIONS [For External Grooving]

RECOMMENDED CUTTING CONDITIONS [For Face Grooving]

a Internal Grooving a Internal Turning

Feed (mm/rev) Feed (mm/rev)

S

h

a

n

k

D

i

a

.

(

m

m

)

R

a

d

i

a

l

D

e

p

t

h

o

f

c

u

t

(

m

m

)

: 1st recommended area

RECOMMENDED CUTTING CONDITIONS [For Internal Grooving]

CUTTING PERFORMANCE

<Cutting Condition>

Work Material : SUS304

Cutting Speed : 130m/min

Feed : 0.1mm/rev

Groove Depth : 1mm

Wet Cutting

Cutting time (min)

S

u

r

f

a

c

e

r

o

u

g

h

n

e

s

s

R

a

(

!

m

)

Comparison with conventional insert

MF breaker maintains good surface nishes.

Conventional (M-class insert with PVD coated grade)

3

B

H

1

F

1

F

2

H

2

W

3

5

0

L1

L2

D

1

45

H1 B L1 L2 H2 F1 F2

D 2.00

R

0.5 30 (3E1R3D1) GYM20LC-D005 a GYHR2020K50-M20L a 20 20 125 40 20 32 1.6

GY2M0200D100N-BM 0.5 30 (3G1R4D1) GYM25LC-D005 a GYHR2525M50-M25L a 25 25 150 45 25 35 1.6

L

0.5 30 (3E1L3D1) GYM20RC-D005 a GYHL2020K50-M20R a 20 20 125 40 20 32 1.6

0.5 30 (3G1L4D1) GYM25RC-D005 a GYHL2525M50-M25R a 25 25 150 45 25 35 1.6

E 2.50

R

0.5 30 (3E1R3E1) GYM20LC-E005 a GYHR2020K50-M20L a 20 20 125 40 20 32 1.8

GY2M0250E125N-BM 0.5 30 (3G1R4E1 GYM25LC-E005 a GYHR2525M50-M25L a 25 25 150 45 25 35 1.8

L

0.5 30 (3E1L3E1) GYM20RC-E005 a GYHL2020K50-M20R a 20 20 125 40 20 32 1.8

0.5 30 (3G1L4E1) GYM25RC-E005 a GYHL2525M50-M25R a 25 25 150 45 25 35 1.8

F

3.00

3.18

R

0.5 30 (3E1R3F1) GYM20LC-F005 a GYHR2020K50-M20L a 20 20 125 40 20 32 2.0

GY2M0300F150N-BM

GY2M0318F159N-BM

0.5 30 (3G1R4F1) GYM25LC-F005 a GYHR2525M50-M25L a 25 25 150 45 25 35 2.0

L

0.5 30 (3E1L3F1) GYM20RC-F005 a GYHL2020K50-M20R a 20 20 125 40 20 32 2.0

0.5 30 (3G1L4F1) GYM25RC-F005 a GYHL2525M50-M25R a 25 25 150 45 25 35 2.0

G 4.00

R

0.5 20 (3E1R3G1) GYM20LC-G005 a GYHR2020K50-M20L a 20 20 125 40 20 32 2.4

GY2M0400G200N-BM 0.5 20 (3G1R4G1) GYM25LC-G005 a GYHR2525M50-M25L a 25 25 150 45 25 35 2.4

L

0.5 20 (3E1L3G1) GYM20RC-G005 a GYHL2020K50-M20R a 20 20 125 40 20 32 2.4

0.5 20 (3G1L4G1) GYM25RC-G005 a GYHL2525M50-M25R a 25 25 150 45 25 35 2.4

H

4.75

5.00

R

0.5 20 (3E1R3H1) GYM20LC-H005 a GYHR2020K50-M20L a 20 20 125 40 20 33 2.8

GY2M0475H238N-BM

GY2M0500H250N-BM

0.5 20 (3G1R4H1) GYM25LC-H005 a GYHR2525M50-M25L a 25 25 150 45 25 36 2.8

L

0.5 20 (3E1L3H1) GYM20RC-H005 a GYHL2020K50-M20R a 20 20 125 40 20 33 2.8

0.5 20 (3G1L4H1) GYM25RC-H005 a GYHL2525M50-M25R a 25 25 150 45 25 36 2.8

J

6.00

6.35

R 0.5 20 (3G1R4J1) GYM25LC-J005 a GYHR2525M50-M25L a 25 25 150 44 25 36 3.4

GY2M0600J300N-BM

GY2M0635J318N-BM

L 0.5 20 (3G1L4J1) GYM25RC-J005 a GYHL2525M50-M25R a 25 25 150 44 25 36 3.4

GY2Mooooooooo-BM

GROOVING SYSTEM

EXTERNAL RECESSING

Seat

Size

Insert

Width

W3

(mm)

Hand

(

R/L

)

Max.

Groove Depth

(mm)

Min. Grooving

Diameter

D1

(mm)

ID

Order Number Dimensions (mm) Insert

Modular Blade Stock Modular Holder Stock Geometry / Insert Number

(Gauge insert)

(Gauge insert)

(Gauge insert)

(Gauge insert)

(Gauge insert)

(Gauge insert)

Insert

Right hand tool holder shown.

*

The blade for external grooving and face grooving cannot be used due to interference with the workpiece.

*

Dimensions shown are when the gauge insert is used. If other insert geometries are used then L1, L2, F1 and F2 values may vary.

*

For modular blades and modular holders, please order separately.

*

Please use left hand modular blades for right hand modular holders, and right hand modular blades for left hand modular holders.

M

a

x

.G

ro

o

v

e

D

e

p

th

0

.

5

m

m

Enlarged view

a : Inventory maintained. (10 inserts in one case)

4

L20.1

ar (Max.)

Re0.05

W

3

0 0.05 0.15 0.2 0.1 0.25

2.0

3.0

4.0

6.0

3.18

2.39

2.5

4.75

5.0

6.35

t

ap

a

p

P

VP20RT

VP10RT

180280HB

VP20RT

VP10RT

MY5015

NX2525

280350HB

VP20RT

VP10RT

MY5015

NX2525

M

VP20RT

VP10RT

K

VP20RT

VP10RT

MY5015

VP20RT

VP10RT

MY5015

S

VP20RT

VP10RT

VP20RT

VP10RT

W3

Re L2

V

P

1

0

R

T

V

P

2

0

R

T

M

Y

5

0

1

5

N

X

2

5

2

5

GY2M0200D100N-BM a a a a D 2.00 0.03 1.00 19.5 20.90

0250E125N-BM a a a a E 2.50 0.03 1.25 19.3 20.90

0300F150N-BM a a a a F 3.00 0.03 1.50 19.0 20.90

0318F159N-BM a a a a F 3.18 0.03 1.59 18.9 20.90

0400G200N-BM a a a a G 4.00 0.04 2.00 23.4 25.80

0475H238N-BM a a a a H 4.75 0.04 2.38 22.9 25.80

0500H250N-BM a a a a H 5.00 0.04 2.50 22.8 25.80

0600J300N-BM a a a a J 6.00 0.04 3.00 22.5 25.90

0635J318N-BM a a a a J 6.35 0.04 3.18 22.3 25.90

2.00 1.50 0.646

2.50 1.75 0.72

3.00 2.00 0.793

3.18 2.09 0.819

4.00 2.50 0.939

4.75 2.88 1.049

5.00 3.00 1.086

6.00 3.50 1.232

6.35 3.68 1.283

50 100 150 200 250

80

90

60

70

90

55

45

50

60

50

60

60

50

30

40

40

30

60

80

70

90

80

180

190

140

150

210

135

105

110

120

110

120

140

110

60

70

70

60

120

160

150

210

160

A

p

p

l

i

c

a

t

i

o

n

s

Geometry Order Number

Stock

Seat

Size

Dimensions (mm)

Coated Cermet

ar

(Max.)

Grooving

Width

Tolerance

F

o

r

C

o

p

y

i

n

g

a

n

d

R

e

c

e

s

s

i

n

g

BM Breaker

INSERTS

BM BREAKER

: 1st

recommended area

aRecessing

I

n

s

e

r

t

w

i

d

t

h

(

m

m

)

Recommended feed rate and depth of cut

Minimum grooving diameter

Distance from the workpiece to the recess depth

Ensure the tool is suitable for the diameter being machined. Refer to the Min. Grooving Diameter

D1 as shown in the table on the rst page to avoid a collision with the workpiece as shown below.

M

i

n

.

G

r

o

o

v

i

n

g

D

i

a

m

e

t

e

r

RECOMMENDED CUTTING SPEED (m/min)

(Note 1) VP20RT is the rst recommended grade for materials other than hardened steel.

(Note 2) For VP10RT, VP20RT and MY5015, wet cutting is recommended.

Work Material Hardness Grade

Cutting Speed (m/min)

Mild Steel

(SS400, S10C etc.)

<180HB

Carbon Steel

Alloy Steel

(S45C, SCM440 etc.)

Carbon Steel

Alloy Steel

(SNCM439 etc.)

Stainless Steel

(SUS304 etc.)

<350HB

Gray Cast Iron

(FC300 etc.)

<350MPa

Ductile Cast Iron

(FCD700 etc.)

<800MPa

Titanium Alloy

(Ti-6Al-4V etc.)

Heat Resistant Alloy

(Inconel718 etc.)

Grooving Width

W (mm)

Recessing Depth

t (mm)

Distance from the workpiece to the recess depth

ap (mm)

5

B

H

2

H

1

L2

S

3

L1

F

1

W

3

ar

H

2

H

1

L2

H

2

H

1

L2

B

W

3

ar

L1

F

1

D

1

D

1

D

1

H1 B L1 L2 H2 F1 S3

K 8.00

R

25 50 (1G1R9K1) GYPR2525M00-K25 a 25 25 150 47 25 28 7 1

25 50 (1Q1R9K1) 3225P00-K25 a 32 25 170 47 32 28 2

25 50 (1J1R9K1) 3232P00-K25 a 32 32 170 47 32 35 3

L

25 50 (1G1L9K1) GYPL2525M00-K25 a 25 25 150 47 25 28 7 1

25 50 (1Q1L9K1) 3225P00-K25 a 32 25 170 47 32 28 2

25 50 (1J1L9K1) 3232P00-K25 a 32 32 170 47 32 35 3

1

GY2Mooooooooo-GS GY2Mooooooooo-MM

GY2Mooooooooo-GM GY2Mooooooooo-MS

GY2Mooooooooo-BM GY2Mooooooooo-GS

GY2Mooooooooo-GM

GROOVING SYSTEM

*

If BM breaker with geometries are used then L1 and L2 values will become 0.3mm longer.

00 type holder

Insert Insert

Insert Insert

Insert Insert

Insert

TOOL HOLDER FOR 8mm INSERT WIDTH

Fig. 1

Fig. 3

Fig. 2

Seat

Size

Insert

Width

W3

(mm)

Hand

(

R/L

)

Max.

Groove Depth

ar

(mm)

Max. Cut off

Diameter

D1

(mm)

ID

Order Number Dimensions (mm)

Fig

Holder Stock

Right hand tool holder shown.

a : Inventory maintained. (10 inserts in one case)

6

Re0.05

Re0.05

W

3

Re0.05

Re0.05

W

3

Re0.05

Re0.05

W

3

Re0.05

Re0.05

W

3

Re0.05

W

3

L20.1 L20.1 L20.1 L20.1 L20.1

ar (Max.) ar (Max.) ar (Max.) ar (Max.) ar (Max.)

4.0

3.0

2.0

1.0

3.5

2.5

1.5

0.5

0

0.2 0.4 0.6 0.8

0.1 0.2 0.3 0.4 0.05 0 0.15 0.25 0.35

BM

MM

MS

GM

GS

MM

MS

BM

P

VP20RT

VP10RT

160280HB

VP20RT

VP10RT

MY5015

VP20RT

VP10RT

MY5015

M

VP20RT

VP10RT

K

VP20RT

VP10RT

MY5015

VP20RT

VP10RT

MY5015

S

VP20RT

VP10RT

W3

Re

ar

(Max.)

L2

V

P

1

0

R

T

V

P

2

0

R

T

M

Y

5

0

1

5

GY2M0800K030N-GS

K 8.00

0.04 0.3 29.1 30.5 a a

0800K050N-GM 0.04 0.5 29.3 30.5 a a a

GY2M0800K080N-MS 0.04 0.8 28.5 30.5 a a a

0800K080N-MM 0.04 0.8 28.5 30.5 a a a

0800K120N-MM 0.04 1.2 28.1 30.5 a a a

GY2M0800K400N-BM 0.04 4.0 26.5 30.8 a a a

50 100 150 200 250 300

100

110

80

90

110

60

60

60

70

70

70

90

80

90

140

90

30

40

220

230

180

190

250

140

140

140

150

150

150

210

180

190

300

210

60

70

z

x

GYHR/Looooo50-MooL/R

zTKY30R

xTKY25D

GYPR/Looooo00-K25 TKY30R

INSERTS

RECOMMENDED CUTTING SPEED (m/min)

(Note 1) VP20RT is the rst recommended grade for materials other than hardened steel.

(Note 2) For VP10RT, VP20RT and MY5015, wet cutting is recommended.

GS Breaker GM Breaker MS Breaker MM Breaker BM Breaker

Work Material Hardness Grade

Cutting Speed (m/min)

Mild Steel

(S10C, SUM22L etc)

<160HB

Carbon Steel

Alloy Steel

(SUJ2, SCr, SCM etc)

280HB<

Stainless Steel <270HB

Gray Cast Iron

Tensile Strength

<300MPa

Ductile Cast Iron

Tensile Strength

<800MPa

Heat Resistant Alloy

Titanium Alloy

Recommended cutting

conditions

Feed (mm/rev)

Applications Order Number

Seat

Size

Dimensions (mm) Stock

Coated

Grooving

Width

Tolerance

Grooving /

Cutting off

Multifunction

Copying

: 1st recommended area

For Grooving / Cutting off

For Turning

Feed (mm/rev)

R

a

d

i

a

l

D

e

p

t

h

o

f

c

u

t

(

m

m

)

B

r

e

a

k

e

r

SPARE PARTS

EXTERNAL RECESSING TOOL HOLDER FOR 8mm INSERT WIDTH

*

Wrench : zFor Clamp Screw xFor Blade Screw

Modular Holder Number

(5 pcs.)

Clamp Screw Blade Screw Wrench

GY06013M

(Tightening torque

: 6.0Nm)

TS55

(Tightening torque

: 5.0Nm)

Modular Holder Number

Clamp Screw Wrench

GY06013M

(Tightening torque

: 6.0Nm)

Anda mungkin juga menyukai

- Parts Manual: Electric Pallet Truck PWS10SDokumen25 halamanParts Manual: Electric Pallet Truck PWS10SSARAMQR100% (1)

- FCOM2Dokumen528 halamanFCOM2hoangaut100% (1)

- SB1257EDokumen624 halamanSB1257EGORD50% (2)

- CONO 11-MAR-15 Trio APS 4034 (T4034S-F) Impact Crusher Parts Manual (SN. 284)Dokumen38 halamanCONO 11-MAR-15 Trio APS 4034 (T4034S-F) Impact Crusher Parts Manual (SN. 284)Cuello Marin Nayely100% (2)

- NewEra Ignition Coil 2016 PDFDokumen34 halamanNewEra Ignition Coil 2016 PDFrexmist50% (2)

- 811 399 000Dokumen36 halaman811 399 000airmasterBelum ada peringkat

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryDari EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryBelum ada peringkat

- ASTM B348-06aStandardSpecificationforTitaniumandTitaniumAlloyBarsandBillets PDFDokumen8 halamanASTM B348-06aStandardSpecificationforTitaniumandTitaniumAlloyBarsandBillets PDFtahirabbasBelum ada peringkat

- Katalog Mesin G360LDokumen20 halamanKatalog Mesin G360LPasha SiregarBelum ada peringkat

- Material For Frame 4.2Dokumen16 halamanMaterial For Frame 4.2vudinhnambrBelum ada peringkat

- Meaning of Aditional Marking "G" Accoridng To EN 10025:1990 + A1:1993Dokumen5 halamanMeaning of Aditional Marking "G" Accoridng To EN 10025:1990 + A1:1993TasmanijskaNemaBelum ada peringkat

- Пазовые фрезы PDFDokumen72 halamanПазовые фрезы PDFstctoolBelum ada peringkat

- Bearing and Eccentric Shaft PartsDokumen6 halamanBearing and Eccentric Shaft PartsjlfyBelum ada peringkat

- Insert: Ems and Jib Parts ManualDokumen74 halamanInsert: Ems and Jib Parts Manualmauricio carmonaBelum ada peringkat

- PVXP Power SupplyDokumen3 halamanPVXP Power SupplyHumberto Souza ArrudaBelum ada peringkat

- Ga 11 A Ga22 PDFDokumen22 halamanGa 11 A Ga22 PDFSAUL OSPINOBelum ada peringkat

- bl01 Aa0104 4Dokumen6 halamanbl01 Aa0104 4chris110Belum ada peringkat

- Sentry and JSHD4 Product CatalogDokumen117 halamanSentry and JSHD4 Product CatalogVictor Hugo Anaya VargasBelum ada peringkat

- ATX Forward 1 PC PowerDokumen36 halamanATX Forward 1 PC PowerAntonio Jose Rodriguez AlvaradoBelum ada peringkat

- Mitsu 14 Technical DataDokumen52 halamanMitsu 14 Technical DataRajesh Mishra100% (1)

- VR20 VR40Dokumen1 halamanVR20 VR40Pedro Pablo Giraldo NuñezBelum ada peringkat

- Threading Tools (SST Series)Dokumen8 halamanThreading Tools (SST Series)Gilberto ManhattanBelum ada peringkat

- BS 10 1962Dokumen3 halamanBS 10 1962S Prabakaran SanmugasundaramBelum ada peringkat

- Parts Manual: 60 HZ Commercial Portable Generator SetDokumen46 halamanParts Manual: 60 HZ Commercial Portable Generator SetDiego Roberto BonattoBelum ada peringkat

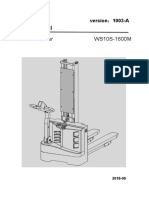

- Parts Manual: Electric Stacker WS10S-1600MDokumen23 halamanParts Manual: Electric Stacker WS10S-1600Mgargi yesareBelum ada peringkat

- MotorssDokumen1 halamanMotorssChang ChangBelum ada peringkat

- ANM003 - CopieDokumen16 halamanANM003 - CopiejoramiandrisoaBelum ada peringkat

- BUL 4462 Product Overview Hose Bulletin UK MainDokumen4 halamanBUL 4462 Product Overview Hose Bulletin UK MainTuan buivietBelum ada peringkat

- Preview 92103Dokumen4 halamanPreview 92103Almir RodriguesBelum ada peringkat

- Price Piese Axima 2012Dokumen94 halamanPrice Piese Axima 2012Paun ValentinBelum ada peringkat

- Oteluri S235JRDokumen4 halamanOteluri S235JRIoan DanguleaBelum ada peringkat

- F) LG B1200Dokumen7 halamanF) LG B1200Monique ScottBelum ada peringkat

- MOTOVARIO Ha H Series Data Package Cover PDFDokumen17 halamanMOTOVARIO Ha H Series Data Package Cover PDFsolihinsjBelum ada peringkat

- Despiece ATV 260 Linhai PDFDokumen53 halamanDespiece ATV 260 Linhai PDFKelly Araujo Smith0% (1)

- FMC Parts Recom Aug16 With Lead Time (UPDATED 08.19.2022)Dokumen238 halamanFMC Parts Recom Aug16 With Lead Time (UPDATED 08.19.2022)Francis DedumoBelum ada peringkat

- En 13121-3 Bridas Pn10Dokumen1 halamanEn 13121-3 Bridas Pn10Ricardo BustamanteBelum ada peringkat

- Largo de Campanas: CampanarioDokumen4 halamanLargo de Campanas: CampanarioStemplar42Belum ada peringkat

- Apqp LCDCDokumen83 halamanApqp LCDCmechtek 20Belum ada peringkat

- Load Flow For Current CaseDokumen8 halamanLoad Flow For Current CaseTana AzeezBelum ada peringkat

- Component partsDokumen1 halamanComponent partslbt BraakmanBelum ada peringkat

- Boss PW-10 Service NotesDokumen14 halamanBoss PW-10 Service NotesFernando GómezBelum ada peringkat

- Parts List for Air Conditioning UnitDokumen19 halamanParts List for Air Conditioning UnitYuvraj BappiBelum ada peringkat

- Lista de Material: Lote Id: Nivel Base Id: Descripcion Qty - Per Fixed - Qty Scrap Perc Qty Hand Drawing - IdDokumen6 halamanLista de Material: Lote Id: Nivel Base Id: Descripcion Qty - Per Fixed - Qty Scrap Perc Qty Hand Drawing - IdRafael TellezBelum ada peringkat

- H07Rn-F Flexible Mains and Control Cable Bs en 50525-2-21Dokumen5 halamanH07Rn-F Flexible Mains and Control Cable Bs en 50525-2-21Kevyn Arnold ArevaloBelum ada peringkat

- Two-Piece Mounts1Dokumen8 halamanTwo-Piece Mounts1VitorMelloBelum ada peringkat

- 0db539ac-a5b0-4015-be7f-84e450e10cdeDokumen12 halaman0db539ac-a5b0-4015-be7f-84e450e10cdeJoaquin GiraldoBelum ada peringkat

- SDG100S 3a1 3a5Dokumen66 halamanSDG100S 3a1 3a5КонстантинBelum ada peringkat

- GE Quotation - RevisedDokumen3 halamanGE Quotation - RevisedRavichandran DBelum ada peringkat

- Ricoh Aficio SP C420DN PARTS CATALOGDokumen82 halamanRicoh Aficio SP C420DN PARTS CATALOGYury Kobzar100% (2)

- bloodDokumen20 halamanbloodjuanBelum ada peringkat

- Wharfedale TITAN SUB-A12 - 1-400wDokumen13 halamanWharfedale TITAN SUB-A12 - 1-400wNguyễn Quang TrânBelum ada peringkat

- Kyocera Fs 6525mfp 6530mfp Parts ListDokumen44 halamanKyocera Fs 6525mfp 6530mfp Parts Listmmcchuck_284436071Belum ada peringkat

- Despiece Completo IMDokumen38 halamanDespiece Completo IMSantiago CruzBelum ada peringkat

- General Motors GM 4.3 LDokumen26 halamanGeneral Motors GM 4.3 LsimonBelum ada peringkat

- 1SNC160001C0205 Cha1Dokumen144 halaman1SNC160001C0205 Cha1Nelson SilvaBelum ada peringkat

- LG936L - E5814215A39 Maintenance PartDokumen127 halamanLG936L - E5814215A39 Maintenance Partyucke fardiansyahBelum ada peringkat

- PAK AMIN PARAMETRIkDokumen525 halamanPAK AMIN PARAMETRIkandratheshithandBelum ada peringkat

- Book 3194Dokumen216 halamanBook 3194Aung Naing Latt AungBelum ada peringkat

- Machine card and parts list for BSF28Z.12L concrete pumpDokumen173 halamanMachine card and parts list for BSF28Z.12L concrete pumpAlonso MtZ100% (1)

- Newnes Workshop Engineer's Pocket BookDari EverandNewnes Workshop Engineer's Pocket BookPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Cutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryDari EverandCutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryPenilaian: 2 dari 5 bintang2/5 (1)

- CBN InsertsDokumen27 halamanCBN InsertsTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: WNMG 08 04 04-FHDokumen4 halamanType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideBelum ada peringkat

- Through Holes Steam Oxide External Cooling: Series 4402Dokumen8 halamanThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideBelum ada peringkat

- CC CC: Type Inserts With HoleDokumen4 halamanCC CC: Type Inserts With HoleTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: WBGT 02 01 V3 L-FDokumen1 halamanType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideBelum ada peringkat

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDokumen2 halamanAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideBelum ada peringkat

- Nnmu200608zen-Hk MC5020Dokumen1 halamanNnmu200608zen-Hk MC5020TungstenCarbideBelum ada peringkat

- Any Size Kits Are All $400.00: Steel ApplicationsDokumen2 halamanAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideBelum ada peringkat

- VFX5UR0203CA10Dokumen3 halamanVFX5UR0203CA10TungstenCarbideBelum ada peringkat

- Aemw150304er Up20mDokumen1 halamanAemw150304er Up20mTungstenCarbideBelum ada peringkat

- CCMXDokumen1 halamanCCMXTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: VPET 08 02 01 R-SRFDokumen1 halamanType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideBelum ada peringkat

- Cpmt1205zpen-M2 VP15TFDokumen1 halamanCpmt1205zpen-M2 VP15TFTungstenCarbideBelum ada peringkat

- Aemw150304er Up20mDokumen1 halamanAemw150304er Up20mTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: XCMT 15 03 02-SVXDokumen1 halamanType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: WPGT 04 02 04 R-FSDokumen1 halamanType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: VBMT 11 03 04 - SVDokumen2 halamanType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: VNMG 16 04 02-FHDokumen3 halamanType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: VCMT 11 03 02-FPDokumen2 halamanType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: TPMH 08 02 02-FVDokumen3 halamanType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: WCGT 02 01 02 RDokumen1 halamanType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: VDGX 16 03 02 RDokumen1 halamanType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideBelum ada peringkat

- TNDokumen6 halamanTNTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: TEGX 16 03 02 RDokumen1 halamanType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: TCMT 09 02 02-FPDokumen2 halamanType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: SPMT 09 03 04Dokumen1 halamanType Inserts With Hole: SPMT 09 03 04TungstenCarbideBelum ada peringkat

- SNDokumen4 halamanSNTungstenCarbideBelum ada peringkat

- Type Inserts Without Hole: Posi 6ºDokumen1 halamanType Inserts Without Hole: Posi 6ºTungstenCarbideBelum ada peringkat

- Type Inserts With Hole: SCMT 09 T3 04-FPDokumen2 halamanType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideBelum ada peringkat

- Application of Titanium & Its Alloys For Automobile Parts PDFDokumen6 halamanApplication of Titanium & Its Alloys For Automobile Parts PDFAhmadreza AminianBelum ada peringkat

- Metals and Materials For Low Temperatures and Cryogenic Applications - Gasparini IndustriesDokumen7 halamanMetals and Materials For Low Temperatures and Cryogenic Applications - Gasparini IndustriesDianna LambertBelum ada peringkat

- Product CatalogDokumen92 halamanProduct CatalogdoctorniravBelum ada peringkat

- Microstructure and Fatigue Performance of SLM Ti6Al4V Alloy After Different Stress Relief TreatmentsDokumen6 halamanMicrostructure and Fatigue Performance of SLM Ti6Al4V Alloy After Different Stress Relief TreatmentsÁlvaro Nieto CastroBelum ada peringkat

- SM - Unit 4 - R1Dokumen105 halamanSM - Unit 4 - R1Jayashree MisalBelum ada peringkat

- Seminar Report HimanshuDokumen36 halamanSeminar Report HimanshuAditya SharmaBelum ada peringkat

- Metals HandbookDokumen33 halamanMetals HandbookAlexandre Sp50% (4)

- Laser Welding of Ti6Al4V Titanium AlloysDokumen9 halamanLaser Welding of Ti6Al4V Titanium Alloysadnan domlogeBelum ada peringkat

- Design and analysis of steam turbine bladesDokumen7 halamanDesign and analysis of steam turbine bladesaliBelum ada peringkat

- BMS Numbers With DescriptionDokumen9 halamanBMS Numbers With DescriptionIvent100% (1)

- Mechanical Properties of Biomedical Ti AlloysDokumen6 halamanMechanical Properties of Biomedical Ti AlloysHugo FernándezBelum ada peringkat

- Mil STD 1587e PDFDokumen43 halamanMil STD 1587e PDFRaj Rajesh100% (1)

- Joint Reconstruction V7.1Dokumen23 halamanJoint Reconstruction V7.1Tusan SidhartaBelum ada peringkat

- Non Ferrous MetalsDokumen30 halamanNon Ferrous MetalsjemahbabesBelum ada peringkat

- Metal Equivalent GradesDokumen2 halamanMetal Equivalent GradesMarcelo CostaBelum ada peringkat

- TitaniumDokumen14 halamanTitaniumTalKanBelum ada peringkat

- (Advances in Intelligent Systems and Computing 623) Marek Gzik, Ewaryst Tkacz, Zbigniew Paszenda, Ewa Piętka (Eds.) - Innovations in Biomedical Engineering-Springer International Publishing (2018)Dokumen417 halaman(Advances in Intelligent Systems and Computing 623) Marek Gzik, Ewaryst Tkacz, Zbigniew Paszenda, Ewa Piętka (Eds.) - Innovations in Biomedical Engineering-Springer International Publishing (2018)Davy Jean DrahaBelum ada peringkat

- DIN English - Aircraft and Space Vehicle Engineering Collection - IHSDokumen3 halamanDIN English - Aircraft and Space Vehicle Engineering Collection - IHSprashant.acharyahnrBelum ada peringkat

- F1580Dokumen3 halamanF1580gaso99Belum ada peringkat

- 1 s2.0 S0264127517311383 Main PDFDokumen26 halaman1 s2.0 S0264127517311383 Main PDFGiridharanVijayKumarBelum ada peringkat

- 1.4 A Tija Centromedulara PFN ScurtDokumen20 halaman1.4 A Tija Centromedulara PFN ScurtGhica CostinBelum ada peringkat

- Optimize SLM Parameters Using Taguchi MethodDokumen7 halamanOptimize SLM Parameters Using Taguchi MethodHa Linh PhanBelum ada peringkat

- Jawaharlal Nehru Technological University Hyderabad Light Metals and Alloys Objective Exam Practice QuestionsDokumen8 halamanJawaharlal Nehru Technological University Hyderabad Light Metals and Alloys Objective Exam Practice Questionsvenkiscribd444Belum ada peringkat

- BASE METAL ALLOYS FOR DENTAL APPLICATIONSDokumen85 halamanBASE METAL ALLOYS FOR DENTAL APPLICATIONSmeghaBelum ada peringkat

- Titanium Alloys For Biomedical ApplicationsDokumen9 halamanTitanium Alloys For Biomedical Applicationsleizar_death64Belum ada peringkat

- Titanium Plate B-265Dokumen10 halamanTitanium Plate B-265Sharad KokateBelum ada peringkat

- TECHNICALDokumen48 halamanTECHNICALPuneeth KumarBelum ada peringkat

- Properties and Microstructures in Metal Selective Laser MeltingDokumen12 halamanProperties and Microstructures in Metal Selective Laser MeltingGabriel Petrea100% (1)